Mechanical and Hygroscopic Properties of Molded Pulp Products Using Different Wood-Based Cellulose Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Used and Production of MPP

- Manufacturing of 3D objects using the molded pulp product (MPP) process.

- Cutting of samples in shouldered bars shape using a punch cutting device.

- Sample conditioning, following the test procedure to be done.

2.2. Description of the Characterisation Techniques of Molded Pulp Products Used

2.2.1. Morphology Analysis Techniques Used

- Fiber’s length and width.

- Fiber’s macro-fibrillation (fibrils amount at the fiber’s surface).

- Curl index (CI) defined as shown in Equation (1) and Figure 2.

- Kinked fiber content and broken fiber content.

- Fines’ content (particles with a length of 200 µm or less).

2.2.2. Hygroscopic and Mechanical Properties Analysis Techniques Used

3. Results

3.1. MorFi Analysis

3.2. SEM Observations

3.3. FTIR Analysis

3.4. Initial Mechanical Properties

3.5. Molded Pulp Products Samples Moisture Uptake in Humid Environment and Resulting GAB Model

3.6. Mechanical Properties of Molded Pulp Product after Sorption Analysis

4. Discussion

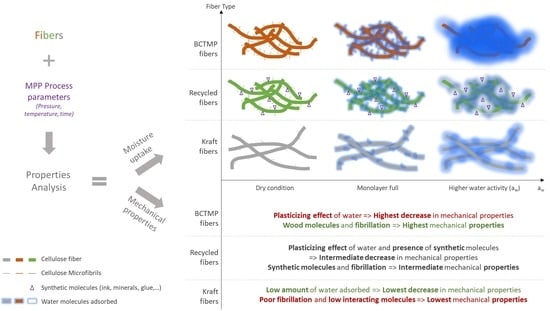

4.1. Influence of Fiber’s Origin and Morhplogy on Molded Pulp Products’ Initial Mechanical Properties

4.2. The Effect of Fiber’s Morphology on Molded Pulp Products’ Moisture Uptake after Sorption Analysis

4.3. Effect of Molded Pulp Products’ Moisture Uptake after Sorption Analysis on Samples’ Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bajpai, P. Biermann’s Handbook of Pulp and Paper: Volume 1; Raw Material and Pulp Making; Elsevier Science: San Diego, CA, USA, 2018; ISBN 978-0‒12-814241-7. [Google Scholar]

- Fernando, D. Ultrastructural Characterization (Morphological and Topochemical) of Wood Pulp Fibres: Effects of Mechanical and Kraft Processes. Ph.D. Thesis, Department of Forest Products, Swedish University of Agricultural Sciences, Uppsala, Sweden, 2007. [Google Scholar]

- Mcdonald, D.; Miles, K.; Amiri, R. The Nature of the Mechanical Pulping Process. Pulp Pap. Can. 2004, 105. [Google Scholar]

- Sixta, H.; Koch, G.; Ressel, J.B.; Potthast, A.; Krotschek, A.W.; Süss, H.U.; Schwanninger, M.; Blechschmidt, J.; Heinemann, S.; Putz, H.-J.; et al. Handbook of Pulp; Wiley-VCH: Hoboken, NJ, USA, 2006; ISBN 978-3-527-30999-3. [Google Scholar]

- Ek, M.; Gellerstedt, G.; Henriksson, G. Pulping Chemistry and Technology; Pulp and Paper; De Gruyter: Berlin, Germany, 2009; ISBN 978-3‒11-021341-6. [Google Scholar]

- Vickerman, K.D. Papermaking: Then and Now. A History of Hand Papermaking from Its Beginning, Plus a Process for Using Natural Fibers To Make Paper; Educational Resources Information Center; Idaho State University: Pocatello, ID, USA, 1995. [Google Scholar]

- Hunter, D. Papermaking: The History and Technique of an Ancient Craft; Courier Corporation: New York, NY, USA, 1978; ISBN 978-0-486-23619-3. [Google Scholar]

- Bajpai, P. Environmentally Benign Approaches for Pulp Bleaching; Elsevier: Amsterdam, The Netherlands, 2005; ISBN 978-0-444-51724. [Google Scholar]

- Keyes, F.E. Method of Molding Pulp Articles. U.S. Patent 424,003, 25 March 1890. [Google Scholar]

