Crystallization Behavior of Poly(ε-Caprolactone)-Hollow Glass Microspheres Composites for Rotational Molding Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hollow Glass Microspheres Surface Functionalization

2.3. Composite Processing

2.4. Methods

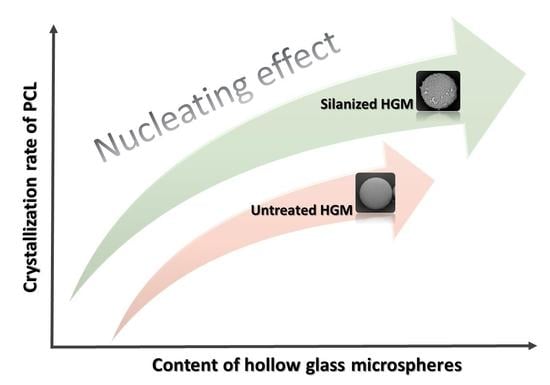

3. Results and Discussion

3.1. Processing and Morphology

3.2. Isothermal Crystallization by DSC

3.3. Non-Isothermal Crystallization by DSC

3.4. Structural Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Crawford, R.J.; Throne, J.L. Rotational Molding Technology; William Andrew Publishing: New York, NY, USA, 2002. [Google Scholar]

- Ogila, K.O.; Shao, M.; Yang, W.; Tan, J. Rotational molding: A review of the models and materials. Express Polym. Lett. 2017, 11, 778–798. [Google Scholar] [CrossRef]

- Gupta, N.; Ramkumar, P.L.; Sangani, V. An approach toward augmenting materials, additives, processability and parameterization in rotational molding: A review. Mater. Manuf. Process. 2020, 35, 1539–1556. [Google Scholar] [CrossRef]

- Cramez, M.C.; Oliveira, M.J.; Fakirov, S.; Crawford, R.J.; Apostolov, A.A.; Krumova, M. Rotationally molded polyethylene: Structural characterization by X-ray and microhardness measurements. Adv. Polym. Technol. 2001, 20, 116–124. [Google Scholar] [CrossRef]

- Cramez, M.C.; Oliveira, M.J.; Crawford, R.J. Effect of pigmentation on the microstructure and properties of rotationally molded polyethylene. J. Mater. Sci. 1998, 33, 4869–4877. [Google Scholar] [CrossRef]

- Glomsaker, T.; Larsen, A.; Andreassen, E.; Ommundsen, E. Experimental and numerical investigation of warpage of semicrystalline polymers in rotational molding. Polym. Eng. Sci. 2005, 45, 945–952. [Google Scholar] [CrossRef]

- Xu, H.; Bellehumeur, C.T. Modeling the morphology development of ethylene copolymers in rotational molding. J. Appl. Polym. Sci. 2006, 102, 5903–5917. [Google Scholar] [CrossRef]

- Martins, C.I.; Gil, V. Processing–Structure–Properties of Cork Polymer Composites. Front. Mater. 2020, 7, 297. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Andrzejewski, J.; Kosmela, P.; Piasecki, A.; Szostak, M.; Kuang, T. Rotational Molding of Linear Low-Density Polyethylene Composites Filled with Wheat Bran. Polymers 2020, 12, 1004. [Google Scholar] [CrossRef]

- Stagnaro, P.; Utzeri, R.; Vignali, A.; Falcone, G.; Iannace, S.; Bertini, F. Lightweight polyethylene-hollow glass microspheres composites for rotational molding technology. J. Appl. Polym. Sci. 2021, 138, 49766. [Google Scholar] [CrossRef]

- Falcone, G.; Vignali, A.; Utzeri, R.; Porta, G.; Bertini, F.; Stagnaro, P.; Iannace, S. Light weight LDPE composites with surface modified hollow glass microspheres. AIP Conf. Proc. 2018, 1981, 020131. [Google Scholar]

- Prasad, K.; Nikzad, M.; Sbarski, I. Mechanical, viscoelastic and gas transport behaviour of rotationally molded polyethylene composites with hard- and soft-wood natural fibres. J. Polym. Res. 2022, 29, 131. [Google Scholar] [CrossRef]

