Malva parviflora Leaves Mucilage: An Eco-Friendly and Sustainable Biopolymer with Antioxidant Properties

Abstract

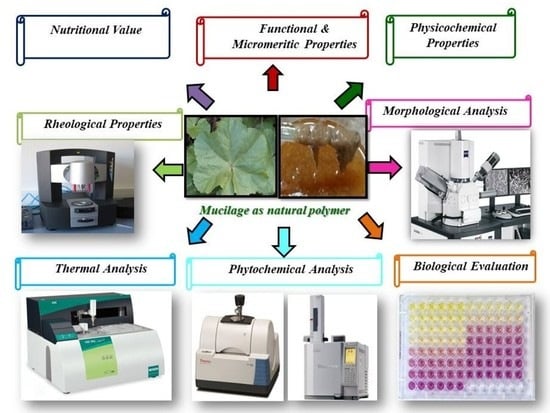

:1. Introduction

2. Materials and Methods

2.1. Plant Material

2.2. Extraction of Mucilage

2.3. Preliminary Confirmative Tests for Mucilage

2.4. Determination of the Yield Percentage

2.5. Determination of the Purity of Mucilage

2.6. Elemental Analysis Using Atomic Absorption Spectroscopy

2.7. Determination of the Nutritional Value of Mucilage

2.7.1. Estimation of Total Carbohydrates

2.7.2. Estimation of Total Proteins

2.7.3. Estimation of Total Free Amino Acids

2.8. Determination of the Physicochemical Properties of the Mucilage

2.8.1. Evaluation of the Organoleptic Properties of the Mucilage

2.8.2. Evaluation of the Solubility of the Mucilage

2.8.3. Determination of the pH of the Mucilage

2.8.4. Determination of the Moisture Content of the Mucilage

2.8.5. Determination of the Ash Content of the Mucilage

2.8.6. Determination of the Swelling Index of the Mucilage

2.8.7. Determination of the Water-Holding Capacity of the Mucilage

2.8.8. Determination of the Oil Binding Capacity of the Mucilage

2.9. Determination of the Rheological Properties of the Mucilage

2.10. Evaluation of the Functional Properties of the Mucilage

2.10.1. Determination of Emulsion Capacity

2.10.2. Determination of Emulsion Stability

2.10.3. Determination of the Foaming Capacity

2.10.4. Determination of the Foaming Stability

2.11. Determination of the Micromeritic Properties of the Mucilage

2.11.1. Determination of the Bulk Density

2.11.2. Determination of the Tapped Density

2.11.3. Determination of Carr’s Index and Hausner Ratio

2.11.4. Determination of Angle of Repose

2.12. Morphological Analysis Using Scanning Electron Microscopy

2.13. Thermal Analysis Using Differential Scanning Calorimetry

2.14. Phytochemical Analysis of the Mucilage

2.14.1. FTIR Spectroscopy Analysis

2.14.2. Gas Chromatography Coupled with Mass Spectrometry Analysis

2.14.3. Estimation of Total Flavonoid Content

2.14.4. Estimation of Total Phenolic Content

2.15. In Vitro Biological Evaluation of the Mucilage

2.15.1. In Vitro Antioxidant Activity Assessment Using 1,1-Diphenyl-2-picrylhydrazyl (DPPH*) Radical Scavenging Capacity Assay

2.15.2. In Vitro Determination of DNA Damage Protective Potential of the Mucilage

2.15.3. In Vitro Evaluation of Sun Protection Factor of the Mucilage

2.16. Statistical Analysis

3. Results and Discussion

3.1. Determination of the Yield Percentage and Purity of Mucilage

3.2. Determination of the Nutritional Value of Mucilage

3.3. Determination of the Physicochemical Properties of the Mucilage

3.4. Determination of the Rheological Properties of the Mucilage

3.5. Determination of the Functional Properties of the Mucilage

3.6. Morphological Analysis Using Scanning Electron Microscopy

3.7. Thermal Analysis Using Differential Scanning Calorimetry

3.8. Phytochemical Analysis of the Mucilage

3.9. In Vitro Biological Evaluation of the Mucilage

3.9.1. In Vitro Antioxidant Activity Assessment Using the 1,1-Diphenyl-2-picrylhydrazyl (DPPH*) Radical Scavenging Capacity Assay