- Keyes, M.L. Apparatus for Making Pulp Articles. U.S. Patent 740,023A, 29 September 1903. [Google Scholar]

- Didone, M.; Saxena, P.; Brilhuis-Meijer, E.; Tosello, G.; Bissacco, G.; McAloone, T.C.; Pigosso, D.C.A.; Howard, T.J. Moulded Pulp Manufacturing: Overview and Prospects for the Process Technology. Packag. Technol. Sci. 2017, 30, 231–249. [Google Scholar] [CrossRef] [Green Version]

- Yang, X.; Berthold, F.; Berglund, L.A. High-Density Molded Cellulose Fibers and Transparent Biocomposites Based on Oriented Holocellulose. ACS Appl. Mater. Interfaces 2019, 11, 10310–10319. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saxena, P.; Bissacco, G.; Meinert, K.; Bedka, F.J. Mold design and fabrication for production of thermoformed paper-based packaging products. J. Manuf. Process. 2020, 58, 311–321. [Google Scholar] [CrossRef]

- IMFA Molded Fiber. Available online: https://www.imfa.org/molded-fiber/ (accessed on 11 July 2018).

- Sharma, N.; Godiyal, R.D.; Thapliyal, B.P. A Review on Pulping, Bleaching and Papermaking Processes. J. Graph. Era Univ. 2020, 8, 18. [Google Scholar]

- Alava, M.; Niskanen, K. The physics of paper. Rep. Prog. Phys. 2006, 69, 669–723. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Venditti, R.A.; Rojas, O.J. What Happens to Cellulosic Fibers during Papermaking and Recycling? A Review. BioResources 2007, 2, 50. [Google Scholar]

- Hubbe, M.A. Prospects for Maintaining Strength of Paper and Paperboard Products While Using Less Forest Resources: A Review. BioResources 2013, 9, 1634–1763. [Google Scholar] [CrossRef] [Green Version]

- Pulkkinen, I.; Alopaeus, V. The effect of fiber dimensions on fiber network activation and tensile strength. Holzforschung 2012, 66. [Google Scholar] [CrossRef]

- Hubbe, M. Bonding between cellulosic fibers in the absence and presence of dry-strength agents A review. BioResources 2006, 1. [Google Scholar] [CrossRef]

- Lindström, T.; Wågberg, L.; Larsson, T. On the Nature of Joint Strength in Paper a Review of Dry and Wet Strength Resins in Paper Manufacturing, in 13th Fundamental Research Symposium; The Pulp and Paper Fundamental Research Society: Cambridge, UK, 2005; Volume 1. [Google Scholar]

- Didone, M.; Tosello, G. Moulded pulp products manufacturing with thermoforming. Packag. Technol. Sci. 2018, 32, 7–22. [Google Scholar] [CrossRef] [Green Version]

- Didone, M.; Mohanty, S.; Hattel, J.H.; Sonne, M.R.; Fiordaliso, E.M.; Checchi, A.; Tosello, G. On the drying process of molded pulp products: Experiments and numerical modelling. Dry. Technol. 2019, 38, 1644–1662. [Google Scholar] [CrossRef]

- AFNOR. AFNOR Standard EN NF ISO 5267‒1: Pulps—Determination of—Part 1: Schopper-Riegler Method; AFNOR: Dartford, Kent, 2000. [Google Scholar]

- Dislaire, C.; Grohens, Y.; Seantier, B.; Muzy, M. The impact of molded pulp product process on the mechanical properties of molded Bleached Chemi-Thermo-Mechanical Pulp. Funct. Compos. Mater. 2021, 2, 1–10. [Google Scholar] [CrossRef]

- AFNOR. AFNOR NF EN ISO 527-2 Plastics Determination of Tensile Properties Part 2: Test Conditions for Moulding and Extrusion Plastics; AFNOR: Dartford, Kent, 2012. [Google Scholar]

- Blahovec, J.; Yanniotis, S. GAB Generalized Equation for Sorption Phenomena. Food Bioprocess. Technol. 2007, 1, 82–90. [Google Scholar] [CrossRef]

- Timmermann, E.O.; Chirife, J.; Iglesias, H.A. Water Sorption Isotherms of Foods and Foodstuffs: BET or GAB Parameters? J. Food Eng. 2001, 13. [Google Scholar] [CrossRef]

