Detailed Process Analysis of Biobased Polybutylene Succinate Microfibers Produced by Laboratory-Scale Melt Electrospinning

Abstract

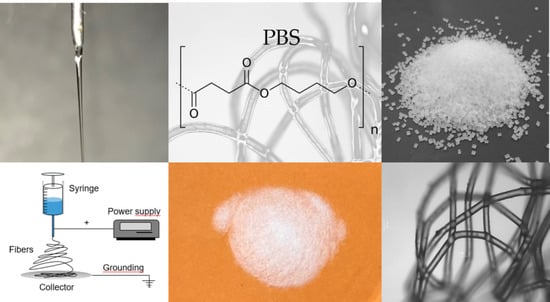

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Melt-Electrospinning Equipment

2.2.2. Polymer Characterization

2.2.3. Characterization of PBS Fibers

2.2.4. Statistical Analysis

3. Results and Discussion

3.1. Thermal Analysis of the Polymer

3.2. Effect of Temperature on Viscosity

3.3. Effect of Temperature on Electrical Conductivity

3.4. Molecular Weight of the Melt Electrospun Fibers

3.5. Fiber Diameter and Distribution

3.6. Thermal Properties of the Electrospun Fibers

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manavitehrani, I.; Fathi, A.; Badr, H.; Daly, S.; Negahi Shirazi, A.; Dehghani, F. Biomedical Applications of Biodegradable Polyesters. Polymers 2016, 8, 20. [Google Scholar] [CrossRef] [Green Version]

- Doustgani, A.; Ahmadi, E. Melt electrospinning process optimization of polylactic acid nanofibers. J. Ind. Text. 2016, 45, 626–634. [Google Scholar] [CrossRef]

- Wu, F.; Huang, C.-L.; Zeng, J.-B.; Li, S.-L.; Wang, Y.-Z. Synthesis and characterization of segmented poly(butylene succinate) urethane ionenes containing secondary amine cation. Polymer 2014, 55, 4358–4368. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Costa-Pinto, A.R.; Correlo, V.M.; Sol, P.C.; Bhattacharya, M.; Srouji, S.; Livne, E.; Reis, R.L.; Neves, N.M. Chitosan-poly(butylene succinate) scaffolds and human bone marrow stromal cells induce bone repair in a mouse calvaria model. J. Tissue Eng. Regen. Med. 2012, 6, 21–28. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Costa-Pinto, A.R.; Martins, A.M.; Castelhano-Carlos, M.J.; Correlo, V.M.; Sol, P.C.; Longatto-Filho, A.; Battacharya, M.; Reis, R.L.; Neves, N.M. In vitro degradation and in vivo biocompatibility of chitosan–poly(butylene succinate) fiber mesh scaffolds. J. Bioact. Compat. Polym. 2014, 29, 137–151. [Google Scholar] [CrossRef] [Green Version]

- Stoyanova, N.; Paneva, D.; Mincheva, R.; Toncheva, A.; Manolova, N.; Dubois, P.; Rashkov, I. Poly(L-lactide) and poly(butylene succinate) immiscible blends: From electrospinning to biologically active materials. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 41, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Kay Obendorf, S. Developing protective textile materials as barriers to liquid penetration using melt-electrospinning. J. Appl. Polym. Sci. 2006, 102, 3430–3437. [Google Scholar] [CrossRef]

- Shin, Y.M.; Hohman, M.M.; Brenner, M.P.; Rutledge, G.C. Electrospinning: A whipping fluid jet generates submicron polymer fibers. Appl. Phys. Lett. 2001, 78, 1149–1151. [Google Scholar] [CrossRef]

- Bhat, G.S. Advances in polymeric nanofiber manufacturing technologies. J. Nanomater. Mol. Nanotechnol. 2016, 5, 1–2. [Google Scholar] [CrossRef]

- Koenig, K.; Langensiepen, F.; Seide, G.; Daenicke, J.; Schubert, D. From Lab to Pilot Scale: Melt Electrospun Nanofibers of Polypropylene with Conductive Additives. J. Nanomater. Mol. Nanotechnol. 2018, 7, 1–8. [Google Scholar] [CrossRef]

- Brown, T.; Dalton, P.; Hutmacher, D.W. Melt electrospinning today: An opportune time for an emerging polymer process. Prog. Polym. Sci. 2016, 56, 116–166. [Google Scholar] [CrossRef]

