Evaluation and Characterization of Tamarind Gum Polysaccharide: The Biopolymer

Abstract

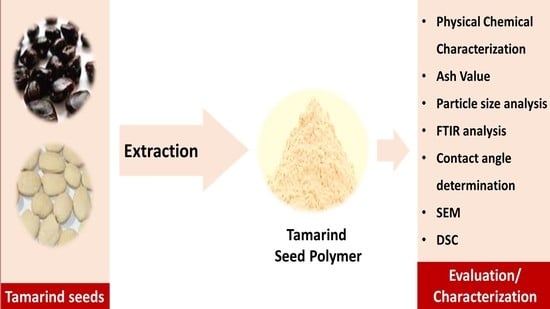

:1. Introduction

2. Materials and Methods

2.1. Collection of Plant Material

2.2. Extraction of Gum

2.3. Physicochemical Characterization of Gum

2.3.1. Identification Tests for Carbohydrates, Proteins, Tannins

Test for Carbohydrates

Test for Proteins

Test for Glycosides

Test for Tannins

Test for Alkaloids

Sudan Red–III Test

2.3.2. Organoleptic Properties

2.3.3. pH of Gum

2.3.4. Viscosity of Gum

2.3.5. Surface Tension

2.3.6. Swelling Index

2.3.7. Bulk Density and Bulkiness

2.3.8. Powder Compressibility (Carr’s Compressibility Index)

2.3.9. Powder Flow Property

2.4. For Powder Blend

2.4.1. Aspect Ratio

Roundness

Irregularity (IR)

Elongation Ratio

Equivalent Circle Diameter (ECD)

Hausner Ratio

Angle of Internal Friction (AIF)

Porosity (ε)

2.5. Ash Value Determination

2.5.1. Total Ash Value

2.5.2. Sulphated Ash Value

2.5.3. Water-Soluble Ash

2.5.4. Acid Insoluble Ash

2.6. Particle Size Analysis

2.7. FT-IR Spectral Analysis

2.8. Contact Angle Determination

2.9. Scanning Electron Microscopy Analysis (SEM)

2.10. Differential Scanning Calorimetric Analysis (DSC)

2.11. Moisture Content

3. Results and Discussion

3.1. Chemical Characterization of Isolated Gum

3.2. Organoleptic Properties and pH

3.3. pH

3.4. Viscosity

3.5. Surface Tension

3.6. Swelling Index

3.7. Micromeritics Properties

3.8. Ash Value

3.8.1. Total Ash Values of TG

3.8.2. Sulphated Ash Value

3.8.3. Water-Soluble Ash Value

3.8.4. Acid-Insoluble Ash Value

3.9. Particle Size Analysis

3.10. FT-IR Spectral Analysis

3.11. Contact Angle Determination

3.12. Scanning Electron Microscopy (SEM)

3.13. Differential Scanning Calorimetric Analysis (DSC)

3.14. Moisture Content

4. Biomedical Application of TGP

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Durai, R.D.; Rajalakshmi, G.; Joseph, J.; Kanchalochana, S.; Hari, V. Tamarind seed polysaccharide: A promising natural excipient for pharmaceuticals. Int. J. Green Pharm. 2012, 6, 270. [Google Scholar] [CrossRef]

- Shankracharyan, B. Tamarind chemistry, technology and uses: A critical Appraisal. J. Food Sci. Technol. 1998, 35, 193–208. [Google Scholar]

- Shao, H.; Zhang, H.; Tian, Y.; Song, Z.; Lai, P.F.H.; Ai, L. Composition and Rheological Properties of Polysaccharide Extracted from Tamarind (Tamarindus indica L.) Seed. Molecules 2019, 24, 1218. [Google Scholar] [CrossRef] [Green Version]

- Sharma, V.; Patnaik, P.; Senthilguru, K. Preparation and characterization of novel tamarind gum-based hydrogels for anti-microbial drug delivery applications. Chem.Pap. 2018, 72, 2101–2113. [Google Scholar] [CrossRef]

- Malviya, R.; Raj, S.; Fuloria, S.; Subramaniyan, V.; Sathasivam, K.; Kumari, U.; Meenakshi, D.U.; Porwal, O.; Kumar, D.H.; Singh, A.; et al. Evaluation of Antitumor Efficacy of Chitosan-Tamarind Gum Polysaccharide Polyelectrolyte Complex Stabilized Nanoparticles of Simvastatin. Int. J. Nanomed. 2021, 16, 2533–2553. [Google Scholar] [CrossRef] [PubMed]

- Nayak, A.K.; Pal, D. Functionalization of Tamarind Gum for Drug Delivery; Springer International Publishing: New York, NY, USA, 2017; pp. 25–56. [Google Scholar] [CrossRef]

- Malviya, R.; Jha, S.; Fuloria, N.K.; Subramaniyan, V.; Chakravarthi, S.; Sathasivam, K.; Kumari, U.; Meenakshi, D.U.; Porwal, O.; Sharma, A.; et al. Determination of Temperature-Dependent Coefficients of Viscosity and Surface Ten-sion of Tamarind Seeds (Tamarindus indica L.). Polymers 2021, 18, 13–610. [Google Scholar]

- Malviya, R.; Srivastava, P.; Bansal, M.; Sharma, P.K. Formulation, evaluation and comparison of sustained release matrix tablets of diclofenac sodium using tamarind gum as release modifier. Asian J. Pharm. Clin. Res. 2010, 3, 238–241. [Google Scholar]

- Da Silva, D.A.; Melo Aires, G.C.; Silva Pena, R.D. Innovation in the Food Sector Through the Valorization of Food and Agro-Food By-Products; Gums—Characteristics and Applications in the Food Industry; IntechOpen: London, UK, 2020. [Google Scholar]

- Singh, R.; Malviya, R.; Sharma, P.K. Extraction and Characterization of Tamarind Seed Polysaccharide as a Pharmaceutical Excipient. Pharm. J. 2011, 3, 17–19. [Google Scholar] [CrossRef] [Green Version]

- Sumathi, S.; Ray, A.R. Release behaviour of drugs from tamarind seed polysaccharide tablets. J. Pharm. Pharm. Sci. 2002, 5, 12–18. [Google Scholar]

- Prabhanjan, H. Studies on Modified Tamarind Kernel Powder. Part I: Preparation and Physicochemical Properties of Sodium Salt of Carboxymethyl. Derivatives 1989, 41, 409–414. [Google Scholar] [CrossRef]

- Rao, P.S.; Beri, R.M. Acetylation of tamarind seed Jellose. Proc. Math. Sci. 1955, 42, 199–203. [Google Scholar] [CrossRef]

- Prabhanjan, H.; Ali, S.Z. Studies on rheological properties of tamarind kernel powder, its derivatives and their blends with maize starch. Carbohydr. Polym. 1995, 28, 245–253. [Google Scholar] [CrossRef]

- Yadav, A.; Vishwakarma, R.K.; Mishra, S.K.; Shukla, A.K. Isolation and characterization of tamarind seed gum as pharmaceutical excipient. Int. J. Health Clin. Res. 2020, 3, 49–57. [Google Scholar]

- Lynch, C.R.; Kondiah, P.P.D.; Choonara, Y.E.; Du Toit, L.C.; Ally, N.; Pillay, V. Hydrogel Biomaterials for Application in Ocular Drug Delivery. Front. Bioeng. Biotechnol. 2020, 8, 228. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaur, H.; Ahuja, M.; Kumar, S.; Dilbaghi, N. Carboxymethyl tamarind kernel polysaccharide nanoparticles for ophthalmic drug delivery. Int. J. Biol. Macromol. 2012, 50, 833–839. [Google Scholar] [CrossRef]

- Dubashynskaya, N.; Poshina, D.; Raik, S.; Urtti, A.; Skorik, Y.A. Polysaccharides in Ocular Drug Delivery. Pharmaceutics 2020, 12, 22. [Google Scholar] [CrossRef] [Green Version]

- Aly, A.S. Self-dissolving chitosan. I. Preparation, characterization and evaluation for drug delivery system. Angew. Makromol. Chem. 1998, 259, 13–18. [Google Scholar] [CrossRef]

- Abdulhady, S.S.; Ibrahim, K.M.H. Preparation and evaluation of mebeverine hydrochloride as mucoadhesive buccal tablet for local anesthesia. Trop. J. Pharm. Res. 2017, 16, 1805. [Google Scholar] [CrossRef] [Green Version]

- Deogire, S.; Mahaparale, S. Development and Evaluation Sustained release Matrices of Lamivudine by Using Synthetic Pol-ymer. Intern. J. Pharm. Res. Health Sci. 2014, 2, 233. [Google Scholar]

