Expanding Poly(lactic acid) (PLA) and Polyhydroxyalkanoates (PHAs) Applications: A Review on Modifications and Effects

Abstract

:1. Introduction

1.1. PLA and Its Properties

1.2. PHAs and Their Properties

2. PLA’s Modifications

2.1. Plasticizers’ Effect

2.2. Impact Modifiers’ Effect

2.3. Belnding’s Effect

2.3.1. PLA/PHAs Blends

2.3.2. PLA/PCL Blends

2.3.3. Blends of PLA with Other Biodegradable/Renewable Resource-Based Polymers

2.3.4. Features of Various PLA Blends

2.4. Composites’/Nanocomposites’ Effect

3. PHAs’ Modifications

3.1. Blending’s Effect

3.2. Composites’/Nanocomposites’ Effect

3.3. Features of Various PHAs Blends and Nanocomposites

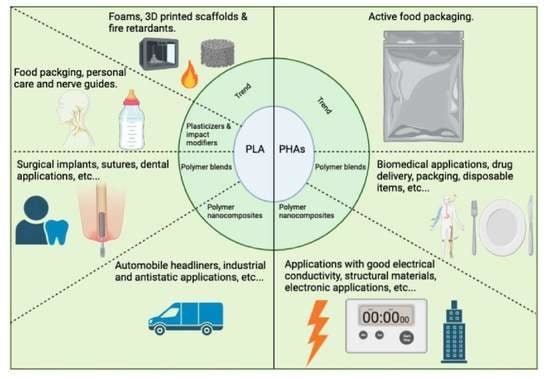

4. Trends of PLA and PHAs Applications

4.1. PLA Foams, 3D-printed Scaffolds and Flame Retardancy

4.2. PHAs in Active Food Packaging

5. Conclusions and Future Insights

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, X.S. Overview of Plant Polymers: Resources, Demands, and Sustainability. In Handbook of Biopolymers and Biodegradable Plastics Properties, Processing and Applications, 1st ed.; Ebnesajjad, S., Ed.; Elsevier: Waltham, MA, USA, 2013. [Google Scholar]

- Ashter, S.A. Introduction to Bioplastics Engineering, 1st ed.; Elsevier: Cambridge, MA, USA, 2016. [Google Scholar] [CrossRef]

- B.F.R. Center. Soybean Car. 1997. Available online: https://www.thehenryford.org/collections-and-research/digital-resources/popular-topics/soy-bean-car/ (accessed on 10 July 2020).

- Mohanty, A.K.; Manjusri, M.; Lawrence, T.D. Natural Fibers, Biopolymers, and Biocomposites, 1st ed.; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Gross, R.A.; Kalra, B. Biodegradable polymers for the environment. Science 2002, 297, 803–807. [Google Scholar] [CrossRef] [Green Version]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from renewable resources: Opportunities and challenges in the green materials world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Netravali, A.N.; Chabba, S. Composites get greener. Mater. Today 2003, 6, 22–29. [Google Scholar] [CrossRef]

- Rudnik, E. Biodegradability Testing of Compostable Polymer Materials. In Handbook of Biopolymers and Biodegradable Plastics Properties, Processing and Applications; Ebnesajjad, S., Ed.; Elsevier: Waltham, MA, USA, 2013. [Google Scholar]

- Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology. Adv. Mater. 2000, 12, 1841–1846. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Wibowo, A.; Misra, M.; Drzal, L.T. Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Compos. Part A Appl. Sci. Manuf. 2004, 35, 363–370. [Google Scholar] [CrossRef]

- Mehta, G.; Mohanty, A.K.; Misra, M.; Drzal, L.T. Biobased resin as a toughening agent for biocomposites. Green Chem. 2004, 6, 254–258. [Google Scholar] [CrossRef]

- Canada One-Step Closer to Zero Plastic Waste by 2030. 2020. Available online: https://www.canada.ca/en/environment-climate-change/news/2020/10/canada-one-step-closer-to-zero-plastic-waste-by-2030.html (accessed on 10 April 2021).

- Clark, J.H.; Deswarte, F.E.I. The Biorefinery Concept-An Integrated Approach. In Introduction to Chemicals from Biomass, 1st ed.; John Wiley & Sons Ltd.: Chichester, UK, 2008. [Google Scholar]

- Niaounakis, M. Biopolymers: Applications and Trends, 1st ed.; Elsevier: Waltham, MA, USA, 2015. [Google Scholar]

- Kricheldorf, H.; Dunsing, R. Polylactones, 8. Mechanism of the cationic polymerization of L,L-dilactide. Die Makromol. Chemie. 1986, 187, 1611–1625. [Google Scholar] [CrossRef]

- Maharana, T.; Mohanty, B.; Negi, Y.S. Melt-solid polycondensation of lactic acid and its biodegradability. Prog. Polym. Sci. 2009, 34, 99–124. [Google Scholar] [CrossRef]

- Singhvi, M.S.; Zinjarde, S.S.; Gokhale, D.V. Polylactic acid: Synthesis and biomedical applications. J. Appl. Microbiol. 2019, 127, 1612–1626. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, S.Y.; Yang, M.; Yu, T.; Ren, T.B.; Ren, J. Synthesis and characterization of biodegradable lactic acid-based polymers by chain extension. Polym. Int. 2008, 57, 982–986. [Google Scholar] [CrossRef]

- Kun, E.; Marossy, K. Effect of crystallinity on PLA’s microbiological behaviour. Mater. Sci. Forum 2013, 752, 241–247. [Google Scholar] [CrossRef]

- Tsuji, H.; Ikada, Y. Crystallization from the melt of poly(lactide)s with different optical purities and their blends. Macromol. Chem. Phys. 1996, 197, 3483–3499. [Google Scholar] [CrossRef]

- Garlotta, D. A literature review of poly(lactic acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Standau, T.; Zhao, C.; Castellón, S.M.; Bonten, C.; Altstädt, V. Chemical modification and foam processing of polylactide (PLA). Polymers 2019, 11, 306. [Google Scholar] [CrossRef] [Green Version]

- Tuominen, J.; Kylma, J.; Kapanen, A.; Venelampi, O.; Itävaara, M.; Seppälä, J. Biodegradation of lactic acid based polymers under controlled composting conditions and evaluation of the ecotoxicological impact. Biomacromolecules 2002, 3, 445–455. [Google Scholar] [CrossRef] [PubMed]

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Massardier-Nageotte, V.; Pestre, C.; Cruard-Pradet, T.; Bayard, R. Aerobic and anaerobic biodegradability of polymer films and physico-chemical characterization. Polym. Degrad. Stab. 2006, 91, 620–627. [Google Scholar] [CrossRef]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and its blends with poly(butylene succinate) (PBS): A brief review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [Green Version]

- Total Corbion, Our Luminy® PLA Portfolio. 2021. Available online: https://www.total-corbion.com/luminy-pla-portfolio/ (accessed on 11 September 2021).

- NatureWorks LLC. Products. 2021. Available online: https://www.natureworksllc.com/Products (accessed on 11 September 2021).

- Loos, K. Biocatalysis in Polymer Chemistry, 1st ed.; Wiley-VCH: Weinheim, Germany, 2010. [Google Scholar] [CrossRef]

- Griffin, G. Chemistry and Technology of Biodegradable Polymers, 1st ed.; Springer: Dordrecht, The Netherlands; London, UK, 1994. [Google Scholar]

- Steinbüchel, A.; Valentin, H.E. Diversity of bacterial polyhydroxyalkanoic acids. FEMS Microbiol. Lett. 1995, 128, 219–228. [Google Scholar] [CrossRef]

- Witholt, B.; Kessler, B. Perspectives of medium chain length poly(hydroxyalkanoates), a versatile set of bacterial bioplastics. Curr. Opin. Biotechnol. 1999, 10, 279–285. [Google Scholar] [CrossRef]

- Steinbüchel, A.; Lütke-Eversloh, T. Metabolic engineering and pathway construction for biotechnological production of relevant polyhydroxyalkanoates in microorganisms. Biochem. Eng. J. 2003, 16, 81–96. [Google Scholar] [CrossRef]

- Madison, L.L.; Huisman, G.W. Metabolic Engineering of Poly(3-Hydroxyalkanoates): From DNA to Plastic. Microbiol. Mol. Biol. Rev. 1999, 63, 21–53. [Google Scholar] [CrossRef] [Green Version]

- Shang, L.; Jiang, M.; Chang, H.N. Poly(3-hydroxybutyrate) synthesis in fed-batch culture of Ralstonia eutropha with phosphate limitation under different glucose concentrations. Biotechnol. Lett. 2003, 25, 1415–1419. [Google Scholar] [CrossRef] [PubMed]

- Williams, S.F.; Peoples, O.P. Biodegradable plastics from plants. Chem Tech. 1996, 26, 38–44. [Google Scholar]

- Girdhar, A.; Bhatia, M.; Nagpal, S.; Kanampalliwar, A.; Tiwari, A. Process Parameters for Influencing Polyhydroxyalkanoate Producing Bacterial Factories: An Overview. J. Pet. Environ. Biotechnol. 2013, 4, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.Y. Plastic bacteria? Progress and prospects for polyhydroxyalkanoate production in bacteria. Trends Biotechnol. 1996, 14, 431–438. [Google Scholar] [CrossRef]

- Chen, G.Q.; Wu, Q. The application of polyhydroxyalkanoates as tissue engineering materials. Biomaterials 2005, 26, 6565–6578. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Yang, J.; Loh, X.J. Polyhydroxyalkanoates: Opening doors for a sustainable future. NPG Asia Mater. 2016, 8, 1–20. [Google Scholar] [CrossRef]

- Zinn, M.; Witholt, B.; Egli, T. Occurrence, synthesis and medical application of bacterial polyhydroxyalkanoate. Adv. Drug Deliv. Rev. 2001, 53, 5–21. [Google Scholar] [CrossRef]

- Zhang, M.; Thomas, N.L. Blending polylactic acid with polyhydroxybutyrate: The effect on thermal, mechanical, and biodegradation properties. Adv. Polym. Technol. 2011, 30, 67–79. [Google Scholar] [CrossRef]

- Steinbüchel, A. Perspectives for Biotechnological Production and Utilization of Biopolymers: Metabolic Engineering of Polyhydroxyalkanoate Biosynthesis Pathways as a Successful Example. Macromol. Biosci. 2001, 1, 1–24. [Google Scholar] [CrossRef]

- De Koning, G.J.M.; Lemstra, P.J. Crystallization phenomena in bacterial poly[(R)-3-hydroxybutyrate]: 2. Embrittlement and rejuvenation. Polymer 1993, 34, 4089–4094. [Google Scholar] [CrossRef] [Green Version]

- Rivera-Briso, A.L.; Serrano-Aroca, Á. Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate): Enhancement strategies for advanced applications. Polymers 2018, 10, 732. [Google Scholar] [CrossRef] [Green Version]

- Fei, B.; Chen, C.; Wu, H.; Peng, S.; Wang, X.; Dong, L.; Xin, J.H. Modified poly(3-hydroxybutyrate-co-3-hydroxyvalerate) using hydrogen bonding monomers. Polymer 2004, 45, 6275–6284. [Google Scholar] [CrossRef]

- Rudnik, E. Compostable polymer materials—Definitions, structures and methods of preparation. In Compostable Polymer Materials; Elsevier: Oxford, UK, 2019. [Google Scholar] [CrossRef]

- Pilla, S. Handbook of Bioplastics and Biocomposites Engineering Applications, 1st ed.; Scrivener Publishing: Beverly, MA, USA, 2011. [Google Scholar] [CrossRef]

- Saito, Y.; Doi, Y. Microbial synthesis and properties of poly(3-hydroxybutyrate-co-4-hydroxybutyrate) in Comamonas acidovorans. Int. J. Biol. Macromol. 1994, 16, 99–104. [Google Scholar] [CrossRef]

- Goldstein, N. Demystifying Biopolymers And Compostable Packaging. 2020. Available online: https://www.biocycle.net/demystifying-biopolymers-and-compostable-packaging/ (accessed on 13 June 2021).

