Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties

Abstract

:1. Introduction

2. Recent Progress and Applications of Composite Materials

3. Manufacturing Processes of Composite Products

4. Transmission Line Systems in Malaysia: Latticed Transmission Tower

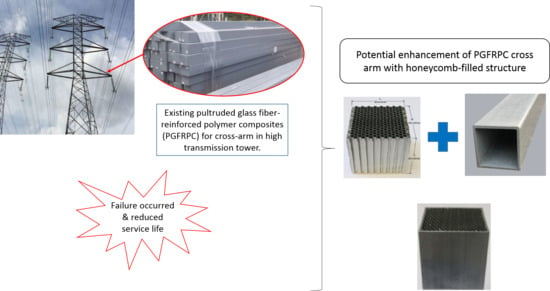

4.1. PGFRPC Cross-Arm in Latticed Transmission Tower

4.2. PGFRPC Cross-Arm: Current Issues and Problems

4.3. Critical Failure Issues of Cross-Arm

5. Overview of Composite-Filled Structures

6. Evaluation of Composite-Filled Structures Behavior

6.1. Flexural Stiffness Behavior

6.2. Load-Carrying Capacity Behavior

6.3. Creep Behavior

6.4. Failure Mode Behavior

7. Conclusions

- Improvement of existing manufacturing process of composite structure to have an Economical and highly efficient manufacturing methods of honeycomb-filled PGFRPC cross arm beams.

- Coupon and actual scale study of honeycomb-filled PGFRPC cross arm on related flexural characteristics behavior, creep responses, load carrying capacity and failure mode behavior.

- Matching properties of honeycomb-core with PGFRPC beams due to deformation mode behavior.

- Environmental and global effects of honeycomb-filled PGFRPC beam structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rawi, I.M.; Rahman, M.S.A.; Kadir, M.Z.A.A.; Izadi, M. Wood and fiberglass crossarm performance against lightning strikes on transmission towers. In Proceedings of the International Conference on Power Systems Transient (IPST), Seoul, Korea, 26–29 June 2017. [Google Scholar]

- The National Electricity Board of the States of Malaya. The National Electricity Board People behind the Lights; The National Electricity Board of the States of Malaya: Kuala Lumpur, Malaysia, 1988. [Google Scholar]

- Grzybowski, S.; Talabathula, S.; Ward, R.J. Added critical flashover voltage by fiberglass crossarm to 15 kV polymer suspension insulator. IEEE Int. Symp. Electr. Insul. 2012, 404–408. [Google Scholar] [CrossRef]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Koloor, S.S.R.; Petrů, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef] [PubMed]

- Ilyas, R.; Sapuan, S.; Atikah, M.; Asyraf, M.; Rafiqah, S.A.; Aisyah, H.; Nurazzi, N.M.; Norrrahim, M. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb) Merr.). Text. Res. J. 2021, 91, 152–167. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Nurazzi, N.M.; Norrrahim, M.N.F.; Ibrahim, R.; Atikah, M.; Huzaifah, M.; Radzi, A.; Izwan, S.; Azammi, A.N.; et al. Macro to nanoscale natural fiber composites for automotive components: Research, development, and application. In Biocomposite and Synthetic Composites for Automotive Applications; Sapuan, M.S., Ilyas, R.A., Eds.; Woodhead Publishing Series: Amsterdam, The Netherland, 2020. [Google Scholar]

- Johari, A.N.; Ishak, M.R.; Leman, Z.; Yusoff, M.Z.M.; Asyraf, M.R.M. Influence of CaCO3 in pultruded glass fibre/unsaturated polyester composite on flexural creep behaviour using conventional and TTSP methods. Polimery 2020, 65, 792–800. [Google Scholar] [CrossRef]

- Johari, A.N.; Ishak, M.; Leman, Z.; Yusoff, M.; Asyraf, M. Creep behaviour monitoring of short-term duration for fiber-glass reinforced composite cross-arms with unsaturated polyester resin samples using conventional analysis. J. Mech. Eng. Sci. 2020, 14, 7361–7368. [Google Scholar] [CrossRef]

- Turvey, G.J.; Zhang, Y. Mechanical properties of pultruded GFRP WF, channel and angle profiles for limit state/permissible stress design. Compos. Part B Eng. 2018, 148, 260–271. [Google Scholar] [CrossRef] [Green Version]

- Vieira, P.R.; Carvalho, E.M.L.; Vieira, J.D.; Filho, R.D.T. Experimental fatigue behavior of pultruded glass fibre reinforced polymer composite materials. Compos. Part B Eng. 2018, 146, 69–75. [Google Scholar] [CrossRef]

- Selvaraj, M.; Kulkarni, S.; Babu, R.R. Analysis and experimental testing of a built-up composite cross arm in a transmission line tower for mechanical performance. Compos. Struct. 2013, 96, 1–7. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical study of composite fiberglass cross arms under statics loading and improvement with sleeve installation. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tatranské Matliare, the High Tatras, Slovakia, 25–26 April 2019; IOP Publishing: Bristol, UK, 2019; Volume 530. [Google Scholar]

- Cao, L.; Guo, L.; Dhanasekar, M. Development of a new outer sleeve assembly for beam-column connections. J. Constr. Steel Res. 2020, 164, 105769. [Google Scholar] [CrossRef]

- Liu, Y.; Li, X.; Zheng, X.; Song, Z. Experimental study on seismic response of precast bridge piers with double-grouted sleeve connections. Eng. Struct. 2020, 221, 111023. [Google Scholar] [CrossRef]

- Mohamad, D.; Syamsir, A.; Itam, Z.; A Bakar, H.; Abas, A.; Ng, F.C.; Razali, M.F.; Seman, S.A.H.A. Numerical simulation on the statics deformation study of composite cross arms of different materials and configurations. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Tatranské Matliare, the High Tatras, Slovakia, 25–26 April 2019; IOP Publishing: Bristol, UK, 2019; Volume 530. [Google Scholar]

- Sharaf, H.K.; Ishak, M.; Sapuan, S.; Yidris, N. Conceptual design of the cross-arm for the application in the transmission towers by using TRIZ–morphological chart–ANP methods. J. Mater. Res. Technol. 2020, 9, 9182–9188. [Google Scholar] [CrossRef]

- Taghipoor, H.; Eyvazian, A.; Musharavati, F.; Sebaey, T.; Ghiaskar, A. Experimental investigation of the three-point bending properties of sandwich beams with polyurethane foam-filled lattice cores. Structures 2020, 28, 424–432. [Google Scholar] [CrossRef]