- Bhosale, R.R.; Ali, R.; Osmani, M.; Moin, A. Natural gums and mucilages: A review on multifaceted excipients in pharmaceu-tical science and research. Intern. J. Pharm. Res. Health Sci. 2015, 6, 901–912. [Google Scholar]

- Mahammed, N.; Deshpande, R.D.; Gowda, D.V. Modified polysaccharides as drug delivery: Review. Intern. J. Pharm. Res. Health Sci. 2011, 11, 42–47. [Google Scholar]

- Glycoside Cardiac Glycosides Classification and Chemical Tests for Cardiac Glycosides. Available online: http://www.yourarticlelibrary.com/biology/glycoside/cardiac-glycosides-classification-and-chemical-tests-for-cardiac-glycosides/49746/ (accessed on 14 May 2021).

- Available online: https://www.google.co.in/search?q=test+for+lipids+pdf&oq=test+for+l pids+pdf&gs_l=psyab.3..0i19k1j0i22i30i19k1l3.1163.2057.0.2457.4.4.0.0.0.0.180.712.0j4.4.0....0...1.1.64.psy ab..0.4.712.TJ4AgyedDDM (accessed on 5 May 2021).

- Anema, S.G.; Lowe, E.K.; Li, Y. Effect of pH on the viscosity of heated reconstituted skim milk. Int. Dairy J. 2004, 14, 541–548. [Google Scholar] [CrossRef]

- Radhika, P.R.; Kharkate, P.R.; Thangavel, S. Formulation of Aceclofenac Sustained Release Matrix Tablet using Hydrophilic Natural Gum. Intern. J. Pharm. Res. Health Sci. 2011, 2, 851. [Google Scholar]

- Stokes, G.G. On the Effect of the Internal Friction of Fluids on the Motion of Pendulums; Cambridge University Press: Cambridge, UK, 2010; pp. 1–10. [Google Scholar] [CrossRef]

- Nayak, B.; Pattanayak, D.; Ellaiah, P.; Das, S. Formulation design preparation and in vitro characterization of nebivolol transdermal patches. Asian J. Pharm. 2011, 5, 175. [Google Scholar] [CrossRef]

- Nauib, H.F.J. Chemically induced graft copolymerization of itaconic acid onto sisal fibers. Polymer Res. 2002, 9, 207. [Google Scholar]

- Yoshida, T.; Hattori, K.; Sawada, Y.; Choi, Y.; Uryu, T. Graft copolymerization of methyl methacrylate onto curdlan. J. Polym. Sci. Part A Polym. Chem. 1996, 34, 3053–3060. [Google Scholar] [CrossRef]

- Durcilene, A.D.S.; Regina, C.M.P.; Judith, P.A. Graft copolymerisation of acrylamide onto cashew gum. Euro. Poly. J. 2007, 43, 2620–2629. [Google Scholar]

- Malviya, R.; Srivastava, P. Preparation, Characterization and Application of Chitosan—Alginate Based Polyelectrolyte Complex as Fast Disintegrating Drug Delivery Carrier. Polym. Med. 2011, 41, 45–54. [Google Scholar]

- Bodhmage, A. Correlation between physical properties and flowability indicators for fine powders. Master’s Thesis, Saskatchewan University, Saskatoon, SK, Canada, 2006. [Google Scholar]

- Sandler, N.; Wilson, D. Prediction of granule packing and flow behaviour based on particle size and shape analysis. J. Pharm. Sci. 2010, 99, 958–968. [Google Scholar] [CrossRef]

- Patel, A.; Shah, D.; Desai, T.R.; Noolvi, M.N. Mucoadhesive buccal films based on chitosan and carboxymethylated Feronia limonia fruit pulp mucilage interpolymer complex for delivery of opioid analgesics. Asian J. Pharm. 2016, 10, 137–143. [Google Scholar]

- Potaś, J.; Szymańska, E.; Basa, A.; Hafner, A.; Winnicka, K. Tragacanth Gum/Chitosan Polyelectrolyte Complexes-Based Hy-drogels Enriched with Xanthan Gum as Promising Materials for Buccal Application. Materials 2021, 14, 86. [Google Scholar] [CrossRef]

- Morse, P.; Loxley, A. Light microscopic determination of particle size distribution in an aqueous gel. Drug Deliv. Technol. 2009, 9, 1–5. [Google Scholar]

