Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding

Abstract

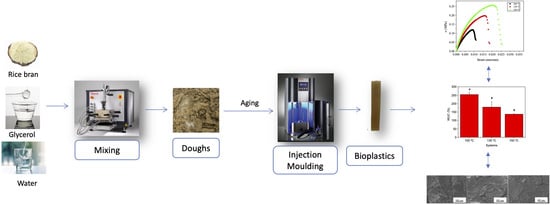

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical Composition

2.3. Sample Preparation

2.4. Ageing of Doughs

2.5. Bioplastics Characterization

2.5.1. Dynamic Mechanical Thermal Analysis (DMTA)

2.5.2. Tensile Tests

2.5.3. Water Uptake Capacity and Soluble Matter Loss

2.5.4. Scanning Electron Microscopy (SEM)

2.6. Statistical Analyses

3. Results

3.1. Chemical Composition

3.2. Doughs Characterization (Ageing)

3.3. Bioplastics Characterization

3.3.1. Dynamic Mechanical Thermal Analysis (DMTA)

3.3.2. Tensile Tests

3.3.3. Water Uptake Capacity and Soluble Matter Loss

3.3.4. Scanning Electron Microscopy (SEM)

4. Discussion

4.1. Chemical Composition

4.2. Doughs Characterization (Ageing)

4.3. Bioplastics Characterization

4.3.1. Dynamic Mechanical Thermal Analysis (DMTA)

4.3.2. Tensile Tests

4.3.3. Water Uptake Capacity and Soluble Matter Loss

4.3.4. Scanning Electron Microscopy (SEM)

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tábi, T.; Kovács, J.G. Examination of injection moulded thermoplastic maize starch. Express Polym. Lett. 2007, 1, 804–809. [Google Scholar] [CrossRef]

- Urista, C.M.; Fernández, R.Á.; Rodriguez, F.R.; Cuenca, A.A.; Jurado, A.T. Review: Production and functionality of active peptides from milk. Food Sci. Technol. Int. 2011, 17, 293–317. [Google Scholar] [CrossRef] [PubMed]

- Yamada, M.; Morimitsu, S.; Hosono, E.; Yamada, T. Preparation of bioplastic using soy protein. Int. J. Biol. Macromol. 2020, 149, 1077–1083. [Google Scholar] [CrossRef] [PubMed]

- Mostafa, N.A.; Farag, A.A.; Abo-dief, H.M.; Tayeb, A.M. Production of biodegradable plastic from agricultural wastes. Arab. J. Chem. 2018, 11, 546–553. [Google Scholar] [CrossRef] [Green Version]

- Shin, B.Y.; Narayan, R.; Lee, S.I.; Lee, T.J. Morphology and rheological properties of blends of chemically modified thermoplastic starch and polycaprolactone. Polym. Eng. Sci. 2008, 48, 2126–2133. [Google Scholar] [CrossRef]

- Ashter, S.A. Types of Biodegradable Polymers in Introduction to Bioplastics Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Felix, M.; Martinez, I.; Romero, A.; Partal, P.; Guerrero, A. Effect of pH and nanoclay content on the morphology and physicochemical properties of soy protein/montmorillonite nanocomposite obtained by extrusion. Compos. Part. B Eng. 2018, 140, 197–203. [Google Scholar] [CrossRef]

- Herald, T.J.; Obuz, E.; Twombly, W.W.; Rausch, K.D. Tensile properties of extruded corn protein low-density polyethylene films. Cereal Chem. 2002, 79, 261–264. [Google Scholar] [CrossRef]

- Chantapet, P.; Kunanopparat, T.; Menut, P.; Siriwattanayotin, S. Extrusion processing of wheat gluten bioplastic: Effect of the addition of kraft lignin. J. Polym. Environ. 2013, 21, 864–873. [Google Scholar] [CrossRef]

