4.1. Selection of Optimum Mixing Time

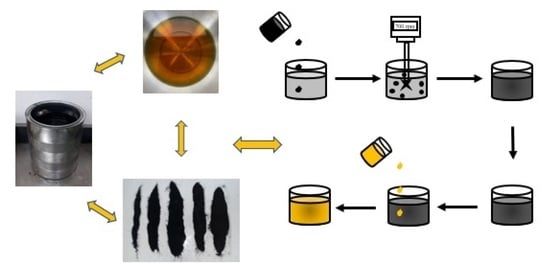

In order to determine the optimum mixing time for each of the CR contents (15, 18 and 21%), three mixing times (30, 45 and 60 min) were evaluated. For each sample, a frequency sweep (46–76 °C) by DSR was adopted.

Figure 5 shows the master curves for both

G* and

δ. For 15% CR, it can be observed that for

G*, there is no significant difference between the mixing times, while for

δ, it increases as the mixing time increases; therefore, the optimum mixing time for 15% CR is 45 min. Meanwhile, for the 18% content of CR, a better rutting performance (higher

G*/sin

δ) was obtained for the mixing time of 45 min, which implies a higher

G* and a lower

δ; therefore, the mixing time of 45 min was selected as optimal for the 18% CR content. Likewise, for the 21% CR, the frequency sweep showed a trend that as the mixing time increases, the higher the

G*, the mixing time of 60 min also presented a higher

G*; it is therefore concluded that the optimum mixing time for the 21% CR content is 60 min.

Table 3 summarises the optimum mixing times for each CR content.

4.2. Conventional Tests

It is worth mentioning that for the conventional tests, six samples were obtained for each one, and the average of these was used for the analysis. In addition, these tests followed ASTM D6114 standards for asphalt–rubber binders.

The penetration test results (

Figure 6a) indicated that adding CR decreases the penetration grade as the CR content increases. Therefore, it can be concluded that as the CR content increases, the asphalt binder presents a higher stiffness (lower penetration grade). This may be due to the crumb rubber components; modifying the asphalt could increase the asphaltenes/resins ratio. The literature establishes that adding crumb rubber implies decreased aromatics and saturated content [

11,

80]. The addition of Evotherm M1 reduced the penetration grade by 4.5% and Iterlow T by 1.15% compared to the control sample. At the same time, the addition of CR reduced the penetration grade by 29.8, 25.9 and 32.5% for CR contents of 15, 18 and 21%, respectively. Therefore, the addition of Evotherm M1 in the CR-modified binder reduction of 29.8, 15.6, and 9.8% for the CR contents of 15, 18, and 21%, respectively. Likewise, adding Iterlow T meant a reduction for the CR-modified binders of 26.3, 13.3, and 7.3% for the contents mentioned above.

The softening point or ring and ball test (

Figure 6b) show that the addition of CR in the asphalt increases the softening point; therefore, as the CR content increases, the softening point increases because the CR produces changes in the elastic components, which is reflected in better resistance to temperature changes. Likewise, the addition of WMA chemical additives decreases the softening point in both unmodified and modified asphalt, with Iterlow T having a more pronounced effect than Evotherm M1, which may be due to the chemical additives’ components or low boiling and melting points. The addition of Evotherm M1 reduced the softening point by 2.5%, while Iterlow T reduced it by 5.5% compared to the control sample. In contrast, adding CR increased the softening point by 30.6, 31.4, and 37.4% for CR contents of 15, 18, and 21%, respectively. The addition of Evotherm M1 in CR-modified binders accounted for a 4.7, 3.3, and 6.6% reduction for CR contents of 15, 18, and 21%, respectively. On the other hand, Iterlow T reduced the CR contents studied by 6.9, 5.3, and 7.4%.

