Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites

Abstract

:1. Introduction

2. Experiment

2.1. Materials and Specimens

2.2. Laser Ablation Test

3. Results and Discussion

3.1. Ablation Performance

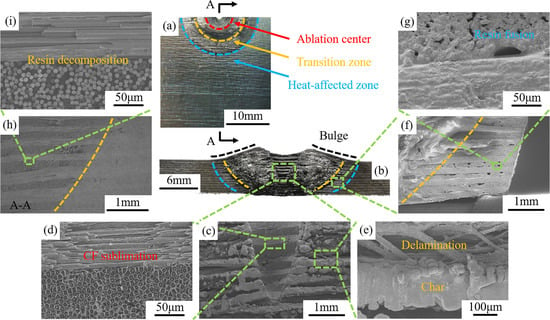

3.2. Morphology and Characteristics

3.3. Ablation Evolution Behavior of Fibres

3.4. Ablation Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kamble, M.; Lakhnot, A.S.; Bartolucci, S.F.; Littlefield, A.G.; Picu, C.R.; Koratkar, N. Improvement in fatigue life of carbon fibre reinforced polymer composites via a Nano-Silica Modified Matrix. Carbon 2020, 170, 220–224. [Google Scholar] [CrossRef]

- Zakaria, M.R.; Akil, H.M.; Kudus, M.H.A.; Ullah, F.; Javed, F.; Nosbi, N. Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: A review. Compos. Part B Eng. 2019, 176, 107313. [Google Scholar] [CrossRef]

- Wang, B.; Fang, G.D.; Tan, X.J.; Liang, J.; Ge, J.R.; Liu, S. Investigation on the longitudinal compressive strength of unidirectional carbon fiber/nanoparticles reinforced polymer composites using FFT-based method. Compos. Struct. 2020, 247, 112448. [Google Scholar] [CrossRef]

- Allheily, V.; Lacroix, F.; Eichhorn, A.; Merlat, L.; L’Hostis, G.; Durand, B. An experimental method to assess the thermo-mechanical damage of CFRP subjected to a highly energetic 1.07 μm-wavelength laser irradiation. Compos. Part B Eng. 2016, 92, 326–331. [Google Scholar] [CrossRef]

- Allheily, V.; Merlat, L.; Lacroix, F.; Eichhorn, A.; L’Hostis, G. The behavior of translucent composite laminates under highly energetic laser radiation. Phys. Proc. 2016, 83, 1044–1054. [Google Scholar] [CrossRef] [Green Version]

- Hong, S.C.; Chong, S.Y.; Lee, J.R.; Park, C.Y. Investigation of laser pulse fatigue effect on unpainted and painted CFRP structures. Compos. Part B Eng. 2014, 58, 343–351. [Google Scholar] [CrossRef]

- Ecault, R.; Boustie, M.; Touchard, F.; Pons, F.; Berthe, L.; Arnault, L.C.; Ehrhart, B.; Bockenheimer, C. A study of composite material damage induced by laser shock waves. Compos. Part A Appl. Sci. Manuf. 2013, 53, 54–64. [Google Scholar] [CrossRef] [Green Version]

- Ferrante, L.; Tirillò, J.; Sarasini, F.; Touchard, F.; Ecault, R.; Urriza, M.A.V.; Arnault, L.C.; Mellier, D. Behaviour of woven hybrid basalt-carbon/epoxy composites subjected to laser shock wave testing: Preliminary results. Compos. Part B Eng. 2015, 78, 162–173. [Google Scholar] [CrossRef]

- Kaludjerovic, B.V.; Sreckovic, M.; Janicijevic, M.; Kovacevic, A.; Bojanic, S. Influence of Nd3+: YAG laser irradiation on the properties of composites with carbon fibers. Compos. Part B Eng. 2017, 125, 165–174. [Google Scholar] [CrossRef]

- Ma, C.; Ma, Z.; Gao, L.H.; Liu, Y.B.; Li, H.Z.; Lv, Y.W.; Wang, F.C. Ablation behavior of glass fiber reinforced polybenzoxazine composites irradiated by high energy continuous-wave laser. Mater. Res. Express 2019, 6, 085315. [Google Scholar] [CrossRef]

- Gay, E.; Berthe, L.; Boustie, M.; Arrigoni, M.; Trombini, M. Study of the response of CFRP composite laminates to a laser-induced shock. Compos. Part B Eng. 2014, 64, 108–115. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.C.; Wu, C.W.; Huang, Y.H.; Song, H.W.; Huang, C.G. Interlaminar damage of carbon fiber reinforced polymer composite laminate under continuous wave laser irradiation. Opt. Lasers Eng. 2017, 88, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.L.; Chang, X.L.; Zhang, X.J.; Zhang, Y.H. Progressive damage analysis of carbon/epoxy laminates under couple laser and mechanical loading. Res. Phys. 2017, 7, 995–1005. [Google Scholar] [CrossRef]

- Nan, P.Y.; Shen, Z.H.; Han, B.; Ni, X.W. The influences of laminated structure on the ablation characteristics of carbon fiber composites under CW laser irradiation. Opt. Laser Technol. 2019, 116, 224–231. [Google Scholar] [CrossRef]

- Sihn, S.; Pitz, J.; Gerzeski, R.H.; Roy, A.K.; Vernon, J.P. Experimentally-validated computational model for temperature evolution within laser heated fiber-reinforced polymer matrix composites. Compos. Struct. 2019, 207, 966–973. [Google Scholar] [CrossRef]

- Sato, Y.; Tsukamoto, M.; Matsuoka, F.; Ohkubo, T.; Abe, N. Thermal effect on CFRP ablation with a 100-W class pulse fiber laser using a PCF amplifier. Appl. Surf. Sci. 2017, 417, 250–255. [Google Scholar] [CrossRef]

- Louet, V.L.; Corre, S.L.; Boyard, N.; Delaunay, D.; Tardif, X. Experimental characterization of the thermal behavior of carbon/PEEK tapes in the laser-assisted AFP process. AIP Conf. Proc. 2019, 2113, 130007. [Google Scholar]

- Xu, J.Y.; Huang, X.H.; Davim, J.P.; Ji, M.; Chen, M. On the machining behavior of carbon fiber reinforced polyimide and PEEK thermoplastic composites. Polym. Compos. 2020, 41, 3649–3663. [Google Scholar] [CrossRef]

- Fujihara, K.; Huang, Z.M.; Ramakrishna, S.; Hamada, H. Influence of processing conditions on bending property of continuous carbon fiber reinforced PEEK composites. Compos. Sci. Technol. 2004, 64, 2525–2534. [Google Scholar] [CrossRef]

- Roux, M.; Eguemann, N.; Dransfeld, C.; Thiebaud, F.; Perreux, D. Thermoplastic carbon fibre-reinforced polymer recycling with electrodynamical fragmentation: From cradle to cradle. J. Thermoplast. Compos. 2017, 30, 381–403. [Google Scholar] [CrossRef]

- Ning, H.B.; Pillay, S.; Vaidya, U.K. Design and development of thermoplastic composite roof door for mass transit bus. Mater. Des. 2009, 30, 983–991. [Google Scholar] [CrossRef]

- Leplat, G.; Huchette, C.; Biasi, V. Thermal and damage analysis of laser-induced decomposition within carbon/epoxy composite laminates. J. Fire Sci. 2016, 34, 361–384. [Google Scholar] [CrossRef]

- Ye, L.; Chen, Z.R.; Lu, M.; Hou, M. De-consolidation and re-consolidation in CF/PPS thermoplastic matrix composites. Compos. Part A Appl. Sci. Manuf. 2005, 36, 915–922. [Google Scholar] [CrossRef]

- Lai, Y.H.; Kuo, M.C.; Huang, J.C.; Chen, M. Thermomechanical properties of nanosilica reinforced PEEK composites. Key Eng. Mater. 2007, 351, 15–20. [Google Scholar] [CrossRef]

- Naffakh, M.; Gomez, M.A.; Marco, C.; Ellis, G. Kinetic analysis of thermo-oxidative degradation of PEEK/thermotropic liquid crystalline polymer blends. Polym. Eng. Sci. 2010, 46, 129–138. [Google Scholar] [CrossRef]

- Zhang, Z.; Modest, M.F. Temperature-dependent absorptances of ceramics for Nd:YAG and CO2 laser processing applications. J. Heat Trans. 1998, 120, 322–327. [Google Scholar] [CrossRef] [Green Version]

- Holman, J.P. Heat Transfer, 10th ed.; McGraw Hill Education: New York, NY, USA, 2010; pp. 117–147. [Google Scholar]

- Dimitrienko, Y.I. Thermomechanical behaviour of composites under local intense heating by irradiation. Compos. Part A Appl. Sci. Manuf. 2000, 31, 591–598. [Google Scholar] [CrossRef]

- Pagano, N.; Ascari, A.; Liverani, E.; Donati, L.; Campana, G.; Fortunato, A. Laser interaction with carbon fibre reinforced polymers. Procedia CIRP 2015, 33, 423–427. [Google Scholar] [CrossRef] [Green Version]

- Wu, C.W.; Wu, X.Q.; Huang, C.G. Ablation behaviors of carbon reinforced polymer composites by laser of different operation modes. Opt. Laser Technol. 2015, 73, 23–28. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.L.; Liu, R.J.; Cao, Y.B.; Zhang, C.R.; Zhang, D.K. Ablation behavior and mechanism of C/ZrC, C/ZrC-SiC and C/SiC composites fabricated by polymer infiltration and pyrolysis process. Corros. Sci. 2014, 86, 131–141. [Google Scholar] [CrossRef]

- Geng, L.; Liu, X.C.; Fu, Q.G.; Cheng, S.; Li, H.J. Laser ablative behavior of C/C modified by Si reactive infiltration. Carbon 2020, 168, 650–658. [Google Scholar] [CrossRef]

- Cheng, C.F.; Tsui, Y.C.; Clyne, T.W. Application of a three-dimensional heat flow model to treat laser drilling of carbon fiber composites. Acta Mater. 1998, 46, 4273–4285. [Google Scholar] [CrossRef]