- Głogowska, K.; Pączkowski, P.; Samujło, B. Study on the Properties and Structure of Rotationally Moulded Linear Low-Density Polyethylene Filled with Quartz Flour. Materials 2022, 15, 2154. [Google Scholar] [CrossRef] [PubMed]

- Sharma, T.; Mahanwar, P.A.; Bambole, V. Study of modified polypropylene for rotational moulding applications. Int. J. Plast. Technol. 2009, 13, 83–94. [Google Scholar] [CrossRef]

- Glomsaker, T.; Hinrichsen, E.L.; Larsen, A.; Doshev, P.; Ommundsen, E.; Bambole, V. Warpage–crystallinity relations in rotational molding of polypropylene. Polym. Eng. Sci. 2009, 49, 523–530. [Google Scholar] [CrossRef]

- Hafsaoui, S.L.; Mahmoud, R.; Farzaneh, S.; Tcharkhtchi, A. Study of polyamide 12 crystallization behavior within rotational molding process. Iran. Polym. J. 2013, 22, 187–197. [Google Scholar] [CrossRef]

- Greco, A.; Ferrari, F.; Maffezzoli, A. Processing of Super Tough Plasticized PLA by Rotational Molding. Adv. Polym. Technol. 2019, 2019, 3835829. [Google Scholar] [CrossRef] [Green Version]

- Barczewski, M.; Hejna, A.; Aniśko, J.; Andrzejewski, J.; Piasecki, A.; Mysiukiewicz, O.; Bąk, M.; Gapiński, B.; Ortega, Z. Rotational molding of polylactide (PLA) composites filled with copper slag as a waste filler from metallurgical industry. Polym. Test. 2022, 106, 107449. [Google Scholar] [CrossRef]

- Vignali, A.; Iannace, S.; Falcone, G.; Utzeri, R.; Stagnaro, P.; Bertini, F. Lightweight poly(ε-caprolactone) composites with surface modified hollow glass microspheres for use in rotational molding: Thermal, rheological and mechanical properties. Polymers 2019, 11, 624. [Google Scholar] [CrossRef] [Green Version]

- Woodruff, M.A.; Hutmacher, D.W. The return of a forgotten polymer. Polycaprolactone in the 21st century. Prog. Polym. Sci. 2010, 35, 1217–1256. [Google Scholar] [CrossRef] [Green Version]

- Malikmammadov, E.; Tanir, T.E.; Kiziltay, A.; Hasirci, V.; Nesrin Hasirci, N. PCL and PCL-based materials in biomedical applications. J. Biomater. Sci. Polym. Ed. 2018, 29, 863–893. [Google Scholar] [CrossRef]

- Zhuravlev, E.; Schmelzer, J.W.P.; Wunderlich, B.; Schick, C. Kinetics of nucleation and crystallization in poly(ε-caprolactone) (PCL). Polymer 2011, 52, 1983–1997. [Google Scholar] [CrossRef]

- Wurm, A.; Zhuravlev, E.; Eckstein, K.; Jehnichen, D.; Pospiech, D.; Androsch, R.; Wunderlich, B.; Schick, C. Crystallization and homogeneous nucleation kinetics of poly(ε-caprolactone) (PCL) with different molar masses. Macromolecules 2012, 45, 3816–3828. [Google Scholar] [CrossRef]

- Acierno, S.; Di Maio, E.; Iannace, S.; Grizzuti, N. Structure development during crystallization of polycaprolactone. Rheol. Acta 2006, 45, 387–392. [Google Scholar] [CrossRef]

- Di Maio, E.; Iannace, S.; Sorrentino, L.; Nicolais, L. Isothermal crystallization in PCL/clay nanocomposites investigated with thermal and rheometric methods. Polymer 2004, 45, 8893–8900. [Google Scholar] [CrossRef]

- Luduena, L.N.; Vazquez, A.; Alvarez, V.A. Crystallization of polycaprolactone–clay nanocomposites. J. Appl. Polym. Sci. 2008, 109, 3148–3156. [Google Scholar] [CrossRef]