3.9.2. In Vitro Determination of DNA Damage Protective Potential of the Mucilage

3.9.3. In Vitro Evaluation of Sun Protection Factor of the Mucilage

4. Limitations and Future Research

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Choudhary, P.D.; Pawar, H.A. Recently investigated natural gums and mucilages as pharmaceutical excipients: An overview. J. Pharm. 2014, 2014, 204849. [Google Scholar] [CrossRef] [Green Version]

- Tosif, M.M.; Najda, A.; Bains, A.; Kaushik, R.; Dhull, S.B.; Chawla, P.; Walasek-Janusz, M. A Comprehensive review on plant-derived mucilage: Characterization, functional properties, applications, and its utilization for nanocarrier fabrication. Polymers 2021, 13, 1066. [Google Scholar] [CrossRef]

- Clifford, S.; Arndt, S.; Popp, M.; Jones, H. Mucilages and polysaccharides in Ziziphus species (Rhamnaceae): Localization, composition and physiological roles during drought-stress. J. Exp. Bot. 2002, 53, 131–138. [Google Scholar] [CrossRef]

- Prajapati, V.D.; Jani, G.K.; Moradiya, N.G.; Randeria, N.P. Pharmaceutical applications of various natural gums, mucilages and their modified forms. Carb. Polym. 2013, 92, 1685–1699. [Google Scholar] [CrossRef] [PubMed]

- Wadhwa, J.; Nair, A.; Kumria, R. Potential of plant mucilages in pharmaceuticals and therapy. Curr. Drug Del. 2013, 10, 198–207. [Google Scholar] [CrossRef]

- Ameri, A.; Heydarirad, G.; Mahdavi Jafari, J.; Ghobadi, A.; Rezaeizadeh, H.; Choopani, R. Medicinal plants contain mucilage used in traditional Persian medicine (TPM). Pharm. Biol. 2015, 53, 615–623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rebah, F.B.; Siddeeg, S. Cactus an eco-friendly material for wastewater treatment: A review. J. Mater. Environ. Sci. 2017, 8, 1770–1782. [Google Scholar]

- Ngwuluka, N.C.; Ochekpe, N.A.; Aruoma, O.I. Naturapolyceutics: The science of utilizing natural polymers for drug delivery. Polymers 2014, 6, 1312–1332. [Google Scholar] [CrossRef] [Green Version]

- Allegra, A.; Sortino, G.; Inglese, P.; Settanni, L.; Todaro, A.; Gallotta, A. The effectiveness of Opuntia ficus-indica mucilage edible coating on post-harvest maintenance of ‘Dottato’fig (Ficus carica L.) fruit. Food Pack. Shelf Life 2017, 12, 135–141. [Google Scholar] [CrossRef]

- Akbar, S.; Hanif, U.; Ali, J.; Ishtiaq, S. Pharmacognostic studies of stem, roots and leaves of Malva parviflora L. Asian Pac. J. Trop. Biomed. 2014, 4, 410–415. [Google Scholar] [CrossRef] [Green Version]

- Dugani, A.; Dakhil, B.; Treesh, S. Protective effect of the methanolic extract of Malva parviflora L. leaves on acetic acid-induced ulcerative colitis in rats. Saudi J. Gastroenterol. 2016, 22, 226–233. [Google Scholar]

- Azab, A. Malva: Food, medicine and chemistry. Eur. Chem. Bull. 2017, 6, 295–320. [Google Scholar] [CrossRef] [Green Version]

- Farhan, H.; Rammal, H.; Hijazi, A.; Badran, B. Preliminary phytochemical screening and extraction of polyphenol from stems and leaves of a Lebanese plant Malva parviflora L. Int. J. Curr. Pharm. Res. 2012, 4, 55–59. [Google Scholar]

- Fakhfakh, N.; Jdir, H.; Jridi, M.; Rateb, M.; Belbahri, L.; Ayadi, M.; Nasri, M.; Zouari, N. The mallow, Malva aegyptiaca L. (Malvaceae): Phytochemistry analysis and effects on wheat dough performance and bread quality. LWT 2017, 75, 656–662. [Google Scholar]

- Mitich, L.W. Cheeseweed–The common mallows. Weed Technol. 1990, 4, 693–695. [Google Scholar] [CrossRef]

- Pakravan, M.; Abedinzadeh, H.; Safaeepur, J. Comparative studies of mucilage cells in different organs in some species of Malva, Althaea and Alcea. Pak. J. Biol. Sci. PJBS 2007, 10, 2603–2605. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malviya, R. Extraction characterization and evaluation of selected mucilage as pharmaceutical excipient. Pol. Med. 2011, 41, 39–44. [Google Scholar]

- Ma, F.; Zhang, Y.; Yao, Y.; Wen, Y.; Hu, W.; Zhang, J.; Liu, X.; Bell, A.E.; Tikkanen-Kaukanen, C. Chemical components and emulsification properties of mucilage from Dioscorea opposita Thunb. Food Chem. 2017, 228, 315–322. [Google Scholar] [CrossRef] [Green Version]

- Raaman, N. Phytochemical Techniques; New India Publishing: New Dehli, India, 2006. [Google Scholar]

- Bader, N.R. Sample preparation for flame atomic absorption spectroscopy: An overview. Rasayan J. Chem. 2011, 4, 49–55. [Google Scholar]

- Sadasivam, S.; Manickam, A. Biochemical Methods; New Age International Publishers: New Delhi, India, 1996. [Google Scholar]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein measurement with the Folin phenol reagent. J. Biol. Chem. 1951, 193, 265–275. [Google Scholar] [CrossRef]

- Archana, G.; Sabina, K.; Babuskin, S.; Radhakrishnan, K.; Fayidh, M.A.; Babu, P.A.S.; Sivarajan, M.; Sukumar, M. Preparation and characterization of mucilage polysaccharide for biomedical applications. Carb. Polym. 2013, 98, 89–94. [Google Scholar] [CrossRef]

- Kalegowda, P.; Chauhan, A.S.; Urs, S.M.N. Opuntia dillenii (Ker-Gawl) Haw cladode mucilage: Physico-chemical, rheological and functional behavior. Carb. Polym. 2017, 157, 1057–1064. [Google Scholar] [CrossRef] [PubMed]

- Aslam, I.; Afridi, M.S.K. Pharmacognostic characterization of Beaumontia grandiflora (Roxb.) Wall. leaf for taxonomic identification for quality control of a drug. J. Appl. Res. Med. Aromat. Plants 2018, 8, 53–59. [Google Scholar] [CrossRef]

- Schuck, P.; Jeantet, R.; Dolivet, A. Analytical Methods for Food and Dairy Powders; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Killedar, S.; More, H.; Nadaf, S.; Pishawikar, S. Optimization of method for determination of swelling factor of ispaghula seeds. J. Drug Metab. Toxicol. 2016, 7, 3. [Google Scholar] [CrossRef] [Green Version]

- Segura-Campos, M.; Acosta-Chi, Z.; Rosado-Rubio, G.; Chel-Guerrero, L.; Betancur-Ancona, D. Whole and crushed nutlets of chia (Salvia hispanica) from Mexico as a source of functional gums. Food Sci. Technol. 2014, 34, 701–709. [Google Scholar] [CrossRef] [Green Version]