- Islam, A.; Sheikh, A.H.; Bennett, T.; Thomsen, O.T. An efficient model for laminated composite thin-walled beams of open or closed cross-section and with or without in-filled materials. Compos. Struct. 2021, 256, 112998. [Google Scholar] [CrossRef]

- Qin, Q.; Zhang, W.; Liu, S.; Li, J.; Zhang, J.; Poh, L. On dynamic response of corrugated sandwich beams with metal foam-filled folded plate core subjected to low-velocity impact. Compos. Part A Appl. Sci. Manuf. 2018, 114, 107–116. [Google Scholar] [CrossRef]

- Qi, C.; Sun, Y.; Yang, S. A comparative study on empty and foam-filled hybrid material double-hat beams under lateral impact. Thin-Walled Struct. 2018, 129, 327–341. [Google Scholar] [CrossRef]

- Sebaey, T.A.; Rajak, D.K.; Mehboob, H. Internally stiffened foam-filled carbon fiber reinforced composite tubes under impact loading for energy absorption applications. Compos. Struct. 2021, 255, 112910. [Google Scholar] [CrossRef]

- Danawade, B.A.; Malagi, R.R. Design and manufacturing of wood filled steel tubes for structural applications. Mater. Today Proc. 2019, 18, 4133–4142. [Google Scholar] [CrossRef]

- Qi, Y.; Fang, H.; Shi, H.; Liu, W.; Bai, Y. Bending performance of GFRP-wood sandwich beams with lattice-web reinforcement in flatwise and sidewise directions. Constr. Build. Mater. 2017, 156, 532–545. [Google Scholar] [CrossRef]

- Niknejad, A.; Abedi, M.M.; Liaghat, G.H.; Nejad, M.Z. Prediction of the mean folding force during the axial compression in foam-filled grooved tubes by theoretical analysis. Mater. Des. 2012, 37, 144–151. [Google Scholar] [CrossRef]

- Güden, M.; Kavi, H. Quasi-static axial compression behavior of constraint hexagonal and square-packed empty and aluminum foam-filled aluminum multi-tubes. Thin-Walled Struct. 2006, 44, 739–750. [Google Scholar] [CrossRef] [Green Version]

- Zarei, H.; Kröger, M. Optimum honeycomb filled crash absorber design. Mater. Des. 2008, 29, 193–204. [Google Scholar] [CrossRef]

- Qin, Q.; Wang, T. Low-velocity impact response of fully clamped metal foam core sandwich beam incorporating local denting effect. Compos. Struct. 2013, 96, 346–356. [Google Scholar] [CrossRef]

- Wierzbicki, T.; Bhat, S. A moving hinge solution for axisymmetric crushing of tubes. Int. J. Mech. Sci. 1986, 28, 135–151. [Google Scholar] [CrossRef]

- Abramowicz, W.; Jones, N. Dynamic axial crushing of square tubes. Int. J. Impact Eng. 1984, 2, 179–208. [Google Scholar] [CrossRef]

- Kavi, H.; Toksoy, A.K.; Guden, M. Predicting energy absorption in a foam-filled thin-walled aluminum tube based on experimentally determined strengthening coefficient. Mater. Des. 2006, 27, 263–269. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Liu, W.; Wang, L.; Ling, Z. Mechanical behavior and damage monitoring of pultruded wood-cored GFRP sandwich components. Compos. Struct. 2019, 215, 502–520. [Google Scholar] [CrossRef]

- Prabhakar, M.M.; Rajini, N.; Ayrilmis, N.; Mayandi, K.; Siengchin, S.; Senthilkumar, K.; Karthikeyan, S.; Ismail, S.O. An overview of burst, buckling, durability and corrosion analysis of lightweight FRP composite pipes and their applicability. Compos. Struct. 2019, 230, 111419. [Google Scholar] [CrossRef]

- Kandasubramanian, V.N.B. Advanced polymeric composites via commingling for critical engineering applications. Polym. Test. 2020, 91, 106774. [Google Scholar] [CrossRef]

- Henning, F.; Kärger, L.; Dörr, D.; Schirmaier, F.J.; Seuffert, J.; Bernath, A. Fast processing and continuous simulation of automotive structural composite components. Compos. Sci. Technol. 2019, 171, 261–279. [Google Scholar] [CrossRef]

- Awais, H.; Nawab, Y.; Amjad, A.; Anjang, A.; Akil, H.M.; Abidin, M.S.Z. Environmental benign natural fibre reinforced thermoplastic composites: A review. Compos. Part C Open Access 2021, 4, 100082. [Google Scholar] [CrossRef]

- Hollaway, L. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Chaudhary, V.; Ahmad, F. A review on plant fiber reinforced thermoset polymers for structural and frictional composites. Polym. Test. 2020, 91, 106792. [Google Scholar] [CrossRef]

- Nguyen, K.T.; Navaratnam, S.; Mendis, P.; Zhang, K.; Barnett, J.; Wang, H. Fire safety of composites in prefabricated buildings: From fibre reinforced polymer to textile reinforced concrete. Compos. Part B Eng. 2020, 187, 107815. [Google Scholar] [CrossRef]

- Kong, C.; Lee, H.; Park, H. Design and manufacturing of automobile hood using natural composite structure. Compos. Part B Eng. 2016, 91, 18–26. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Najibi, A.; Ahmadabadi, M.R. Pedestrian safety investigation of the new inner structure of the hood to mitigate the impact injury of the head. Thin-Walled Struct. 2014, 77, 77–85. [Google Scholar] [CrossRef]

- Fang, Y.; Cui, P.; Ding, Z.; Zhu, J.-X. Properties of a magnesium phosphate cement-based fire-retardant coating containing glass fiber or glass fiber powder. Constr. Build. Mater. 2018, 162, 553–560. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, M.-R.; Dai, J.-G.; Dong, B.-Q.; Zhang, M.-J.; Hong, S.-X.; Xing, F. Strengthening concrete using phosphate cement-based fiber-reinforced inorganic composites for improved fire resistance. Constr. Build. Mater. 2019, 212, 755–764. [Google Scholar] [CrossRef]