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–372. [Google Scholar] [CrossRef] [Green Version]

- NatureWorks LLC. IngeoTM Biopolymer 2003D, 3052D, and 3801 X Technical Data Sheets; NatureWorks LLC: Minnetonka, MN, USA, 2018. [Google Scholar]

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly(lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: A review. RSC Adv. 2021, 28, 17151–17196. [Google Scholar] [CrossRef]

- Daniels, A.U.; Chang, M.K.; Andriano, K.P. Mechanical properties of biodegradable polymers and composites proposed for internal fixation of bone. J. Appl. Biomater. 1990, 1, 57–78. [Google Scholar] [CrossRef]

- Anderson, K.S.; Schreck, K.M.; Hillmyer, M.A. Toughening polylactide. Polym. Rev. 2008, 48, 85–108. [Google Scholar] [CrossRef]

- Mascia, L.; Xanthos, M. An overview of additives and modifiers for polymer blends: Facts, deductions, and uncertainties. Adv. Polym. Technol. 1992, 11, 237–248. [Google Scholar] [CrossRef]

- Sinclair, R.G. The case for polylactic acid as a commodity packaging plastic. J. Macromol. Sci. Part A Pure Appl. Chem. 1996, 33, 585–597. [Google Scholar] [CrossRef]

- Jacobsen, S.; Fritz, H.G. Plasticizing polylactide—The effect of different plasticizers on the mechanical properties. Polym. Eng. Sci. 1999, 39, 1303–1310. [Google Scholar] [CrossRef]

- Martin, O.; Averous, L. Poly(lactic acid): Plasticization and properties of biodegradable multiphase systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Baiardo, M.; Frisoni, G.; Scandola, M.; Rimelen, M.; Lips, D.; Ruffieux, K.; Wintermantel, E. Thermal and mechanical properties of plasticized poly(L-lactic acid). J. Appl. Polym. Sci. 2003, 90, 1731–1738. [Google Scholar] [CrossRef]

- Pillin, I.; Montrelay, N.; Grohens, Y. Thermo-mechanical characterization of plasticized PLA: Is the miscibility the only significant factor? Polymer 2006, 47, 4676–4682. [Google Scholar] [CrossRef]

- Kulinski, Z.; Piorkowska, E.; Gadzinowska, K.; Stasiak, M. Plasticization of poly(L-lactide) with poly(propylene glycol). Biomacromolecules 2006, 7, 2128–2135. [Google Scholar] [CrossRef]

- Nijenhuis, A.J.; Colstee, E.; Grijpma, D.W.; Pennings, A.J. High molecular weight poly(L-lactide) and poly(ethylene oxide) blends: Thermal characterization and physical properties. Polymer 1996, 37, 5849–5857. [Google Scholar] [CrossRef]

- Labrecque, L.V.; Kumar, R.A.; Davé, V.; Gross, R.A.; Mccarthy, S.P. Citrate esters as plasticizers for poly(lactic acid). J. Appl. Polym. Sci. 1997, 66, 1507–1513. [Google Scholar] [CrossRef]

- Yoon, J.S.; Oh, S.H.; Kim, M.N.; Chin, I.J.; Kim, Y.H. Thermal and mechanical properties of poly(L-lactic acid)-poly (ethylene co-vinyl acetate) blends. Polymer 1999, 40, 2303–2312. [Google Scholar] [CrossRef]

- Ren, Z.; Dong, L.; Yang, Y. Dynamic mechanical and thermal properties of plasticized poly(lactic acid). J. Appl. Polym. Sci. 2006, 101, 1583–1590. [Google Scholar] [CrossRef]

- Brüster, B.; Adjoua, Y.O.; Dieden, R.; Grysan, P.; Federico, C.E.; Berthé, V.; Addiego, F. Plasticization of polylactide with myrcene and limonene as bio-based plasticizers: Conventional vs. reactive extrusion. Polymers 2019, 11, 1363. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chaochanchaikul, K.; Pongmuksuwan, P. Influence of Ozonized Soybean Oil as a Biobased Plasticizer on the Toughness of Polylactic Acid. J. Polym. Environ. 2021, 1–11. [Google Scholar] [CrossRef]

- Dominguez-candela, I.; Ferri, J.M.; Cardona, S.C.; Lora, J.; Fombuena, V. Dual plasticizer/thermal stabilizer effect of epoxidized chia seed oil (Salvia hispanica l.) to improve ductility and thermal properties of poly(lactic acid). Polymers 2021, 13, 283. [Google Scholar] [CrossRef]

- Llanes, L.C.; Clasen, S.H.; Pires, A.T.N.; Gross, I.P. Mechanical and thermal properties of poly(lactic acid) plasticized with dibutyl maleate and fumarate isomers: Promising alternatives as biodegradable plasticizers. Eur. Polym. J. 2021, 142, 1–11. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Taib, R.M.; Ghaleb, Z.A.; Mohd Ishak, Z.A. Thermal, mechanical, and morphological properties of polylactic acid toughened with an impact modifier. J. Appl. Polym. Sci. 2012, 123, 2715–2725. [Google Scholar] [CrossRef]

- Barletta, M.; Pizzi, E.; Puopolo, M.; Vesco, S. Design and manufacture of degradable polymers: Biocomposites of micro-lamellar talc and poly(lactic acid). Mater. Chem. Phys. 2017, 196, 62–74. [Google Scholar] [CrossRef]

- Diaz, C.; Pao, H.Y.; Kim, S. Film Performance of Poly(lactic acid) Blends for Packaging Applications. J. Appl. Packag. Res. 2016, 8, 4. [Google Scholar]

- Choochottiros, C.; Chin, I.J. Potential transparent PLA impact modifiers based on PMMA copolymers. Eur. Polym. J. 2013, 49, 957–966. [Google Scholar] [CrossRef]

- Wang, L.; Ma, W.; Gross, R.A.; McCarthy, S.P. Reactive compatibilization of biodegradable blends of poly(lactic acid) and poly(ε-caprolactone). Polym. Degrad. Stab. 1998, 59, 161–168. [Google Scholar] [CrossRef]

- Broz, M.E.; VanderHart, D.L.; Washburn, N.R. Structure and mechanical properties of poly(D,L-lactic acid)/poly(ε-caprolactone) blends. Biomaterials 2003, 24, 4181–4190. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.M.; Duquesne, E.; Dubois, P. Random aliphatic copolyesters as new biodegradable impact modifiers for polylactide materials. Eur. Polym. J. 2012, 48, 331–340. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Scaffaro, R.; Morreale, M.; Mirabella, F.; La Mantia, F.P. Preparation and recycling of plasticized PLA. Macromol. Mater. Eng. 2011, 296, 141–150. [Google Scholar] [CrossRef]

- Murariu, M.; Da Silva Ferreira, A.; Duquesne, E.; Bonnaud, L.; Dubois, P. Polylactide (PLA) and highly filled PLA—Calcium sulfate composites with improved impact properties. Macromol. Symp. 2008, 272, 1–12. [Google Scholar] [CrossRef]

- Afrifah, K.A.; Matuana, L.M. Impact modification of polylactide with a biodegradable ethylene/acrylate copolymer. Macromol. Mater. Eng. 2010, 295, 802–811. [Google Scholar] [CrossRef]

- PARALOIDTM BPM-520 Impact Modifier. 2021. Available online: https://www.dow.com/en-us/pdp.paraloid-bpm-520-impact-modifier.185484z.html (accessed on 29 June 2021).

- Niaounakis, M. Biopolymers: Processing and Products, 1st ed.; Elsevier: Oxford, UK, 2015. [Google Scholar]

- Qin, Y. Applications of advanced technologies in the development of functional medical textile materials. In Medical Textile Materials, 1st ed.; Woodhead Publishing: London, UK, 2016. [Google Scholar] [CrossRef]

- Vogel, C.; Wessel, E.; Siesler, H.W. FT-IR spectroscopic imaging of anisotropic poly(3-hydroxybutyrate)/poly(lactic acid) blends with polarized radiation. Macromolecules 2008, 41, 2975–2977. [Google Scholar] [CrossRef]

- Furukawa, T.; Sato, H.; Murakami, R.; Zhang, J.; Duan, Y.X.; Noda, I.; Ochiai, S.; Ozaki, Y. Structure, dispersibility, and crystallinity of poly(hydroxybutyrate)/poly(L-lactic acid) blends studied by FT-IR microspectroscopy and differential scanning calorimetry. Macromolecules 2005, 38, 6445–6454. [Google Scholar] [CrossRef]

- Ohkoshi, I.; Abe, H.; Doi, Y. Miscibility and solid-state structures for blends of poly[(S)-lactide] with atactic poly[(R,S)-3-hydroxybutyrate]. Polymer 2000, 41, 5985–5992. [Google Scholar] [CrossRef]

- Blümm, E.; Owen, A.J. Miscibility, crystallization and melting of poly(3-hydroxybutyrate)/poly(l-lactide) blends. Polymer 1995, 36, 4077–4081. [Google Scholar] [CrossRef]

- Iannace, S.; Ambrosio, L.; Huang, S.J.; Nicolais, L. Poly(3-hydroxybutyrate)-co-(3-hydroxyvalerate)/Poly-L-lactide blends: Thermal and mechanical properties. J. Appl. Polym. Sci. 1994, 54, 1525–1536. [Google Scholar] [CrossRef]

- Ferreira, B.M.P.; Zavaglia, C.A.C.; Duek, E.A.R. Films of PLLA/PHBV: Thermal, morphological, and mechanical characterization. J. Appl. Polym. Sci. 2002, 86, 2898–2906. [Google Scholar] [CrossRef]

- Yoon, J.S.; Lee, W.S.; Kim, K.S.; Chin, I.J.; Kim, M.N.; Kim, C. Effect of poly(ethylene glycol)-block-poly(L-lactide) on the poly[(R)-3-hydroxybutyrate]/poly(L-lactide) blends. Eur. Polym. J. 2000, 36, 435–442. [Google Scholar] [CrossRef]

- Takagi, Y.; Yasuda, R.; Yamaoka, M.; Yamane, T. Morphologies and mechanical properties of polylactide blends with medium chain length poly(3-hydroxyalkanoate) and chemically modified poly(3-hydroxyalkanoate). J. Appl. Polym. Sci. 2004, 93, 2363–2369. [Google Scholar] [CrossRef]

- Noda, I.; Satkowski, M.M.; Dowrey, A.E.; Marcott, C. Polymer alloys of nodax copolymers and poly(lactic acid). Macromol. Biosci. 2004, 4, 269–275. [Google Scholar] [CrossRef]

- Schreck, K.M.; Hillmyer, M.A. Block copolymers and melt blends of polylactide with NodaxTM microbial polyesters: Preparation and mechanical properties. J. Biotechnol. 2007, 132, 287–295. [Google Scholar] [CrossRef] [PubMed]

- Bartczak, Z.; Galeski, A.; Kowalczuk, M.; Sobota, M.; Malinowski, R. Tough blends of poly(lactide) and amorphous poly([R,S]-3-hydroxy butyrate)—Morphology and properties. Eur. Polym. J. 2013, 49, 3630–3641. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. The effects of process engineering on the performance of PLA and PHBV blends. Macromol. Mater. Eng. 2011, 273, 719–728. [Google Scholar] [CrossRef]

- Noda, I.; Green, P.R.; Satkowski, M.M.; Schechtman, L.A. Preparation and properties of a novel class of polyhydroxyalkanoate copolymers. Biomacromolecules 2005, 6, 580–586. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Wang, S.; Kong, M.; Geng, W.; Li, R.K.Y.; Song, C.; Kong, D. Phase morphology, physical properties, and biodegradation behavior of novel PLA/PHBHHx blends. J. Biomed. Mater. Res. Part B Appl. Biomater. 2012, 100, 23–31. [Google Scholar] [CrossRef]

- Rasal, R.M.; Hirt, D.E. Toughness decrease of PLA-PHBHHx blend films upon surface-confined photopolymerization. J. Biomed. Mater. Res. Part A 2009, 88, 1079–1086. [Google Scholar] [CrossRef]

- Lim, J.S.; Park, K.I.; Chung, G.S.; Kim, J.H. Effect of composition ratio on the thermal and physical properties of semicrystalline PLA/PHB-HHx composites. Mater. Sci. Eng. C 2013, 33, 2131–2137. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; López, J.; Kenny, J.M. Bionanocomposite films based on plasticized PLA-PHB/cellulose nanocrystal blends. Carbohydr. Polym. 2015, 121, 265–275. [Google Scholar] [CrossRef] [Green Version]

- El-Hadi, A.M. Development of novel biopolymer blends based on poly(L-lactic acid), poly((R)-3-hydroxybutyrate), and plasticizer. Polym. Eng. Sci. 2014, 54, 1394–1402. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Rayón, E.; Jiménez, A. Disintegrability under composting conditions of plasticized PLA–PHB blends. Polym. Degrad. Stab. 2014, 108, 307–318. [Google Scholar] [CrossRef] [Green Version]

- Arrieta, M.P.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J.M. Multifunctional PLA-PHB/cellulose nanocrystal films: Processing, structural and thermal properties. Carbohydr. Polym. 2014, 107, 16–24. [Google Scholar] [CrossRef]

- Arrieta, M.P.; López, J.; Hernández, A.; Rayón, E. Ternary PLA-PHB-Limonene blends intended for biodegradable food packaging applications. Eur. Polym. J. 2014, 50, 255–270. [Google Scholar] [CrossRef]

- Abdelwahab, M.A.; Flynn, A.; Chiou, B.S.; Imam, S.; Orts, W.; Chiellini, E. Thermal, mechanical and morphological characterization of plasticized PLA-PHB blends. Polym. Degrad. Stab. 2012, 97, 1822–1828. [Google Scholar] [CrossRef]

- Guessasma, S.; Belhabib, S.; Nouri, H. Thermal cycling, microstructure and tensile performance of PLA-PHA polymer printed using fused deposition modelling technique. Rapid Prototyp. J. 2020, 26, 122–133. [Google Scholar] [CrossRef]

- Olejnik, O.; Masek, A.; Zawadziłło, J. Processability and mechanical properties of thermoplastic polylactide/polyhydroxybutyrate (PLA/PHB) bioblends. Materials 2021, 14, 898. [Google Scholar] [CrossRef] [PubMed]

- Hiljanen-Vainio, M.; Varpomaa, P.; Seppälä, J.; Törmälä, P. Modification of poly(L-lactides) by blending: Mechanical and hydrolytic behavior. Macromol. Chem. Phys. 1996, 197, 1503–1523. [Google Scholar] [CrossRef]

- Tsuji, H.; Ikada, Y. Blends of aliphatic polyesters. I. Physical properties and morphologies of solution-cast blends from poly(DL-lactide) and poly(ε-caprolactone). J. Appl. Polym. Sci. 1996, 60, 2367–2375. [Google Scholar] [CrossRef]

- Maglio, G.; Migliozzi, A.; Palumbo, R.; Immirzi, B.; Volpe, M.G. Compatibilized poly(ε-caprolactone)/poly(L-lactide) blends for biomedical uses. Macromol. Rapid Commun. 1999, 20, 236–238. [Google Scholar] [CrossRef]

- Tsuji, H.; Yamada, T.; Suzuki, M.; Itsuno, S. Blends of aliphatic polyesters. Part 7. Effects of poly(L-lactide-co-ε-caprolactone) on morphology, structure, crystallization, and physical properties of blends of poly(L-lactide) and poly(ε-caprolactone). Polym. Int. 2003, 52, 269–275. [Google Scholar] [CrossRef]

- Semba, T.; Kitagawa, K.; Ishiaku, U.S.; Hamada, H. The effect of crosslinking on the mechanical properties of polylactic acid/polycaprolactone blends. J. Appl. Polym. Sci. 2006, 101, 1816–1825. [Google Scholar] [CrossRef]

- Grijpma, D.W.; Van Hofslot, R.D.A.; Supèr, H.; Nijenhuis, A.J.; Pennings, A.J. Rubber toughening of poly(lactide) by blending and block copolymerization. Polym. Eng. Sci. 1994, 34, 1674–1684. [Google Scholar] [CrossRef]

- Joziasse, C.A.P.; Topp, M.D.C.; Pennings, D.W.G.J. Rubber toughened linear and star-shaped. Polymer 1998, 39, 467–474. [Google Scholar] [CrossRef]

- Chen, C.C.; Chueh, J.Y.; Tseng, H.; Huang, H.M.; Lee, S.Y. Preparation and characterization of biodegradable PLA polymeric blends. Biomaterials 2003, 24, 1167–1173. [Google Scholar] [CrossRef]

- Hasook, A.; Tanoue, S.; Lemoto, Y.; Unryu, T. Characterization and mechanical properties of poly(lactic acid)/poly(ε-caprolactone)/organoclay nanocomposites prepared by melt compounding. Polym. Eng. Sci. 2006, 46, 1001–1007. [Google Scholar] [CrossRef]

- Jeantet, L.; Regazzi, A.; Taguet, A.; Pucci, M.F.; Caro, A.S.; Quantin, J.C. Biopolymer blends for mechanical property gradient 3D printed parts. Express Polym. Lett. 2021, 15, 137–152. [Google Scholar] [CrossRef]

- Doganci, M.D. Effects of star-shaped PCL having different numbers of arms on the mechanical, morphological, and thermal properties of PLA/PCL blends. J. Polym. Res. 2021, 28, 1–13. [Google Scholar] [CrossRef]

- Ebrahimifar, M.; Taherimehr, M. Evaluation of in-vitro drug release of polyvinylcyclohexane carbonate as a CO2-derived degradable polymer blended with PLA and PCL as drug carriers. J. Drug Deliv. Sci. Technol. 2021, 63, 1–13. [Google Scholar] [CrossRef]

- Yang, Z.T.; Yang, J.X.; Fan, J.H.; Feng, Y.H.; Huang, Z.X. Preparation of super-toughened Poly(L-lactide) composites under elongational flow: A strategy for balancing stiffness and ductility. Compos. Sci. Technol. 2021, 208, 1–8. [Google Scholar] [CrossRef]

- Pezzin, A.P.T.; Alberda van Ekenstein, G.O.R.; Zavaglia, C.A.C.; Ten Brinke, G.; Duek, E.A.R. Poly(para-dioxanone) and poly(1-lactic acid) blends: Thermal, mechanical, and morphological properties. J. Appl. Polym. Sci. 2003, 88, 2744–2755. [Google Scholar] [CrossRef]

- Ma, X.; Jiugao, Y.; Wang, N. Compatibility characterization of poly(lactic acid)/poly(propylene carbonate) blends. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 94–101. [Google Scholar] [CrossRef]

- Liu, T.Y.; Lin, W.C.; Yang, M.C.; Chen, S.Y. Miscibility, thermal characterization and crystallization of poly(l-lactide) and poly(tetramethylene adipate-co-terephthalate) blend membranes. Polymer 2005, 46, 12586–12594. [Google Scholar] [CrossRef]

- Jiang, L.; Wolcott, M.P.; Zhang, J. Study of biodegradable polylactide/poly(butylene adipate-co-terephthalate) blends. Biomacromolecules 2006, 7, 199–207. [Google Scholar] [CrossRef]

- Liu, X.; Dever, M.; Fair, N.; Benson, R.S. Thermal and mechanical properties of poly(lactic acid) and poly(ethylene/butylene succinate) blends. J. Environ. Polym. Degrad. 1997, 5, 225–235. [Google Scholar] [CrossRef]

- Shibata, M.; Inoue, Y.; Miyoshi, M. Mechanical properties, morphology, and crystallization behavior of blends of poly(l-lactide) with poly(butylene succinate-co-l-lactate) and poly(butylene succinate). Polymer 2006, 47, 3557–3564. [Google Scholar] [CrossRef]

- Chen, G.X.; Kim, H.S.; Kim, E.S.; Yoon, J.S. Compatibilization-like effect of reactive organoclay on the poly(l-lactide)/poly(butylene succinate) blends. Polymer 2005, 46, 11829–11836. [Google Scholar] [CrossRef]

- Chen, C.X.; Yoon, J.S. Morphology and thermal properties of poly(L -lactide)/poly (butylene succinate-co-butylene adipate) compounded with twice functionalized clay. J. Polym. Sci. Part B Polym. Phys. 2005, 43, 478–487. [Google Scholar] [CrossRef]

- Shibata, M.; Teramoto, N.; Inoue, Y. Mechanical properties, morphologies, and crystallization behavior of plasticized poly(l-lactide)/poly(butylene succinate-co-l-lactate) blends. Polymer 2007, 48, 2768–2777. [Google Scholar] [CrossRef]

- Zhang, L.; Xiong, C.; Deng, X. Miscibility, crystallization and morphology of poly(β-hydroxybutyrate)/poly(d,l-lactide) blends. Polymer 1996, 37, 235–241. [Google Scholar] [CrossRef]

- Jandas, P.J.; Mohanty, S.; Nayak, S.K. Sustainability, compostability, and specific microbial activity on agricultural mulch films prepared from poly(lactic acid). Ind. Eng. Chem. Res. 2013, 52, 17714–17724. [Google Scholar] [CrossRef]

- Burgos, N.; Armentano, I.; Fortunati, E.; Dominici, F.; Luzi, F.; Fiori, S.; Cristofaro, F.; Visai, L.; Jiménez, A.; Kenny, J.M. Functional Properties of Plasticized Bio-Based Poly(Lactic Acid)_Poly(Hydroxybutyrate) (PLA_PHB) Films for Active Food Packaging. Food Bioprocess Technol. 2017, 10, 770–780. [Google Scholar] [CrossRef] [Green Version]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.M.; Hsiao, B.S.; Zhong, G.J. Unprecedented access to strong and ductile poly(lactic acid) by introducing in situ nanofibrillar poly(butylene succinate) for green packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef] [PubMed]

- Fortunati, E.; Puglia, D.; Iannoni, A.; Terenzi, A.; Kenny, J.M.; Torre, L. Processing conditions, thermal and mechanical responses of stretchable poly (lactic acid)/poly (butylene succinate) films. Materials 2017, 10, 809. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 120, 98971–98982. [Google Scholar] [CrossRef]

- Jost, V.; Kopitzky, R. Blending of polyhydroxybutyrate-co-valerate with polylactic acid for packaging applications—Reflections on miscibility and effects on the mechanical and barrier properties. Chem. Biochem. Eng. Q. 2015, 29, 221–246. [Google Scholar] [CrossRef]