- Malviya, R.; Awasthi, R.; Sharma, P.K.; Dubey, S.K. Stabilization of Etoricoxib Nanosuspension Using Acacia chundra Gum and Copolymers: Preparation, Characterization, and In Vitro Cytotoxic Study. Assay Drug Dev. Technol. 2021, 19, 306–321. [Google Scholar] [CrossRef]

- Naghshbandi, M.P.; Moghimi, H. Stabilization of phytase on multi-walled carbon nanotubes via covalent immobilization. Method. Enzym. 2020, 630, 431–451. [Google Scholar]

- Soumya, R.S.; Ghosh, S.; Abraham, E.T. Preparation and characterization of guar gum nanoparticles. Int. J. Biol. Macromol. 2010, 46, 267–269. [Google Scholar] [CrossRef] [PubMed]

- Sharma, P.K.; Dubey, S.K. Microwave Facilitated Green Synthesis and Characterization of Acrylamide Grafted Copolymer of Kheri (Acacia chundra) Gum Polysaccharide. Nat. Prod. J. 2020, 10, 467–487. [Google Scholar] [CrossRef]

- Saikia, F.; Ali, J.O.N.A.B.; Das, B.I.S.W.A.J.I.T. Isolation and characterization of tamarind seed polysaccharides—A natural release retardant. Int. J. Curr. Pharm. Res. 2017, 9, 114–117. [Google Scholar] [CrossRef] [Green Version]

- Kumar, P.; Kumar, R.; Bala, V.; Singh, H.; Singh, S. Purification characterization and analytical evaluation of suspending properties of azadirachta indicia and acacia nilotica gum. World J. Pharm. Res. 2019, 8, 812–825. [Google Scholar]

- Farooq, U.; Malviya, R.; Sharma, P.K. Extraction and characterization of artocarpus integer gum as pharmaceutical excipient. Polym. Med. 2014, 44, 69–74. [Google Scholar]

- Malviya, R.; Sharma, P.; Dubey, S. Kheri (Acacia chundra, family: Mimosaceae) gum: Characterization using analytical, mathematical and pharmaceutical approaches. Polym. Med. 2017, 47, 65–76. [Google Scholar] [CrossRef]

- Farooq, U.; Malviya, R. Extraction and Characterization of Almond (Prunus sulcis) Gum Pharmaceutical Excipient. Am.-Eurasian J. Agric. Environ. Sci. 2014, 14, 269–274. [Google Scholar] [CrossRef]

- Vanerek, A.; Van de Ven, T.G.M. Coacervate complex formation between cationic polyacrylamide and anionic sulfonated kraft lignin. Colloids Surf. 2006, 273, 55–62. [Google Scholar] [CrossRef]

- Patel, Y.; Katsuyoshi, N. Gelation and gel properties of polysaccharides gellan gum and tamarind xyloglucan. J. Biol. Macromol. 2011, 5, 47. [Google Scholar]

- Sharma, A.; Pravin, R.B.; Annapure, U.S. Purification and physicochemical characterization of Prunus domestica exudate gum polysaccharide. Carbohydr. Polym. Technol. Appl. 2020, 1, 100003. [Google Scholar] [CrossRef]

- Malviya, R.; Sharma, P.K. Extraction and Characterization of Aegle Marmelos Derived Polymer as a Pharmaceutical Excipient. Polim. Med. 2014, 44, 141–146. [Google Scholar]

- Sumedha, P.; Malviya, R.; Sharma, P. Extraction and Characterization of Moringo olifera Gum as Pharmaceutical Sus-pending Agent. Nat. Prod. J. 2015, 5, 109–114. [Google Scholar]

- Sundaram, M.M.; Watcharatharapong, T.; Chakraborty, S.; Ahuja, R.; Duraisamy, S.; Rao, P.T.; Munichandraiah, N. Synthesis, and crystal and electronic structure of sodium metal phosphate for use as a hybrid capacitor in non-aqueous electrolyte. Dalton Trans. 2015, 44, 20108–20120. [Google Scholar] [CrossRef] [Green Version]

- Nair, A.B.; Shah, J.; Aljaeid, B.M.; Al-Dhubiab, B.E.; Jacob, S. Gellan Gum-Based Hydrogel for the Transdermal Delivery of Nebivolol: Optimization and Evaluation. Polymers 2019, 11, 1699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rezaei, A.; Nasirpour, A.; Tavanai, H. Fractionation and some physicochemical properties of almond gum (Amygdalus communis L.) exudates. Food Hydrocoll. 2016, 60, 461–469. [Google Scholar] [CrossRef]