- Lanfranconi, M.; Alvarez, V.A.; Luduena, L.N. Isothermal crystallization of polycaprolactone/modified clay biodegradable nanocomposites. J. Therm. Anal. Calorim. 2016, 126, 1273–1280. [Google Scholar] [CrossRef]

- Wu, T.M.; Chen, E.C. Isothermal and nonisothermal crystallization kinetics of poly(ε-caprolactone)/multi-walled carbon nanotube composites. Polym. Eng. Sci. 2006, 46, 1309–1317. [Google Scholar] [CrossRef]

- Chen, E.C.; Wu, T.M. Isothermal crystallization kinetics and thermal behavior of poly(ε-caprolactone)/multi-walled carbon nanotube composites. Polym. Degrad. Stab. 2007, 92, 1009–1015. [Google Scholar] [CrossRef]

- Zhuravlev, E.; Wurma, A.; Pötschke, P.; Androsch, R.; Schmelzer, J.W.P.; Schick, C. Kinetics of nucleation and crystallization of poly(ε-caprolactone)—Multiwalled carbon nanotube composites. Eur. Polym. J. 2014, 52, 1–11. [Google Scholar] [CrossRef]

- Zhao, T.H.; Yang, K.L.; Zeng, R.T.; Du, A.K.; Wang, M.; Zeng, J.B. Crystallization behavior of poly(sodium 4-styrenesulfonate)-functionalized carbon nanotubes filled poly(ε-caprolactone) nanocomposites. Ind. Eng. Chem. Res. 2016, 55, 1881–1889. [Google Scholar] [CrossRef]

- Lv, Q.; Wua, D.; Qiu, Y.; Chen, J.; Yao, X.; Ding, K.; Wei, N. Crystallization of poly(ε-caprolactone) composites with graphite nanoplatelets: Relations between nucleation and platelet thickness. Thermochim. Acta 2015, 612, 25–33. [Google Scholar] [CrossRef]

- Liu, H.; Huang, Y.; Yuan, L.; He, P.; Cai, Z.; Shen, Y.; Xu, Y.; Yu, Y.; Xiong, H. Isothermal crystallization kinetics of modified bamboo cellulose/PCL composites. Carbohydr. Polym. 2010, 79, 513–519. [Google Scholar] [CrossRef]

- Cai, J.; Xiong, Z.; Zhou, M.; Tan, J.; Zeng, F.; Ma, M.; Lin, S.; Xiong, H. Thermal properties and crystallization behavior of thermoplastic starch/poly(ε-caprolactone) composites. Carbohydr. Polym. 2014, 102, 746–754. [Google Scholar] [CrossRef] [PubMed]

- Lv, Q.; Xu, C.; Wua, D.; Wang, Z.; Lan, R.; Wu, L. The role of nanocrystalline cellulose during crystallization of poly(ε-caprolactone) composites: Nucleation agent or not? Compos. Part A 2017, 92, 17–26. [Google Scholar] [CrossRef]

- Mondal, K.; Bhagabati, P.; Goud, V.V.; Sakurai, S.; Katiyar, V. Utilization of microalgae residue and isolated cellulose nanocrystals: A study on crystallization kinetics of poly(ε-caprolactone) bio-composites. Int. J. Bio. Macromol. 2021, 191, 521–530. [Google Scholar] [CrossRef] [PubMed]

- Siqueira, D.D.; Luna, C.B.B.; Ferreira, E.S.B.; Araújo, E.M.; Wellen, R.M.R. Tailored PCL/Macaíba fiber to reach sustainable biocomposites. J. Mater. Res. Technol. 2020, 9, 9691–9708. [Google Scholar] [CrossRef]

- Pires, L.S.O.; Fernandes, M.H.F.V.; de Oliveira, J.M. Crystallization kinetics of PCL and PCL–glass composites for additive manufacturing. J. Therm. Anal. Calorim. 2018, 134, 2115–2125. [Google Scholar] [CrossRef]

- Amestoy, H.; Diego, P.; Meaurio, E.; Muñoz, J.; