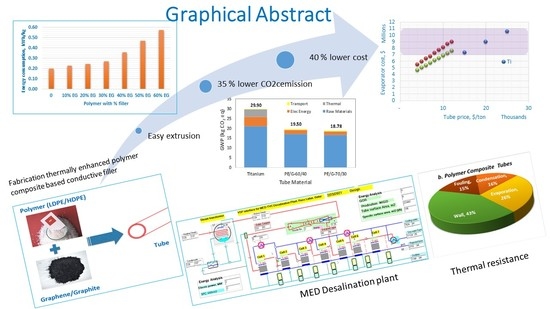

Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology

Abstract

:1. Introduction

2. Methodology

2.1. Techno-Economic Modeling

2.2. Simulation of Required Energy for the Polymer Composite Extrusion

2.3. LCA Model Framework

- (a)

- The tube production and all the Ti raw materials are available in Germany, and the final product is transported to Qatar via sea route.

- (b)

- The use of chemicals, water, and air for intermediate processes are not considered, as shown in Figure 2.

- (c)

- (d)

- Forty percent annual recycling of the final titanium tubes is considered [30].

- (e)

3. Results and Discussion

3.1. Techno-Economic Analysis

3.2. Life-Cycle Assessment

3.3. Socioeconomic Aspect

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AC—acidification |

| CAPEX—capital expenditure |

| FD—fossil depletion |

| FE—freshwater eutrophication |

| G—graphite |

| GOR—gain output ratio |

| GWP—global warming potential |

| HDPE—high-density polyethylene |

| HT—heat transfer |

| LCA—life-cycle assessment |

| LCI—life-cycle inventory |

| LCIA—life-cycle impact assessment |

| LDPE—low-density polyethylene |

| MED—multi-effect desalination |

| OD—ozone depletion |

| OPEX—operating expenditure |

| PE/G—low-density polyethylene + expanded graphite |

| PP—polypropylene |

| WE—water eutrophication |

References

- FAO. Water Resources. 2018. Available online: http://www.fao.org/nr/water/aquastat/water_res/index.stm (accessed on 14 June 2020).

- Abouhatab, A. Water Scarcity And Water Trade: An Analysis of the Determinants of Virtual Water Flows to the GCC Countries. In Qatar Foundation Annual Research Conference Proceedings; Hamad bin Khalifa University Press (HBKU Press): Ar-Rayyan, Qatar, 2018. [Google Scholar] [CrossRef]

- Darwish, M.A.; Mohtar, R. Qatar water challenges, Desalin. Water Treat. 2013, 51, 75–86. [Google Scholar] [CrossRef]

- Mannan, M.; Alhaj, M.; Mabrouk, A.N.; Al-Ghamdi, S.G. Examining the life-cycle environmental impacts of desalination: A case study in the State of Qatar. Desalination 2019, 452, 238–246. [Google Scholar] [CrossRef]

- Tahir, F.; Baloch, A.A.B.; Ali, H. Resilience of Desalination Plants for Sustainable Water Supply in Middle East. In Sustainability Perspectives: Science, Policy and Practice; Khaiter, P.A., Erechtchoukova, M.G., Eds.; Springer: Cham, Switzerland, 2020; pp. 303–329. [Google Scholar] [CrossRef]

- Mabrouk, A.A.; Bourouni, K.; Abdulrahim, H.K.; Darwish, M.; Sharif, A.O. Impacts of tube bundle arrangement and feed flow pattern on the scale formation in large capacity MED desalination plants. Desalination 2015, 357, 275–285. [Google Scholar] [CrossRef]

- Tahir, F.; Atif, M.; Antar, M.A. The Effect of Fouling on Performance and Design Aspects of Multiple-Effect Desalination Systems. In Recent Progress in Desalination, Environmental and Marine Outfall Systems; Springer: Cham, Switzerland, 2015; pp. 35–52. [Google Scholar] [CrossRef]

- Stärk, A.; Loisel, K.; Odiot, K.; Feßenbecker, A.; Kempter, A.; Nied, S.; Glade, H. Wetting behaviour of different tube materials and its influence on scale formation in multiple-effect distillers. Desalin. Water Treat. 2015, 55, 2502–2514. [Google Scholar] [CrossRef]

- Deisenroth, D.C.; Moradi, R.; Shooshtari, A.H.; Singer, F.; Bar-Cohen, A.; Ohadi, M. Review of Heat Exchangers Enabled by Polymer and Polymer Composite Additive Manufacturing. Heat Transf. Eng. 2018, 39, 1648–1664. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- Chaudhry, A.U.; Mabrouk, A.; Abdala, A. Thermally enhanced pristine polyolefins: Fundamentals, progress and prospective. J. Mater. Res. Technol. 2020, 9, 10796–10806. [Google Scholar] [CrossRef]