- Sundarrajan, S.; Tan, K.L.; Lim, S.H. Electrospun nanofibers for air filtration applications. Procedia Eng. 2014, 75, 159–163. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Li, Y.; Sun, X. Challenges and opportunities of nanostructured materials for aprotic rechargeable lithium–air batteries. Nano Energy 2013, 2, 1459–1478. [Google Scholar] [CrossRef]

- Wang, X.; Drew, C.; Lee, S.-H. Electrospun Nanofibrous membranes for highly sensitive optical sensors. Nano Lett. 2002, 2, 1273–1275. [Google Scholar] [CrossRef]

- Research, G.V. Nanofibers Market Size, Share & Trends Analysis Report By Product (Polymer, Carbon, Composite, Cellulose, Metallic), By Application (Electronics, MCE, Energy, MLP), By Region, And Segment Forecasts, 2017–2024. Available online: https://www.grandviewresearch.com/industry-analysis/nanofibers-market (accessed on 18 March 2021).

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef] [PubMed]

- Ekram, B.; Abd El-Hady, B.M.; El-Kady, A.M.; Amr, S.M.; Gabr, H.; Waly, A.I.; Guirguis, O.W. Enhancing the Stability, Hydrophilicity, Mechanical and Biological Properties of Electrospun Polycaprolactone in Formic Acid/Acetic Acid Solvent System. Fibers Polym. 2019, 20, 715–724. [Google Scholar] [CrossRef]

- Van der Schueren, L.; Steyaert, I.; De Schoenmaker, B.; De Clerck, K. Polycaprolactone/chitosan blend nanofibres electrospun from an acetic acid/formic acid solvent system. Carbohydr. Polym. 2012, 88, 1221–1226. [Google Scholar] [CrossRef]

- Koenig, K.; Balakrishnan, N.; Hermanns, S.; Langensiepen, F.; Seide, G. Biobased Dyes as Conductive Additives to Reduce the Diameter of Polylactic Acid Fibers during Melt Electrospinning. Materials 2020, 13, 1055. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Qin, Y.; Cheng, L.; Zhang, Y.; Chen, X.; Wang, X.; He, X.; Yang, W.; An, Y.; Li, H. Efficient preparation of poly(lactic acid) nanofibers by melt differential electrospinning with addition of acetyl tributyl citrate. J. Appl. Polym. Sci. 2018, 135, 46554. [Google Scholar] [CrossRef]

- Ogata, N.; Shimada, N.; Yamaguchi, S.; Nakane, K.; Ogihara, T. Melt-electrospinning of poly(ethylene terephthalate) and polyalirate. J. Appl. Polym. Sci. 2007, 105, 1127–1132. [Google Scholar] [CrossRef]

- Zaiss, S.; Brown, T.D.; Reichert, J.C.; Berner, A. Poly(epsilon-caprolactone) Scaffolds Fabricated by Melt Electrospinning for Bone Tissue Engineering. Materials 2016, 9, 232. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jing, X.; Mi, H.Y.; Salick, M.R.; Cordie, T.M.; Peng, X.F.; Turng, L.S. Electrospinning thermoplastic polyurethane/graphene oxide scaffolds for small diameter vascular graft applications. Mater. Sci. Eng. C Mater. Biol. Appl. 2015, 49, 40–50. [Google Scholar] [CrossRef] [PubMed]

- Ko, J.; Kan, D.; Jun, M.B.G. Combining melt electrospinning and particulate leaching for fabrication of porous microfibers. Manuf. Lett. 2015, 3, 5–8. [Google Scholar] [CrossRef]

- Hacker, C.; Seide, G.; Gries, T.; Thomas, H.; Moeller, M. Electrospinning of polymer melt: Steps toward an upscaled multi-jet process. In Proceedings of the International Conference Latest Advances in High Tech Textiles and Textile-Based Materials, Ghent, Belgium, 23–25 September 2009; pp. 71–76. [Google Scholar]

- Phiriyawirut, M.; Sarapat, K.; Sirima, S.; Prasertchol, A. Porous Electrospun Nanofiber from Biomass-Based Polyester Blends of Polylactic Acid and Polybutylene Succinate. Open J. Polym. Chem. 2019, 9, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Cooper, C.J.; Mohanty, A.K.; Misra, M. Electrospinning Process and Structure Relationship of Biobased Poly(butylene succinate) for Nanoporous Fibers. ACS Omega 2018, 3, 5547–5557. [Google Scholar] [CrossRef]