On the other hand, the rotational viscosity test (

Figure 7) allows for analysis of the workability of the asphalt and determining its mixing and compaction temperatures. In this study, 135, 160, and 175 °C were considered because construction temperatures for unmodified asphalts are generally below 135 °C, but these temperatures are much higher for modified asphalts. From the literature, it can be noted that crumb rubber increases resins and asphaltenes, thus decreasing the colloidal stability index and increasing viscosity [

11,

80]. As expected, the addition of CR increased the viscosity by 249.2, 663.5, and 82.6% for CR contents of 15, 18, and 21%, respectively, at a temperature of 175 °C compared to the control sample. On the other hand, Evotherm M1 and Iterlow T slightly reduced the viscosity of CR-modified binders at all temperatures but were still superior to the control. In the literature, the effect of WMA chemical actives is discussed because it should not alter the viscosity since its purpose is to reduce the friction between aggregates and asphalt [

58], but in other research, it is observed that the additive does slightly reduce the viscosity [

42,

81], which is also observed in this research.

4.3. Frequency Sweep

The information obtained from the frequency sweeps was analysed to describe the rheological behaviour of the modified and unmodified asphalt binders. As mentioned above, the Black diagram and Cole–Cole space. In the Black diagram (

Figure 8a), it is observed that all the materials are thermorheologically simple due to the continuity of all their data; on the other hand, it is also observed that all the modified asphalts present a similar viscoelastic response among them. From the Black diagram, it can also be observed that the CR-modified asphalt binders show an inverse “S” as in previous investigations [

20,

29,

82], only the control asphalt and the one modified only with Evotherm M1 and Iterlow T present a slightly different response.

In the Cole–Cole space (

Figure 8b), in all samples, the elastic component is greater than the viscous component, except in the original asphalt, the one modified with Evotherm M1 and the Iterlow T is reflected in a high phase angle. The addition of CR confirmed an increase in the elastic component as expected since CR improves the elastic properties of asphalt, and the higher the CR content, the more the elastic component increases; this is because the swelling and dispersion processes of the crumb rubber give the asphalt its elasticity [

11]. In addition, the WMA chemical additives in CR-modified binders decrease the elastic component but still show the same trend and remain superior to the original asphalt binder.

Likewise, to observe more clarity in the behaviour of the rheological parameters,

G* and

δ were plotted versus temperature independently of the unaged and RTFO-aged samples. In

Figure 9, it can be concluded that as the temperature increases,

G* decreases. In addition, the samples modified only with Evotherm M1 and with Iterlow T had a lower

G* than the control sample at all temperatures. On the other hand, all CR-modified binders had a higher

G* than the control sample; at 64 °C, there was an increase in

G* of 304.5, 403.2, and 683.4% for CR contents of 15, 18, and 21%, respectively, compared to the control sample; the addition of CR showed a trend directly proportional to the increase in

G* at all temperatures analysed. WMA chemical additives in CR-modified binders decreased

G* for all contents, but all presented a higher

G* than the control sample at all temperatures. The addition of Evotherm M1 decreased the

G* of the control sample by 34.4%, while for the CR-modified binders, by 23.5, 10.6, and 16.9% for the 15, 18, and 21% contents. Likewise, Iterlow T reduced

G* by 37.6%, and for CR-modified binders, it represented a reduction of 29.1, 26.8, and 19.8% for the respective contents. Finally, given the results described above, it can be concluded that the chemical additives decrease the effect of the CR, the Iterlow T more than the Evotherm M1, but present a higher complex modulus than the control.

RTFO aged samples show a higher G*, this is due to the fact that ageing induces some of the less polar fractions to change to more polar fractions, causing the molecular weight to increase, resulting in lower ductility and higher viscosity, which implies a higher stiffness [

11]. The

G* of the control sample had a 60.5% increase in

G* compared to the unaged sample, while the CR-modified binders had a more notable increase for all their contents (146.9, 217.7, and 183.8% increases). Likewise, WMA-CR-modified binders showed a lower

G* than CR-modified binders without WMA but a higher

G* than the control sample. On the other hand, the phase angle of these samples aged by RTFO showed a decrease in that parameter; unlike the control samples, the Evotherm M1 presented lower phase angles than the Iterlow T modified ones.