- Samyn, P. Wetting and hydrophobic modification of cellulose surfaces for paper applications. J. Mater. Sci. 2013, 48, 6455–6498. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Provisional). Pure Appl. Chem. 1982, 54, 2201–2218. [Google Scholar] [CrossRef]

- Chen, H.; Ferrari, C.; Angiuli, M.; Yao, J.; Raspi, C.; Bramanti, E. Qualitative and quantitative analysis of wood samples by Fourier transform infrared spectroscopy and multivariate analysis. Carbohydr. Polym. 2010, 82, 772–778. [Google Scholar] [CrossRef]

- Kristó, J.; Frost, R.; Felinger, A.; Mink, J. FTIR spectroscopic study of intercalated kaolinite. J. Mol. Struct. 1997, 410–411, 119–122. [Google Scholar] [CrossRef]

- Hospodarova, V.; Singovszka, E.; Stevulova, N. Characterization of Cellulosic Fibers by FTIR Spectroscopy for Their Further Implementation to Building Materials. Am. J. Anal. Chem. 2018, 09, 303–310. [Google Scholar] [CrossRef] [Green Version]

- Traoré, M.; Kaal, J.; Cortizas, A.M. Application of FTIR spectroscopy to the characterization of archeological wood. Spectrochim. ACTA Mol. Biomol. Spectrosc. 2016, 153, 63–70. [Google Scholar] [CrossRef] [PubMed]

- Özgenç, Ö.; Durmaz, S.; Boyaci, I.H.; Eksi-Kocak, H. Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry. Spectrochim. ACTA Mol. Biomol. Spectrosc. 2017, 171, 395–400. [Google Scholar] [CrossRef]

- Heitner, C.; Dimmel, D.; Schmidt, J. Lignin and Lignans: Advances in Chemistry; CRC Press: Boca Raton, FL, USA, 2010; ISBN 978‒1-4200‒1580-5. [Google Scholar] [CrossRef]

- Müller, G.; Schöpper, C.; Vos, H.; Kharazipour, A.; Polle, A. FTIR-ATR Spectroscopic Analyses of Changes in Wood Properties during Particle- and Fibreboard Production of Hard- and Softwood Trees. Bioresources 2009, 23. [Google Scholar] [CrossRef]

- Anupam, K.; Sharma, A.K.; Lal, P.S.; Bist, V. Physicochemical, Morphological, and Anatomical Properties of Plant Fibers Used for Pulp and Papermaking. In Fiber Plants; Sustainable Development and Biodiversity; Springer International Publishing: Cham, Switzerland, 2016; Volume 13, pp. 235–248. ISBN 978-3-319-44569-4. [Google Scholar]

- Larsson, P.T.; Lindström, T.; Carlsson, L.A.; Fellers, C. Fiber length and bonding effects on tensile strength and toughness of kraft paper. J. Mater. Sci. 2017, 53, 3006–3015. [Google Scholar] [CrossRef]

- Watson, A.J.; Dadswell, H.E. Influence of Fibre Morphology on Paper Properties. Appita Technol. Innov. Manuf. Environ. 2017, 70, 271–282. [Google Scholar]

- Fišerová, M.; Gigac, J.; Balber, J. Relationship between Fibre Characteristics and Tensile Strength of Hardwood and Softwood Kraft Pulps. Cellul. Chem. Technol. 2010, 44, 5. [Google Scholar]

- Wistara, N.; Young, R.A. Properties and treatments of pulps from recycled paper. Part I. Physical and chemical properties of pulps. Cellulose 1999, 6, 291–324. [Google Scholar] [CrossRef]

- Forsström, J. Fundamental Aspects on the Re-Use of Wood Based Fibres Porous Structure of Fibres and Ink Detachment. Ph.D. Thesis, The Royal Institute of Technology, Stockholm, Sweden, 2004. [Google Scholar]

- Hubbe, M.A.; Gill, R.A. Fillers for Papermaking: A Review of their Properties, Usage Practices, and their Mechanistic Role. BioResources 2015, 11, 2886–2963. [Google Scholar] [CrossRef] [Green Version]

- Indriati, L.; Romas, M.S.; Rostika, I. Mixed-Refining of BCTMP and LBKP for Lightweight Papers. Chem. Mater. Res. 2019, 11, 22–29. [Google Scholar] [CrossRef]

- Osong, S.H.; Norgren, S.; Engstrand, P. Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: A review. Cellulose 2015, 23, 93–123. [Google Scholar] [CrossRef]

