The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Raw Materials

2.1.2. Alkaline Treatment

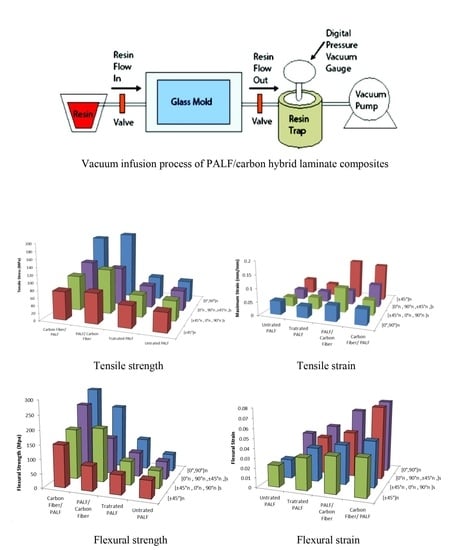

2.2. Fabrication Process

2.3. Void Content

2.4. Evaluation Method

2.4.1. Tensile Strength

2.4.2. Flexural Strength

2.4.3. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Void Contents

3.2. Composite Mechanical Properties

3.2.1. Tensile Properties

3.2.2. Flexural Properties

3.3. Surface Fracture Morphology

3.3.1. Tensile Fracture

3.3.2. Flexural Fracture

4. Conclusions

- The maximum tensile strength and modulus were recorded for the laminate with interior carbon plies (PCCP) and ply orientation [0°, 90°]. This is because the principal loading direction was aligned with the ply orientation, thus allowing the laminates to behave in an orthogonal manner, where the material had mutually perpendicular degrees of symmetry. The carbon ply interior (PCCP) contributed to the overall tensile properties of the laminate because the adhesion between the carbon ply and matrix was strong; this strong bonding at the interface imparted higher tensile strength to the laminates.

- When the laminates were tested in the flexural mode, the highest flexural strength and modulus were identified for the laminate with exterior carbon plies (CPPC) and ply orientation [0°, 90°]. The exterior carbon layer on the compression side absorbed most of the applied load.

- Morphological analyses indicated that the laminates failed under tensile and flexural loading in typical modes of fibre pull-out, fibre breaking, delamination, debonding, and matrix cracking. For tensile loading, cracking propagated from the exterior layer to the interior layer. For flexural loading, failure initiated at the exterior extension side before slowly developing to the compression side.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Brádaigh, C.M.Ó. The fatigue of carbon fibre reinforced plastics—A review. Compos. Part B Eng. 2019, 166, 555–579. [Google Scholar] [CrossRef] [Green Version]

- Bellini, C.; Parodo, G.; Polini, W.; Sorrentino, L. Experimental investigation of hydrothermal ageing on single lap bonded CFRP joints. Procedia Struct. Integr. 2018, 9, 101–107. [Google Scholar] [CrossRef]

- Yao, S.-S.; Jin, F.-L.; Rhee, K.Y.; Hui, D.; Park, S.-J. Recent advances in carbon-fiber-reinforced thermoplastic composites: A review. Compos. Part B Eng. 2018, 142, 241–250. [Google Scholar] [CrossRef]

- Bellini, C.; Sorrentino, L. Analysis of cure induced deformation of CFRP U-shaped laminates. Compos. Struct. 2018, 197, 1–9. [Google Scholar] [CrossRef]

- Zhang, J.; Chaisombat, K.; He, S.; Wang, C.H. Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Mater. Des. 2012, 36, 75–80. [Google Scholar] [CrossRef]

- Dér, A.; Kaluza, A.; Kurle, D.; Herrmann, C.; Kara, S.; Varley, R. Life Cycle Engineering of Carbon Fibres for Lightweight Structures. Procedia CIRP 2018, 69, 43–48. [Google Scholar] [CrossRef]

- Santulli, C. Mechanical and Impact Damage Analysis on Carbon/Natural Fibers Hybrid Composites: A Review. Materials 2019, 12, 517. [Google Scholar] [CrossRef] [Green Version]

- Faizi, M.K.; Shahriman, A.B.; Abdul Majid, M.S.; Shamsul, B.M.T.; Ng, Y.G.; Basah, S.N.; Cheng, E.M.; Afendi, M.; Zuradzman, M.R.; Wan, K.; et al. An overview of the Oil Palm Empty Fruit Bunch (OPEFB) potential as reinforcing fibre in polymer composite for energy absorption applications. MATEC Web Conf. 2017, 90, 1064. [Google Scholar] [CrossRef] [Green Version]

- Fowler, P.A.; Hughes, J.M.; Elias, R.M. Biocomposites: Technology, environmental credentials and market forces. J. Sci. Food Agric. 2006, 86, 1781–1789. [Google Scholar] [CrossRef]

- Mohanty, A.R.; St. Pierre, B.D.; Suruli-Narayanasami, P. Structure-borne noise reduction in a truck cab interior using numerical techniques. Appl. Acoust. 2000, 59, 1–17. [Google Scholar] [CrossRef]

- Ahmed, K.S.; Vijayarangan, S. Tensile, flexural and interlaminar shear properties of woven jute and jute-glass fabric reinforced polyester composites. J. Mater. Process. Technol. 2008, 7, 330–335. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, Y.; Ma, H.; Yu, T. Tensile and interfacial properties of unidirectional flax/glass fiber reinforced hybrid composites. Compos. Sci. Technol. 2013, 88, 172–177. [Google Scholar] [CrossRef]

- Aabdul Khalil, H.P.S.; Kang, C.W.; Khairul, A.; Ramli, R.; Adawi, T.O. The Effect of Different Laminations on Mechanical and Physical Properties of Hybrid Composites. J. Reinf. Plast. Compos. 2009, 28, 1123–1137. [Google Scholar] [CrossRef]

- Amico, S.C.; Angrizani, C.C.; Drummond, M.L. Influence of the Stacking Sequence on the Mechanical Properties of Glass/Sisal Hybrid Composites. J. Reinf. Plast. Compos. 2010, 29, 179–189. [Google Scholar] [CrossRef]

- Lin Feng, N.; Dhar Malingam, S.; Subramaniam, K.; Selamat, M.; Juan, W. The Investigation of the Tensile And Quasi-Static Indentation Properties of Pineapple Leaf/Kevlar Fibre Reinforced Hybrid Composites. Def. S T Tech. Bull. 2020, 13, 117–129. [Google Scholar]

- Krenchel, H. Fibre Reinforcement; Theoretical and Practical Investigations of the Elasticity and Strength of Fibre-Reinforced Materials; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Potluri, R.; Diwakar, V.; Venkatesh, K.; Reddy, B.S. Analytical Model Application for Prediction of Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today Proc. 2018, 5, 5809–5818. [Google Scholar]

- Lopattananon, N.; Panawarangkul, K.; Sahakaro, K.; Ellis, B. Performance of pineapple leaf fiber–natural rubber composites: The effect of fiber surface treatments. J. Appl. Polym. Sci. 2006, 102, 1974–1984. [Google Scholar]

- Chollakup, R.; Tantatherdtam, R.; Ujjin, S.; Sriroth, K. Pineapple leaf fiber reinforced thermoplastic composites: Effects of fiber length and fiber content on their characteristics. J. Appl. Polym. Sci. 2011, 119, 1952–1960. [Google Scholar] [CrossRef]

- Asim, M.; Jawaid, M.; Abdan, K.; Ishak, M.R. Effect of Alkali and Silane Treatments on Mechanical and Fibre-matrix Bond Strength of Kenaf and Pineapple Leaf Fibres. J. Bionic Eng. 2016, 13, 426–435. [Google Scholar] [CrossRef]

- Ibrahim, H.; Farag, M.; Megahed, H.; Mehanny, S. Characteristics of starch-based biodegradable composites reinforced with date palm and flax fibers. Carbohydr. Polym. 2014, 101, 11–19. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.; Misra, M.; Tripathy, S.S.; Nayak, S.K.; Mohanty, A.K. Potentiality of Pineapple Leaf Fibre as Reinforcement in PALF-Polyester Composite: Surface Modification and Mechanical Performance. J. Reinf. Plast. Compos. 2001, 20, 321–334. [Google Scholar] [CrossRef]

- Pavithran, C.; Mukherjee, P.S.; Brahmakumar, M.; Damodaran, A.D. Impact properties of natural fibre composites. J. Mater. Sci. Lett. 1987, 6, 882–884. [Google Scholar] [CrossRef]