- Luzi, F.; Fortunati, E.; Jiménez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crop. Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Songtipya, L.; Limchu, T.; Phuttharak, S.; Songtipya, P.; Kalkornsurapranee, E. Poly(lactic acid)-based Composites Incorporated with Spent Coffee Ground and Tea Leave for Food Packaging Application: A Waste to Wealth. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar] [CrossRef]

- Ma, Y.; Li, L.; Wang, Y. Development of PLA-PHB-based biodegradable active packaging and its application to salmon. Packag. Technol. Sci. 2018, 31, 739–746. [Google Scholar] [CrossRef]

- Hongsriphan, N.; Sanga, S. Antibacterial food packaging sheets prepared by coating chitosan on corona-treated extruded poly(lactic acid)/poly(butylene succinate) blends. J. Plast. Film Sheeting 2018, 34, 160–178. [Google Scholar] [CrossRef]

- Zhang, K.; Mohanty, A.K.; Misra, M. Fully biodegradable and biorenewable ternary blends from polylactide, poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) with balanced properties. ACS Appl. Mater. Interfaces 2012, 4, 3091–3101. [Google Scholar] [CrossRef]

- Balakrishnan, H.; Hassan, A.; Wahit, M.U.; Yussuf, A.A.; Razak, S.B.A. Novel toughened polylactic acid nanocomposite: Mechanical, thermal and morphological properties. Mater. Des. 2010, 31, 3289–3298. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, T.G.; Park, H.S.; Lee, D.S.; Lee, Y.K.; Yoon, S.C.; Nam, J.D. Thermal and mechanical characteristics of poly(L-lactic acid) nanocomposite scaffold. Biomaterials 2003, 24, 2773–2778. [Google Scholar] [CrossRef]

- Jiang, L.; Zhang, J.; Wolcott, M.P. Comparison of polylactide/nano-sized calcium carbonate and polylactide/montmorillonite composites: Reinforcing effects and toughening mechanisms. Polymer 2007, 48, 7632–7644. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Improving mechanical performance of injection molded PLA by controlling crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Yu, F.; Liu, T.; Zhao, X.; Yu, X.; Lu, A.; Wang, J. Effects of talc on the mechanical and thermal properties of polylactide. J. Appl. Polym. Sci. 2012, 125, E99–E109. [Google Scholar] [CrossRef]

- Ouchiar, S.; Stoclet, G.; Cabaret, C.; Georges, E.; Smith, A.; Martias, C.; Addad, A.; Gloaguen, V. Comparison of the influence of talc and kaolinite as inorganic fillers on morphology, structure and thermomechanical properties of polylactide based composites. Appl. Clay Sci. 2015, 116–117, 231–240. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/polylactic acid nanocomposites prepared by twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- Silva, A.P.B.; Montagna, L.S.; Passador, F.R.; Rezende, M.C.; Lemes, A.P. Biodegradable nanocomposites based on PLA/PHBV blend reinforced with carbon nanotubes with potential for electrical and electromagnetic applications. Express Polym. Lett. 2021, 15, 987–1003. [Google Scholar] [CrossRef]

- Chen, P.Y.; Lian, H.Y.; Shih, Y.F.; Chen-Wei, S.M.; Jeng, R.J. Preparation, characterization and crystallization kinetics of Kenaf fiber/multi-walled carbon nanotube/polylactic acid (PLA) green composites. Mater. Chem. Phys. 2017, 196, 249–255. [Google Scholar] [CrossRef]

- Quan, H.; Li, Z.M.; Yang, M.B.; Huang, R. On transcrystallinity in semi-crystalline polymer composites. Compos. Sci. Technol. 2005, 65, 999–1021. [Google Scholar] [CrossRef]

- Reverte, J.M.; Caminero, M.Á.; Chacón, J.M.; García-Plaza, E.; Núñez, P.J.; Becar, J.P. Mechanical and geometric performance of PLA-based polymer composites processed by the fused filament fabrication additive manufacturing technique. Matererials 2020, 13, 1924. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wootthikanokkhan, J.; Cheachun, T.; Sombatsompop, N.; Thumsorn, S.; Kaabbuathong, N.; Wongta, N.; Wong-On, J.; Na Ayutthaya, S.I.; Kositchaiyong, A. Crystallization and thermomechanical properties of PLA composites: Effects of additive types and heat treatment. J. Appl. Polym. Sci. 2013, 129, 215–223. [Google Scholar] [CrossRef]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. 3d printing pla waste to produce ceramic based particulate reinforced composite using abundant silica-sand: Mechanical properties characterization. Polymers 2020, 12, 2579. [Google Scholar] [CrossRef] [PubMed]

- Swaroop, C.; Shukla, M. Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. Int. J. Biol. Macromol. 2018, 113, 729–736. [Google Scholar] [CrossRef] [Green Version]

- John, M.J.; Anandjiwala, R.D. Recent developments in chemical modification and characterization of natural fiber-reinforced composites. Polym. Compos. 2008, 29, 187–207. [Google Scholar] [CrossRef]

- Foruzanmehr, M.; Vuillaume, P.Y.; Elkoun, S.; Robert, M. Physical and mechanical properties of PLA composites reinforced by TiO2 grafted flax fibers. Mater. Des. 2016, 106, 295–304. [Google Scholar] [CrossRef]

- Lee, B.H.; Kim, H.S.; Lee, S.; Kim, H.J.; Dorgan, J.R. Bio-composites of kenaf fibers in polylactide: Role of improved interfacial adhesion in the carding process. Compos. Sci. Technol. 2009, 69, 15–16. [Google Scholar] [CrossRef]

- Kumar, R.; Yakabu, M.K.; Anandjiwala, R.D. Effect of montmorillonite clay on flax fabric reinforced poly lactic acid composites with amphiphilic additives. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1620–1627. [Google Scholar] [CrossRef]

- Kanakannavar, S.; Pitchaimani, J. Fracture toughness of flax braided yarn woven PLA composites. Int. J. Polym. Anal. Charact. 2021, 26, 364–379. [Google Scholar] [CrossRef]

- Wang, A.; Qi, R.; Xiong, C.; Huang, M. Effects of coupling agent and interfacial modifiers on mechanical properties of poly(lactic acid) and wood flour biocomposites. Iran. Polym. J. Engl. Ed. 2011, 20, 281–294. [Google Scholar]

- Da Silva, W.A.; Luna, C.B.B.; de Melo, J.B.d.C.A.; Araújo, E.M.; Filho, E.A.d.S.; Duarte, R.N.C. Feasibility of Manufacturing Disposable Cups using PLA/PCL Composites Reinforced with Wood Powder. J. Polym. Environ. 2021, 29, 2932–2951. [Google Scholar] [CrossRef]

- Wasti, S.; Triggs, E.; Farag, R.; Auad, M.; Adhikari, S.; Bajwa, D.; Li, M.; Ragauskas, A.J. Influence of plasticizers on thermal and mechanical properties of biocomposite filaments made from lignin and polylactic acid for 3D printing. Compos. Part B Eng. 2021, 205, 1–8. [Google Scholar] [CrossRef]

- Paul, U.C.; Fragouli, D.; Bayer, I.S.; Zych, A.; Athanassiou, A. Effect of Green Plasticizer on the Performance of Microcrystalline Cellulose/Polylactic Acid Biocomposites. ACS Appl. Polym. Mater. 2021, 3, 3071–3081. [Google Scholar] [CrossRef]

- Rasheed, M.; Jawaid, M.; Parveez, B. Bamboo fiber based cellulose nanocrystals/poly(Lactic acid)/poly(butylene succinate) nanocomposites: Morphological, mechanical and thermal properties. Polymers 2021, 13, 1076. [Google Scholar] [CrossRef]

- Frone, A.N.; Batalu, D.; Chiulan, I.; Oprea, M.; Gabor, A.R.; Nicolae, C.A.; Raditoiu, V.; Trusca, R.; Panaitescu, D.M. Morpho-structural, thermal and mechanical properties of PLA/PHB/Cellulose biodegradable nanocomposites obtained by compression molding, extrusion, and 3d printing. Nanomaterials 2020, 10, 51. [Google Scholar] [CrossRef] [Green Version]

- Alam, F.; Verma, P.; Mohammad, W.; Teo, J.; Varadarajan, K.M.; Kumar, S. Architected poly(lactic acid)/poly(ε-caprolactone)/halloysite nanotube composite scaffolds enabled by 3D printing for biomedical applications. J. Mater. Sci. 2021, 56, 14070–14083. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Singh, I. Processing of PLA/pineapple fiber based next generation composites. Mater. Manuf. Process. 2021, 36, 1–16. [Google Scholar] [CrossRef]

- Mohamad, S.N.K.; Ramli, I.; Abdullah, L.C.; Mohamed, N.H.; Islam, M.S.; Ibrahim, N.A.; Ishak, N.S. Evaluation on structural properties and performances of graphene oxide incorporated into chitosan/poly-lactic acid composites: Cs/pla versus cs/pla-go. Polymers 2021, 13, 1839. [Google Scholar] [CrossRef]

- McChalicher, C.W.J.; Srienc, F. Investigating the structure-property relationship of bacterial PHA block copolymers. J. Biotechnol. 2007, 123, 296–302. [Google Scholar] [CrossRef]

- Sudesh, K.; Iwata, T. Sustainability of biobased and biodegradable plastics. Clean Soil Air Water 2008, 36, 433–442. [Google Scholar] [CrossRef]

- Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable polymers with a range of applications. J. Chem. Technol. Biotechnol. 2007, 82, 233–247. [Google Scholar] [CrossRef]

- Khanna, S.; Srivastava, A.K. Recent advances in microbial polyhydroxyalkanoates. Process Biochem. 2005, 40, 607–619. [Google Scholar] [CrossRef]

- Rai, R.; Keshavarz, T.; Roether, J.A.; Boccaccini, A.R.; Roy, I. Medium chain length polyhydroxyalkanoates, promising new biomedical materials for the future. Mater. Sci. Eng. R Rep. 2011, 72, 29–47. [Google Scholar] [CrossRef]

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808. [Google Scholar] [CrossRef] [Green Version]

- Kushwah, B.S.; Kushwah, A.V.S.; Singh, V. Towards understanding polyhydroxyalkanoates and their use. J. Polym. Res. 2016, 23, 1–14. [Google Scholar] [CrossRef]

- Bucci, D.Z.; Tavares, L.B.B.; Sell, I. PHB packaging for the storage of food products. Polym. Test. 2005, 24, 564–571. [Google Scholar] [CrossRef]

- Aldor, I.S.; Kim, S.W.; Jones Prather, K.L.; Keasling, J.D. Metabolic engineering of a novel propionate-independent pathway for the production of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) in recombinant Salmonella enterica serovar typhimurium. Appl. Environ. Microbiol. 2002, 68, 3848–3854. [Google Scholar] [CrossRef] [Green Version]

- Ha, C.S.; Cho, W.J. Miscibility, properties, and biodegradability of microbial polyester containing blends. Prog. Polym. Sci. 2002, 27, 759–809. [Google Scholar] [CrossRef]

- Ohashi, E.; Drumond, W.S.; Zane, N.P.; Barros, P.W.D.F.; Lachtermacher, M.G.; Wiebeck, H.; Wang, S.H. Biodegradable poly(3-hydroxybutyrate) nanocomposite. Macromol. Symp. 2009, 279, 138–144. [Google Scholar] [CrossRef]

- Sudesh, K.; Abe, H.; Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: Biological polyesters. Prog. Polym. Sci. 2000, 25, 1503–1555. [Google Scholar] [CrossRef]