- Chaudhry, A.U.; Mabrouk, A.N.; Abdala, A. Thermally enhanced polyolefin composites: Fundamentals, progress, challenges, and prospects. Sci. Technol. Adv. Mater. 2020, 21, 737–766. [Google Scholar] [CrossRef]

- Moses, D.; Glade, H.; Joseph, D.B. Corrosion and Scaling on Polymer Composite Evaporator tubes for Industrial water treatment application. In Proceedings of the IDA 2017 World Congress on Water Reuse and Desalination, Sao Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Chaudhry, A.U.; Lonkar, S.P.; Chudhary, R.G.; Mabrouk, A.; Abdala, A.A. Thermal, electrical, and mechanical properties of highly filled HDPE/graphite nanoplatelets composites. Mater. Today Proc. 2020, 29, 704–708. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Abdulgader, A.; Mrlik, M.; Popelka, A.; Abdala, A.A.; Aboukhlewa, A.A.; Karkri, M.; Kiepfer, H.; Bart, H.J.; Krupa, I. Thermally conductive high-density polyethylene/expanded graphite composites as heat transfer surface for multi-effect distillation apparatus: Mechanical, thermo-physical and surface behavior. Polymers 2020, 12, 2863. [Google Scholar] [CrossRef]

- Mabrouk, A.; Usman, C.; Ahmed Abdalla, M. Thermoplastic and method of manufacturing the same. US provision 63049803, D2020-057-01, 2020-07-09.

- Mabrouk, A.; Abotaleb, A.; Tahir, F.; Darwish, M.; Aini, R.; Koc, M.; Abdelrashid, A. High Performance MED Desalination Plants Part I: Novel Design MED Evaporator. In Proceedings of the IDA 2017 World Congress on Water Reuse and Desalination, Sao Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Mabrouk, A.; Abotaleb, A.; Abdelrehim, H.; Tahir, F.; Koc, M.; Abdelrashid, A.; Nasralla, A. HP MED Plants, Part II: Novel Integration MED-Absorption Vapor Compression. In Proceedings of the IDA 2017 World Congress on Water Reuse and Desalination, Sao Paulo, Brazil, 15–20 October 2017. [Google Scholar]

- Harding, K.; Dennis, J.; Vonblottnitz, H.; Harrison, S. Environmental analysis of plastic production processes: Comparing petroleum-based polypropylene and polyethylene with biologically-based poly-β-hydroxybutyric acid using life cycle analysis. J. Biotechnol. 2007, 130, 57–66. [Google Scholar] [CrossRef]

- Pizza, A.; Metz, R.; Hassanzadeh, M.; Bantignies, J.-L. Life cycle assessment of nanocomposites made of thermally conductive graphite nanoplatelets. Int. J. Life Cycle Assess. 2014, 19, 1226–1237. [Google Scholar] [CrossRef]

- Jungbluth, N. Life Cycle Inventory of Sodium Acetate and Expanded Graphite. 2008. Available online: https://www.osti.gov/etdeweb/biblio/22119615 (accessed on 14 June 2020).

- Levinjobet, N. Energy Analysis in the Extrusion of Plastics; University of Applied Sciences: Helsinki, Finland, 2012. [Google Scholar]

- Abeykoon, C.; Kelly, A.L.; Brown, E.C.; Vera-Sorroche, J.; Coates, P.D.; Harkin-Jones, E.; Howell, K.B.; Deng, J.; Li, K.; Price, M. Investigation of the process energy demand in polymer extrusion: A brief review and an experimental study. Appl. Energy 2014, 136, 726–737. [Google Scholar] [CrossRef]

- Vera-Sorroche, J.; Kelly, A.L.; Brown, E.C.; Gough, T.; Abeykoon, C.; Coates, P.D.; Deng, J.; Li, K.; Harkin-Jones, E.; Price, M. The effect of melt viscosity on thermal efficiency for single screw extrusion of HDPE. Chem. Eng. Res. Des. 2014, 92, 2404–2412. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.P.; Wang, H.Z.; Ruan, G.L.; Wang, S.H.; Xiao, Y.X.; Jiang, L.D. Applications and prospects of titanium and its alloys in seawater desalination industry. IOP Conf. Ser. Mater. Sci. Eng. 2019, 688, 033036. [Google Scholar] [CrossRef]

- US Department of Energy. Bandwidth Study on Energy Use and Potential Energy Savings Opportunities in U.S. Titanium Manufacturing. 2017. Available online: https://www.energy.gov/eere/amo/downloads/bandwidth-study-us-titanium-manufacturing (accessed on 14 June 2020).

