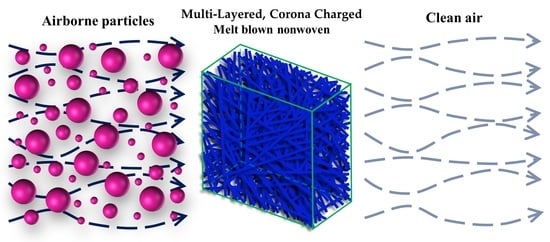

Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Melt Blown Nonwovens

2.3. Corona Charging

2.4. Characteristics of the Manufactured Nonwovens

2.5. Filtration Performances of Manufactured Nonwovens

3. Results

3.1. Design and Fabrication of Melt Blown Nonwovens

3.2. The Mechanism for the Improvement of Filtration Efficiency

3.3. Removal of Paraffin Oil by Multi-Layered Melt Blown Nonwovens

3.4. Evaluation of Air Filtration Performances

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Burnett, R.; Chen, H.; Szyszkowicz, M.; Fann, N.; Hubbell, B.; Pope, C.A., 3rd; Apte, J.S.; Brauer, M.; Cohen, A.; Weichenthal, S.; et al. Global estimates of mortality associated with long-term exposure to outdoor fine particulate matter. Proc. Natl. Acad. Sci. USA 2018, 115, 9592–9597. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rajagopalan, S.; Al-Kindi, S.G.; Brook, R.D. Air Pollution and Cardiovascular Disease: JACC State-of-the-Art Review. J. Am. Coll. Cardiol. 2018, 72, 2054–2070. [Google Scholar] [CrossRef] [PubMed]

- Leung, N.H.L.; Chu, D.K.W.; Shiu, E.Y.C.; Chan, K.H.; McDevitt, J.J.; Hau, B.J.P.; Yen, H.L.; Li, Y.; Ip, D.K.M.; Peiris, J.S.M.; et al. Respiratory virus shedding in exhaled breath and efficacy of face masks. Nat. Med. 2020, 26, 676–680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, J.; Zhang, X.; Zhang, H.; Zheng, L.; Huang, C.; Wu, H.; Wang, R.; Jin, X. Low resistance bicomponent spunbond materials for fresh air filtration with ultra-high dust holding capacity. RSC Adv. 2017, 7, 43879–43887. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Xu, Y.; Wang, D.; Zhang, Y.; Zhang, X.; Liu, J.; Zhao, Y.; Huang, C.; Jin, X. Polytetrafluoroethylene/Polyphenylene Sulfide Needle-Punched Triboelectric Air Filter for Efficient Particulate Matter Removal. ACS Appl. Mater. Interfaces 2019, 11, 48437–48449. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Zhang, Y.; Fu, Y.; Jin, X. Design of three-dimensional gradient nonwoven composites with robust dust holding capacity for air filtration. J. Appl. Polym. Sci. 2019, 136, 136. [Google Scholar] [CrossRef]

- Dai, Z.; Su, J.; Zhu, X.; Xu, K.; Zhu, J.; Huang, C.; Ke, Q. Multifunctional polyethylene (PE)/polypropylene (PP) bicomponent fiber filter with anchored nanocrystalline MnO2 for effective air purification. J. Mater. Chem. A 2018, 6, 14856–14866. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Gong, H.; Zhang, X.; Wang, Y.; Jin, X. Polyethylene/Polypropylene Bicomponent Spunbond Air Filtration Materials Containing Magnesium Stearate for Efficient Fine Particle Capture. ACS Appl. Mater. Interfaces 2019, 11, 40592–40601. [Google Scholar] [CrossRef]

- Anandjiwala, R.D.; Boguslavsky, L. Development of Needle-punched Nonwoven Fabrics from Flax Fibers for Air Filtration Applications. Text. Res. J. 2008, 78, 614–624. [Google Scholar] [CrossRef]

- Chen, X.; Xu, Y.; Liang, M.; Ke, Q.; Fang, Y.; Xu, H.; Jin, X.; Huang, C. Honeycomb-like polysulphone/polyurethane nanofiber filter for the removal of organic/inorganic species from air streams. J. Hazard. Mater. 2018, 347, 325–333. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.; Ding, B. Cleanable Air Filter Transferring Moisture and Effectively Capturing PM2.5. Small 2017, 13, 13. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. A Fluffy Dual-Network Structured Nanofiber/Net Filter Enables High-Efficiency Air Filtration. Adv. Funct. Mater. 2019, 29, 29. [Google Scholar] [CrossRef]

- Dai, Z.; Zhu, J.; Yan, J.; Su, J.; Gao, Y.; Zhang, X.; Ke, Q.; Parsons, G.N. An Advanced Dual-Function MnO2-Fabric Air Filter Combining Catalytic Oxidation of Formaldehyde and High-Efficiency Fine Particulate Matter Removal. Adv. Funct. Mater. 2020, 30. [Google Scholar] [CrossRef]

- Ellison, C.J.; Phatak, A.; Giles, D.W.; Macosko, C.W.; Bates, F.S. Melt blown nanofibers: Fiber diameter distributions and onset of fiber breakup. Polymer 2007, 48, 3306–3316. [Google Scholar] [CrossRef]

