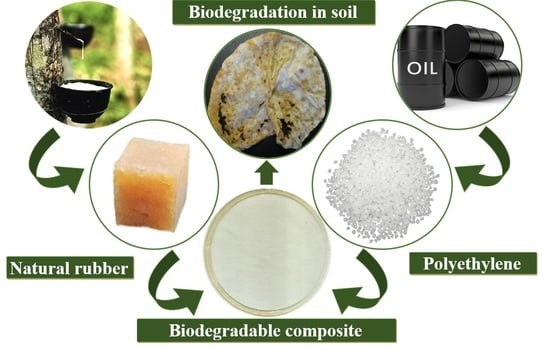

Biodegradable Polymer Materials Based on Polyethylene and Natural Rubber: Acquiring, Investigation, Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Materials

2.3. Methods

2.3.1. Contact Angle

2.3.2. Differential Scanning Calorimetry

2.3.3. Mechanical Analysis

2.3.4. Biodegradation

2.3.5. Microscopy

3. Results

3.1. Distribution of Natural Rubber Particles in the Polyethylene Matrix

3.2. Mechanical Properties

3.3. Contact Angle

3.4. Differential Scanning Calorimetry

3.5. Biodegradation

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bras, J.; Hassan, M.; Bruzesse, C.; Hassan, E.; El-Wakil, N.A.; Dufresne, A. Dufresne. Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind. Crop. Prod. 2010, 32, 627–633. [Google Scholar] [CrossRef]

- Pichaiyut, S.; Nakason, C.; Wisunthorn, S. Biodegradability and thermal properties of novel natural rubber/linear low density polyethylene/thermoplastic starch ternary blends. J. Polym. Environ. 2018, 26, 2855–2866. [Google Scholar] [CrossRef]

- Zhao, X.; Venoor, V.; Koelling, K.; Cornish, K.; Vodovotz, Y. Bio-based blends from poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and natural rubber for packaging applications. J. Appl. Polym. Sci. 2018, 136, 47334. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ammala, A.; Bateman, S.; Dean, K.; Petinakis, E.; Sangwan, P.; Wong, S.; Yuan, Q.; Yu, L.; Patrick, C.; Leong, K. An overview of degradable and biodegradable polyolefins. Prog. Polym. Sci. 2011, 36, 1015–1049. [Google Scholar] [CrossRef]

- Dautova, A.N.; Yanov, V.V.; Alekseev, E.I.; Zenitova, L.A. Biodegradable polymer composite materials using natural rubber. Butl. Commun. 2017, 52, 56–73. (In Russian). Available online: https://butlerov.com/stat/reports/details.asp?lang=ru&id=28591 (accessed on 4 November 2017).

- Takiyama, E.; Fujimaki, T. Biodegradable Plastics and Polymers; Doi, Y., Fukuda, K., Eds.; Elsevier: Amsterdam, The Netherlands, 1994; Volume 12, p. 150. [Google Scholar]

- Sauter, D.W.; Taoufik, M.; Boisson, C. Polyolefins, a success story. Polymers 2017, 9, 185. [Google Scholar] [CrossRef] [Green Version]

- Jia, M.Z. Biodegradable Plastics: Breaking down the Facts. Production, Composition and Environmental Impact. Greenpeace East Asia. 2020. Available online: https://www.greenpeace.org/static/planet4-eastasia-stateless/84075f56-biodegradable-plastics-report.pdf (accessed on 8 October 2020).

- Auras, R.; Harte, B.; Selke, S. An overview of polylactides as packaging materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Mastalygina, E.; Varyan, I.; Kolesnikova, N.; Gonzalez, M.I.C.; Popov, A. Effect of Natural Rubber in Polyethylene Composites on Morphology, Mechanical Properties and Biodegradability. Polymers 2020, 12, 437. [Google Scholar] [CrossRef] [Green Version]

- Bhoopathi, R.; Ramesh, M.; Deepa, C. Fabrication and property evaluation of banana-hemp-glass fiber reinforced composites. Procedia Eng. 2014, 97, 2032–2041. [Google Scholar] [CrossRef] [Green Version]

- Varyan, I.A.; Mastalygina, E.E.; Kolesnikova, N.N.; Popov, A.A. Impact of natural rubber on biological fouling and degradation of polyethylene composites. AIP Conf. Proc. 2018, 1981, 020119. [Google Scholar] [CrossRef]

- Faibunchan, P.; Pichaiyut, S.; Chueangchayaphan, W.; Kummerlöwe, C.; Venneman, N.; Nakason, C. Influence type of natural rubber on properties of green biodegradable thermoplastic natural rubber based on poly(butylene succinate). Polym. Adv. Technol. 2019, 30, 1010–1026. [Google Scholar] [CrossRef]

- Vudjung, C.; Chaisuwan, U.; Pangan, U.; Chaipugdee, N.; Boonyod, S.; Santawitee, O.; Saengsuwan, S. Effect of natural rubber contents on biodegradation and water absorption of interpenetrating polymer network (IPN) hydrogel from natural rubber and cassava starch. Energy Procedia 2014, 56, 255–263. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, T.; Shahid, M.; Azeem, F.; Rasul, I.; Shah, A.A.; Noman, M.; Hameed, A.; Manzoor, N.; Manzoor, I.; Muhammad, S. Biodegradation of plastics: Current scenario and future prospects for environmental safety. Environ. Sci. Pollut. Res. 2018, 25, 7287–7298. [Google Scholar] [CrossRef] [PubMed]

- Varyan, I.A.; Bobkov, A.L.; Mikhailov, I.A.; Kolesnikova, N.N. Ensuring environmental safety and economic benefits from the use of biodegradable materials based on low-density polyethylene with natural rubber additives as products with a short service life. Macromol. Symp. 2021, 395, 2000268. [Google Scholar] [CrossRef]

- Litvyak, V.V. Prospects for the production of modern packaging materials using biodegradable polymer compositions. Journal of the Belarusian State University. Ecology 2019, 2, 84–94. (In Russian). Available online: https://journals.bsu.by/index.php/ecology/article/view/2711 (accessed on 9 November 2019).

- Maharana, T.; Mohanty, B.; Negi, Y. Melt-solid polycondensation of lactic acid and its biodegradability. Prog. Polym. Sci. 2009, 34, 99–124. [Google Scholar] [CrossRef]

- Wang, X.; Zhou, J.; Li, L. Multiple melting behavior of poly(butylene succinate). Eur. Polym. J. 2007, 43, 3163–3170. [Google Scholar] [CrossRef]

- SJacobsen, S.; Fritz, H.G. Plasticizing polylactide – the effect of different plasticizers on the mechanical properties. Polym. Eng. Sci. 1999, 39, 1303–1310. [Google Scholar] [CrossRef]

- Youssef, A.M.; El-Gendy, A.; Kamel, S. Evaluation of corn husk fibers reinforced recycled low density polyethylene composites. Mater. Chem. Phys. 2015, 152, 26–33. [Google Scholar] [CrossRef]

- Luckachan, G.E.; Pillai, C.K.S. Biodegradable polymers- A review on recent trends and emerging perspectives. J. Polym. Environ. 2011, 19, 637–676. [Google Scholar] [CrossRef]

- Varyan, I.A.; Mastalygina, E.E.; Kolesnikova, N.N.; Popov, A.A.; Perepelitsina, E.O. Analysis of stress-strain characteristics of composite films based on polyethylene polymers with natural rubber. AIP Conf. Proc. 2017, 1909, 020226. [Google Scholar] [CrossRef]

- Potivara, K.; Phisalaphong, M. Development and characterization of bacterial cellulose reinforced with natural rubber. Materials 2019, 12, 2323. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Winfield, J.; Ieropoulos, I.; Rossiter, J.; Greenman, J.; Patton, D. Biodegradation and proton exchange using natural rubber in microbial fuel cells. Biogeochemistry 2013, 24, 733–739. [Google Scholar] [CrossRef]