With the data obtained, the failure temperatures were calculated for each sample. This procedure was carried out by calculating the temperatures at which the rutting parameter (

G*/sin

δ) is equal to 1 kPa for the unaged samples and 2.2 kPa for the samples aged with RTFO. The preceding can be observed in

Figure 10.

To complement the above information,

Figure 11 shows the failure temperature for each sample. It can be concluded that the addition of CR significantly improves the high-temperature performance of asphalt binders, as well as their sensitivity to these temperatures, because this additive improves the stability of the asphalt due to its crystalline network/lattice structure [

26,

40,

83], the addition of WMA additives led, in some cases, to a decrease in PG. However, the performance is still far superior to that of unmodified asphalt binders [

33].

Continuing the analysis of the rutting behaviour of the asphalt binders, the Shenoy parameter is then calculated. It can be mentioned that this parameter is very similar to that of the Superpave protocol; the effect of the additives used in this research maintains the same trends in the results of this parameter, in addition to the fact that the effect of ageing is also observed in the RTFO aged samples. The most notable difference between the Shenoy and Superpave parameters is that slightly higher values are obtained in the former.

Figure 12 presents the comparison of the Shenoy and Superpave parameters for the unaged samples.

Table 4 shows the sensitivity of the parameters analysed for each CR content and the WMA, Evotherm M1, and Iterlow T additives. It can be concluded that for CR contents from 0 to 18% and from 0 to 21%, the changes in the

G*/sin

δ parameter are less pronounced compared to

G*/(1 − (1/(tan

δ * sin

δ)), this indicates that the Shenoy parameter is more sensitive to the changes in asphalt structures generated by the modifying agents evaluated. As a result, a more accurate description of the non-recoverable strains is achieved [

48,

79].

On the other hand, the Glover–Rowe (G–R) parameter allows us to understand the fatigue performance of asphalt binders. The analysis was performed for unaged and RTFO aged samples in this research. G–R parameter was calculated through a frequency sweep in the DSR at a temperature of 44.7 °C, and a frequency of 10 rad/s due to these conditions is equivalent to that of 15 °C and 0.005 rad/s [

84,

85].

Figure 13 shows the results obtained for the G–R parameter. It can be mentioned that the addition of CR meant an increase in the G–R parameter, which translates into a decrease in fatigue resistance. On the other hand, the WMA chemical additives improved the performance of these binders, even in the presence of CR, the Iterlow T having more noticeable benefits than the Evotherm M1.

4.4. Multiple Stress Creep Recovery (MSCR) Tests

From

Figure 14, it was observed that the addition of CR significantly increased rutting resistance; the addition of Evotherm M1 and Iterlow T to CR-modified binders was reflected in a decrease in rutting resistance but still performed much better than the control sample. The asphalt binder modified only with Evotherm M1 had an increase of 2.4% of

Jnr 3.2 and the Iterlow T an increase of 4.5% compared to the control sample; also, the decrease in

Jnr 3.2 of 93.4, 94.6, and 96.4% were observed for the contents of 15, 18 and 21% CR, respectively. Furthermore, an increase in

Jnr of CR-modified binders with Evotherm M1 of 68.8, 43.5, and 60.8% was presented for 15, 18, and 21%, respectively, compared to those modified only with CR. At the same time, the addition of Iterlow T represented a decrease of 51.13, 56.48, and 51.75% for CR-modified binders. On the other hand, the

Jnr results are congruent with those obtained with frequency sweeps, showing increased asphalt stiffness and better

G*/sin

δ parameter behaviour (high

G* and low

δ). With the addition of CR and a slight decrease in rutting resistance of CR-modified binders with WMA compared to those modified only with CR. Although the addition of Evotherm M1 and Iterlow T to the CR-modified binders increased the

Jnr parameter, these modified asphalts still showed higher rutting resistance than the control sample.