- Mohmeyer, N.; Behrendt, N.; Zhang, X.; Smith, P.; Altstädt, V.; Sessler, G.M.; Schmidt, H.-W. Additives to improve the electret properties of isotactic polypropylene. Polymer 2007, 48, 1612–1619. [Google Scholar] [CrossRef]

- Hassan, M.A.; Yeom, B.Y.; Wilkie, A.; Pourdeyhimi, B.; Khan, S.A. Fabrication of nanofiber meltblown membranes and their filtration properties. J. Membr. Sci. 2013, 427, 336–344. [Google Scholar] [CrossRef]

- Podgórski, A.; Bałazy, A.; Gradoń, L. Application of nanofibers to improve the filtration efficiency of the most penetrating aerosol particles in fibrous filters. Chem. Eng. Sci. 2006, 61, 6804–6815. [Google Scholar] [CrossRef]

- Geiser, M.; Rothen-Rutishauser, B.; Kapp, N.; Schurch, S.; Kreyling, W.; Schulz, H.; Semmler, M.; Im Hof, V.; Heyder, J.; Gehr, P. Ultrafine particles cross cellular membranes by nonphagocytic mechanisms in lungs and in cultured cells. Environ. Health Perspect. 2005, 113, 1555–1560. [Google Scholar] [CrossRef] [Green Version]

- Barhate, R.S.; Ramakrishna, S. Nanofibrous filtering media: Filtration problems and solutions from tiny materials. J. Membr. Sci. 2007, 296, 1–8. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Electret Air Filters. Sep. Purif. Rev. 2013, 42, 87–129. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Jin, X. Design of electret polypropylene melt blown air filtration material containing nucleating agent for effective PM2.5 capture. RSC Adv. 2018, 8, 7932–7941. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Jin, X. Online prediction of the filtration performance of polypropylene melt blown nonwovens by blue-colored glow. J. Appl. Polym. Sci. 2018, 135, 135. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, N.; Zeng, Q.; Liu, J.; Zhang, X.; Ge, M.; Zhang, W.; Li, S.; Fu, Y.; Zhang, Y. Design of Polypropylene Electret Melt Blown Nonwovens with Superior Filtration Efficiency Stability through Thermally Stimulated Charging. Polymers 2020, 12, 2341. [Google Scholar] [CrossRef] [PubMed]

- Gao, Y.; Wang, J.; Liu, F.; Du, B. Surface Potential Decay of Negative Corona Charged Epoxy/Al2O3 Nanocomposites Degraded by 7.5-MeV Electron Beam. IEEE Trans. Plasma Sci. 2018, 46, 2721–2729. [Google Scholar] [CrossRef]

- Huiming, X.; Gangjin, C.; Xumin, C.; Zhi, C. Author Correction: A Flexible Electret Membrane with Persistent Electrostatic Effect and Resistance to Harsh Environment for Energy Harvesting. Sci. Rep. 2018, 8, 5235. [Google Scholar] [CrossRef] [Green Version]

- Wintle, H.J. Introduction to electrets. J. Acoust. Soc. Am. 1972, 53, 1578–1588. [Google Scholar] [CrossRef]

- Wan, H.; Wang, N.; Yang, J.; Si, Y.; Chen, K.; Ding, B.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Yu, J. Hierarchically structured polysulfone/titania fibrous membranes with enhanced air filtration performance. J. Colloid Interface Sci. 2014, 417, 18–26. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Yang, Y.; Al-Deyab, S.S.; El-Newehy, M.; Yu, J.; Ding, B. Ultra-light 3D nanofibre-nets binary structured nylon 6–polyacrylonitrile membranes for efficient filtration of fine particulate matter. J. Mater. Chem. A 2015, 3, 23946–23954. [Google Scholar] [CrossRef]

- Leung, W.F.; Hung, C.H.; Yuen, P.T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Purif. Technol. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Wang, Q.; Lin, X.; Chen, D.-R. Effect of dust loading rate on the loading characteristics of high efficiency filter media. Powder Technol. 2016, 287, 20–28. [Google Scholar] [CrossRef]

| Screw Zone 1 Temperature (°C) | Screw Zone 2 Temperature (°C) | Screw Zone 3 Temperature (°C) | Air Temperature (°C) | Distance (mm) | Screw Speed(r/min) | Air Pressure (MPa) |

|---|---|---|---|---|---|---|

| 280 | 340 | 345 | 300 | 100 | 3 | 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Liu, J.; Zhang, H.; Hou, J.; Wang, Y.; Deng, C.; Huang, C.; Jin, X. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers 2021, 13, 485. https://doi.org/10.3390/polym13040485

Zhang X, Liu J, Zhang H, Hou J, Wang Y, Deng C, Huang C, Jin X. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers. 2021; 13(4):485. https://doi.org/10.3390/polym13040485

Chicago/Turabian StyleZhang, Xing, Jinxin Liu, Haifeng Zhang, Jue Hou, Yuxiao Wang, Chao Deng, Chen Huang, and Xiangyu Jin. 2021. "Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters" Polymers 13, no. 4: 485. https://doi.org/10.3390/polym13040485

APA StyleZhang, X., Liu, J., Zhang, H., Hou, J., Wang, Y., Deng, C., Huang, C., & Jin, X. (2021). Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers, 13(4), 485. https://doi.org/10.3390/polym13040485