- Fang, Z.Z.; Chandran, R.; Koopman, M. A New Method for Low Cost Production of Titanium Alloys for Reducing Energy Consumption of Mechanical Systems. 2015. Available online: https://www.energy.gov/eere/amo/downloads/new-method-low-cost-production-ff-titanium-alloys-reducing-energy-consumption (accessed on 10 June 2020).

- Liao, W.; Heijungs, R.; Huppes, G. Thermodynamic resource indicators in LCA: A case study on the titania produced in Panzhihua city, southwest China. Int. J. Life Cycle Assess. 2012, 17, 951–961. [Google Scholar] [CrossRef] [Green Version]

- Gupta, M.K.; Song, Q.; Liu, Z.; Pruncu, C.I.; Mia, M.; Singh, G.; Lozano, J.A.; Carou, D.; Khan, A.M.; Jamil, M.; et al. Machining characteristics based life cycle assessment in eco-benign turning of pure titanium alloy. J. Clean. Prod. 2020, 251, 119598. [Google Scholar] [CrossRef]

- Takeda, O.; Okabe, T.H. Current Status of Titanium Recycling and Related Technologies. JOM 2019, 71, 1981–1990. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Deng, Y.; Guo, Y.; Wu, P.; Ingarao, G. Optimal design of flax fiber reinforced polymer composite as a lightweight component for automobiles from a life cycle assessment perspective. J. Ind. Ecol. 2019, 23, 986–997. [Google Scholar] [CrossRef]

- Zhang, L.; Spatari, S.; Sun, Y. Life cycle assessment of novel heat exchanger for dry cooling of power plants based on encapsulated phase change materials. Appl. Energy 2020, 271, 115227. [Google Scholar] [CrossRef]

- Ren, C.; Deng, Y.; Cao, S.-J. evaluation of polyethylene and steel heat exchangers of ground source heat pump systems based on seasonal performance comparison and life cycle assessment. Energy Build. 2018, 162, 54–64. [Google Scholar] [CrossRef]

- Assaf, S.A. Existing and the future planned desalination facilities in the Gaza Strip of Palestine and their socio-economic and environmental impact. Desalination 2001, 138, 17–28. [Google Scholar] [CrossRef]

- Nafey, A.S.; Fath, H.E.S.; Mabrouk, A.A. Thermo-economic investigation of multi effect evaporation (MEE) and hybrid multi effect evaporation—multi stage flash (MEE-MSF) systems. Desalination 2006, 201, 241–254. [Google Scholar] [CrossRef]

- Nafey, A.S.; Fath, H.E.S.; Mabrouk, A.A. A new visual package for design and simulation of desalination processes. Desalination 2006, 194, 281–296. [Google Scholar] [CrossRef]

- Gabi [Computer Software], Thinkstep, Sphera Solutions, leinfelden-echterdingen, Germany, 2020.

- Chen, L.; Liu, M.; Huang, J. GB/T 24040-2008 environmental management-life cycle assessment-principles and framework national standard understanding. Stand. Sci. 2009, 2. [Google Scholar]

- Forming of Titanium and Titanium Alloys: Part Two, Total Mater. 2007. Available online: https://www.totalmateria.com/page.aspx?ID=CheckArticle&site=KTN&NM=167 (accessed on 19 June 2020).

- Frank, A.; Pinter, G.; Lang, R.W. Prediction of the remaining lifetime of polyethylene pipes after up to 30 years in use. Polym. Test. 2009, 28, 737–745. [Google Scholar] [CrossRef]

- Poduška, J.; Dlhý, P.; Hutař, P.; Frank, A.; Kučera, J.; Sadílek, J.; Náhlík, L. Design of plastic pipes considering content of recycled material. Procedia Struct. Integr. 2019, 23, 293–298. [Google Scholar] [CrossRef]

- Tahir, F.; Mabrouk, A.; Koc, M. Review on CFD analysis of horizontal falling film evaporators in multi effect desalination plants. Desalin. Water Treat. 2019, 166, 296–320. [Google Scholar] [CrossRef]

- Effects of Annealing Temperature on Titanium Grade 2 Seamless Tubes. MTS Ferr & Nonferrous Alloy Pip, 2016. Available online: http://www.metalspiping.com/effects-of-annealing-temp-on-ti-gr2-smls-tubes.html#:~:text=Analysis%26Conclusion%3Aallmechanicalproperties,ASTMB338grade2titanium.&text=Hence%2Crelativelylowerstrengthandbeat600°C (accessed on 19 June 2020).