- La Cara, F.; Immirzi, B.; Ionata, E.; Mazzella, A.; Portofino, S.; Orsello, G.; De Prisco, P.P. Biodegradation of poly-ε-caprolactone/poly-β-hydroxybutyrate blend. Polym. Degrad. Stab. 2003, 79, 37–43. [Google Scholar] [CrossRef]

- Lovera, D.; Márquez, L.; Balsamo, V.; Taddei, A.; Castelli, C.; Müller, A.J. Crystallization, morphology, and enzymatic degradation of polyhydroxybutyrate/polycaprolactone (PHB/PCL) blends. Macromol. Chem. Phys. 2007, 208, 924–937. [Google Scholar] [CrossRef]

- Gonçalves, S.P.C.; Martins Franchetti, S.M. Respirometric evaluation of the biodegradability of films of PE/PHBV blends. Int. J. Mater. Sci. 2013, 11, 54–60. [Google Scholar]

- Masood, F.; Yasin, T.; Hameed, A. Comparative oxo-biodegradation study of poly-3-hydroxybutyrate-co-3-hydroxyvalerate/polypropylene blend in controlled environments. Int. Biodeterior. Biodegrad. 2014, 87, 1–8. [Google Scholar] [CrossRef]

- Gonçalves, S.P.C.; Martins-Franchetti, S.M.; Chinaglia, D.L. Biodegradation of the films of PP, PHBV and its blend in soil. J. Polym. Environ. 2009, 17, 280–285. [Google Scholar] [CrossRef]

- Burlein, G.A.D.; Rocha, M.C.G. Mechanical and morphological properties of LDPE/PHB blends filled with castor oil pressed cake. Mater. Res. 2014, 17, 97–105. [Google Scholar] [CrossRef]

- Quental, A.C.; de Carvalho, F.P.; Rezende, M.L.; Rosa, D.S.; Felisberti, M.I. Aromatic/Aliphatic Polyester Blends. J. Polym. Environ. 2010, 18, 308–317. [Google Scholar] [CrossRef]

- Ma, P.; Hristova-Bogaerds, D.G.; Lemstra, P.J.; Zhang, Y.; Wang, S. Toughening of PHBV/PBS and PHB/PBS blends via in situ compatibilization using dicumyl peroxide as a free-radical grafting initiator. Macromol. Mater. Eng. 2012, 297, 402–410. [Google Scholar] [CrossRef] [Green Version]

- Zhao, H.; Cui, Z.; Wang, X.; Turng, L.S.; Peng, X. Processing and characterization of solid and microcellular poly(lactic acid)/polyhydroxybutyrate-valerate (PLA/PHBV) blends and PLA/PHBV/Clay nanocomposites. Compos. Part B Eng. 2013, 51, 79–91. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Ferri, J.M.; Boronat, T.; Lopez-Martinez, J.; Balart, R. Processing and characterization of binary poly(hydroxybutyrate) (PHB) and poly(caprolactone) (PCL) blends with improved impact properties. Polym. Bull. 2016, 73, 3333–3350. [Google Scholar] [CrossRef] [Green Version]

- Chee, M.J.K.; Ismail, J.; Kammer, H.W.; Kummerloöwe, C. Study on miscibility of PEO and PCL in blends with PHB by solution viscometry. Polymer 2001, 43, 1235–1239. [Google Scholar] [CrossRef]

- Nishida, M.; Tanaka, T.; Hayakawa, Y.; Ogura, T.; Ito, Y.; Nishida, M. Multi-scale instrumental analyses of plasticized polyhydroxyalkanoates (PHA) blended with polycaprolactone (PCL) and the effects of crosslinkers and graft copolymers. RSC Adv. 2019, 9, 1551–1561. [Google Scholar] [CrossRef] [Green Version]

- Mendibil, X.; González-Pérez, F.; Bazan, X.; Díez-Ahedo, R.; Quintana, I.; Rodríguez, F.J.; Basnett, P.; Nigmatullin, R.; Lukasiewicz, B.; Roy, I.; et al. Bioresorbable and Mechanically Optimized Nerve Guidance Conduit Based on a Naturally Derived Medium Chain Length Polyhydroxyalkanoate and Poly(ϵ-Caprolactone) Blend. ACS Biomater. Sci. Eng. 2021, 7, 672–689. [Google Scholar] [CrossRef]

- Qiu, Z.; Ikehara, T.; Nishi, T. Poly(hydroxybutyrate)/poly(butylene succinate) blends: Miscibility and nonisothermal crystallization. Polymes 2003, 44, 2503–2508. [Google Scholar] [CrossRef]

- Qiu, Z.; Ikehara, T.; Nishi, T. Miscibility and crystallization behaviour of biodegradable blends of two aliphatic polyesters. Poly(3-hydroxybutyrate-co-hydroxyvalerate) and poly(butylene succinate) blends. Polymer 2003, 44, 7519–7527. [Google Scholar] [CrossRef]

- Meléndez-Rodríguez, B.; Torres-Giner, S.; Reis, M.A.M.; Silva, F.; Matos, M.; Cabedo, L.; Lagarón, J.M. Blends of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with fruit pulp biowaste derived poly(3-hydroxybutyrate-co-3- hydroxyvalerate-co-3-hydroxyhexanoate) for organic recycling food packaging. Polymers 2021, 13, 1155. [Google Scholar] [CrossRef]

- Lim, S.T.; Hyun, Y.H.; Lee, C.H.; Choi, H.J. Preparation and characterization of microbial biodegradable poly(3-hydroxybutyrate)/organoclay nanocomposite. J. Mater. Sci. Lett. 2003, 22, 299–302. [Google Scholar] [CrossRef]

- Shan, G.F.; Gong, X.; Chen, W.P.; Chen, L.; Zhu, M.F. Effect of multi-walled carbon nanotubes on crystallization behavior of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Colloid Polym. Sci. 2011, 289, 1005–1014. [Google Scholar] [CrossRef]

- Lai, M.; Li, J.; Yang, J.; Liu, J.; Tong, X.; Cheng, H. The morphology and thermal properties of multi-walled carbon nanotube and poly(hydroxybutyrate-co-hydroxyvalerate) composite. Polym. Int. 2004, 53, 1479–1484. [Google Scholar] [CrossRef]

- Maiti, P.; Batt, C.A.; Giannelis, E.P. New biodegradable polyhydroxybutyrate/layered silicate nanocomposites. Biomacromolecules 2007, 8, 3393–3400. [Google Scholar] [CrossRef]

- Wang, S.; Song, C.; Chen, G.; Guo, T.; Liu, J.; Zhang, B.; Takeuchi, S. Characteristics and biodegradation properties of poly(3-hydroxybutyrate-co- 3-hydroxyvalerate)/organophilic montmorillonite (PHBV/OMMT) nanocomposite. Polym. Degrad. Stab. 2005, 87, 69–76. [Google Scholar] [CrossRef]

- Chen, G.X.; Hao, G.J.; Guo, T.Y.; Song, M.D.; Zhang, B.H. Crystallization kinetics of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/clay nanocomposites. J. Appl. Polym. Sci. 2004, 93, 655–661. [Google Scholar] [CrossRef]

- Botana, A.; Mollo, M.; Eisenberg, P.; Torres Sanchez, R.M. Effect of modified montmorillonite on biodegradable PHB nanocomposites. Appl. Clay Sci. 2010, 47, 263–270. [Google Scholar] [CrossRef]

- Carli, L.N.; Crespo, J.S.; Mauler, R.S. PHBV nanocomposites based on organomodified montmorillonite and halloysite: The effect of clay type on the morphology and thermal and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1601–1608. [Google Scholar] [CrossRef]

- Misra, M.; Desai, S.M.; Mohanty, A.K.; Drzal, L.T. Novel solvent-free method for functionalization of polyhydroxyalkanoates: Synthesis and chracterizations. In Proceedings of the Annual Technical Conference—ANTEC, Chicago, IL, USA, 16–20 May 2004. [Google Scholar]

- Martínez-Sanz, M.; Villano, M.; Oliveira, C.; Albuquerque, M.G.E.; Majone, M.; Reis, M.; Lopez-Rubio, A.; Lagaron, J.M. Characterization of polyhydroxyalkanoates synthesized from microbial mixed cultures and of their nanobiocomposites with bacterial cellulose nanowhiskers. N. Biotechnol. 2014, 31, 364–376. [Google Scholar] [CrossRef]

- Ten, E.; Turtle, J.; Bahr, D.; Jiang, L.; Wolcott, M. Thermal and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhiskers composites. Polymer 2010, 51, 2652–2660. [Google Scholar] [CrossRef]

- Jiang, L.; Morelius, E.; Zhang, J.; Wolcott, M.; Holbery, J. Study of the poly(3-hydroxybutyrate-co-3-hydroxyvalerate)/cellulose nanowhisker composites prepared by solution casting and melt processing. J. Compos. Mater. 2008, 42, 2629–2645. [Google Scholar] [CrossRef]

- Xie, Y.; Kohls, D.; Noda, I.; Schaefer, D.W.; Akpalu, Y.A. Poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) nanocomposites with optimal mechanical properties. Polymer 2009, 50, 4656–4670. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.D.; Lagaron, J.M.; Hoa, S.V. Effect of addition of carbon nanofibers and carbon nanotubes on properties of thermoplastic biopolymers. Compos. Sci. Technol. 2010, 70, 1095–1105. [Google Scholar] [CrossRef]

- Jo, J.; Kim, H.; Jeong, S.Y.; Park, C.; Hwang, H.S.; Koo, B. Changes in mechanical properties of polyhydroxyalkanoate with double silanized cellulose nanocrystals using different organosiloxanes. Nanomaterials 2021, 11, 1542. [Google Scholar] [CrossRef]

- Liao, H.T.; Wu, C.S. Poly(3-hydroxybutyrate)/multi-walled carbon nanotubes nanocomposites: Preparation and characterizations. Des. Monomers Polym. 2013, 16, 99–107. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Fan, Y.; Xue, Y.; Wu, L.; Lu, Y.; Chen, J.; Wang, X.; Dong, D.; Meng, F.; Lu, Y.; et al. Electrospun CF-PHA nanocomposites: Effect of surface modifications of carbon fibers. Int. J. Polym. Mater. Polym. Biomater. 2014, 63, 262–267. [Google Scholar] [CrossRef]

- Gumel, A.M.; Annuar, M.S.M.; Ishak, K.A.; Ahmad, N. Carbon nanofibers-poly-3-hydroxyalkanoates nanocomposite: Ultrasound-assisted dispersion and thermostructural properties. J. Nanomater. 2014, 2014, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Cataldi, P.; Steiner, P.; Raine, T.; Lin, K.; Kocabas, C.; Young, R.J.; Bissett, M.; Kinloch, I.A.; Papageorgiou, D.G. Multifunctional Biocomposites Based on Polyhydroxyalkanoate and Graphene/Carbon Nanofiber Hybrids for Electrical and Thermal Applications. ACS Appl. Polym. Mater. 2020, 2, 3525–3534. [Google Scholar] [CrossRef]

- Kotnis, M.A.; O’Brien, G.S.; Willett, J.L. Processing and mechanical properties of biodegradable Poly(hydroxybutyrate-co-valerate)-starch compositions. J. Environ. Polym. Degrad. 1995, 3, 97–105. [Google Scholar] [CrossRef]

- Shogren, R.L. Poly(ethylene oxide)-coated granular starch-poly(hydroxybutyrate-co-hydroxyvalerate) composite materials. J. Environ. Polym. Degrad. 1995, 3, 75–80. [Google Scholar] [CrossRef]