- Adomavičiūtė, E.; Pupkevičiūtė, S.; Juškaitė, V.; Žilius, M.; Stanys, S.; Pavilonis, A.; Briedis, V. Formation and Investigation of Electrospun PLA Materials with Propolis Extracts and Silver Nanoparticles for Biomedical Applications. J. Nanomater. 2017, 2017, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Koenig, K.; Hermanns, S.; Ellerkmann, J.; Saralidze, K.; Langensiepen, F.; Seide, G. The effect of additives and process parameters on the pilot-scale manufacturing of polylactic acid sub-microfibers by melt electrospinning. Text. Res. J. 1177, 1–14. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, X.; Wu, H.; Wang, H.; Su, Y.; Mi, H. Study on Performance and Structure of Electrospun Polybutylenes Succinate (PBS)/Meltblown Composite Materials. J. Inst. Eng. (India) Ser. E 2020, 1–5. [Google Scholar] [CrossRef]

- Zhmayev, E.; Cho, D.; Joo, Y.L. Nanofibers from gas-assisted polymer melt electrospinning. Polymer 2010, 51, 4140–4144. [Google Scholar] [CrossRef]

- Duncan Phillips, J.S.; Wilding, M.; Farrington, D.; Sandukas, S.; Boned, J.; Dervand, S. Effect of heat setting on dimensional stability and dyeing properties of poly(lactic acid) fibres. Coloration Technol. 2003, 119, 128–133. [Google Scholar] [CrossRef]

- Balakrishnan, N.K.; Koenig, K.; Seide, G. The Effect of Dye and Pigment Concentrations on the Diameter of Melt-Electrospun Polylactic Acid Fibers. Polymers 2020, 12, 2321. [Google Scholar] [CrossRef] [PubMed]

- Takayama, T.; Todo, M. Improvement of impact fracture properties of PLA/PCL polymer blend due to LTI addition. J. Mater. Sci. 2006, 41, 4989–4992. [Google Scholar] [CrossRef]

- Fabbri, M.; Soccio, M.; Costa, M.; Lotti, N.; Gazzano, M.; Siracusa, V.; Gamberini, R.; Rimini, B.; Munari, A.; García-Fernández, L.; et al. New fully bio-based PLLA triblock copoly(ester urethane)s as potential candidates for soft tissue engineering. Polym. Degrad. Stab. 2016, 132, 169–180. [Google Scholar] [CrossRef]

- Vannaladsaysy, V.; Todo, M.; Takayama, T.; Jaafar, M.; Ahmad, Z.; Pasomsouk, K. Effects of lysine triisocyanate on the mode I fracture behavior of polymer blend of poly (l-lactic acid) and poly (butylene succinate-co-l-lactate). J. Mater. Sci. 2009, 44, 3006–3009. [Google Scholar] [CrossRef]

- Jompang, L.; Thumsorn, S.; On, J.W.; Surin, P.; Apawet, C.; Chaichalermwong, T.; Kaabbuathong, N.; O-Charoen, N.; Srisawat, N. Poly(Lactic Acid) and Poly(Butylene Succinate) Blend Fibers Prepared by Melt Spinning Technique. Energy Procedia 2013, 34, 493–499. [Google Scholar] [CrossRef] [Green Version]

- Correlo, V.M.; Boesel, L.F.; Bhattacharya, M.; Mano, J.F.; Neves, N.M.; Reis, R.L. Properties of melt processed chitosan and aliphatic polyester blends. Mater. Sci. Eng. A 2005, 403, 57–68. [Google Scholar] [CrossRef] [Green Version]

- Chen, R.; Zou, W.; Zhang, H.; Zhang, G.; Qu, J. Crystallization behavior and thermal stability of poly(butylene succinate)/poly(propylene carbonate) blends prepared by novel vane extruder. AIP Conf. Proc. 2016, 1713, 050002. [Google Scholar]

- Nattakarn Hongsriphan, K.C.; Kantipongpipat, P.; Thanokiang, J.; Patanathabutr, P. Rheological and Viscoelastic Properties of Poly(Butylene Succinate)/Poly(Ethylene Terephthalate) Blends. In Proceedings of the International Polymer Conference of Thailand: PCT-8, Amari Watergate Bangkok Hotel, Bangkok, Thailand, 14–15 June 2018; pp. 82–88. [Google Scholar]

- Roy, M.; Zhelezniakov, M.; de Kort, G.W.; Hawke, L.G.D.; Leoné, N.; Rastogi, S.; Wilsens, C.H.R.M. On the nucleation of polylactide by melt-soluble oxalamide based organic compounds. Polymer 2020, 202, 1–10. [Google Scholar] [CrossRef]