- Njintang, N.Y.; Boudjeko, T.; Tatsadjieu, L.N.; Nguema-Ona, E.; Scher, J.; Mbofung, C.M. Compositional, spectroscopic and rheological analyses of mucilage isolated from taro (Colocasia esculenta L. Schott) corms. J. Food Sci. Technol. 2014, 51, 900–907. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gemede, H.F.; Haki, G.D.; Beyene, F.; Rakshit, S.K.; Woldegiorgis, A.Z. Indigenous Ethiopian okra (Abelmoschus esculentus) mucilage: A novel ingredient with functional and antioxidant properties. Food Sci. Nutr. 2018, 6, 563–571. [Google Scholar] [CrossRef] [Green Version]

- Arasi, M.A.G.; Rao, M.G. Physiochemical characterization of mucilage obtained from the fresh fruits of Psidium guajava L. Int. J. Phytopharm. 2015, 5, 30–36. [Google Scholar]

- Sandeep, Y.; Sharma, P.K.; Goyal, N. Comparative study of mucilage extracted from seeds of Cassia fistula and gum Karaya. Adv. Biol. Res. 2015, 9, 177–181. [Google Scholar]

- Singh, S.; Bothara, S.B. Manilkara zapota (Linn.) Seeds: A potential source of natural gum. ISRN Pharm. 2014, 2014. [Google Scholar] [CrossRef] [Green Version]

- Punia, S.; Dhull, S.B. Chia seed (Salvia hispanica L.) mucilage (a heteropolysaccharide): Functional, thermal, rheological behaviour and its utilization. Int. J. Biol. Macromol. 2019, 140, 1084–1090. [Google Scholar] [CrossRef]

- Gheribi, R.; Puchot, L.; Verge, P.; Jaoued-Grayaa, N.; Mezni, M.; Habibi, Y.; Khwaldia, K. Development of plasticized edible films from Opuntia ficus-indica mucilage: A comparative study of various polyol plasticizers. Carb. Polym. 2018, 190, 204–211. [Google Scholar] [CrossRef]

- Xia, Y.-G.; Sun, H.-M.; Wang, T.-L.; Liang, J.; Yang, B.-Y.; Kuang, H.-X. A modified GC-MS analytical procedure for separation and detection of multiple classes of carbohydrates. Molecules 2018, 23, 1284. [Google Scholar] [CrossRef] [Green Version]

- Ribarova, F.; Atanassova, M. Total phenolics and flavonoids in Bulgarian fruits and vegetables. J. Univ. Chem. Technol. Metal. 2005, 40, 255–260. [Google Scholar]

- Saeed, N.; Khan, M.R.; Shabbir, M. Antioxidant activity, total phenolic and total flavonoid contents of whole plant extracts Torilis leptophylla L. BMC Complement. Altern. Med. 2012, 12, 221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Petera, B.; Delattre, C.; Pierre, G.; Wadouachi, A.; Elboutachfaiti, R.; Engel, E.; Poughon, L.; Michaud, P.; Fenoradosoa, T.A. Characterization of arabinogalactan-rich mucilage from Cereus triangularis cladodes. Carb. Polym. 2015, 127, 372–380. [Google Scholar] [CrossRef]

- Aboulwafa, M.M.; Youssef, F.S.; Gad, H.A.; Sarker, S.D.; Nahar, L.; Al-Azizi, M.M.; Ashour, M.L. Authentication and discrimination of green tea samples using UV–vis, FTIR and HPLC techniques coupled with chemometrics analysis. J. Pharm. Biomed. Anal. 2019, 164, 653–658. [Google Scholar] [CrossRef] [PubMed]

- Mamadalieva, N.Z.; Youssef, F.S.; Ashour, M.L.; Sasmakov, S.A.; Tiezzi, A.; Azimova, S.S. Chemical composition, antimicrobial and antioxidant activities of the essential oils of three Uzbek Lamiaceae species. Nat. Prod. Res. 2019, 33, 2394–2397. [Google Scholar] [CrossRef]

- Kaur, R.; Arora, S.; Singh, B. Antioxidant activity of the phenol rich fractions of leaves of Chukrasia tabularis A. Juss. Bioresource Technol. 2008, 99, 7692–7698. [Google Scholar] [CrossRef]