- Koller, I.; Owen, A.J. Starch-filled PHB and PHB/HV copolymer. Polym. Int. 1996, 39, 175–181. [Google Scholar] [CrossRef]

- Rosa, D.D.S.; Rodrigues, T.C.; Das Graças Fassina Guedes, C.; Calil, M.R. Effect of thermal aging on the biodegradation of PCL, PHB-V, and their blends with starch in soil compost. J. Appl. Polym. Sci. 2003, 89, 3539–3546. [Google Scholar] [CrossRef]

- Ramsay, B.A.; Langlade, V.; Carreau, P.J.; Ramsay, J.A. Biodegradability and mechanical properties of poly-(β-hydroxybutyrate- co-β-hydroxyvalerate)-starch blends. Appl. Environ. Microbiol. 1993, 59, 1242–1246. [Google Scholar] [CrossRef] [Green Version]

- Avella, M.; Errico, M.E.; Rimedio, R.; Sadocco, P. Preparation of biodegradable polyesters/high-amylose-starch composites by reactive blending and their characterization. J. Appl. Polym. Sci. 2002, 83, 1432–1442. [Google Scholar] [CrossRef]

- Innocentini-Mei, L.H.; Bartoli, J.R.; Baltieri, R.C. Mechanical and thermal properties of poly(3-hydroxybutyrate) blends with starch and starch derivatives. In Macromolecular Symposia; Wiley: Weinheim, Germany, 2003. [Google Scholar]

- Willett, J.L.; Kotnis, M.A.; O’Brien, G.S.; Fanta, G.F.; Gordon, S.H. Properties of starch-graft-poly(glycidyl methacrylate)-PHBV composites. J. Appl. Polym. Sci. 1998, 70, 1121–1127. [Google Scholar] [CrossRef]

- Liao, H.T.; Wu, C.S. Performance of an acrylic-acid-grafted poly(3-hydroxybutyric acid)/starch bio-blend: Characterization and physical properties. Des. Monomers Polym. 2007, 10, 1–18. [Google Scholar] [CrossRef]

- Koenig, M.F.; Huang, S.J. Biodegradable blends and composites of polycaprolactone and starch derivatives. Polymer 1995, 36, 1877–1882. [Google Scholar] [CrossRef]

- Zhang, L.; Deng, X.; Zhao, S.; Huang, Z. Biodegradable polymer blends of poly(3-hydroxybutyrate) and starch acetate. Polym. Int. 1997, 44, 104–110. [Google Scholar] [CrossRef]

- Seves, A.; Beltrame, P.L.; Selli, E.; Bergamasco, L. Morphology and thermal behaviour of poly(3-hydroxybutyrate-co-hydroxyvalerate)/starch valerate blends. Angew. Makromol. Chem. 1998, 260, 65–70. [Google Scholar] [CrossRef]

- Godbole, S.; Gote, S.; Latkar, M.; Chakrabarti, T. Preparation and characterization of biodegradable poly-3-hydroxybutyrate-starch blend films. Bioresour. Technol. 2003, 86, 33–37. [Google Scholar] [CrossRef]

- Reis, K.C.; Pereira, J.; Smith, A.C.; Carvalho, C.W.P.; Wellner, N.; Yakimets, I. Characterization of polyhydroxybutyrate-hydroxyvalerate (PHB-HV)/maize starch blend films. J. Food Eng. 2008, 89, 361–369. [Google Scholar] [CrossRef]

- Zhang, M.; Thomas, N.L. Preparation and properties of polyhydroxybutyrate blended with different types of starch. J. Appl. Polym. Sci. 2009, 116, 688–694. [Google Scholar] [CrossRef]

- Parulekar, Y.; Mohanty, A.K. Extruded biodegradable cast films from polyhydroxyalkanoate and thermoplastic starch blends: Fabrication and characterization. Macromol. Mater. Eng. 2007, 292, 1218–1228. [Google Scholar] [CrossRef]

- Martin, O.; Schwach, E.; Avérous, L.; Couturier, Y. Properties of biodegradable multilayer films based on plasticized wheat starch. Starch/Staerke 2001, 53, 372–380. [Google Scholar] [CrossRef]

- Wang, L.; Shogren, R.L.; Carriere, C. Preparation and properties of thermoplastic starch-polyester laminate sheets by coextrusion. Polym. Eng. Sci. 2000, 40, 499–506. [Google Scholar] [CrossRef]

- Lawton, J.W. Biodegradable Coatings for Thermoplastic Starch. In Cereals: Novel Uses and Processes, 1st ed.; Springer: New York, NY, USA, 1997. [Google Scholar]

- Willett, J.L.; Shogren, R.L. Processing and properties of extruded starch/polymer foams. Polymer 2002, 43, 5935–5947. [Google Scholar] [CrossRef]

- Gordon, S.H.; Imam, S.H.; Shogren, R.L.; Govind, N.S.; Greene, R.V. Semiempirical model for predicting biodegradation profiles of individual polymers in starch-poly(β-hydroxybutyrate-co-β-hydroxyvalerate) bioplastic. J. Appl. Polym. Sci. 2000, 76, 1767–1776. [Google Scholar] [CrossRef]

- Allen, A.L.; Mayer, J.; Stote, R.; Kaplan, D.L. Simulated marine respirometry of biodegradable polymers. J. Environ. Polym. Degrad. 1994, 2, 237–244. [Google Scholar] [CrossRef]

- Vikman, M.; Itävaara, M.; Poutanen, K. Measurement of the biodegradation of starch-based materials by enzymatic methods and composting. J. Environ. Polym. Degrad. 1995, 3, 23–29. [Google Scholar] [CrossRef]

- Yasin, M.; Holland, S.J.; Jolly, A.M.; Tighe, B.J. Polymers for biodegradable medical devices. VI. Hydroxybutyrate-hydroxyvalerate copolymers: Accelerated degradation of blends with polysaccharides. Biomaterials 1989, 10, 400–412. [Google Scholar] [CrossRef]

- Tanna, S.T.; Gross, R.; McCarthy, S.P. Biodegradation of blends of bacterial polyester and starch in a compost environment. Polym. Mater. Sci. Eng. Proc. ACS Div. Polym. Mater. Sci. Eng. 1992. [Google Scholar]

- Lauzier, C.; Monasterios, C.; Saracovan, I.; Marchessault, R.; Ramsay, B. Film formation and paper coating with poly(β-hydroxyalkanoate), a biodegradable latex. Tappi J. 1993, 76. [Google Scholar]

- Yasin, M.; Tighe, B.J. Strategies for the design of biodegradable polymer systems: Manipulation of polyhydroxybutyrate-based materials. Plast. Rubber Compos. Process. Appl. 1993, 19, 15–27. [Google Scholar]

- Imam, S.H.; Gordon, S.H.; Shogren, R.L.; Greene, R.V. Biodegradation of starch-poly(β-hydroxybutyrate-co-valerate) composites in municipal activated sludge. J. Environ. Polym. Degrad. 1995, 3, 205–213. [Google Scholar] [CrossRef]

- Imam, S.H.; Chen, L.; Gorden, S.H.; Shogren, R.L.; Weisleder, D.; Greene, R.V. Biodegradation of injection molded starch-poly(3-hydroxybutyrate-co-3-hydroxyvalerate) blends in a natural compost environment. J. Environ. Polym. Degrad. 1998, 6, 91–98. [Google Scholar] [CrossRef]

- Imam, S.H.; Gordon, S.H.; Shogren, R.L.; Tosteson, T.R.; Govind, N.S.; Greene, R.V. Degradation of starch-poly([β-hydroxybutyrate-Co-β-hydroxyvalerate) bioplastic in tropical coastal waters. Appl. Environ. Microbiol. 1999, 65, 431–437. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaihara, S.; Osanai, Y.; Nishikawa, K.; Toshima, K.; Doi, Y.; Matsumura, S. Enzymatic transformation of bacterial polyhydroxyalkanoates into repolymerizable oligomers directed towards chemical recycling. Macromol. Biosci. 2005, 5, 644–652. [Google Scholar] [CrossRef]

- Reddy, C.S.K.; Ghai, R.; Kalia, V.C. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146. [Google Scholar] [CrossRef]

- Patel, M.; Narayan, R. How sustainable are biopolymers and biobased products? The hope, the doubts, and the reality. In Natural Fibers, Biopolymers, and Biocomposites, 1st ed.; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar] [CrossRef]

- Bruzaud, S.; Bourmaud, A. Thermal degradation and (nano)mechanical behavior of layered silicate reinforced poly(3-hydroxybutyrate-co-3-hydroxyvalerate) nanocomposites. Polym. Test. 2007, 26, 652–659. [Google Scholar] [CrossRef]

- Hsu, S.F.; Wu, T.M.; Liao, C.S. Nonisothermal crystallization behavior and crystalline structure of poly(3-hydroxybutyrate)/layered double hydroxide nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2007, 45, 995–1002. [Google Scholar] [CrossRef]

- Bruno, M.; Tavares, M.I.B.; Motta, L.M.; Miguez, E.; Preto, M.; Fernandez, A.O.R. Evaluation of PHB/clay nanocomposite by spin-lattice relaxation time. Mater. Res. 2008, 11, 483–485. [Google Scholar] [CrossRef]

- Erceg, M.; Kovačić, T.; Klarić, I. Poly(3-hydroxybutyrate) nanocomposites: Isothermal degradation and kinetic analysis. Thermochim. Acta 2009, 485, 26–32. [Google Scholar] [CrossRef]

- Erceg, M.; Kovačić, T.; Sanja, P. Isothermal degradation of poly(3-hydroxybutyrate)/organically modified montmorillonite nanocomposites. Polym. Compos. 2010, 31, 272–278. [Google Scholar] [CrossRef]

- Parulekar, Y.; Mohanty, A.K.; Imam, S.H. Biodegradable nanocomposites from toughened polyhydroxybutyrate and titanate-modified montmorillonite clay. J. Nanosci. Nanotechnol. 2007, 7, 3580–3589. [Google Scholar] [CrossRef]

- Hablot, E.; Bordes, P.; Pollet, E.; Avérous, L. Thermal and thermo-mechanical degradation of poly(3-hydroxybutyrate)-based multiphase systems. Polym. Degrad. Stab. 2008, 93, 413–421. [Google Scholar] [CrossRef]

- Sanchez-Garcia, M.D.; Gimenez, E.; Lagaron, J.M. Morphology and barrier properties of nanobiocomposites of poly(3-hydroxybutyrate) and layered silicates. J. Appl. Polym. Sci. 2008, 108, 2787–2801. [Google Scholar] [CrossRef]

- Maiti, P.; Prakash Yadav, J.P. Renewable plastics: Synthesis and properties of PHB nanocomposites. Polym. Mater. Sci. Eng. 2003, 88, 58–59. [Google Scholar]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Choi, W.M.; Kim, T.W.; Park, O.O.; Chang, Y.K.; Lee, J.W. Preparation and characterization of poly(hydroxybutyrate-co-hydroxyvalerate)-organoclay nanocomposites. J. Appl. Polym. Sci. 2003, 90, 525–529. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, G.; Abou-Hussein, R.; Hassan, M.K.; Noda, I.; Mark, J.E. Some novel layered-silicate nanocomposites based on a biodegradable hydroxybutyrate copolymer. Eur. Polym. J. 2007, 43, 3128–3135. [Google Scholar] [CrossRef]

- Wu, T.M.; Hs, S.F.; Shih, Y.F.; Liao, C.S. Thermal degradation kinetics of biodegradable poly(3-hydroxybutyrate)/layered double hydroxide nanocomposites. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 1207–1213. [Google Scholar] [CrossRef]

- Dagnon, K.L.; Chen, H.H.; Innocentini-Mei, L.H.; D’Souza, N.A. Poly[(3-hydroxybutyrate)-co-(3-hydroxyvalerate)]/layered double hydroxide nanocomposites. Polym. Int. 2009, 58, 133–141. [Google Scholar] [CrossRef]

- Dufresne, A.; Kellerhals, M.B.; Witholt, B. Transcrystallization in Mcl-PHAs/cellulose whiskers composites. Macromolecules 1999, 32, 7396–7401. [Google Scholar] [CrossRef]

- Chen, G.X.; Hao, G.J.; Guo, T.Y.; Song, M.D.; Zhang, B.H. Structure and mechanical properties of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV)/clay nanocomposites. J. Mater. Sci. Lett. 2002, 21, 1587–1589. [Google Scholar] [CrossRef]

- Thellen, C.; Coyne, M.; Froio, D.; Auerbach, M.; Wirsen, C.; Ratto, J.A. A processing, characterization and marine biodegradation study of melt-extruded polyhydroxyalkanoate (PHA) films. J. Polym. Environ. 2008, 16, 1–11. [Google Scholar] [CrossRef]

- Gregorova, A.; Wimmer, R.; Hrabalova, M.; Koller, M.; Ters, T.; Mundigler, N. Effect of surface modification of beech wood flour on mechanical and thermal properties of poly (3-hydroxybutyrate)/wood flour composites. Holzforschung 2009, 63, 565–570. [Google Scholar] [CrossRef]

- Sinha Ray, S.; Okamoto, M. Polymer/layered silicate nanocomposites: A review from preparation to processing. Prog. Polym. Sci. 2003, 28, 1539–1641. [Google Scholar] [CrossRef]

- Gigante, V.; Seggiani, M.; Cinelli, P.; Signori, F.; Vania, A.; Navarini, L.; Amato, G.; Lazzeri, A. Utilization of coffee silverskin in the production of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biopolymer-based thermoplastic biocomposites for food contact applications. Compos. Part A Appl. Sci. Manuf. 2021, 140, 1–10. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, R.; Wu, Y.; Xue, P. Additive manufacturing of wood flour/polyhydroxyalkanoates (PHA) fully bio-based composites based on micro-screw extrusion system. Mater. Des. 2021, 199, 1–14. [Google Scholar] [CrossRef]

- Wu, C.S.; Wu, D.Y.; Wang, S.S. Biodegradable Composite Nanofiber Containing Fish-Scale Extracts. ACS Appl. Bio Mater. 2021, 4, 462–469. [Google Scholar] [CrossRef]

- de Almeida Neto, G.R.; Barcelos, M.V.; Ribeiro, M.E.A.; Folly, M.M.; Rodríguez, R.J.S. Formulation and characterization of a novel PHBV nanocomposite for bone defect filling and infection treatment. Mater. Sci. Eng. C 2019, 104, 1–13. [Google Scholar] [CrossRef]

- Shahi, S.; Karbasi, S.; Ahmadi, T.; Naeimi, F.; Goodarzi, V.; Ebrahimi-Barough, S. Evaluation of physical, mechanical and biological properties of β-tri-calcium phosphate/Poly-3-hydroxybutyrate nano composite scaffold for bone tissue engineering application. Mater. Technol. 2021, 36, 237–249. [Google Scholar] [CrossRef]

- Koyama, R.; Kuboki, T.; Ding, W.D.; Adhikary, K.B.; Chen, N.; Park, C.B. Extrusion foaming of cellulose fiber reinforced polylactic acid biocomposites. In Proceedings of the Annual Technical Conference—ANTEC, Boston, MA, USA, 1–5 May 2011. [Google Scholar]

- Cho, S.Y.; Park, H.H.; Yun, Y.S.; Jin, H.J. Influence of cellulose nanofibers on the morphology and physical properties of poly(lactic acid) foaming by supercritical carbon dioxide. Macromol. Res. 2013, 21, 529–533. [Google Scholar] [CrossRef]

- Oluwabunmi, K.; D’Souza, N.A.; Zhao, W.; Choi, T.Y.; Theyson, T. Compostable, fully biobased foams using PLA and micro cellulose for zero energy buildings. Sci. Rep. 2020, 10, 1–20. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O. Effect of gas saturation conditions on the expansion ratio of microcellular poly (lactic acid)/wood-flour composites. Express Polym. Lett. 2010, 4, 621–631. [Google Scholar] [CrossRef]

- Rizvi, R.; Cochrane, B.; Naguib, H.; Lee, P.C. Fabrication and characterization of melt-blended polylactide-chitin composites and their foams. J. Cell. Plast. 2011, 47, 283–300. [Google Scholar] [CrossRef]

- Ding, W.D.; Kuo, P.Y.; Kuboki, T.; Park, C.B.; Sain, M. Foaming of cellulose fiber reinforced polylactic acid composites: The effect of cellulose fiber type. In Proceedings of the Annual Technical Conference—ANTEC, Cincinnati, OH, USA, 22–24 April 2013. [Google Scholar]

- Neagu, R.C.; Cuénoud, M.; Berthold, F.; Bourban, P.E.; Gamstedt, E.K.; Lindström, M.; Månson, J.A.E. The potential of wood fibers as reinforcement in cellular biopolymers. J. Cell. Plast. 2012, 48, 71–103. [Google Scholar] [CrossRef]

- Matuana, L.M.; Diaz, C.A. Strategy to produce microcellular foamed poly(lactic acid)/wood-flour composites in a continuous extrusion process. Ind. Eng. Chem. Res. 2013, 52, 12032–12040. [Google Scholar] [CrossRef]

- Bergeret, A.; Benezet, J.C. Natural fibre-reinforced biofoams. Int. J. Polym. Sci. 2011, 2011, 1–14. [Google Scholar] [CrossRef]

- Pilla, S.; Kramschuster, A.; Lee, J.; Auer, G.K.; Gong, S.; Turng, L.S. Microcellular and solid polylactide-flax fiber composites. Compos. Interfaces 2009, 16, 869–890. [Google Scholar] [CrossRef]

- Zafar, M.T.; Zarrinbakhsh, N.; Mohanty, A.K.; Misra, M.; Ghosh, A.K. Biocomposites based on poly(Lactic acid)/willow-fiber and their injection moulded microcellular foams. Express Polym. Lett. 2016, 10, 176–186. [Google Scholar] [CrossRef]

- Noorani, R. 3D Printing Technology, Applications, and Selection, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Horvath, J. Mastering 3D Printing, 1st ed.; Apress: New York, NY, USA, 2014. [Google Scholar]

- Yan, Q.; Dong, H.; Su, J.; Han, J.; Song, B.; Wei, Q.; Shi, Y. A Review of 3D Printing Technology for Medical Applications. Engineering 2018, 4, 729–742. [Google Scholar] [CrossRef]

- Kikuchi, M.; Suetsugu, Y.; Tanaka, J.; Akao, M. Preparation and mechanical properties of calcium phosphate/copoly-L-lactide composites. J. Mater. Sci. Mater. Med. 1997, 8, 361–364. [Google Scholar] [CrossRef]

- Niaza, K.V.; Senatov, F.S.; Kaloshkin, S.D.; Maksimkin, A.V.; Chukov, D.I. 3D-printed scaffolds based on PLA/HA nanocomposites for trabecular bone reconstruction. In Proceedings of the Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2016; pp. 1–5. [Google Scholar]

- Gregor, A.; Filová, E.; Novák, M.; Kronek, J.; Chlup, H.; Buzgo, M.; Blahnová, V.; Lukášová, V.; Bartoš, M.; Nečas, A.; et al. Designing of PLA scaffolds for bone tissue replacement fabricated by ordinary commercial 3D printer. J. Biol. Eng. 2017, 11, 1–21. [Google Scholar] [CrossRef]

- Zhu, H.; Zhu, Q.; Li, J.; Tao, K.; Xue, L.; Yan, Q. Synergistic effect between expandable graphite and ammonium polyphosphate on flame retarded polylactide. Polym. Degrad. Stab. 2011, 96, 183–189. [Google Scholar] [CrossRef]

- Ke, C.H.; Li, J.; Fang, K.Y.; Zhu, Q.L.; Zhu, J.; Yan, Q.; Wang, Y.Z. Synergistic effect between a novel hyperbranched charring agent and ammonium polyphosphate on the flame retardant and anti-dripping properties of polylactide. Polym. Degrad. Stab. 2010, 95, 763–770. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, R.; Wang, X.; Wang, B.; Song, L.; Hu, Y.; Gong, X. Enhancement of flame retardant performance of bio-based polylactic acid composites with the incorporation of aluminum hypophosphite and expanded graphite. J. Macromol. Sci. Part A Pure Appl. Chem. 2013, 50, 255–269. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.; Zhao, D.; Zhai, W. Preparation of microcellular poly(lactic acid) composites foams with improved flame retardancy. J. Cell. Plast. 2017, 53, 45–63. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Q.; Zheng, W.; Zhai, W. Improved flame-retardant properties of poly(lactic acid) foams using starch as a natural charring agent. Ind. Eng. Chem. Res. 2014, 53, 1422–1430. [Google Scholar] [CrossRef]

- Vadas, D.; Igricz, T.; Sarazin, J.; Bourbigot, S.; Marosi, G.; Bocz, K. Flame retardancy of microcellular poly(lactic acid) foams prepared by supercritical CO2-assisted extrusion. Polym. Degrad. Stab. 2018, 153, 100–108. [Google Scholar] [CrossRef] [Green Version]

- Wu, N.; Yu, J.; Lang, W.; Ma, X.; Yang, Y. Flame retardancy and toughness of poly(lactic acid)/GNR/SiAHP composites. Polymers 2019, 11, 1129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, W.; Zhang, L.; Chai, W.; Yin, N.; Semple, K.; Li, L.; Zhang, W.; Dai, C. Enhancement of flame retardancy and mechanical properties of polylactic acid with a biodegradable fire-retardant filler system based on bamboo charcoal. Polymers 2021, 13, 2167. [Google Scholar] [CrossRef] [PubMed]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-based active food packaging materials: Sustainable alternative to conventional petrochemical-based packaging materials. Food Res. Int. 2020, 137, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Hany, R.; Böhlen, C.; Geiger, T.; Schmid, M.; Zinn, M. Toward non-toxic antifouling: Synthesis of hydroxy-cinnamic acid-, sulfate-, and zosteric acid-labeled poly[3-hydroxyalkanoates]. Biomacromolecules 2004, 5, 1452–1456. [Google Scholar] [CrossRef]

- Gonta, S.; Savenkova, L.; Krallish, I.; Kirilova, E. Antimicrobial Activity of PHB Based Polymeric Compositions. Environ. Eng. Manag. J. 2012, 11, 99–104. [Google Scholar]

- Kwiecień, I.; Adamus, G.; Bartkowiak, A.; Kowalczuk, M. Synthesis and structural characterization at the molecular level of oligo(3-hydroxybutyrate) conjugates with antimicrobial agents designed for food packaging materials. Des. Monomers Polym. 2014, 17, 311–321. [Google Scholar] [CrossRef] [Green Version]