- Mali, K.K.; Dhawale, S.C.; Dias, R.J. Extraction, Characterization and Functionalization of Tamarind Gum. Res. J. Pharm. Tech. 2019, 12, 1745–1752. [Google Scholar] [CrossRef]

- Chawananorasest, K.; Saengtongdee, P.; Kaemchantuek, P. Extraction and Characterization of Tamarind (Tamarind indica L.) Seed Polysaccharides (TSP) from Three Difference Sources. Molecules 2016, 21, 775. [Google Scholar] [CrossRef] [PubMed]

- Malviya, R.; Sharma, P.K.; Dubey, S.K. Microwave-assisted preparation of biodegradable, hemocompatible, and antimicrobial neem gum–grafted poly (acrylamide) hydrogel using (3)2 factorial design. Emergent Mater. 2019, 2, 95–112. [Google Scholar] [CrossRef]

- Wickramaarachchi, K.; Sundaram, M.M.; Henry, D.J.; Gao, X. Alginate Biopolymer Effect on the Electrodeposition of Manganese Dioxide on Electrodes for Supercapacitors. ACS Appl. Energy Mater. 2021, 4, 7040–7051. [Google Scholar] [CrossRef]

- Ramkumar, R.; Sundaram, M.M. A biopolymer gel-decorated cobalt molybdate nanowafer: Effective graft polymer cross-linked with an organic acid for better energy storage. New J. Chem. 2016, 40, 2863–2877. [Google Scholar] [CrossRef]

- Fuloria, N.K.; Fuloria, S. Structural Elucidation of Small Organic Molecules by 1D, 2D and Multi Dimensional-Solution NMR Spectroscopy. J. Anal. Bioanal. Tech. 2013, 4. [Google Scholar] [CrossRef]

- Samrot, A.V.; Angalene, J.L.A.; Roshini, S.M.; Stefi, S.M.; Preethi, R.; Raji, P.; Kumar, A.M.; Kumar, S.S. Purification, characterization and exploitation of Azadirachta indica gum for the production of drug loaded nanocarrier. Mater. Res. Express 2020, 7, 055007. [Google Scholar] [CrossRef]

- Malsawmtluangi, C.; Thanzami, K.; Lalhlenmawia, H.; Selvan, V.; Palanisamy, S.; Kandasamy, R.; Pachuau, L. Physico-chemical characteristics and antioxidant activity of Prunus cerasoides D. Don gum exudates. Int. J. Biol. Macromol. 2014, 69, 192–199. [Google Scholar] [CrossRef]

- Gaur, N.; Parvez, N. extraction and characterization of polysaccharide from tamarind seed for its pharmaceutical applications. World J. Pharm. Res. 2019, 8, 1219–1230. [Google Scholar]

- Kumar, A.; Singh, K.; Ahuja, M. Xanthan-g-poly (acrylamide): Microwave-assisted synthesis, characterization and in vitro release behavior. Carbohydr. Polym. 2009, 76, 261–267. [Google Scholar] [CrossRef]

- Giri, T.K.; Pradhan, M.; Tripathi, D.K. Synthesis of graft copolymer of kappa-carrageenan using microwave energy and studies of swelling capacity, flocculation properties, and preliminary acute toxicity. Turk. J. Chem. 2016, 40, 283–295. [Google Scholar] [CrossRef]

- Malviya, R.; Sharma, P.; Dubey, S. Microwave controlled green synthesis of acrylamide graft copolymers of Azadirachita indica gum for the waste water management. Curr. Appl. Polym. Sci. 2018, 2, 130–149. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Lazim, N.A.M.; Selvakumaran, S. Natural polysaccharide-based composites for drug delivery and biomedical applications. In Natural Polysaccharides in Drug Delivery and Biomedical Applications; Academic Press: Cambridge, MA, USA, 2019; pp. 419–440. [Google Scholar] [CrossRef]