- Suva, M.A. Evaluation of sun protection factor of Zingiber officinale Roscoe extract by ultraviolet spectroscopy method. J. Pharm. Sci. Technol. 2014, 3, 95–97. [Google Scholar]

- Arasi, M.; Rao, M.G.; Bagyalakshmi, J. The Comparison and Analysis of Two Extraction Methods for Polysaccharides in Psidium guajava L. Fruits. Indian J. Pharm. Educ. Res. 2016, 50, 218–224. [Google Scholar] [CrossRef] [Green Version]

- Raheem, Z.H.; Jebor, A.A.A.; Mohammed, S.K. Evaluation of some heavy metal contamination in Malva parviflora L. plant and soil obtained from gardens of College of Agriculture-University of Baghdad. Pak. J. Nut. 2014, 13, 310. [Google Scholar] [CrossRef] [Green Version]

- Farooq, U.; Malviya, R.; Sharma, P.K. Extraction and characterization of okra mucilage as pharmaceutical excipient. Acad. J. Plant Sci. 2013, 6, 168–172. [Google Scholar]

- Rahim, H.; Sadiq, A.; Khan, S.; Chishti, K.A.; Amin, F.; Khan, M.A.; Abbas, S. Isolation and preliminary evaluation of Mulva Neglecta mucilage: A novel tablet binder. Braz. J. Pharm. Sci. 2016, 52, 201–210. [Google Scholar] [CrossRef] [Green Version]

- Choy, S.; Prasad, K.; Wu, T.; Ramanan, R. A review on common vegetables and legumes as promising plant-based natural coagulants in water clarification. Int. J. Environ. Sci. Technol. 2015, 12, 367–390. [Google Scholar] [CrossRef] [Green Version]

- Suvakanta, D.; Narsimha, M.P.; Pulak, D.; Joshabir, C.; Biswajit, D. Optimization and characterization of purified polysaccharide from Musa sapientum L. as a pharmaceutical excipient. Food Chem. 2014, 149, 76–83. [Google Scholar]

- Boruah, A.K.; Nath, L.K. Extraction, purification and physicochemical evaluation of mucilage of Chrysophyllum lanceolatum (blume) dc fruits: An investigation for bioadhesive property. Int. J. Pharm. Pharm. Sci. 2016, 8, 282–288. [Google Scholar]

- Liu, K. Effects of sample size, dry ashing temperature and duration on determination of ash content in algae and other biomass. Algal Res. 2019, 40, 101486. [Google Scholar] [CrossRef]

- Samavati, V.; Lorestani, M.; Joolazadeh, S. Identification and characterization of hydrocolloid from Cordia myxa leaf. Int. J. Biol. Macromol. 2014, 65, 215–221. [Google Scholar] [CrossRef]

- Thanatcha, R.; Pranee, A. Extraction and characterization of mucilage in Ziziphus mauritiana Lam. Int. Food Res. J. 2011, 18, 201–212. [Google Scholar]

- Inglett, G.E.; Chen, D.; Lee, S. Rheological properties of barley and flaxseed composites. Food Nutr. Sci. 2013, 4, 26635. [Google Scholar] [CrossRef] [Green Version]

- Trigui, I.; Yaich, H.; Sila, A.; Cheikh-Rouhou, S.; Bougatef, A.; Blecker, C.; Attia, H.; Ayadi, M. Physicochemical properties of water-soluble polysaccharides from black cumin seeds. Int. J. Biol. Macromol. 2018, 117, 937–946. [Google Scholar] [CrossRef] [PubMed]

- Cerqueira, M.A.; Souza, B.W.; Simões, J.; Teixeira, J.A.; Domingues, M.R.M.; Coimbra, M.A.; Vicente, A.A. Structural and thermal characterization of galactomannans from non-conventional sources. Carb. Polym. 2011, 83, 179–185. [Google Scholar] [CrossRef]

- Singh, A.V. A DSC study of some biomaterials relevant to pharmaceutical industry. J. Ther. Anal. Calorim. 2013, 112, 791–793. [Google Scholar] [CrossRef]