- Abed, F.; AlHafiz, A.R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Huang, B.-T.; Li, Q.-H.; Xu, S.-L.; Zhou, B. Strengthening of reinforced concrete structure using sprayable fiber-reinforced cementitious composites with high ductility. Compos. Struct. 2019, 220, 940–952. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part B Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Mao, K.; Greenwood, D.; Ramakrishnan, R.; Goodship, V.; Shrouti, C.; Chetwynd, D.; Langlois, P. The wear resistance improvement of fibre reinforced polymer composite gears. Wear 2019, 1033–1039. [Google Scholar] [CrossRef]

- Catera, P.G.; Mundo, D.; Treviso, A.; Gagliardi, F.; Visrolia, A. On the Design and Simulation of Hybrid Metal-Composite Gears. Appl. Compos. Mater. 2018, 26, 817–833. [Google Scholar] [CrossRef]

- Rigaud, E.; Cornuault, P.-H.; Bazin, B.; Grandais-Menant, E. Numerical and experimental analysis of the vibroacoustic behavior of an electric window-lift gear motor. Arch. Appl. Mech. 2018, 88, 1395–1410. [Google Scholar] [CrossRef] [Green Version]

- Solazzi, L.; Buffoli, A. Telescopic Hydraulic Cylinder Made of Composite Material. Appl. Compos. Mater. 2019, 26, 1189–1206. [Google Scholar] [CrossRef]

- Forintos, N.; Czigany, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Schäkel, M.; Janssen, H.; Brecher, C. Increased Reliability for the Manufacturing of Composite Pressure Vessels. Light. Des. Worldw. 2019, 12, 10–17. [Google Scholar] [CrossRef]

- Wagh, P.H.; Pagar, D. Investigation of mechanical and tribological behavior of composite material filled with black epoxy resin and aluminum tri-hydroxide using reinforcement of glass fiber. In Proceedings of the AIP Conference, Karnataka, India, 19–20 April 2018; AIP Publishing LLC: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. A molecular dynamics simulation study on enhancement of mechanical and tribological properties of polymer composites by introduction of graphene. Carbon 2017, 111, 538–545. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C. Mechanical characterization of carbon fiber-reinforced plastic specimens for aerospace applications. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Cambridge, UK, 2018; pp. 387–407. [Google Scholar] [CrossRef]

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable bio composites for aircraft components. Sustain. Compos. Aerosp. Appl. 2018, 109–123. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Nayak, R.K. Improvement of mechanical properties of hybrid composites through interply rearrangement of glass and carbon woven fabrics for marine application. Compos. Part B Eng. 2019, 168, 467–475. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E.; Marsavina, L. The Temperature Effect on the Compressive Behavior of Closed-Cell Aluminum-Alloy Foams. J. Mater. Eng. Perform. 2018, 27, 99–108. [Google Scholar] [CrossRef]

- Taherishargh, M.; Linul, E.; Broxtermann, S.; Fiedler, T. The mechanical properties of expanded perlite-aluminium syntactic foam at elevated temperatures. J. Alloy. Compd. 2018, 737, 590–596. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Yu, J.; Zhuang, J.; Wu, S.; Tong, J. Development and characterization of alkali treated abaca fiber reinforced friction composites. Compos. Interfaces 2018, 26, 67–82. [Google Scholar] [CrossRef]

- Al-Mahaidi, R.; Kalfat, R. Fiber-Reinforced Polymers and Their Use in Structural Rehabilitation. In Rehabilitation of Concrete Structures with Fiber-Reinforced Polymer; Elsevier: Amsterdam, The Netherlands, 2018; pp. 15–20. [Google Scholar]

- Linul, E.; Marşavina, L. Assesment of sandwich beams with rigid polyurethane foam core using failure-mode maps. Proc. Rom. Acad. Ser. A Math. Phys. Tech. Sci. Inf. Sci. 2016, 16, 522–530. [Google Scholar]

- Kulkarni, P.; Mali, K.D.; Singh, S. An overview of the formation of fibre waviness and its effect on the mechanical performance of fibre reinforced polymer composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106013. [Google Scholar] [CrossRef]

- Adeniyi, A.G.; Onifade, D.V.; Ighalo, J.O.; Adeoye, A.S. A review of coir fiber reinforced polymer composites. Compos. Part B Eng. 2019, 176, 176. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [Green Version]

- Jaafar, C.N.A.; Asyraf, M.R.M.; Zainol, I. Effect of Kenaf Alkalization Treatment on Morphological and Mechanical Properties of Epoxy/Silica/Kenaf Composite. Int. J. Eng. Technol. 2018, 7, 258–263. [Google Scholar] [CrossRef]

- La Mantia, F.; Morreale, M. Green composites: A brief review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Jaafar, C.N.A.; Zainol, I.; Rizal, M.A.M. Preparation and characterisation of epoxy/silica/kenaf composite using hand lay-up method. In Proceedings of the 27th Scientific Conference of the Microscopy Society Malaysia (27th SCMSM 2018), Melaka, Malaysia, 3–4 December 2018; pp. 2–6. [Google Scholar]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Mafeld, A. The Automation of Polymer Composites Manufacturing; JEC Composites Publications: Paris, France, 2014. [Google Scholar]

- Ho, M.-P.; Wang, H.; Lee, J.-H.; Ho, C.-K.; Lau, K.-T.; Leng, J.; Hui, D. Critical factors on manufacturing processes of natural fibre composites. Compos. Part B Eng. 2012, 43, 3549–3562. [Google Scholar] [CrossRef]

- Kim, S.-Y.; Shim, C.S.; Sturtevant, C.; Kim, D.; Song, H.C. Mechanical properties and production quality of hand-layup and vacuum infusion processed hybrid composite materials for GFRP marine structures. Int. J. Nav. Arch. Ocean Eng. 2014, 6, 723–736. [Google Scholar] [CrossRef] [Green Version]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N.; Ilyas, R. Woods and composites cantilever beam: A comprehensive review of experimental and numerical creep methodologies. J. Mater. Res. Technol. 2020, 9, 6759–6776. [Google Scholar] [CrossRef]

- Alsubari, S.; Zuhri, M.Y.M.; Sapuan, S.M.; Ishak, M.R.; Ilyas, R.A.; Asyraf, M.R.M. Potential of Natural Fiber Reinforced Polymer Composites in Sandwich Structures: A Review on Its Mechanical Properties. Polymers 2021, 13, 423. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Rafidah, M.; Azrina, A.; Razman, M.R. Dynamic mechanical behaviour of kenaf cellulosic fibre biocomposites: A comprehensive review on chemical treatments. Cellulose 2021, 1–21. [Google Scholar] [CrossRef]