- George, J.; Bhagawan, S.S.; Prabhakaran, N.; Thomas, S. Short pineapple-leaf-fiber-reinforced low-density polyethylene composites. J. Appl. Polym. Sci. 1995, 57, 843–854. [Google Scholar] [CrossRef]

- George, J.; Joseph, K.; Bhagawan, S.S.; Thomas, S. Influence of short pineapple fiber on the viscoelastic properties of low-density polyethylene. Mater. Lett. 1993, 18, 163–170. [Google Scholar] [CrossRef]

- Wisittanawat, U.; Thanawan, S.; Amornsakchai, T. Mechanical properties of highly aligned short pineapple leaf fiber reinforced—Nitrile rubber composite: Effect of fiber content and Bonding Agent. Polym. Test. 2014, 35, 20–27. [Google Scholar] [CrossRef]

- Luo, S.; Netravali, A.N. Interfacial and mechanical properties of environment-friendly “green” composites made from pineapple fibers and poly(hydroxybutyrate-co-valerate) resin. J. Mater. Sci. 1999, 34, 3709–3719. [Google Scholar] [CrossRef]

- Liu, W.; Misra, M.; Askeland, P.; Drzal, L.T.; Mohanty, A.K. ‘Green’ composites from soy based plastic and pineapple leaf fiber: Fabrication and properties evaluation. Polymer 2005, 46, 2710–2721. [Google Scholar]

- Sadashiv, S.; Abasaheb, S. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. Part B 2019, 174, 106927. [Google Scholar]

- Jeon, Y.-P.; Alway-Cooper, R.; Morales, M.; Ogale, A.A. Chapter 2.8—Carbon Fibers. In Handbook of Advanced Ceramics, 2nd ed.; Somiya, S., Ed.; Academic Press: Oxford, UK, 2013; pp. 143–154. ISBN 978-0-12-385469-8. [Google Scholar]

- Salleh, Z.; Taib, Y.M.; Hyie, K.M.; Mihat, M.; Berhan, M.N.; Ghani, M.A.A. Fracture Toughness Investigation on Long Kenaf/Woven Glass Hybrid Composite Due To Water Absorption Effect. Procedia Eng. 2012, 41, 1667–1673. [Google Scholar]

- Nopparut, A.; Amornsakchai, T. Influence of pineapple leaf fiber and it’s surface treatment on molecular orientation in, and mechanical properties of, injection molded nylon composites. Polym. Test. 2016, 52, 141–149. [Google Scholar] [CrossRef]

- Júnior, J.H.S.A.; Júnior, H.L.O.; Amico, S.C.; Amado, F.D.R. Study of hybrid intralaminate curaua/glass composites. Mater. Des. 2012, 42, 111–117. [Google Scholar] [CrossRef]

- Ahmad, M.A.A.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Mazlee, M.N.; Gibson, A.G. Dynamic mechanical analysis and effects of moisture on mechanical properties of interwoven hemp/polyethylene terephthalate (PET) hybrid composites. Constr. Build. Mater. 2018, 179, 265–276. [Google Scholar] [CrossRef] [Green Version]

- Boey, F.Y.C.; Lye, S.W. Void reduction in autoclave processing of thermoset composites: Part 1: High pressure effects on void reduction. Composites 1992, 23, 261–265. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Kang, M.; Lee, W.I.; Hahn, H. Formation of microvoids during resin-transfer molding process. Compos. Sci. Technol. 2000, 60, 2427–2434. [Google Scholar] [CrossRef]

- Gourichon, B.; Deléglise, M.; Binetruy, C.; Krawczak, P. Dynamic void content prediction during radial injection in liquid composite molding. Compos. Part A Appl. Sci. Manuf. 2008, 39, 46–55. [Google Scholar] [CrossRef]

- Matuzaki, R.; Seto, D.; Naito, M.; Todoroki, A.; Mizutani, Y. Analytical prediction of void formation in geometrically anisotropic woven fabrics during resin transfer molding. Compos. Sci. Technol. 2015, 107, 154–161. [Google Scholar]

- Chan, A.W.; Morgan, R.J. Modeling prefrom impregnation and void formation in resin transfer molding of unidirectional composites. SAMPE Q. 1992, 23, 48–52. [Google Scholar]

- Parnas, R.S.; Phelan, F.R. The effect of heterogeneous porous media on mold filling in resin transfer molding. SAMPE Q. 1991, 22, 53–60. [Google Scholar]

- Hart-Smith, L.J. A New Approach to Fibrous Composite Laminate Strength Prediction. 1990. Available online: https://ntrs.nasa.gov/citations/19920023344 (accessed on 28 November 2020).