- Cai, Z.; Čadek, D.; Šmejkalová, P.; Kadeřábková, A.; Nová, M.; Kuta, A. The modification of properties of thermoplastic starch materials: Combining potato starch with natural rubber and epoxidized natural rubber. Mater. Today Commun. 2020, 26, 101912. [Google Scholar] [CrossRef]

- Sareena, C.; Sreejith, M.; Ramesan, M.; Purushothaman, E. Biodegradation behaviour of natural rubber composites reinforced with natural resource fillers–monitoring by soil burial test. J. Reinf. Plast. Compos. 2013, 33, 412–429. [Google Scholar] [CrossRef]

- Han, Y.; Wei, M.; Shi, X.; Wang, D.; Zhang, X.; Zhao, Y.; Kong, M.; Song, X.; Xie, Z.; Li, F. Effects of tensile stress and soil burial on mecical and chemical degradation potential of agricultural plastic films. Sustainability 2020, 12, 7985. [Google Scholar] [CrossRef]

- Jakubowicz, I. Evaluation of degradability of biodegradable polyethylene (PE). Polym. Degrad. Stab. 2003, 80, 39–43. [Google Scholar] [CrossRef]

- Södergård, A.; Stolt, M. Properties of lactic acid based polymers and their correlation with composition. Prog. Polym. Sci. 2002, 27, 1123–1163. [Google Scholar] [CrossRef]

- Mochizuki, M.; Hirami, M. Structural effects on biodegradation of aliphatic polyesters. Polym. Adv. Technol. 1997, 8, 203–209. [Google Scholar] [CrossRef]

- Sivan, A. New perspectives in plastic biodegradation. Curr. Opin. Biotechnol. 2011, 22, 422–426. [Google Scholar] [CrossRef]

- Rutot, D.; Dubois, P. Les (bio)polymères biodégradables: L’enjeu de demain? Chim. Nouv. 2004, 86, 66–75. [Google Scholar]

- Ahmed, S. Bio-based materials for food packaging. In Green and Sustainable Advanced Packaging Materials; Springer Nature Singapore Pte Ltd.: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Zhong, Y.; Godwin, P.; Jin, Y.; Xiao, H. Biodegradable polymers and green-based antimicrobial packaging materials: A mini-review. Adv. Ind. Eng. Polym. Res. 2020, 3, 27–35. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Sutera, F.; Gulino, E.F.; Morreale, M. Degradation and recycling of films based on biodegradable polymers: A short review. Polymers 2019, 11, 651. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bardají, D.K.R.; Moretto, J.A.S.; Furlan, J.P.R.; Stehling, E.G. A mini-review: Current advances in polyethylene biodegradation. World J. Microbiol. Biotechnol. 2020, 36, 32. [Google Scholar] [CrossRef] [PubMed]

- Shimao, M. Biodegradation of plastics. Curr. Opin. Biotechnol. 2001, 12, 242–247. [Google Scholar] [CrossRef]

- Sable, S.; Mandal, D.K.; Ahuja, S.; Bhunia, H. Biodegradation kinetic modeling of oxo-biodegradable polypropylene/polylactide/nanoclay blends and composites under controlled composting conditions. J. Environ. Manag. 2019, 249, 109186. [Google Scholar] [CrossRef]

- Schiavo, S.; Oliviero, M.; Chiavarini, S.; Manzo, S. Adverse effects of oxo-degradable plastic leachates in freshwater environment. Environ. Sci. Pollut. Res. 2020, 27, 8586–8595. [Google Scholar] [CrossRef]

- Manfra, L.; Marengo, V.; Libralato, G.; Costantini, M.; De Falco, F.; Cocca, M. Biodegradable polymers: A real opportunity to solve marine plastic pollution? J. Hazard. Mater. 2021, 416, 125763. [Google Scholar] [CrossRef]

- Zimmermann, L.; Dombrowski, A.; Völker, C.; Wagner, M. Are bioplastics and plant-based materials safer than conventional plastics? In vitro toxicity and chemical composition. Environ. Int. 2020, 145, 106066. [Google Scholar] [CrossRef]