- Vinod, V.; Sashidhar, R.; Suresh, K.; Rao, B.R.; Saradhi, U.V.; Rao, T.P. Morphological, physico-chemical and structural characterization of gum kondagogu (Cochlospermum gossypium): A tree gum from India. Food Hydrocoll. 2008, 22, 899–915. [Google Scholar] [CrossRef]

- Behbahani, B.A.; Yazdi, F.T.; Shahidi, F.; Hesarinejad, M.A.; Mortazavi, S.A.; Mohebbi, M. Plantago major seed mucilage: Optimization of extraction and some physicochemical and rheological aspects. Carb. Polym. 2017, 155, 68–77. [Google Scholar] [CrossRef]

- Derenne, A.; Derfoufi, K.-M.; Cowper, B.; Delporte, C.; Goormaghtigh, E. FTIR spectroscopy as an analytical tool to compare glycosylation in therapeutic monoclonal antibodies. Anal. Chim. Acta. 2020, 1112, 62–71. [Google Scholar] [CrossRef]

- Pereira, G.A.; Silva, E.K.; Araujo, N.M.P.; Arruda, H.S.; Meireles, M.A.A.; Pastore, G.M. Obtaining a novel mucilage from mutamba seeds exploring different high-intensity ultrasound process conditions. Ultrasonics Sonochem. 2019, 55, 332–340. [Google Scholar] [CrossRef]

- Coates, J. Interpretation of Infrared Spectra a Practical Approach. In Encyclopedia of Analytical Chemistry: Applications, Theory and Instrumentation; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Bouaziz, F.; Koubaa, M.; Barba, F.J.; Roohinejad, S.; Chaabouni, S.E. Antioxidant properties of water-soluble gum from flaxseed hulls. Antioxidants 2016, 5, 26. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aslam, I.; Iqbal, J.; Peerzada, S.; Afridi, M.S.; Ishtiaq, S. Microscopic investigations and pharmacognostic techniques for the standardization of Caralluma edulis (Edgew.) Benth. ex Hook. f. Microscopy Res. Tech. 2019, 82, 1891–1902. [Google Scholar]

- Golla, U.; Bhimathati, S.S.R. Evaluation of antioxidant and DNA damage protection activity of the hydroalcoholic extract of Desmostachya bipinnata L. Stapf. Sci. World J. 2014, 2014, 215084. [Google Scholar] [CrossRef] [Green Version]

- Napagoda, M.T.; Malkanthi, B.M.A.S.; Abayawardana, S.A.K.; Qader, M.M.; Jayasinghe, L. Photoprotective potential in some medicinal plants used to treat skin diseases in Sri Lanka. BMC Complement. Altern. Med. 2016, 16, 479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ebrahimzadeh, M.A.; Enayatifard, R.; Khalili, M.; Ghaffarloo, M.; Saeedi, M.; Charati, J.Y. Correlation between sun protection factor and antioxidant activity, phenol and flavonoid contents of some medicinal plants. Iran. J. Pharm. Res. IJPR 2014, 13, 1041–1047. [Google Scholar] [PubMed]

- Li, H.; Li, Z.; Peng, L.; Jiang, N.; Liu, Q.; Zhang, E.; Liang, B.; Li, R.; Zhu, H. Lycium barbarum polysaccharide protects human keratinocytes against UVB-induced photo-damage. Free Rad. Res. 2017, 51, 200–210. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Liu, Y.; Xiao, J.; Wang, Y. Protective effects of tea polysaccharides and polyphenols on skin. J. Agric. Food Chem. 2009, 57, 7757–7762. [Google Scholar] [CrossRef]

| Physicochemical Parameter | MLM |

|---|---|

| Solubility | Soluble in cold and hot water, less soluble in 1 M NaOH, HCl, citric acid and NaCl, and insoluble in all other organic solvents |