- Rowell, R.M. Chapter 14 Chemical Modification of Wood. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; p. 42. ISBN 9781032099163. [Google Scholar]

- Geueke, B.; Groh, K.; Muncke, J. Food packaging in the circular economy: Overview of chemical safety aspects for commonly used materials. J. Clean. Prod. 2018, 193, 491–505. [Google Scholar] [CrossRef]

- Pivnenko, K.; Eriksson, E.; Astrup, T.F. Wastepaper for recycling: Overview and identification of potentially critical substances. Waste Manag. 2015, 45, 134–142. [Google Scholar] [CrossRef] [Green Version]

- Kumar, V.; Pathak, P.; Bhardwaj, N.K. Wastepaper: An underutilized but promising source for nanocellulose mining. Waste Manag. 2019, 102, 281–303. [Google Scholar] [CrossRef] [PubMed]

- Brodin, I.; Kungliga Tekniska högskolan. Skolan för kemivetenskap Chemical Properties and Thermal Behaviour of Kraft Lignins; Skolan för Kemivetenskap, Kungliga Tekniska högskolan: Stockholm, Sweden, 2009; ISBN 978-91-7415-406. [Google Scholar]

- Naijian, F.; Rudi, H.; Resalati, H.; Torshizi, H.J. Application of bio-based modified kaolin clay engineered as papermaking additive for improving the properties of filled recycled papers. Appl. Clay Sci. 2019, 182, 105258. [Google Scholar] [CrossRef]

- Yoon, S.-Y. Bonding Material Coated Clay for Improving Paper Properties. Ph.D. Thesis, Georgia Institute of Technology, Atlanta, GA, USA, 2007. [Google Scholar]

- Hill, C.A.S.; Norton, A.; Newman, G. The water vapor sorption behavior of natural fibers. J. Appl. Polym. Sci. 2009, 112, 1524–1537. [Google Scholar] [CrossRef]

- Zhang, Y.; Hosseinaei, O.; Wang, S.; Zhou, Z. Influence of Hemicellulose Extraction on Water Uptake Behavior of Wood Strands. Wood Fiber Sci. 2011, 43, 7. [Google Scholar]

- Salmén, L. On the Interaction between Moisture and Wood Fibre Materials. MRS Proc. 1990, 197. [Google Scholar] [CrossRef]

- Haslach, H.W. The Moisture and Rate-Dependent Mechanical Properties of Paper: A Review. Mech. Time-Depend. Mater. 2000, 4, 42. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Rojas, O.; Habibi, Y.; Pawlak, J.J. The effect of chemical composition on microfibrillar cellulose films from wood pulps: Water interactions and physical properties for packaging applications. Cellulose 2010, 17, 835–848. [Google Scholar] [CrossRef]

- Diniz, J.M.B.F.; Gil, M.H.; Castro, J.A.A.M. Hornification: Its origin and interpretation in wood pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef] [Green Version]

- Laivins, G.V.; Scallan, A.M. The Mechanism of Hornification of Wood Pulps. Products of Papermaking. In Proceedings of the Tenth Fundamental Research Symposium, Oxford, UK, September 1993; Volume 2, pp. 1235–1260. [Google Scholar]

- Marta, K.; Piotr, P.; Marcin, D.; Kamila, B. Influence of Drying Temperature on Cellulose Fibers Hornification Process. For. Wood Technol. 2014, 86. [Google Scholar]

- Vukoje, M.; Rožić, M. Various Valorisation Routes of Paper Intended for Recycling a Review. Cellul. Chem. Technol. 2018, 57. [Google Scholar]

| Samples | Description of Fibers | Supplier | Wood Species Used | Fibers’ Mean Length (µm) | Schopper–Riegler Degree (°SR) |

|---|---|---|---|---|---|

| R-NPM | Recycled newspapers and magazines | Locally collected | Unknown | 555 | 53 |

| R-CBB | Recycled cardboard box | CBB wastes | Unknown | 642 | 32 |

| BCTMP | Bleached chemi-thermomechanical pulp | Rottneros | Spruce | 615 | 27 |

| BSKP | Bleached softwood kraft pulp | Fibre Excellence | Pine | 1286 | 14 |

| BHKP | Bleached hardwood kraft pulp | Fibre Excellence | Mix of hardwood | 711 | 16 |