- Miller, M.E.; Hamann, M.; Kroon, F.J. Bioaccumulation and biomagnification of microplastics in marine organisms: A review and meta-analysis of current data. PLoS ONE 2020, 15, e0240792. [Google Scholar] [CrossRef] [PubMed]

- Paul, M.B.; Stock, V.; Cara-Carmona, J.; Lisicki, E.; Shopova, S.; Fessard, V.; Braeuning, A.; Sieg, H.; Böhmert, L. Micro- and nanoplastics—Current state of knowledge with the focus on oral uptake and toxicity. Nanoscale Adv. 2020, 2, 4350–4367. [Google Scholar] [CrossRef]

- Ferreira-Filipe, D.A.; Paço, A.; Duarte, A.C.; Rocha-Santos, T.; Patrício Silva, A.L. Are Biobased Plastics Green Alternatives?—A Critical Review. Int. J. Environ. Res. Public Health 2021, 18, 7729. [Google Scholar] [CrossRef]

- Viera, J.S.; Marques, M.R.; Nazareth, M.C.; Jimenez, P.C.; Sanz-Lázaro, C.; Castro, B. Are biodegradable plastics an environmental rip off? J. Hazard. Mater. 2021, 416, 125957. [Google Scholar] [CrossRef] [PubMed]

- Beltrán-Sanahuja, A.; Casado-Coy, N.; Simó-Cabrera, L.; Sanz-Lazaro, C. Monitoring polymer degradation under different conditions in the marine environment. Environ. Pollut. 2019, 259, 113836. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Hamidian, A.H.; Tubić, A.; Zhang, Y.; Fang, J.K.; Wu, C.; Lam, P.K. Understanding plastic degradation and microplastic formation in the environment: A review. Environ. Pollut. 2021, 274, 116554. [Google Scholar] [CrossRef]

- Nabeoka, R.; Suzuki, H.; Akasaka, Y.; Ando, N.; Yoshida, T. Evaluating the Ready Biodegradability of Biodegradable Plastics. Environ. Toxicol. Chem. 2021, 40, 2443–2449. [Google Scholar] [CrossRef]

- Liao, J.; Chen, Q. Biodegradable plastics in the air and soil environment: Low degradation rate and high microplastics formation. J. Hazard. Mater. 2021, 418, 126329. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Saikrishnan, S.; Tzoganakis, C.; Mekonnen, T. A comprehensive review of global production and recycling methods of polyolefin (PO) based products and their post-recycling applications. Sustain. Mater. Technol. 2020, 25, e00188. [Google Scholar] [CrossRef]

- Abraham, E.; Elbi, P.; Deepa, B.; Jyotishkumar, P.; Pothen, L.; Narine, S.; Thomas, S. X-ray diffraction and biodegradation analysis of green composites of natural rubber/nanocellulose. Polym. Degrad. Stab. 2012, 97, 2378–2387. [Google Scholar] [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers 2020, 12, 1127. [Google Scholar] [CrossRef] [PubMed]

- Liang, H.; Xie, F.; Chen, B.; Guo, F.; Jin, Z.; Luo, F. Miscibility and melting behavior of poly(ethylene terephthalate)/poly(trimethylene terephthalate) blends. J. Appl. Polym. Sci. 2007, 107, 431–437. [Google Scholar] [CrossRef]

- Magurudeniya, H.D.; Huang, P.; Gunathilake, S.S.; Rainbolt, E.A.; Biewer, M.C.; Stefan, M.C. Semiconducting Polymers: Poly(thiophenes). Encycl. Polym. Sci. Technol. 2014, 1, 1–36. [Google Scholar] [CrossRef]

- Shah, A.A.; Hasan, F.; Shah, Z.; Kanwal, N.; Zeb, S. Biodegradation of natural and synthetic rubbers: A review. Int. Biodeterior. Biodegradation 2013, 83, 145–157. [Google Scholar] [CrossRef]

- Ghaffar, A.M.A.; Ali, H.E.; Maziad, N.A. Modification of low density polyethylene films by blending with natural polymers and curing by gamma radiation. Polym. Sci. Ser. B 2019, 61, 776–784. [Google Scholar] [CrossRef]