- Liu, M.; Thygesen, A.; Summerscales, J.; Meyer, A.S. Targeted pre-treatment of hemp bast fibres for optimal performance in biocomposite materials: A review. Ind. Crop. Prod. 2017, 108, 660–683. [Google Scholar] [CrossRef] [Green Version]

- Deogonda, P.; Chalwa, V.N. Mechanical Property of Glass Fiber Reinforcement Epoxy Composites. Int. J. Sci. Eng. Res. 2013, 1, 6–9. [Google Scholar]

- Elkington, M.; Ward, C.; Chatzimichali, A.; Potter, K. Studying effects of preshearing on hand layup. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 80–93. [Google Scholar] [CrossRef]

- Ha, S.K.; Jang, J.G.; Park, S.H.; Lee, H.K. Advanced Spray Multiple Layup Process for Quality Control of Sprayed FRP Composites Used to Retrofit Concrete Structures. J. Constr. Eng. Manag. 2015, 141, 04014060. [Google Scholar] [CrossRef]

- Ervina, J.; Ghaleb, Z.; Hamdan, S.; Mariatti, M. Colloidal stability of water-based carbon nanotube suspensions in electrophoretic deposition process: Effect of applied voltage and deposition time. Compos. Part A Appl. Sci. Manuf. 2019, 117, 1–10. [Google Scholar] [CrossRef]

- Parghi, A.; Alam, M.S. A review on the application of sprayed-FRP composites for strengthening of concrete and masonry structures in the construction sector. Compos. Struct. 2018, 187, 518–534. [Google Scholar] [CrossRef]

- Hindersmann, A. Confusion about infusion: An overview of infusion processes. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105583. [Google Scholar] [CrossRef]

- Brouwer, W.; Van Herpt, E.; Labordus, M. Vacuum injection moulding for large structural applications. Compos. Part A Appl. Sci. Manuf. 2003, 34, 551–558. [Google Scholar] [CrossRef]

- Govignon, Q.; Bickerton, S.; Morris, J.; Kelly, P. Full field monitoring of the resin flow and laminate properties during the resin infusion process. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1412–1426. [Google Scholar] [CrossRef] [Green Version]

- Williams, C.; Summerscales, J.; Grove, S. Resin Infusion under Flexible Tooling (RIFT): A review. Compos. Part A Appl. Sci. Manuf. 1996, 27, 517–524. [Google Scholar] [CrossRef]

- Dixit, D.; Pal, R.; Kapoor, G.; Stabenau, M. Lightweight composite materials processing. In Lightweight Ballistic Composites, 2nd ed.; Woodhead Publishing: Cambridge, UK, 2016; pp. 157–216. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, W. Il Compression molding in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix Composites; 2012; pp. 47–94. [Google Scholar] [CrossRef]

- Song, Y.; Gandhi, U.; Sekito, T.; Vaidya, U.K.; Vallury, S.; Yang, A.; Osswald, T. CAE method for compression molding of carbon fiber-reinforced thermoplastic composite using bulk materials. Compos. Part A Appl. Sci. Manuf. 2018, 114, 388–397. [Google Scholar] [CrossRef]

- Ye, H.; Liu, X.Y.; Hong, H. Fabrication of metal matrix composites by metal injection molding—A review. J. Mater. Process. Technol. 2008, 200, 12–24. [Google Scholar] [CrossRef] [Green Version]

- Manas, D.; Manas, M.; Gajzlerova, L.; Ovsik, M.; Kratky, P.; Senkerik, V.; Skrobak, A.; Danek, M.; Manas, M. Effect of low doses beta irradiation on micromechanical properties of surface layer of injection molded polypropylene composite. Radiat. Phys. Chem. 2015, 114, 25–30. [Google Scholar] [CrossRef]

- Hamidi, M.; Harun, W.; Samykano, M.; Ghani, S.; Ghazalli, Z.; Ahmad, F.; Sulong, A. A review of biocompatible metal injection moulding process parameters for biomedical applications. Mater. Sci. Eng. C 2017, 78, 1263–1276. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Leong, Y.W.; Thitithanasarn, S.; Yamada, K.; Hamada, H. Compression and injection molding techniques for natural fiber composites. Nat. Fibre Compos. 2014, 2013, 216–232. [Google Scholar] [CrossRef]

- Castro, A.C.M.; Carvalho, J.P.; Ribeiro, M.C.S.; Meixedo, J.P.; Silva, F.J.; Fiúza, A.; Dinis, M.D.L. An integrated recycling approach for GFRP pultrusion wastes: Recycling and reuse assessment into new composite materials using Fuzzy Boolean Nets. J. Clean. Prod. 2014, 66, 420–430. [Google Scholar] [CrossRef] [Green Version]

- Fairuz, A.M.; Sapuan, S.M.; Zainudin, E.S.; Jaafar, C.N. Polymer composite manufacturing using a pultrusion process: A review. Am. J. Appl. Sci. 2014, 11, 1798–1810. [Google Scholar] [CrossRef]

- Liu, T.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Bank, L.C. Composite for construction: Structural design with FRP materials. In Technology & Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 560. ISBN 0471681261/9780471681267. [Google Scholar]

- Bazli, M.; Jafari, A.; Ashrafi, H.; Zhao, X.-L.; Bai, Y.; Raman, R.S. Effects of UV radiation, moisture and elevated temperature on mechanical properties of GFRP pultruded profiles. Constr. Build. Mater. 2020, 231, 117137. [Google Scholar] [CrossRef]

- Yoganantham, C.; Joanna, P. Flexural behaviour of pultruded GFRP beams infilled with HVFA ECC. Mater. Today Proc. 2020. [Google Scholar] [CrossRef]

- Nadhirah, A.; Mohamad, D.; Zainoodin, M.; Nabihah, S.; Mubin, N.; Itam, Z.; Mansor, H.; Kamal, N.M.; Muda, Z.C.; Nasional, U.T.; et al. Properties of fiberglass crossarm in transmission tower—A review. Prop. Fiberglass Crossarm Transm. Tower A Rev. 2017, 12, 15228–15233. [Google Scholar]

- Alhassan, A.B.; Zhang, X.; Shen, H.; Xu, H. Power transmission line inspection robots: A review, trends and challenges for future research. Int. J. Electr. Power Energy Syst. 2020, 118, 105862. [Google Scholar] [CrossRef]

- Kishore, T.; Singal, S. Optimal economic planning of power transmission lines: A review. Renew. Sustain. Energy Rev. 2014, 39, 949–974. [Google Scholar] [CrossRef]

- Rosnazri, A.; Ismail, D.; Soib, T. A review on existing and future energy sources for electrical power generation in Malaysia. Renew. Sustain. Energy Rev. 2012, 16, 4047–4055. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Evaluation of design and simulation of creep test rig for full-scale Crossarm structure. Adv. Civ. Eng. 2020, 2020, 6980918. [Google Scholar] [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Conceptual design of creep testing rig for full-scale cross arm using TRIZ-Morphological chart-analytic network process technique. J. Mater. Res. Technol. 2019, 8, 5647–5658. [Google Scholar] [CrossRef]

- Rawi, I.M.; Ab Kadir, M.Z.A. Investigation on the 132kV overhead lines lightning-related flashovers in Malaysia. In Proceedings of the International Symposium on Lightning Protection (XIII SIPDA), Balneario, Camboriu, Brazil, 28 September–2 October 2015; pp. 239–243. [Google Scholar]

- Ilyas, R.; Sapuan, S.; Norrrahim, M.N.F.; Yasim-Anuar, T.A.T.; Kadier, A.; Kalil, M.S.; Atikah, M.; Ibrahim, R.; Asrofi, M.; Abral, H.; et al. Nanocellulose/Starch Biopolymer Nanocomposites: Processing, Manufacturing, and Applications. In Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers; Al-Oqla, F.M., Ed.; Elsevier Inc.: Amsterdam, The Netherland, 2021. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Atikah, M.S.N.; Ibrahim, R.; Norrahim, M.N.F.; Yasim-Anuar, T.A.T.; Megatshah, L.N. Mechanical and dynamic mechanical properties of macro-nanosized natural fibre reinforced polymer composite. In Mechanical and Dynamic Mechanical Analysis of Biocomposite; Kumar, S.M.K., Ed.; John Wiley & Sons Ltd: West Sussex, UK, 2020. [Google Scholar]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Shahroze, R.M.; Johari, A.N.; Rafidah, M.; Ilyas, R.A. Creep test rig for cantilever beam: Fundamentals, prospects and present views. J. Mech. Eng. Sci. 2020, 14, 6869–6887. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Asyraf, M.; Atikah, M.; Ibrahim, R.; Dele-Afolabi, T.; Hazrol, M. Introduction to Biofiller-Reinforced Degradable Polymer Composites. In Biofiller-Reinforced Biodegradable Polymer Composites; AL-Oqla, F.M., Sapuan, S.M., Eds.; CRC Press: Boca Raton, FL, USA, 2020. [Google Scholar]

- Ilyas, R.A.; Sapuan, S.M.; Atiqah, A.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Nurazzi, N.M.; Atikah, M.S.N.; Ansari, M.N.M.; et al. Sugar palm (Arenga pinnata (Wurmb.) Merr.) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym. Compos. 2019, 41, 459–467. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Chandrasekar, M. Fundamentals of creep, testing methods and development of test rig for the full-scale crossarm: A review. J. Teknol. 2019, 81, 155–164. [Google Scholar] [CrossRef] [Green Version]

- Rao, N.P.; Mohan, S.J.; Lakshmanan, N. A study on failure of cross arms in transmission line towers during prototype testing. Int. J. Struct. Stab. Dyn. 2005, 5, 435–455. [Google Scholar] [CrossRef]

- Beddu, S.; Syamsir, A.; Arifin, Z.; Ishak, M. Creep behavior of glass fibre reinforced polymer structures in crossarms transmission line towers. In Proceedings of the AIP Conference, Karnataka, India, 19–20 April 2018; AIP Publishing LLC: New York, NY, USA, 2018; Volume 2031, p. 04020025. [Google Scholar]

- Liu, T.; Vieira, J.D.; Harries, K.A. Predicting Flange Local Buckling Capacity of Pultruded GFRP I-Sections Subject to Flexure. J. Compos. Constr. 2020, 24, 04020025. [Google Scholar] [CrossRef]

- Cardoso, D.C.T.; Harries, K.A. A viscoelastic model for time-dependent behavior of pultruded GFRP. Constr. Build. Mater. 2019, 208, 63–74. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N.; Ilyas, R.A.; Rafidah, M.; Razman, M.R. Potential Application of Green Composites for Cross Arm Component in Transmission Tower: A Brief Review. Int. J. Polym. Sci. 2020, 2020, 1–15. [Google Scholar] [CrossRef]

- Andreotti, A.; Araneo, R.; Mahmood, F.; Pierno, A. An accurate approach for the evaluation of the performance of overhead distribution lines due to indirect lightning. Electr. Power Syst. Res. 2020, 186, 106411. [Google Scholar] [CrossRef]

- Liew, A. Assessment of the lightning performance of quadruple-circuit transmission lines with steel and wooden crossarms. Electr. Power Syst. Res. 1993, 27, 91–97. [Google Scholar] [CrossRef]

- Shariatinasab, R.; Gholinezhad, J.; Sheshyekani, K.; Alemi, M.R. The effect of wide band modeling of tower-footing grounding system on the lightning performance of transmission lines: A probabilistic evaluation. Electr. Power Syst. Res. 2016, 141, 1–10. [Google Scholar] [CrossRef]

- Koehler, F.; Swingler, J. Practical model for tower earthing systems in lightning simulations. Electr. Power Syst. Res. 2018, 158, 306–314. [Google Scholar] [CrossRef]

- Yeh, H.-Y.; Yang, S.C. Building of a Composite Transmission Tower. J. Reinf. Plast. Compos. 1997, 16, 414–424. [Google Scholar] [CrossRef]

- Marzuki, H.F.A.; Jaafar, M. Laminate Design of Lightweight Glass Fiber Reinforced Epoxy Composite for Electrical Transmission Structure. Procedia Chem. 2016, 19, 871–878. [Google Scholar] [CrossRef]

- Selvaraj Structural evaluation of FRP Pultruded Sections in overhead transmission line Towers. Int. J. Civ. Struct. Eng. 2012, 2. [CrossRef] [Green Version]

- Selvaraj, M.; Kulkarni, S.M.; Babu, R.R. Behavioral Analysis of built up transmission line tower from FRP pultruded sections. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 39–47. [Google Scholar]

- Mohamad, D.; Syamsir, A.; Beddu, S.; Kamal, N.L.M.; Zainoodin, M.M.; Razali, M.F.; Abas, A.; Seman, S.A.H.A.; Ng, F.C. Effect of Laminate Properties on the Failure of Cross Arm Structure under Multi-Axial Load. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Bangkok, Thailand, 17–19 May 2019; IOP Publishing: Bristol, UK, 2019; Volume 530. [Google Scholar]

- Mohamad, D.; Syamsir, A.; Sa’Don, S.N.; Zahari, N.M.; Seman, S.A.H.A.; Razali, M.F.; Abas, A.; Ng, F.C. Stacking sequence effects on performance of composite laminate structure subjected to multi-axial quasi-static loading. In Proceedings of the IOP Conference Series: Materials Science and Engineering, International Conference on Recent Advances in Industrial Engineering and Manufacturing, Penang, Malaysia, 12–13 December 2018; IOP Publishing: Bristol, UK, 2019; Volume 530. [Google Scholar]

- Numerical Modelling of Glass Fiber Reinforced Polymer (GFRP) Cross Arm. Int. J. Recent Technol. Eng. 2019, 8, 6484–6489. [CrossRef]

- Asyraf, M.; Ishak, M.; Sapuan, S.; Yidris, N. Conceptual design of multi-operation outdoor flexural creep test rig using hybrid concurrent engineering approach. J. Mater. Res. Technol. 2020, 9, 2357–2368. [Google Scholar] [CrossRef]

- Cardoso, D.C.; Harries, K.A.; Batista, E.D.M. Compressive strength equation for GFRP square tube columns. Compos. Part B Eng. 2014, 59, 1–11. [Google Scholar] [CrossRef]

- Önder, A.; Robinson, M. Investigating the feasibility of a new testing method for GFRP/polymer foam sandwich composites used in railway passenger vehicles. Compos. Struct. 2020, 233, 111576. [Google Scholar] [CrossRef]

- Li, X.; Liu, W.; Fang, H.; Huo, R.; Wu, P. Flexural creep behavior and life prediction of GFRP-balsa sandwich beams. Compos. Struct. 2019, 224, 111009. [Google Scholar] [CrossRef]

- Bai, R.; Ou, H.; Peng, K.; Wu, W.; Lei, Z.; Liu, T.; Chen, M.; Song, L.; Lin, R. Failure study of honeycomb sandwich structure with embedded part under axial pullout loading. Thin-Walled Struct. 2020, 146, 106489. [Google Scholar] [CrossRef]

- Ferdous, W.; Manalo, A.; Aravinthan, T. Effect of beam orientation on the static behaviour of phenolic core sandwich composites with different shear span-to-depth ratios. Compos. Struct. 2017, 168, 292–304. [Google Scholar] [CrossRef]

- Xiang, J.; Du, J. Energy absorption characteristics of bio-inspired honeycomb structure under axial impact loading. Mater. Sci. Eng. A 2017, 696, 283–289. [Google Scholar] [CrossRef]

- Shi, S.; Sun, Z.; Hu, X.; Chen, H. Flexural strength and energy absorption of carbon-fiber–aluminum-honeycomb composite sandwich reinforced by aluminum grid. Thin-Walled Struct. 2014, 84, 416–422. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J.; Lu, Z.; Hui, D. Mechanical behavior of composited structure filled with tandem honeycombs. Compos. Part B Eng. 2017, 114, 128–138. [Google Scholar] [CrossRef]

- Birman, V.; Kardomateas, G.A. Review of current trends in research and applications of sandwich structures. Compos. Part B Eng. 2018, 142, 221–240. [Google Scholar] [CrossRef]

- CMH-17, A division of Wichita State University. Composite Materials Handbook, Volume 6, Structural Sandwich Composites; SAE International Publisher: Warrendale, PA, USA, 2013. [Google Scholar]

- Li, M.; Liu, R.Q.; Luo, C.J.; Guo, H.W.; Ding, B.C. Numerical and experimental analyses on series aluminum honeycomb structures under quasi-static load. Zhendong Chongji J. Vib. Shock 2013, 32, 50–56. [Google Scholar]

- Yasui, Y. Dynamic axial crushing of multi-layer honeycomb panels and impact tensile behavior of the component members. Int. J. Impact Eng. 2000, 24, 659–671. [Google Scholar] [CrossRef]

- Zhao, J.; Xie, F.; Wang, A.; Shuai, C.; Tang, J.; Wang, Q. Dynamics analysis of functionally graded porous (FGP) circular, annular and sector plates with general elastic restraints. Compos. Part B Eng. 2019, 159, 20–43. [Google Scholar] [CrossRef]

- Boldrin, L.; Hummel, S.; Scarpa, F.; Di Maio, D.; Lira, C.; Ruzzene, M.; Remillat, C.D.L.; Lim, T.-C.; Rajasekaran, R.; Patsias, S. Dynamic behaviour of auxetic gradient composite hexagonal honeycombs. Compos. Struct. 2016, 149, 114–124. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z. Recent advances in novel metallic honeycomb structure. Compos. Part B Eng. 2019, 166, 731–741. [Google Scholar] [CrossRef]

- Mahmoudabadi, M.Z.; Sadighi, M. A study on the static and dynamic loading of the foam filled metal hexagonal honeycomb—Theoretical and experimental. Mater. Sci. Eng. A 2011, 530, 333–343. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Axial crushing of circular multi-cell columns. Int. J. Impact Eng. 2014, 65, 110–125. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Energy absorption of multi-cell stub columns under axial compression. Thin-Walled Struct. 2013, 68, 156–163. [Google Scholar] [CrossRef]

- Aktay, L.; Çakıroğlu, C.; Guden, M. Quasi-Static Axial Crushing Behavior of Honeycomb-Filled Thin-Walled Aluminum Tubes. Open Mater. Sci. J. 2011, 5, 184–193. [Google Scholar] [CrossRef] [Green Version]

- Zhu, G.; Li, S.; Sun, G.; Li, G.; Li, Q. On design of graded honeycomb filler and tubal wall thickness for multiple load cases. Thin-Walled Struct. 2016, 109, 377–389. [Google Scholar] [CrossRef]

- Yin, H.; Wen, G.; Hou, S.; Chen, K. Crushing analysis and multiobjective crashworthiness optimization of honeycomb-filled single and bitubular polygonal tubes. Mater. Des. 2011, 32, 4449–4460. [Google Scholar] [CrossRef]