- Abdul Majid, M.S.; Daud, R.; Afendi, M.; Amin, N.A.M.; Cheng, E.M.; Gibson, A.G.; Hekman, M. Stress-strain response modelling of glass fibre reinforced epoxy composite pipes under multiaxial loadings. J. Mech. Eng. Sci. 2014, 6, 916–928. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Khan, B.; Hallett, S.R. Size effects in unnotched tensile strength of unidirectional and quasi-isotropic carbon/epoxy composites. Compos. Struct. 2008, 84, 21–28. [Google Scholar] [CrossRef]

- Fotouhi, M.; Jalalvand, M.; Wisnom, M.R. High performance quasi-isotropic thin-ply carbon/glass hybrid composites with pseudo-ductile behaviour in all fibre orientations. Compos. Sci. Technol. 2017, 152, 101–110. [Google Scholar] [CrossRef]

- Wu, X.; Fuller, J.D.; Wisnom, M.R. Role of fibre fragmentation on pseudo-ductility of thin-ply [±277/0]s carbon fibre laminates with high modulus 0° plies under compressive and flexural loading. Compos. Sci. Technol. 2020, 199, 108377. [Google Scholar] [CrossRef]

- Fuller, J.D.; Wisnom, M.R. Exploration of the potential for pseudo-ductility in thin ply CFRP angle-ply laminates via an analytical method. Compos. Sci. Technol. 2015, 112, 8–15. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y.; Cai, Y.; Zhao, Z.; Liu, P.; Han, L.; Zhang, C. Predicting the tensile and compressive failure behavior of angle-ply spread tow woven composites. Compos. Struct. 2020, 234, 111701. [Google Scholar] [CrossRef]

- Caminero, M.A.; Rodríguez, G.P.; Muñoz, V. Effect of stacking sequence on Charpy impact and flexural damage behavior of composite laminates. Compos. Struct. 2016, 136, 345–357. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Nayak, R.K. Improvement of mechanical properties of hybrid composites through interply rearrangement of glass and carbon woven fabrics for marine application. Compos. Part B Eng. 2019, 168, 467–475. [Google Scholar] [CrossRef]

- Sezgin, H.; Berkalp, O.B. The effect of hybridization on significant characteristics of jute/glass and jute/carbon-reinforced composites. J. Ind. Text. 2017, 47, 283–296. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Manalo, A.C.; Wani, E.; Zukarnain, N.A.; Karunasena, W.; Lau, K. Effects of alkali treatment and elevated temperature on the mechanical properties of bamboo fibre–polyester composites. Compos. Part B Eng. 2015, 80, 73–83. [Google Scholar] [CrossRef] [Green Version]

- Chunhong, W.; Shengkai, L.; Zhanglong, Y. Mechanical, hygrothermal ageing and moisture absorption properties of bamboo fibers reinforced with polypropylene composites. J. Reinf. Plast. Compos. 2016, 35, 1062–1074. [Google Scholar] [CrossRef]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; Macmullen, J.; Bennett, N. Development of flax/carbon fibre hybrid composites for enhanced properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hung, P.; Lau, K.; Cheng, L.; Leng, J.; Hui, D. Impact response of hybrid carbon/glass fibre reinforced polymer composites designed for engineering applications. Compos. Part B Eng. 2018, 133, 86–90. [Google Scholar] [CrossRef]

- Hossain, M.; Islam, A.; Vuure, A.W.; Ignaas, V. Effect of Fiber Orientation on the Tensile Properties of Jute Epoxy Laminated Composite. J. Sci. Res. 2012, 5, 43–54. [Google Scholar] [CrossRef]

- GuruRaja, M.; HariRao, A. Influence of Angle Ply Orientation on Tensile Properties of Carbon/Glass Hybrid Composite. J. Miner. Mater. Charact. Eng. 2013, 1, 231–235. [Google Scholar] [CrossRef] [Green Version]