- Xavier, J.R.; Babusha, S.T.; George, J.; Ramana, K.V. Material Properties and Antimicrobial Activity of Polyhydroxybutyrate (PHB) Films Incorporated with Vanillin. Appl. Biochem. Biotechnol. 2015, 176, 1498–1510. [Google Scholar] [CrossRef] [PubMed]

| Bioplastic | Company | Country | Commercial Name | Applications/Notes |

|---|---|---|---|---|

| PLA | NatureWorks LLC | USA | -Ingeo™ 8000 series, 8052D. -Ingeo™ 7000 series, 7001D TDS and 7032D TDS. -Ingeo™ 6000 series, 6060D TDS, 6201D TDS, 6202D TDS, 6204D TDS, 6251D TDS, 6252D TDS,6302D TDS, 6400D TDS, 6751D TDS, 6752D TDS. -Ingeo™ 4000 series, 4032D TDS, 4043D TDS, 4060D TDS. -Ingeo™ 3000 series, 3001D SDS, 3052D SDS, 3251D SDS, 3801X SDS. -Ingeo™ 2000 series, 2003D TDS. -Ingeo™ 3D850. | -Foams. -Bottles (7001D TDS and 7032D TDS). -Nonwovens (6060D TDS, 6202D TDS, 6251D TDS, 6252D TDS, 6302D TDS, 6751D TDS, 6752D TDS). -Apparel (6201D TDS, 6204D TDS). -Home textiles (knitted and woven) (6201D TDS, 6202D TDS, 6204D TDS, 6400D TDS). -Cards, folded cartons and films (4032D TDS, 4043D TDS, 4060D TDS). -3D printing (3D850, 4043D). -Durable goods (3001D SDS, 3052D SDS, 3251D SDS, 3801X SDS). -Service war (2003D TDS, 3001D TDS, 3052D TDS, 3251D TDS). -Food packaging (2003D TDS). |

| PLA, PDLA | Total Corbion PLA | The Netherlands | -Luminy® PLA (L175, L130, L105, LX575, LX530, LX175, LX975, LX930, D120, D070) | -High heat PLA for demanding applications (L175, L130, L105, LX575, LX530). -Standard PLA for general purpose applications (LX175). -Low heat PLA for usage in seal layers (LX975, LX930). -PDLA utilized to produce full stereocomplex compounds or used as a nucleating agent (D120, D070). |

| PLLA | Purac | The Netherlands | -Purasorb® (PL 18, PL 24, PL 32, PL 38, PL 49, PL 65, PL 10). | -Medical equipment. |

| PLLA, scPLA | Tejin | Japan | -Biofront® (HL L201 (PLLA), J20 (scPLA), J201 (scPLA)). | -Eyeglass frames, sheets, films, fibers, injection molding, medical care, automobiles, electronics, construction and packages. |

| Amorphous PLA | Toyobo | Japan | -Vyloecol series (BE-400, BE-600, BE-910, HYD-306, BE-450, BE-410, HYD-006). | -Adhesive, paint, printing ink. -BE-400 in the form of pellet, used as agent for different coating and is a general-purpose resin. -BE-600 in the form of sheet, used as anchor coating for printing ink and vapor deposition films. |

| PDLA | Purac | The Netherlands | -Purasorb® -PD 24 -PD 38 -Purapol® | -Medical equipment (Purasorb®). -Nucleating agents for PLLA (Purapol®). |

| PDLLA | Evonik | Germany | -R 202 H -R 203 H -R 202 S -R 203 S -R 205 S -R 207 S | -Medical equipment (R 207 S) and drug delivery. |

| PLDLLA | Purac | The Netherlands | -Purasorb® (PLDL 8038, PLDL 8058, PLDL 7028, PLDL 7038, PLDL 7060). | -Medical equipment. |

| PLDA | Purac | The Netherlands | -Purasorb® (PLD 9620, PLD 9655). | -Medical equipment. |

| PLA (Nature- Works)/ copolyester blend | FKuR Kunststoff GmbH | Germany | -Bio-flex® (Bio-flex® A4100 CL, Bio-flex® F 1110, Bio-flex® F 1130, Bio-flex® F 1137, Bio-flex® F 2110, Bio-flex® F 2201 CL, Bio-flex® F 6510, Bio-flex® F 6513, Bio-flex® F 6611, Bio-flex® S 5630, Bio-flex® S 6540, Bio-flex® S 9533). | -Flower wrapping, blown film extrusion and packaging (Bio-flex® A4100 CL). -Waste bag, air pillow and carrier bag (Bio-flex® F 1130). -Shopping bags (Bio-flex® F 1137). -Waste bag, netting and deep freeze packaging (Bio-flex® F 2110). -Film (Bio-flex® F 2201 CL). -Multi-layer films (Bio-flex® A4100 CL and Bio-flex® F 2201 CL). -Straws, mugs and ball pen (Bio-flex® F 6510). -Thermoforming (Bio-flex® F 6611). -Injection molding (Bio-flex® F 6513). -Thermoformed inlay (Bio-flex® S 5630). -Cosmetic jars (Bio-flex® S 6540 and Bio-flex® S 9533). |

| PLA/polyether copolymer | Toray Industries | Japan | -Ecodear® (V554R10, V554X51, V554X52, V751X52, V751X53, V911X51). | -Bags, films, fibers, packaging, personal care, accessories, office supplies and electronics. |

| Bioplastic | Company | Country | Commercial Name | Applications/Notes |

|---|---|---|---|---|

| PHB | Mitsubishi Gas Chemical Company Inc. | Japan | -Biogreen® | -Cast films and natural latex gloves. |

| PHB | PHB Industrial S/A | Brazil | -Biocycle™ (B1000, B18BC-1, B189C-1, B189D-1) | -Medical devices, films and disposables). |

| PHB and PHBV | Biomer Inc. | Germany | -Biomer®300 (P300E, P300F) | -Extrusion (P300E) -Extrusion and food contact (P300F). |

| PHBV and PHBV/PLA | Tianan Biologic, Ningbo | China | -Enmat™ (Y1000, Y1010, Y1000P, Y3000, Y3000P, F9000P). | -Thermoforming, nonwovens and fiber, injection molding, extrusion and water treatment. |

| P4HB | Tepha, Inc. | USA | -TephaFLEX® | -Surgical absorbable films and sutures. |

| PHBHHx | Kaneka Co. | Japan | -Kaneka PHBH -Aonilex® | -Foams, fibers, interior automotive materials, electrical equipment, sheets and injection molding. -Containers, bottles, interior automotive materials and electrical equipment. |

| PHBHHx | Danimer Scientific | USA | -Nodax™ | -Coating, laminates, non-woven Fibers and packaging. |

| P3HB4HB | Tianjin Green Bio- Science Co./DSM | China/The netherlands | -GreenBio® | -Films for wrapping, laminating film, fresh film, heat shrinkable film, garbage bags, food packaging, shopping and gift bags. |

| Several PHAs | CJ CheilJedang Corporation | South Korea | -CJ PHA® | -Rigid packaging, 3D printing, paper coating, agriculture and flexible packaging. |

| Several PHAs | Alterra Holdings | USA | -TerraBio® | -Paper coating, packaging, utensils, straws and disposals. |

| Properties/Applications | Ingeo™ 2003D | Ingeo™ 3052D | Ingeo™ 3801X | ASTM Method |

|---|---|---|---|---|

| Specific Gravity | 1.24 | 1.24 | 1.25 | D792 |

| Melt Flow Rate, g/10 min (210 °C, 2.16 Kg) | 6 | 14 | 8 | D1238 |

| Relative viscosity | NP | 3.3 | 3.1 | - |

| Clarity | Transparent | Transparent | Opaque | - |

| Tensile strength at break, psi (MPa) | 7700 (53) | NP | NP | D882 |

| Tensile yield strength, psi (MPa) | 8700 (60) | 9000 (62) | 3750 (25.9) | D882 |

| Tensile modulus, Kpsi (GPa) | 500 (3.5) | NP | 432 (2.98) | D882 |

| Flexural Strength, psi (MPa) | NP | 15,700 (108) | 6400 (44) | D790 |

| Flexural Modulus, psi (MPa) | NP | 515,000 (3600) | 413,000 (2850) | D790 |

| Tensile elongation, % | 6.0 | 3.5 | 8.1 | D882 |

| Notched Izod impact, ft-lb/in (J/m) | 0.3 (16) | 0.3 (16) | 2.7 (144) | D256 |

| Heat distortion temperature (°C) | 55 | 55 | 65 (at 66 psi) 140 (at 16.5 psi) | E2092 |

| Melt temperature (°C) | 210 | 200 | 188 | - |

| Crystallinity melt temperature (°C) | NP | 145–160 | 155–170 | D3418 |

| Glass transition temperature (°C) | NP | 55–60 | 45 | D3418 |

| Applications | -Designed for fresh food packaging and food service ware applications such as: dairy containers, food service ware, transparent food containers, hinged ware and cold drink cups. | -Designed for injection molding applications that require clarity with heat deflection temperatures lower than 49 °C. -Applications include: cutlery, cups, plates and saucers as well as outdoor novelties. | -Designed for non-food contact injection molding applications that require opaque molded parts with heat deflection temperatures between 65 °C and 140 °C. | - |

| Polymer | Tensile Strength (MPa) | Tensile Modulus (GPa) | Percentage Elongation | Notched Izod (J/m) |

|---|---|---|---|---|

| PLLA | 59 | 3.8 | 4–7 | 26 |

| PS | 45 | 3.2 | 3 | 21 |

| PET | 57 | 2.8–4.1 | 300 | 59 |

| Plasticizer | Plasticizer’s Concentration (wt.%) | PLA’s Type and Reference | Tensile Strength (MPa) | Young’s Modulus (MPa) | Percentage Elongation | Charpy Impact, (MJ/mm2) | Application | Comments |

|---|---|---|---|---|---|---|---|---|

| Lactide | - 25.5% - 19.2% - 17.3% - 1.3% | PLA, in the form of films [58]. | - 16.8 - 29.2 - 15.8 - 51.7 | - 232 - 658 - 820 - 1993 | - 546% - 536% - 288% - 3.00% | - | General Packaging. | Degradation increased with increasing the content of plasticizer. |

| PEG | - 0% - PEG 1500 (2.5%) - PEG 1500 (5%) - PEG 1500 (10%) | PLA (92% L-lactide and 8% meso-lactide) [59]. | - 58 - 50 - 44 - 28 | - 3800 - 3200 - 2500 - 1200 | - 3% - 4% - 7% - 40% | - 32 b - 29 - 31 - 80 | Applications demanding higher impact resistance and flexibility. | - |

| - 0% - m-PEG (10%) - m-PEG (20%) - PEG 400 (10%) - PEG 400 (20%) | PLA (92% L-lactide and 8% meso-lactide) [60]. | - | - 2050 - 1571 - 1124 - 1488 - 976 | - 9% - 18% - 142% - 26% - 160% | - | - | Biocompatible plasticizers. | |

| - 0% - PEG 400 (5%) - PEG 400 (10%) - PEG 400 (12.5%) - PEG 400 (15%) - PEG 400 (20%) - PEG 1500 (5%) - PEG 1500 (10%) - PEG 1500 (12.5%) - PEG 1500 (15%) - PEG 1500 (20%) - PEG 10,000 (5%) - PEG 10,000 (10%) - PEG 10,000 (15%) - PEG 10,000 (20%) | PLA [61]. | - 66.0 - 41.6 - 32.5 - 18.7 - 19.1 - 15.6 - 52.3 - 46.6 - 18.5 - 23.6 - 21.8 - 53.9 - 48.5 - 42.3 - 22.1 | - 3300 - 2500 - 1200 - 500 - 600 - 500 - 2900 - 2800 - 700 - 800 - 600 - 2800 - 2800 - 2500 - 700 | - 1.8% - 1.6% - 140% - 115% - 88% - 71% - 3.5% - 5.0% - 194% - 216% - 235% - 2.4% - 2.8% - 3.5% - 130% | - | Medical, personal care and food packaging applications. | - | |