- Mamalis, A.; Manolakos, D.; Ioannidis, M.; Chronopoulos, D.; Kostazos, P. On the crashworthiness of composite rectangular thin-walled tubes internally reinforced with aluminium or polymeric foams: Experimental and numerical simulation. Compos. Struct. 2009, 89, 416–423. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Vetiyatil, L.; Ahmad, S. The effect of hybridization on the ballistic impact behavior of hybrid composite armors. Compos. Part B Eng. 2015, 76, 300–319. [Google Scholar] [CrossRef]

- Muhi, R.; Najim, F.; de Moura, M. The effect of hybridization on the GFRP behavior under high velocity impact. Compos. Part B Eng. 2009, 40, 798–803. [Google Scholar] [CrossRef]

- Ashraf, W.; Nawab, Y.; Umair, M.; Shaker, K.; Karahan, M. Investigation of mechanical behavior of woven/knitted hybrid composites. J. Text. Inst. 2016, 108, 1–8. [Google Scholar] [CrossRef]

- Bulut, M.; Erkliğ, A.; Yeter, E. Hybridization effects on quasi-static penetration resistance in fiber reinforced hybrid composite laminates. Compos. Part B Eng. 2016, 98, 9–22. [Google Scholar] [CrossRef]

- Randjbaran, E.; Zahari, R.; Jalil, N.A.A.; Majid, D.L.A.A. Hybrid Composite Laminates Reinforced with Kevlar/Carbon/Glass Woven Fabrics for Ballistic Impact Testing. Sci. World J. 2014, 2014, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Bhudolia, S.K.; Kam, K.K.; Joshi, S.C. Mechanical and vibration response of insulated hybrid composites. J. Ind. Text. 2018, 47, 1887–1907. [Google Scholar] [CrossRef]

- Carlsson, L.A.; Kardomateas, G.A. Introduction. Solid Mech. Appl. 2011, 121, 1–17. [Google Scholar] [CrossRef]

- Fu, Y.; Sadeghian, P. Flexural and shear characteristics of bio-based sandwich beams made of hollow and foam-filled paper honeycomb cores and flax fiber composite skins. Thin-Walled Struct. 2020, 153, 106834. [Google Scholar] [CrossRef]

- Wei, X.; Wu, Q.; Gao, Y.; Xiong, J. Bending characteristics of all-composite hexagon honeycomb sandwich beams: Experimental tests and a three-dimensional failure mechanism map. Mech. Mater. 2020, 148, 103401. [Google Scholar] [CrossRef]

- Vitale, J.P.; Francucci, G.; Xiong, J.; Stocchi, A. Failure mode maps of natural and synthetic fiber reinforced composite sandwich panels. Compos. Part A Appl. Sci. Manuf. 2017, 94, 217–225. [Google Scholar] [CrossRef]

- Corradi, M.; Vo, T.P.; Poologanathan, K.; Osofero, A.I. Flexural behaviour of hardwood and softwood beams with mechanically connected GFRP plates. Compos. Struct. 2018, 206, 610–620. [Google Scholar] [CrossRef] [Green Version]

- Florence, A.; Jaswin, M.A.; Prakash, M.D.A.A.; Jayaram, R.S. Effect of energy-absorbing materials on the mechanical behaviour of hybrid FRP honeycomb core sandwich composites. Mater. Res. Innov. 2019, 24, 244–255. [Google Scholar] [CrossRef]

- Seemann, R.; Krause, D. Numerical modelling of partially potted inserts in honeycomb sandwich panels under pull-out loading. Compos. Struct. 2018, 203, 101–109. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure—Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, J. Mechanical performance of honeycomb filled with circular CFRP tubes. Compos. Part B Eng. 2018, 135, 232–241. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, X.; Wang, X.; Wang, Y.; Zhao, T. Response of foam concrete-filled aluminum honeycombs subject to quasi-static and dynamic compression. Compos. Struct. 2020, 239, 112025. [Google Scholar] [CrossRef]

- Han, B.; Zhang, Z.-J.; Zhang, Q.-C.; Zhang, Q.; Lu, T.J.; Lu, B.-H. Recent advances in hybrid lattice-cored sandwiches for enhanced multifunctional performance. Extreme Mech. Lett. 2017, 10, 58–69. [Google Scholar] [CrossRef]

- Bai, Y.; Zhang, J.; Shen, H. Residual compressive load-carrying capacity of cross-laminated timber walls after exposed to one-side fire. J. Build. Eng. 2021, 34, 101931. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Comparison of static and long-term creep behaviors between Balau wood and glass fiber reinforced polymer composite for cross-arm application. Fibers Polym. 2020. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Utilization of Bracing Arms as Additional Reinforcement in Pultruded Glass Fiber-Reinforced Polymer Composite Cross-Arms: Creep Experimental and Numerical Analyses. Polymers 2021, 13, 423. [Google Scholar] [CrossRef]

- Asyraf, M.R.M.; Ishak, M.R.; Sapuan, S.M.; Yidris, N. Influence of Additional Bracing Arms as Reinforcement Members in Wooden Timber Cross-Arms on Their Long-Term Creep Responses and Properties. Appl. Sci. 2021, 11, 1–16. [Google Scholar] [CrossRef]

- Hussein, R.D.; Ruan, D.; Lu, G.; Guillow, S.; Yoon, J.W. Crushing response of square aluminium tubes filled with polyurethane foam and aluminium honeycomb. Thin-Walled Struct. 2017, 110, 140–154. [Google Scholar] [CrossRef]

- Garrido, M.; Correia, J.R.; Keller, T. Effect of service temperature on the shear creep response of rigid polyurethane foam used in composite sandwich floor panels. Constr. Build. Mater. 2016, 118, 235–244. [Google Scholar] [CrossRef]

- Seiler, P.; Tankasala, H.; Fleck, N. Creep failure of honeycombs made by rapid prototyping. Acta Mater. 2019, 178, 122–134. [Google Scholar] [CrossRef] [Green Version]

- Hussein, R.D.; Ruan, D.; Lu, G.; Sbarski, I. Axial crushing behaviour of honeycomb-filled square carbon fibre reinforced plastic (CFRP) tubes. Compos. Struct. 2016, 140, 166–179. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, L.; Zhang, C.; Guo, S. Low-velocity impact response of tube-reinforced honeycomb sandwich structure. Thin-Walled Struct. 2021, 158, 107188. [Google Scholar] [CrossRef]