- Meek, N.; Penumadu, D. Nonlinear elastic response of pan based carbon fiber to tensile loading and relations to microstructure. Carbon 2021, 178, 133–143. [Google Scholar] [CrossRef]

- Nunna, S.; Creighton, C.; Hameed, N.; Naebe, M.; Henderson, L.C.; Setty, M.; Fox, B.L. Radial structure and property relationship in the thermal stabilization of PAN precursor fibres. Polym. Test. 2017, 59, 203–211. [Google Scholar] [CrossRef]

- Nunna, S.; Naebe, M.; Hameed, N.; Creighton, C.; Naghashian, S.; Jennings, M.J.; Atkiss, S.; Setty, M.; Fox, B.L. Investigation of progress of reactions and evolution of radial heterogeneity in the initial stage of thermal stabilization of PAN precursor fibres. Polym. Degrad. Stabil. 2016, 125, 105–114. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.Z.; Wang, G.F.; Wang, Z.F.; Gao, L. New ablation evolution behaviors in micro-hole drilling of 2.5D Cf/SiC composites with millisecond laser. Ceram. Int. 2021, 47, 29670–29680. [Google Scholar] [CrossRef]

- Chen, Z.F.; Fang, D.; Miao, Y.L.; Bo, Y. Comparison of morphology and microstructure of ablation centre of C/SiC composites by oxy-acetylene torch at 2900 °C and 3550 °C. Corros. Sci. 2008, 50, 3378–3381. [Google Scholar] [CrossRef]

- Li, W.; Xiang, Y.; Wang, S.; Ma, Y.; Chen, Z.H. Ablation behavior of three-dimensional braided C/SiC composites by oxyacetylene torch under different environments. Ceram. Int. 2013, 39, 463–468. [Google Scholar]

- Patel, P.; Hull, T.R.; McCabe, R.W.; Flath, D.; Grasmeder, J.; Percy, M. Mechanism of thermal decomposition of poly(ether ether ketone) (PEEK) from a review of decomposition studies. Polym. Degrad. Stabil. 2010, 95, 709–718. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Yan, L.W.; Zhou, S.T.; Zou, H.W.; Chen, Y.; Liang, M.; Ren, X.C. A comparison of ablative resistance properties of liquid silicone rubber composites filled with different fibers. Polym. Eng. Sci. 2021, 61, 442–452. [Google Scholar] [CrossRef]

- Sabagh, S.; Arefazar, A.; Bahramian, A.R. Thermochemical erosion and thermophysical properties of phenolic resin/carbon fiber/graphite nanocomposites. J. Reinf. Plast. Compos. 2016, 35, 1814–1825. [Google Scholar] [CrossRef]

- Patel, P.; Hull, T.R.; Lyon, R.E.; Stoliarov, S.I.; Walters, R.N.; Crowley, S.; Safronava, N. Investigation of the thermal decomposition and flammability of PEEK and its carbon and glass-fibre composites. Polym. Degrad. Stabil. 2011, 96, 12–22. [Google Scholar] [CrossRef]

| Number | LP/W | IT/s | SD/mm | MLR/mg·s−1 | DA/mm2 |

|---|---|---|---|---|---|

| 1 | 600 | 2 | 4 | 14.7 | 82.4 |

| 2 | 900 | 2 | 4 | 19.7 | 93.4 |

| 3 | 1200 | 2 | 4 | 35.9 | 118.4 |

| 4 | 1500 | 2 | 4 | 38.6 | 121.4 |

| 5 | 1500 | 4 | 4 | 36.1 | 201.4 |

| 6 | 1500 | 6 | 4 | 38.2 | 290.4 |

| 7 | 1500 | 8 | 4 | 35.8 | 376.4 |

| 8 | 1500 | 2 | 3 | 43.4 | 121.9 |

| 9 | 1500 | 2 | 2 | 42.5 | 121.9 |

| 10 | 1500 | 2 | 1 | 40.2 | 120.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Bi, R.; Jiang, S.; Wen, Z.; Luo, C.; Yao, J.; Liu, G.; Chen, C.; Wang, M. Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites. Polymers 2022, 14, 2676. https://doi.org/10.3390/polym14132676

Zhang J, Bi R, Jiang S, Wen Z, Luo C, Yao J, Liu G, Chen C, Wang M. Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites. Polymers. 2022; 14(13):2676. https://doi.org/10.3390/polym14132676

Chicago/Turabian StyleZhang, Jindong, Ran Bi, Shengda Jiang, Zihao Wen, Chuyang Luo, Jianan Yao, Gang Liu, Chunhai Chen, and Ming Wang. 2022. "Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites" Polymers 14, no. 13: 2676. https://doi.org/10.3390/polym14132676

APA StyleZhang, J., Bi, R., Jiang, S., Wen, Z., Luo, C., Yao, J., Liu, G., Chen, C., & Wang, M. (2022). Laser Ablation Mechanism and Performance of Carbon Fiber-Reinforced Poly Aryl Ether Ketone (PAEK) Composites. Polymers, 14(13), 2676. https://doi.org/10.3390/polym14132676