- Xia, X.; Weng, G.J.; Zhang, J.; Li, Y. The effect of temperature and graphene concentration on the electrical conductivity and dielectric permittivity of graphene–polymer nanocomposites. Acta Mech. 2020, 231, 1305–1320. [Google Scholar] [CrossRef]

- Oi, T.; Shinyama, K.; Fujita, S. Electrical properties of heat-treated polylactic acid. Electr. Eng. Jpn. 2012, 180, 1–8. [Google Scholar] [CrossRef]

- Yarin, A.L.; Koombhongse, S.; Reneker, D.H. Taylor cone and jetting from liquid droplets in electrospinning of nanofibers. J. Appl. Phys. 2001, 90, 4836–4846. [Google Scholar] [CrossRef] [Green Version]

- Bautista, M.; de Ilarduya, A.; Alla, A.; Muñoz-Guerra, S. Poly(butylene succinate) Ionomers with Enhanced Hydrodegradability. Polymers 2015, 7, 1232–1247. [Google Scholar] [CrossRef] [Green Version]

- Zhan, J.; Chen, Y.; Tang, G.; Pan, H.; Zhang, Q.; Song, L.; Hu, Y. Crystallization and melting properties of poly(butylene succinate) composites with titanium dioxide nanotubes or hydroxyapatite nanorods. J. Appl. Polym. Sci. 2014, 131, 1–10. [Google Scholar] [CrossRef]

| Temperature (°C) | Electric Field (kV) | Nozzle-to-Collector Distance (cm) | Throughput (mL/min) |

|---|---|---|---|

| 235 | 50 | 8 | 0.1 |

| 50 | 8 | 4 | |

| 50 | 10 | 0.1 | |

| 50 | 10 | 4 | |

| 60 | 8 | 0.1 | |

| 60 | 8 | 4 | |

| 60 | 10 | 0.1 | |

| 60 | 10 | 4 | |

| 265 | 50 | 8 | 0.1 |

| 50 | 8 | 4 | |

| 50 | 10 | 0.1 | |

| 50 | 10 | 4 | |

| 60 | 8 | 0.1 | |

| 60 | 8 | 4 | |

| 60 | 10 | 0.1 | |

| 60 | 10 | 4 |

| Factor | Significance Level (p) |

|---|---|

| EF | <0.001 |

| Th | <0.001 |

| D | <0.001 |

| Te | 0.209 |

| Te*EF | <0.001 |

| Te*Th | 0.015 |

| Te*D | 0.113 |

| EF*Th | 0.001 |

| EF*D | 0.009 |

| Th*D | 0.183 |

| Te*EF*Th | 0.003 |

| Te*EF*D | 0.055 |

| Te*Th*D | 0.439 |

| EF*Th*D | 0.051 |

| Te*EF*Th*D | 0.343 |

| Material | Tm1 (°C) | Trc (°C) | Tm2 (°C) | Xc (%) |

|---|---|---|---|---|

| G | 91.1 ± 2 | - | 116.3 ± 2 | 59.97 ± 1 |

| S | - | 88.6 ± 3 | 114.2 ± 1 | 55.6 ± 1 |

| B | - | 90.4 ± 2 | 115.2 ± 2 | 58.9 ± 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ostheller, M.-E.; Balakrishnan, N.K.; Groten, R.; Seide, G. Detailed Process Analysis of Biobased Polybutylene Succinate Microfibers Produced by Laboratory-Scale Melt Electrospinning. Polymers 2021, 13, 1024. https://doi.org/10.3390/polym13071024

Ostheller M-E, Balakrishnan NK, Groten R, Seide G. Detailed Process Analysis of Biobased Polybutylene Succinate Microfibers Produced by Laboratory-Scale Melt Electrospinning. Polymers. 2021; 13(7):1024. https://doi.org/10.3390/polym13071024

Chicago/Turabian StyleOstheller, Maike-Elisa, Naveen Kumar Balakrishnan, Robert Groten, and Gunnar Seide. 2021. "Detailed Process Analysis of Biobased Polybutylene Succinate Microfibers Produced by Laboratory-Scale Melt Electrospinning" Polymers 13, no. 7: 1024. https://doi.org/10.3390/polym13071024

APA StyleOstheller, M. -E., Balakrishnan, N. K., Groten, R., & Seide, G. (2021). Detailed Process Analysis of Biobased Polybutylene Succinate Microfibers Produced by Laboratory-Scale Melt Electrospinning. Polymers, 13(7), 1024. https://doi.org/10.3390/polym13071024