- Xiao, Y.; Hu, Y.; Zhang, J.; Song, C.; Liu, Z.; Yu, J. Dynamic bending responses of CFRP thin-walled square beams filled with aluminum honeycomb. Thin-Walled Struct. 2018, 132, 494–503. [Google Scholar] [CrossRef]

| Applications | Material | Field Area | Properties | Ref |

|---|---|---|---|---|

| Fire resistance concrete | Fiber-reinforced inorganic polymer (FRiP) composites | Civil | Improve fire resistance, strengthen concrete structure | [41,42,43] |

| Concrete beams | Basalt fiber-reinforced polymer (BFRP) composites | Civil | Increase flexural capacity, Improve ductility | [44] |

| Bridge System-girders, bridge decks, and slab-on-girder bridge systems | Hybrid fiber-reinforced polymer (FRP)-concrete | Civil | Higher durability, less stiffness | [45] |

| Automobile body parts: Engine hood, dashboard, and storage tank | Natural fiber-reinforced polymer composites | Automobile | Reduce weight, enhance stability and strength, improve in safety features | [39,40,46] |

| Mechanical Gear pair | Polyoxymethylene (POM) with glass fiber-reinforced polymer composites | Mechanical | Enhance load-carrying capacity | [47,48,49] |

| Hydraulic cylinder | Carbon fiber-reinforced polymer (CFRP) composites | Mechanical | Weight reduction | [50] |

| Trunk lid and body stiffeners | Carbon fiber-reinforced polymer (CFRP) composites | Automobile | Higher strength to weight ratio | [51] |

| Pressure vessel | Fiber-reinforced polymer (FRP) composites | Mechanical | High strength and rigidity, improve corrosion resistance, improved fatigue strength, reduce weight | [52] |

| Engine hood | Glass fiber-reinforced polymer (GFRP) composites | Automobile | Improve tensile strength and wear resistance properties | [53] |

| Aircraft interior panels | Natural fiber-reinforced thermoplastic composites | Aerospace | Heat and flame resistance, lightweight, easy recycling | [54,55] |

| Aircraft parts | Hybrid kenaf/glass fiber-reinforced polymer (KFRP/GFRP) composites | Aerospace | Enhanced rain erosion resistance | [56] |

| Marine | Hybrid glass-carbon fiber-reinforced polymer composites (GCG2C) | Marine | High flexural strength, lowest water absorption tendency | [57] |

| Mode of Study | Research | Findings | Ref |

|---|---|---|---|

| Numerical simulation | Effect of laminate properties on cross arm’s failure. | Greater value of young modulus and ultimate strength of a cross arm structure would produce smaller deflection and reduce amount of failure upon multi-axial load condition. | [125] |

| Impact of laminate stacking sequence on cross arm’s performance. | Layers proportion with different fiber directions has extraordinary effect on static displacement. | [126] | |

| Effect of static loading with various configurations on cross arm behaviors. | Addition of bracing system would improve the overall static deformation and stress performance of cross arm | [15] | |

| Influence of static loadings and sleeve installation on cross arm structure. | The incorporation of sleeve aids to decrease both deformation and stress concentration at the cross arms assembly, which subsequently cause less potential to fatigue failure and higher reliability for the long term service. | [12] | |

| Modelling of GFRP cross arm using ANSYS and SOLIDWORKS tools. | GFRP cross arm was discovered that it is safe from the failure modes of fiber, matrix, in-plane shear, out-of-plane shear, and delamination under all load conditions which satisfies the ultimate limit state requirements but the concern was on the serviceability limit state which had a deflection of 34 mm. | [127] | |

| Mechanical test rigs development specialized for cross arms | Conceptual design of creep testing rig for full-scale cross arm. | The study implements the TRIZ inventive principles to identify actual test rig problems, morphological chart method to refine the design features, and analytic network process use to select designs. Concept design 5 and 3 were chosen for full-scale and coupon-scale cross arms test rigs. | [103,104] |

| Conceptual design of multi-operation outdoor flexural creep test rig | [128] | ||

| Experiments | Experimental testing on compressive strength equation for GFRP square tube columns. | Short and intermediate PGFRP beam columns exhibited a significant reduction of capacity due to interaction of rushing, local buckling and global buckling which correspond to each failure. | [129] |

| Mechanical evaluation on composite cross arm performance | The axial forces in the main member beams are linearly varying with applied load, whereby the tie member of cross arms which experience axial forces is found to be lesser in magnitude. | [11] |

| Hybrid | Configuration | Absorbed Energy (J) | Ref |

|---|---|---|---|

| Woven Carbon-Kevlar-glass-fiber | CGC/GCG/KGK | 57/59/78 | [155] |

| GKG/KCK/CKC | 90/103/105 | ||

| Kevlar-Carbon-glass woven fabrics | KCGKGC/GCKCKG/KGCGCK/GKCCGK/KCGGCK | 94.36/95.17/95.01/95.15/95.04/93.16 | [156] |

| Carbon-Kevlar-E-glass fabrics | S | 20.35 | [157] |

| S | 22 | ||

| S | 22.6 |

| Type | Filler | Flexural Stiffness (Nm2) |

|---|---|---|

| GFRP Hollow Beam | - | 23.8 |

| GFRP Honeycomb-filled tube | Honeycomb | 46.49 |

| FRP Honeycomb Foam-filled tube | Honeycomb with Foam-filled | 52.94 |

| GFRP wood–filled Beam | Wood | 203 G |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amir, A.L.; Ishak, M.R.; Yidris, N.; Zuhri, M.Y.M.; Asyraf, M.R.M. Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties. Polymers 2021, 13, 1341. https://doi.org/10.3390/polym13081341

Amir AL, Ishak MR, Yidris N, Zuhri MYM, Asyraf MRM. Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties. Polymers. 2021; 13(8):1341. https://doi.org/10.3390/polym13081341

Chicago/Turabian StyleAmir, Abd Latif, Mohamad Ridzwan Ishak, Noorfaizal Yidris, Mohamed Yusoff Mohd Zuhri, and Muhammad Rizal Muhammad Asyraf. 2021. "Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties" Polymers 13, no. 8: 1341. https://doi.org/10.3390/polym13081341

APA StyleAmir, A. L., Ishak, M. R., Yidris, N., Zuhri, M. Y. M., & Asyraf, M. R. M. (2021). Potential of Honeycomb-Filled Composite Structure in Composite Cross-Arm Component: A Review on Recent Progress and Its Mechanical Properties. Polymers, 13(8), 1341. https://doi.org/10.3390/polym13081341