- Nayyar, T.; Sabharwal, S.; Jain, U.K.; Taneja, R. Recent approaches and pharmaceutical applications of natural polysaccha-rides: A review. Int. J. Pharm. Sci. Res. (IJPSR) 2015, 6, 4904–4919. [Google Scholar]

| Test | Observation | Inference |

|---|---|---|

| Molish’s test | Purple ring at the junction of two liquid | Carbohydrate present |

| Benedict’s | Brick red precipitate | Carbohydrate confirmed |

| Osazone test | Needle shaped crystals | Confirmatory test for fructose and galactose |

| Biuret test | Red color | Protein absent |

| Test for tannins | No greenish precipitate obtained | Tannins absent |

| Sudan red III test | No change in color | Lipids absent |

| Dragendorff’s test | No red color obtained | Glycosides absent |

| Property | Observation | Average |

|---|---|---|

| Bulk Density (g/cm2) | 0.80 g/cm2 | 0.80 ± 0 |

| Tapped Density (g/cm2) | 0.83 g/cm2 | 2.55 ± 0.0071 |

| 0.86 g/cm2 | ||

| 0.86 g/cm2 | ||

| Carr’s Index | 3.75 | 6.25 ± 0.0071 |

| 7.5 | ||

| 7.5 | ||

| Hausner’s Ratio | 0.96 | 0.94 ± 0.0071 |

| 0.93 | ||

| 0.93 | ||

| Angle of repose (θ) | 0.14 θ | 0.14 ± 0.1979 |

| 0.13 θ | ||

| 0.16 θ | ||

| Aspect Ratio | 0.5 | 0.52 ± 0.071 |

| 0.75 | ||

| 0.33 | ||

| Roundness | 0.69 | 0.67 ± 0.073 |

| 0.76 | ||

| 0.58 | ||

| Irregularity | 3 | 3.05 ± 0.071 |

| 3.5 | ||

| 2.66 | ||

| Equivalent circle diameter | 1.9 | 3.75 ± 0.072 |

| 7.03 | ||

| 2.34 | ||

| Elongation Ratio | 2 | 2.11 ± 0.074 |

| 1.33 | ||

| 3 | ||

| 0.13 | ||

| Degree of volume | 0.032 | 0.053 ± 0.073 |

| 0.064 | ||

| 0.064 | ||

| Porosity (ε) | 0.197 ε | 0.197 ± 0.072 |

| Angle of internal friction | 0.946 | 1.88 ± 0.074 |

| 1.892 | ||

| 2.83 |

| S.no | Parameters | Observation |

|---|---|---|

| 1 | Total ash value (%) | 14.00 ± 1.00 |

| 2 | Sulphated ash (%) | 13.00 ± 0.05 |

| 3 | Water-soluble ash (%) | 7.29 ± 0.06 |

| 5 | Acid-insoluble ash (%) | 14.04 ± 0.57 |

| Size Range (µm) | No. of Particles |

|---|---|

| 0–20 | 30 |

| 20–40 | 67 |

| 40–80 | 114 |

| 80–90 | 90 |

| >90 | 40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malviya, R.; Sundram, S.; Fuloria, S.; Subramaniyan, V.; Sathasivam, K.V.; Azad, A.K.; Sekar, M.; Kumar, D.H.; Chakravarthi, S.; Porwal, O.; et al. Evaluation and Characterization of Tamarind Gum Polysaccharide: The Biopolymer. Polymers 2021, 13, 3023. https://doi.org/10.3390/polym13183023

Malviya R, Sundram S, Fuloria S, Subramaniyan V, Sathasivam KV, Azad AK, Sekar M, Kumar DH, Chakravarthi S, Porwal O, et al. Evaluation and Characterization of Tamarind Gum Polysaccharide: The Biopolymer. Polymers. 2021; 13(18):3023. https://doi.org/10.3390/polym13183023

Chicago/Turabian StyleMalviya, Rishabha, Sonali Sundram, Shivkanya Fuloria, Vetriselvan Subramaniyan, Kathiresan V. Sathasivam, Abul Kalam Azad, Mahendran Sekar, Darnal Hari Kumar, Srikumar Chakravarthi, Omji Porwal, and et al. 2021. "Evaluation and Characterization of Tamarind Gum Polysaccharide: The Biopolymer" Polymers 13, no. 18: 3023. https://doi.org/10.3390/polym13183023

APA StyleMalviya, R., Sundram, S., Fuloria, S., Subramaniyan, V., Sathasivam, K. V., Azad, A. K., Sekar, M., Kumar, D. H., Chakravarthi, S., Porwal, O., Meenakshi, D. U., & Fuloria, N. K. (2021). Evaluation and Characterization of Tamarind Gum Polysaccharide: The Biopolymer. Polymers, 13(18), 3023. https://doi.org/10.3390/polym13183023