- Kaur, I.; Bhalla, T.C.; Deepika, N.; Gautam, N. Study of the biodegradation behavior of soy protein-grafted polyethylene by the soil burial method. J. Appl. Polym. Sci. 2009, 111, 2460–2467. [Google Scholar] [CrossRef]

- Ramli, R.; Jaapar, J.; Singh, M.S.J.; Haque, S.N.S.M.U.; Yatim, A.H.M. Characterizing Mechanical Properties of Peroxide-Vulcanized Natural Rubber Latex Films. Adv. Mater. Res. 2015, 1134, 236–242. [Google Scholar] [CrossRef]

- Aydemir, C.; Altay, B.N.; Akyol, M. Surface analysis of polymer films for wettability and ink adhesion. Color Res. Appl. 2020, 46, 489–499. [Google Scholar] [CrossRef]

- do Nascimento, R.M.; Ramos, S.M.M.; Bechtold, I.H.; Hernandes, A.C. Wettability Study on Natural Rubber Surfaces for Applications as Biomembranes. ACS Biomater. Sci. Eng. 2018, 4, 2784–2793. [Google Scholar] [CrossRef] [PubMed]

- Boucher, E.A. Wettability and Adhesion of Polyethylene. Nature 1967, 215, 1054. [Google Scholar] [CrossRef]

- Wei, C.; Yu, R.; Tauer, K. The wettability of polymer films depends on the polymerization conditions. Colloid Polym. Sci. 2014, 292, 1545–1552. [Google Scholar] [CrossRef]

- Taguet, A.; Cassagnau, P.; Lopez-Cuesta, J.-M. Structuration, selective dispersion and compatibilizing effect of (nano)fillers in polymer blends. Prog. Polym. Sci. 2014, 39, 1526–1563. [Google Scholar] [CrossRef]

- Xia, L.; Gao, H.; Bi, W.; Fu, W.; Qiu, G.; Xin, Z. Shape Memory Behavior of Carbon Black-reinforced Trans-1,4-polyisoprene and Low-density Polyethylene Composites. Polymers 2019, 11, 807. [Google Scholar] [CrossRef] [Green Version]

- Runt, J.P.; Martynowicz, L.M. Crystallization and Melting in Compatible Polymer Blends. Multicomponent Polym. Mater. 1985, 7, 111–123. [Google Scholar] [CrossRef]

- Keith, H.D.; Padden, F.J. Spherulitic Crystallization from the Melt. I. Fractionation and Impurity Segregation and Their Influence on Crystalline Morphology. J. Appl. Phys. 1964, 35, 1270–1285. [Google Scholar] [CrossRef]

- Datta, S. The Science and Technology of Rubber, 4th ed.; Academic Press: Oxford, UK, 2013. [Google Scholar] [CrossRef]

- Song, K. Interphase characterization in rubber nanocomposites. In Progress in Rubber Nanocomposites; Elsevier Inc.: Amsterdam, The Netherlands, 2017; pp. 115–152. [Google Scholar] [CrossRef]

- Sherieva, M.L.; Shustov, G.B.; Shetov, R.A. Biodegradable compositions based on starch. Plast. Masses 2004, 32, 29–31. [Google Scholar] [CrossRef]

| Sample | LDPE wt. % | NR wt. % |

|---|---|---|

| LDPE 100 | 100 | 0 |

| LDPE/NR 90/10 | 90 | 10 |

| LDPE/NR 70/30 | 70 | 30 |

| LDPE/NR 50/50 | 50 | 50 |

| Sample | Average Value, Microns |

|---|---|

| LDLDPE 100 | 0 |

| LDLDPE/NR 90/10 | 34.9 |

| LDLDPE/NR 70/30 | 10.2 |

| LDLDPE/NR 50/50 | 0.6 |

| Sample | Tensile Strength (±0.5 MPa) | Relative Extension, (±10%) |

|---|---|---|

| LDPE 100 | 15.1 | 610 |

| LDPE/NR 90/10 | 6.3 | 120 |

| LDPE/NR 70/30 | 6.4 | 330 |

| LDPE/NR 50/50 | 3.9 | 330 |

| Sample | Contact Angle, Deg. (±1 Deg.) |

|---|---|

| LDPE 100 | 79 |

| LDPE/NR 90/10 | 72 |

| LDPE/NR 70/30 | 65 |

| LDPE/NR 50/50 | 50 |

| Samples | Tm, °C | ΔH, J/g | χ, % | Tm, °C | ΔH, J/g | χ, % | Tm, °C | ΔH, J/g | Tm, °C | ΔH, J/g |