- Ramakrishnan, N.; Sharma, S.; Gupta, A.; Alashwal, B.Y. Keratin based bioplastic film from chicken feathers and its characterization. Int. J. Biol. Macromol. 2018, 111, 352–358. [Google Scholar] [CrossRef] [PubMed]

- Verbeek, C.J.R.; Low, A.; Lay, M.C.; Hicks, T.M. Processability and mechanical properties of bioplastics produced from decoloured bloodmeal. Adv. Polym. Technol. 2018, 37, 2102–2113. [Google Scholar] [CrossRef]

- Félix, M.; Martín-Alfonso, J.E.; Romero, A.; Guerrero, A. Development of albumen/soy biobased plastic materials processed by injection molding. J. Food Eng. 2014, 125, 7–16. [Google Scholar] [CrossRef]

- Mekonnen, T.; Mussone, P.; Khalil, H.; Bressler, D. Progress in bio-based plastics and plasticizing modifications. J. Mater. Chem. A 2013, 1, 13379–13398. [Google Scholar] [CrossRef] [Green Version]

- Verbeek, C.J.R.; van den Berg, L.E. Extrusion processing and properties of protein-based thermoplastics. Macromol. Mater. Eng. 2010, 295, 10–21. [Google Scholar] [CrossRef]

- Silviana, S.; Rahayu, P. Central composite design for optimization of starch-based bioplastic with bamboo microfibrillated cellulose as reinforcement assisted by potassium chloride. J. Phys. Conf. Ser. 2019, 1295, 012073. [Google Scholar] [CrossRef] [Green Version]

- Klanwan, Y.; Kunanopparat, T.; Menut, P.; Siriwattanayotin, S. Valorization of industrial by-products through bioplastic production: Defatted rice bran and kraft lignin utilization. J. Polym. Eng. 2016, 36, 529–536. [Google Scholar] [CrossRef] [Green Version]

- Félix, M.; Lucio-Villegas, A.; Romero, A.; Guerrero, A. Development of rice protein bio-based plastic materials processed by injection molding. Ind. Crops Prod. 2016, 79, 152–159. [Google Scholar] [CrossRef]

- AOAC International. Official Methods of Analysis of AOAC International; AOAC International: Rockville, MD, USA, 2005. [Google Scholar]

- Mariotti, F.; Tomé, D.; Mirand, P.P. Converting nitrogen into protein—Beyond 6.25 and Jones’ factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- López-Bascón-Bascon, M.A.; Luque de Castro, M.D. Soxhlet extraction in liquid-phase extraction. In Liquid-Phase Extraction; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–354. [Google Scholar]

- Forssell, P.M.; Mikkilä, J.M.; Moates, G.K.; Parker, R. Phase and glass transition behaviour of concentrated barley starch-glycerol-water mixtures, a model for thermoplastic starch. Carbohydr. Polym. 1997, 34, 275–282. [Google Scholar] [CrossRef]

- Rudnik, E. Compostable Polymer Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Felix, M.; Perez-Puyana, V.; Romero, A.; Guerrero, A. Production and characterization of bioplastics obtained by injection moulding of various protein systems. J. Polym. Environ. 2017, 25, 91–100. [Google Scholar] [CrossRef]

- Zárate-Ramírez, L.S.; Romero, A.; Bengoechea, C.; Partal, P.; Guerrero, A. Thermo-mechanical and hydrophilic properties of polysaccharide/gluten-based bioplastics. Carbohydr. Polym. 2014, 112, 16–23. [Google Scholar] [CrossRef]

- International Organization for Standardization. Plastics—Determination of Tensile Properties—Part 1: General Principles; ISO 527-1:2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- ASTM International. Standard Test. Method for Water Absorption of Plastics; ASTM D570; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Gibbs, J.H.; DiMarzio, E.A. Nature of the glass transition and the glassy state. J. Chem. Phys. 1958, 28, 373. [Google Scholar] [CrossRef]

- Felix, M.; Romero, A.; Cordobes, F.; Guerrero, A. Development of crayfish bio-based plastic materials processed by small-scale injection moulding. J. Sci. Food Agric. 2015, 95, 679–687. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Espada, L.; Bengoechea, C.; Cordobés, F.; Guerrero, A. Protein/glycerol blends and injection-molded bioplastic matrices: Soybean versus egg albumen. J. Appl. Polym. Sci. 2016, 133, 43524. [Google Scholar] [CrossRef]

- Anandito, R.B.K.; Nurhartadi, E.; Iskandar, B.D. Effect of various heat treatment on physical and chemical characteristics of red rice bran (Oryza nivara L.) Rojolele. IOP Conf. Ser. Mater. Sci. Eng. 2019, 633, 012046. [Google Scholar] [CrossRef]

- Kunanopparat, T.; Menut, W.; Srichumpoung, W.; Siriwattanayotin, S. Characterization of defatted rice bran properties for biocomposite production. J. Polym. Environ. 2014, 22, 559–568. [Google Scholar] [CrossRef]

- Álvarez-Castillo, E.; Bengoechea, C.; Guerrero, A. Composites from by-products of the food industry for the development of superabsorbent biomaterials. Food Bioprod. Process. 2020, 119, 296–305. [Google Scholar] [CrossRef]

- Bourny, V.; Perez-Puyana, V.; Felix, M.; Romero, A.; Guerrero, A. Evaluation of the injection moulding conditions in soy/nanoclay based composites. Eur. Polym. J. 2017, 95, 539–546. [Google Scholar] [CrossRef]

- Fernández-Espada, L.; Bengoechea, C.; Cordobés, F.; Guerrero, A. Thermomechanical properties and water uptake capacity of soy protein-based bioplastics processed by injection molding. J. Appl. Polym. Sci. 2016, 133, 43524. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Tensile Properties of Plastics; ASTM-D638-14; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Delgado, M.; Felix, M.; Bengoechea, C. Development of bioplastic materials: From rapeseed oil industry by products to added-value biodegradable biocomposite materials. Ind. Crops Prod. 2018, 125, 401–407. [Google Scholar] [CrossRef]

- Perez, V.; Felix, M.; Romero, A.; Guerrero, A. Characterization of pea protein-based bioplastics processed by injection moulding. Food Bioprod. Process. 2016, 97, 100–108. [Google Scholar] [CrossRef]

- Zárate-Ramírez, L.S.; Martínez, I.; Romero, A.; Partal, P.; Guerrero, A. Wheat gluten-based materials plasticised with glycerol and water by thermoplastic mixing and thermomoulding. J. Sci. Food Agric. 2011, 91, 625–633. [Google Scholar] [CrossRef] [PubMed]

| System | Young’s Modulus (MPa) | Maximum Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| 100 C | 12 ± 7 a | 0.12 ± 0.04 a | 1.1 ± 0.3 a |

| 130 C | 23 ± 6 a,b | 0.18 ± 0.03 b | 1.6 ± 0.4 a |

| 150 C | 33 ± 6 b | 0.26 ± 0.01 c | 2.4 ± 0.3 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alonso-González, M.; Felix, M.; Guerrero, A.; Romero, A. Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding. Polymers 2021, 13, 398. https://doi.org/10.3390/polym13030398

Alonso-González M, Felix M, Guerrero A, Romero A. Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding. Polymers. 2021; 13(3):398. https://doi.org/10.3390/polym13030398

Chicago/Turabian StyleAlonso-González, María, Manuel Felix, Antonio Guerrero, and Alberto Romero. 2021. "Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding" Polymers 13, no. 3: 398. https://doi.org/10.3390/polym13030398

APA StyleAlonso-González, M., Felix, M., Guerrero, A., & Romero, A. (2021). Effects of Mould Temperature on Rice Bran-Based Bioplastics Obtained by Injection Moulding. Polymers, 13(3), 398. https://doi.org/10.3390/polym13030398