- Kumar, K.V.; Reddy, P.R.; Shankar, D.V.R. Effect of Angle Ply Orientation On Tensile Properties Of Bi Directional Woven Fabric Glass Epoxy Composite Laminate. Int. J. Comput. Eng. Res. 2013, 3, 55–61. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ridzuan, M.J.M.; Majid, M.S.A.; Afendi, M.; Azduwin, K.; Kanafiah, S.N.A.; Dan-mallam, Y. The Effects of the Alkaline Treatment’s Soaking Exposure on the Tensile Strength of Napier Fibre. Procedia Manuf. 2015, 2, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Mahjoub, R.; Yatim, J.M.; Mohd Sam, A.R.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Gowda, T.M.; Naidu, A.C.B.; Chhaya, R. Some mechanical properties of untreated jute fabric-reinforced polyester composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 277–284. [Google Scholar] [CrossRef]

- Srivathsan, A.; Vijayaram, B.; Ramesh, R. Gokuldass Investigation on Mechanical Behavior of Woven Fabric Glass/Kevlar Hybrid Composite Laminates Made of Varying Fibre Inplane Orientation and Stacking Sequence. Mater. Today Proc. 2017, 4, 8928–8937. [Google Scholar] [CrossRef]

- Pinto, F.; Boccarusso, L.; De Fazio, D.; Cuomo, S.; Durante, M.; Meo, M. Carbon/hemp bio-hybrid composites: Effects of the stacking sequence on flexural, damping and impact properties. Compos. Struct. 2020, 242, 112148. [Google Scholar] [CrossRef]

- Ary Subagia, I.D.G.; Kim, Y.; Tijing, L.D.; Kim, C.S.; Shon, H.K. Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Compos. Part B Eng. 2014, 58, 251–258. [Google Scholar] [CrossRef]

- Varna, J.; Joffe, R.; Akshantala, N.V.; Talreja, R. Damage in composite laminates with off-axis plies. Compos. Sci. Technol. 1999, 59, 2139–2147. [Google Scholar] [CrossRef]

- Mujika, F. On the effect of shear and local deformation in three-point bending tests. Polym. Test. 2007, 26, 869–877. [Google Scholar] [CrossRef]

- Shahirul, M.; Jusoh, M.; Santulli, C.; Yazid, M.; Yahya, M.; Hussein, N.S.; Ahmad, H.; Ahmad, I. Material Science and Engineering with Advanced Research Effect of Stacking Sequence on the Tensile and Flexural Properties of Glass Fibre Epoxy Composites Hybridized with Basalt, Flax or Jute Fibres. Mater. Sci. Eng. Adv. 2016, 1, 19–25. [Google Scholar]

- Katerelos, D.G.; McCartney, L.N.; Galiotis, C. Effect of Off—Axis Matrix Cracking on Stiffness of Symmetric Angle-Ply Composite Laminates. Int. J. Fract. 2006, 139, 529–536. [Google Scholar] [CrossRef]

- Singh, C.V.; Talreja, R. Analysis of multiple off-axis ply cracks in composite laminates. Int. J. Solids Struct. 2008, 45, 4574–4589. [Google Scholar]

- Ridzuan, M.J.M.; Abdul Majid, M.S.; Afendi, M.; Aqmariah Kanafiah, S.N.; Zahri, J.M.; Gibson, A.G. Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater. Des. 2016, 89, 839–847. [Google Scholar] [CrossRef]

- Dassios, K. A Review of the Pull-Out Mechanism in the Fracture of Brittle-Matrix Fibre-Reinforced Cowosites. Adv. Compos. Lett. 2007, 161. [Google Scholar] [CrossRef] [Green Version]

- Ridzuan, M.J.M.; Majid, M.S.A.; Afendi, M.; Mazlee, M.N.; Gibson, A.G. Thermal behaviour and dynamic mechanical analysis of Pennisetum purpureum/glass-reinforced epoxy hybrid composites. Compos. Struct. 2016, 152, 850–859. [Google Scholar] [CrossRef]

- Ogin, S.L.; Brøndsted, P.; Zangenberg, J. 1—Composite materials: Constituents, architecture, and generic damage. In Modeling Damage, Fatigue and Failure of Composite Materials; Talreja, R., Varna, J., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2016; pp. 3–23. ISBN 978-1-78242-286-0. [Google Scholar]

- Fikry, M.M.; Ogihara, S.; Vinogradov, V. Effect of matrix cracking on mechanical properties in FRP angle-ply laminates. In Proceedings of the ECCM 2018—18th European Conference on Composite Materials, AML, Athens, Greece, 25–28 June 2018; Applied Mechanics Laboratory: Tokyo, Japan, 2020. [Google Scholar]