|---|---|---|---|---|---|---|---|---|---|---|

| First Heating | Second Heating | First Cooling | Second Cooling | |||||||

| PE 100 | 105.7 | 65.2 | 22.2 | 105.0 | 57.0 | 19.5 | 90.7 | 93.2 | 90.8 | 83.2 |

| LDPE/NR 90/10 | 104.1 | 60.4 | 20.6 | 105.0 | 53.4 | 18.2 | 91.2 | 76.2 | 91.1 | 76.7 |

| LDPE/NR 70/30 | 105.1 | 47.1 | 16.1 | 104.7 | 42.7 | 14.6 | 91.4 | 45.6 | 91.3 | 46.4 |

| LDPE/NR 50/50 | 105.5 | 37.9 | 12.9 | 104.2 | 24.6 | 16.4 | 91.2 | 32.3 | 91.2 | 33.7 |

| Samples after Exposure in the Soil | Tm, °C | ΔH, J/g | χ, % | Tm, °C | ΔH, J/g | χ, % | Tm, °C | ΔH, J/g | Tm, °C | ΔH, J/g |

|---|---|---|---|---|---|---|---|---|---|---|

| First Heating | Second Heating | First Cooling | Second Cooling | |||||||

| LDPE 100 | 107.3 | 74.59 | 25.46 | 104.8 | 60.41 | 20.62 | 91 | 80.79 | 90.8 | 89.05 |

| LDPE/NR 90/10 | 105.1 | 66.87 | 22.82 | 105 | 53.79 | 18.36 | 90.7 | 75.36 | 91.1 | 76.06 |

| LDPE/NR 70/30 | 103.7 | 56.66 | 19.34 | 104.7 | 49.9 | 17.03 | 91.3 | 62.02 | 91.3 | 57.31 |

| LDPE/NR 50/50 | 105.4 | 55.52 | 18.95 | 104.2 | 48.17 | 16.43 | 91.5 | 61.35 | 91.4 | 57.2 |

| Sample | Initial | After Exposure in the Soil |

|---|---|---|

| LDPE 100 | 0.0071 | 0.0077 |

| LDPE/NR 90/10 | 0.0078 | 0.0073 |

| LDPE/NR 70/30 | 0.0104 | 0.0081 |

| LDPE/NR 50/50 | 0.0131 | 0.0089 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Varyan, I.; Tyubaeva, P.; Kolesnikova, N.; Popov, A. Biodegradable Polymer Materials Based on Polyethylene and Natural Rubber: Acquiring, Investigation, Properties. Polymers 2022, 14, 2457. https://doi.org/10.3390/polym14122457

Varyan I, Tyubaeva P, Kolesnikova N, Popov A. Biodegradable Polymer Materials Based on Polyethylene and Natural Rubber: Acquiring, Investigation, Properties. Polymers. 2022; 14(12):2457. https://doi.org/10.3390/polym14122457

Chicago/Turabian StyleVaryan, Ivetta, Polina Tyubaeva, Natalya Kolesnikova, and Anatoly Popov. 2022. "Biodegradable Polymer Materials Based on Polyethylene and Natural Rubber: Acquiring, Investigation, Properties" Polymers 14, no. 12: 2457. https://doi.org/10.3390/polym14122457

APA StyleVaryan, I., Tyubaeva, P., Kolesnikova, N., & Popov, A. (2022). Biodegradable Polymer Materials Based on Polyethylene and Natural Rubber: Acquiring, Investigation, Properties. Polymers, 14(12), 2457. https://doi.org/10.3390/polym14122457