- Sikirica, S.J. Low-Cost Production of Titanium Alloys to Reduce Energy Consumption. Ind. Heat. “Industrial Gases/Combustion.” 2017. Available online: industrialheating.com/articles/93319-low-cost-production-of-titanium-alloys-to-reduce-energy-consumption (accessed on 14 June 2020).

| Ti | PE/EG 70/30 | PE/EG 60/40 | |

|---|---|---|---|

| Plant capacity, ton/h | 1148 | 1148 | 1148 |

| Top brine temperature (TBT), C | 65 | 65 | 65 |

| Number of evaporators | 7 | 7 | 7 |

| Feed salinity, g/L | 45 | 45 | 45 |

| Rejected brine salinity, g/L | 65 | 65 | 65 |

| Tube length for effect 1, 2, 3, and 4, in m Steam | 5 | 5 | 5 |

| Tube diameter for effect 1, 2, 3, and 4, in mm | 25.4 | 25.4 | 25.4 |

| Tube length for effect 5, 6, and 7, in m | 9 | 9 | 9 |

| Tube diameter for effect 5, 6, and 7, in mm | 38 mm | 38 mm | 38 mm |

| Wall thickness, mm | 0.5 | 1.25 | 1.25 |

| Density, kg/m3 | 4500 | 1150 | 1250 |

| Thermal conductivity, W/m·K | 17 | 3 | 5 |

| Fouling factor, m2·K/kW | 0.1 | 0.1 | 0.1 |

| Process | Electrical Energy (kWh/kg) | Thermal Energy (kWh/kg) | Remarks | |

|---|---|---|---|---|

| 1 | Ore to Ingot | Gabi | ||

| 2 | Forging/Billet | 0.0885 | 1.23 | [27] |

| 3 | Hot/Cold Rolling | 0.2 | 0.6 | 730–815 °C [40] |

| 4 | Extrusion | 0.128 | 0.43 | 980–1040 °C [40] |

| 5 | Heat Treatment (Annealing) | 0.109 | − | 600 °C, Soaking 1 h [44] |

| 6 | Scrap melting to ingot | 1.949 | − | [45] |

| Category | Abbreviation | Units | |

|---|---|---|---|

| 1 | Global warming potential | GWP | kg CO2 eq. |

| 2 | Ozone depletion | OD | kg CFC-11 eq. |

| 3 | Acidification | AC | g SO2 eq. |

| 4 | Water eutrophication | WE | g P eq. |

| 5 | Fossil depletion | FD | Kg oil eq. |

| Filler Percentage, % | 0 | 10 | 20 | 30 | 40 | 50 | 60 |

|---|---|---|---|---|---|---|---|

| Material cost, $/ton | 1200 | 1780 | 2360 | 2940 | 3520 | 4100 | 4680 |

| Mixing, $/ton | 900 | 900 | 900 | 950 | 1000 | 1050 | |

| Extrusion, $/ton | 400 | 400 | 400 | 400 | 430 | 470 | 500 |

| Total cost, $/ton | 1600 | 3080 | 3660 | 4240 | 4900 | 5570 | 6230 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tahir, F.; Mabrouk, A.; Al-Ghamdi, S.G.; Krupa, I.; Sedlacek, T.; Abdala, A.; Koc, M. Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology. Polymers 2021, 13, 681. https://doi.org/10.3390/polym13050681

Tahir F, Mabrouk A, Al-Ghamdi SG, Krupa I, Sedlacek T, Abdala A, Koc M. Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology. Polymers. 2021; 13(5):681. https://doi.org/10.3390/polym13050681

Chicago/Turabian StyleTahir, Furqan, Abdelnasser Mabrouk, Sami G. Al-Ghamdi, Igor Krupa, Tomas Sedlacek, Ahmed Abdala, and Muammer Koc. 2021. "Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology" Polymers 13, no. 5: 681. https://doi.org/10.3390/polym13050681

APA StyleTahir, F., Mabrouk, A., Al-Ghamdi, S. G., Krupa, I., Sedlacek, T., Abdala, A., & Koc, M. (2021). Sustainability Assessment and Techno-Economic Analysis of Thermally Enhanced Polymer Tube for Multi-Effect Distillation (MED) Technology. Polymers, 13(5), 681. https://doi.org/10.3390/polym13050681