Likewise, the percentage recovery is used to determine the elastic, and the stress-dependent response of the asphalt binders analysed [

27,

60]. The percentage recovery results mirrored those obtained with

Jnr, i.e., the CR-modified samples showed a considerable increase compared to the control sample. This increase in R goes hand in hand with the increase in CR content. The CR-modified binders with Evotherm M1, and Iterlow T showed the same trend but with slightly lower percentage values, presenting Evotherm M1 decreases of 57.6, 5.0 and 6.8%, for contents of 15, 18 and 21%, respectively, and Iterlow T decreases of 48.5, 12.7 and 10.5%. The results obtained for these parameters were as expected since the CR improves the elastic response compared to the original asphalt, which these results can confirm.

On the other hand, research has shown that the

Jnrdiff parameter does not best characterise the stress sensitivity of modified asphalts [

27,

86]. Moreover, they recommend the alternative parameter

Jnrslope defined by the following equation (Equation (4)):

where

Jnr is creep compliance, and

τ is applied stress.

Table 5 summarises all the parameters obtained from the MSCR test for the modified and unmodified asphalt binders. Most of the

Jnrdiff exceed the 75% limit; for this reason, the

Jnrslope parameter described above is considered. The lower the

Jnrdiff value, the lower the binder sensitivity to stress change [

86]. It is observed that the addition of CR increases the binder sensitivity to such stress changes. In contrast, the addition of Evotherm M1 and Iterlow T slightly decreases the binder sensitivity.

Figure 15 shows the graph of

Jnr vs. R, in which we can observe which samples have a higher performance and resistance to rutting since the objective is to have a lower

Jnr and a higher R. The data is sought to be in the box bordered in red, which is the case in this case study, i.e., the CR-modified binder samples with and without WMA show a considerable increase in rolling resistance according to the data obtained from the MSCR test. On the other hand, the representative line of R (%) = 29.371 (

Jnr) − 0.263, proposed by AASHTO M332, can also be observed in this graph, which establishes that points above this line present an acceptable amount of elastomeric polymers in the asphalt binder. Under these conditions, the sample that does not meet the acceptable level is the asphalt modified with 15% CR and Evotherm M1, which indicates that most of the samples with the different modifiers analysed in this study meet the sufficient amount for each modifier.

4.5. Statical Analysis

A comparison of the averages was carried out through an analysis of the variance of the data (ANOVA). This analysis was performed using R Studio software, in which a

p < 0.05 signified a significant change.

Table 6 summarises the significance of the results obtained from the rheology tests. From the viscosity at 135 °C, it can be concluded that only for the 18% content did the addition of both WMA additives represent a significant change, in addition to the fact that the addition of CR was significant for all contents in comparison with the control samples, even this trend is observed in the presence of the WMA additives. For viscosity at 175 °C, only the 18% CR sample modified with Evotherm M1 significantly decreased compared to the CR-modified binder. As for the 135 °C viscosity, the presence of CR with and without WMA represented a significant increase. Likewise, for the Superpave protocol rutting resistance parameter (

G*/sin

δ), the addition of Evotherm M1 and Iterlow T indicated a significant decrease in that parameter for all control samples. The increase in rheological performance due to the modifying agents in asphalt is because CR is composed of several materials, including many polymers, which increase the elastic component of the asphalt, increasing deformation resistance, i.e., asphalt binders modified with RC contain more heavy fractions, increasing

G* and resulting in a lower phase angle. It should also be mentioned that the heating of the asphalt can influence the stiffening of this material.

Overall, CR addition significantly increased the rutting parameter. For Jnr, the addition of only Evotherm M1 for the control sample and the addition of Iterlow for the 15% CR sample did not represent a significant increase in the parameter; for the others, the WMA implied a significant increase. Furthermore, the addition of CR did indicate a significant decrease. Finally, in the G–R parameter, the addition of the WMA chemical additives did not represent a significant increase or decrease compared to the CR-modified binder samples. The addition of CR showed a significant increase with and without the addition of WMA.