| USKP | Unbleached softwood kraft pulp | Ahlstrom-Munksjö | Pine and spruce | 1375 | 17 |

| Step Number in Figure 1 | Process Parameter | |

|---|---|---|

| Pulp concentration | 1 | 0.5% |

| Time of pulping | 1 | 15 min |

| Dehydration time | 2 | 15 s |

| Mould B temperature | 3 | 120 °C |

| Mould C and D temperature | 4 | 240 °C |

| Press closing time | 4 | 0.1 s |

| Pressing time | 4 | 30 s |

| Sample | Weight (g) | Density (g·cm−3) |

|---|---|---|

| R-NPM | 0.64 (±0.05) | 0.61 (±0.05) |

| R-CBB | 0.68 (±0.09) | 0.55 (±0.06) |

| BCTMP | 0.65 (±0.06) | 0.57 (±0.05) |

| BSKP | 0.65 (±0.09) | 0.53 (±0.02) |

| BHKP | 0.65 (±0.09) | 0.52 (±0.03) |

| USKP | 0.64 (±0.1) | 0.57 (±0.03) |

| aw | 0.10 | 0.33 | 0.50 | 0.75 | 0.98 |

|---|---|---|---|---|---|

| Saturated salt | KOH | MgCl2 | Climatic chamber | NaCl | K2SO4 |

| Sample | K | C0 | τm | x1 | R2 |

|---|---|---|---|---|---|

| R-NPM | 0.89 (±0.03) | 9.69 (±2.99) | 2.42 (±0.60) | −2.67 (±3.12) | 0.9862 (±0.0012) |

| R-CBB | 0.90 (±0.01) | 27.57 (±14.07) | 2.56 (±0.26) | −6.47 (±1.58) | 0.9972 (±0.0020) |

| BCTMP | 0.84 (±0.04) | 12.83 (±2.01) | 6.67 (±3.34) | 10.60 (±15.12) | 0.9843 (±0.0105) |

| BSKP | 0.88 (±0.00) | 19.14 (±0.79) | 2.91 (±0.14) | −5.05 (±1.15) | 0.9910 (±0.0034) |

| BHKP | 0.88 (±0.01) | 41.17 (±13.98) | 2.90 (±0.24) | −3.24 (±4.86) | 0.9931 (±0.0033) |

| USKP | 0.90 (±0.01) | 16.15 (±5.12) | 2.73 (±0.35) | −6.42 (±2.75) | 0.9948 (±0.0059) |

| Sample | Fiber’s Length (µm) | Fiber’s Width (µm) | Length/Width Ratio |

|---|---|---|---|

| R-NPM | 555 (±10.7) | 20.5 (±0.06) | 27.05 |

| R-CBB | 642 (±20.7) | 23.2 (±0.32) | 27.63 |

| BCTMP | 634 (±24.3) | 25.2 (±0.67) | 25.13 |

| BSKP | 1286 (±27.5) | 27.4 (±0.32) | 46.89 |

| BHKP | 711 (±6.9) | 18.6 (±0.15) | 38.15 |

| USKP | 1375 (±24.5) | 26.7 (±0.20) | 51.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dislaire, C.; Seantier, B.; Muzy, M.; Grohens, Y. Mechanical and Hygroscopic Properties of Molded Pulp Products Using Different Wood-Based Cellulose Fibers. Polymers 2021, 13, 3225. https://doi.org/10.3390/polym13193225

Dislaire C, Seantier B, Muzy M, Grohens Y. Mechanical and Hygroscopic Properties of Molded Pulp Products Using Different Wood-Based Cellulose Fibers. Polymers. 2021; 13(19):3225. https://doi.org/10.3390/polym13193225

Chicago/Turabian StyleDislaire, Claire, Bastien Seantier, Marion Muzy, and Yves Grohens. 2021. "Mechanical and Hygroscopic Properties of Molded Pulp Products Using Different Wood-Based Cellulose Fibers" Polymers 13, no. 19: 3225. https://doi.org/10.3390/polym13193225

APA StyleDislaire, C., Seantier, B., Muzy, M., & Grohens, Y. (2021). Mechanical and Hygroscopic Properties of Molded Pulp Products Using Different Wood-Based Cellulose Fibers. Polymers, 13(19), 3225. https://doi.org/10.3390/polym13193225