| pH (1% solution) | 6.94 ± 0.02 |

| Moisture content (%) | 5.84 ± 0.03 |

| Ash content (%) | 15.60 ± 0.75 |

| Water-soluble ash (%) | 12.03 ± 0.55 |

| Acid-insoluble ash (%) | 0.87 ± 0.15 |

| Swelling index | 12.33 ± 2.51 |

| Water-holding capacity (g/g) | 2.57 ± 0.60 |

| Oil-binding capacity (g/g) | 2.03 ± 0.15 |

| Property | MLM |

|---|---|

| Bulk density (g/cm3) | 0.69 ± 0.06 |

| Tapped density (g/cm3) | 0.84 ± 0.05 |

| Carr’s index (%) | 17.86 ± 0.12 |

| Hausner ratio | 1.22 ± 0.12 |

| Angle of repose | 28.5 ± 0.5 |

| Concentration (µg/mL) | Ascorbic Acid | MLM |

|---|---|---|

| 10 | 12.20 ± 0.96 | 9.29 ± 1.38 |

| 20 | 18.69 ± 0.20 | 19.05 ± 1.09 |

| 40 | 40.34 ± 0.61 | 34.26 ± 1.84 |

| 80 | 71.21 ± 1.07 | 58.54 ± 1.46 |

| 100 | 80.27 ± 1.24 | 67.63 ± 2.72 |

| 200 | 87.35 ± 2.00 | 77.26 ± 0.94 |

| 400 | 91.60 ± 1.70 | 84.54 ± 0.56 |

| 800 | 94.87 ± 1.0 | 89.03 ± 0.39 |

| 1000 | 96.20 ± 1.08 | 91.07 ± 1.00 |

| Wavelength (λ nm) | EE × I (Normalize) | MLM (200 µg/mL) | MLM (400 µg/mL) |

|---|---|---|---|

| 290 | 0.0150 | 0.595 ± 0.01 | 1.071 ± 0.03 |

| 295 | 0.0817 | 0.587 ± 0.04 | 1.142 ± 0.11 |

| 300 | 0.2874 | 0.506 ± 0.18 | 1.062 ± 0.05 |

| 305 | 0.3278 | 0.574 ± 0.02 | 1.099 ± 0.16 |

| 310 | 0.1864 | 0.572 ± 0.05 | 1.106 ± 0.04 |

| 315 | 0.0839 | 0.569 ± 0.11 | 1.098 ± 0.02 |

| 320 | 0.0180 | 0.588 ± 0.03 | 1.091 ± 0.10 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Munir, A.; Youssef, F.S.; Ishtiaq, S.; Kamran, S.H.; Sirwi, A.; Ahmed, S.A.; Ashour, M.L.; Elhady, S.S. Malva parviflora Leaves Mucilage: An Eco-Friendly and Sustainable Biopolymer with Antioxidant Properties. Polymers 2021, 13, 4251. https://doi.org/10.3390/polym13234251

Munir A, Youssef FS, Ishtiaq S, Kamran SH, Sirwi A, Ahmed SA, Ashour ML, Elhady SS. Malva parviflora Leaves Mucilage: An Eco-Friendly and Sustainable Biopolymer with Antioxidant Properties. Polymers. 2021; 13(23):4251. https://doi.org/10.3390/polym13234251

Chicago/Turabian StyleMunir, Ans, Fadia S. Youssef, Saiqa Ishtiaq, Sairah H. Kamran, Alaa Sirwi, Safwat A. Ahmed, Mohamed L. Ashour, and Sameh S. Elhady. 2021. "Malva parviflora Leaves Mucilage: An Eco-Friendly and Sustainable Biopolymer with Antioxidant Properties" Polymers 13, no. 23: 4251. https://doi.org/10.3390/polym13234251

APA StyleMunir, A., Youssef, F. S., Ishtiaq, S., Kamran, S. H., Sirwi, A., Ahmed, S. A., Ashour, M. L., & Elhady, S. S. (2021). Malva parviflora Leaves Mucilage: An Eco-Friendly and Sustainable Biopolymer with Antioxidant Properties. Polymers, 13(23), 4251. https://doi.org/10.3390/polym13234251