- Davis, D.C.; Wilkerson, J.W.; Zhu, J.; Ayewah, D.O.O. Improvements in mechanical properties of a carbon fiber epoxy composite using nanotube science and technology. Compos. Struct. 2010, 92, 2653–2662. [Google Scholar] [CrossRef]

| Property | PALF | Carbon Fibre | Epoxy |

|---|---|---|---|

| Tensile Strength (MPa) | 148.44 | 3530 | 55 |

| Tensile Modulus (GPa) | 10.46 | 230 | 1.75 |

| Strain of failure (%) | 1.05 | 1.5 | 6 |

| Reference | [30] | [31] | [32] |

| Lamination | Orientation | Layering Pattern | Fibre Volume Fraction (%) | ||

|---|---|---|---|---|---|

| PALF | Carbon Fiber | Total | |||

| Cross-ply symmetric | [0°, 90°]n | PPPP-untreated | 24 | - | 24 |

| PPPP-treated | 21 | - | 21 | ||

| PCCP | 16.7 | 6.2 | 22.9 | ||

| CPPC | 16.7 | 6.2 | 22.9 | ||

| Angle-ply symmetric | [±45°]n | PPPP-untreated | 24 | - | 24 |

| PPPP-treated | 21 | - | 21 | ||

| PCCP | 16.7 | 6.2 | 22.9 | ||

| CPPC | 16.7 | 6.2 | 22.9 | ||

| Symmetric Quasi-isotropic | [±45°n, 0°n, 90°n]s | PPPP-untreated | 24 | - | 24 |

| PPPP-treated | 21 | - | 21 | ||

| PCCP | 16.7 | 6.2 | 22.9 | ||

| CPPC | 16.7 | 6.2 | 22.9 | ||

| [0°n, 90°n, ±45°n]s | PPPP-untreated | 24 | - | 24 | |

| PPPP-treated | 21 | - | 21 | ||

| PCCP | 16.7 | 6.2 | 22.9 | ||

| CPPC | 16.7 | 6.2 | 22.9 | ||

| Orientation | Layering | Void Content (%) |

|---|---|---|

| [0°, 90°]n | PPPP-untreated | 1.63 ± 0.03 |

| PPPP-treated | 2.33 ± 0.02 | |

| PCCP | 0.99 ± 0.14 | |

| CPPC | 1.23 ± 0.04 | |

| [±45°]n | PPPP-untreated | 2.69 ± 0.10 |

| PPPP-treated | 2.99 ± 0.16 | |

| PCCP | 2.33 ± 0.04 | |

| CPPC | 2.02 ± 0.05 | |

| [±45°n, 0°n, 90°n]s | PPPP-untreated | 1.73 ± 0.04 |

| PPPP-treated | 2.63 ± 0.06 | |

| PCCP | 2.02 ± 0.07 | |

| CPPC | 2.23 ± 0.11 | |

| [0°n, 90°n, ±45°n]s | PPPP-untreated | 1.86 ± 0.06 |

| PPPP-treated | 2.53 ± 0.09 | |

| PCCP | 2.03 ± 0.09 | |

| CPPC | 1.53 ± 0.04 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashim, M.K.R.; Abdul Majid, M.S.; Jamir, M.R.M.; Kasim, F.H.; Sultan, M.T.H. The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers 2021, 13, 455. https://doi.org/10.3390/polym13030455

Hashim MKR, Abdul Majid MS, Jamir MRM, Kasim FH, Sultan MTH. The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers. 2021; 13(3):455. https://doi.org/10.3390/polym13030455

Chicago/Turabian StyleHashim, Mohd Khairul Rabani, Mohd Shukry Abdul Majid, Mohd Ridzuan Mohd Jamir, Farizul Hafiz Kasim, and Mohamed Thariq Hameed Sultan. 2021. "The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites" Polymers 13, no. 3: 455. https://doi.org/10.3390/polym13030455

APA StyleHashim, M. K. R., Abdul Majid, M. S., Jamir, M. R. M., Kasim, F. H., & Sultan, M. T. H. (2021). The Effect of Stacking Sequence and Ply Orientation on the Mechanical Properties of Pineapple Leaf Fibre (PALF)/Carbon Hybrid Laminate Composites. Polymers, 13(3), 455. https://doi.org/10.3390/polym13030455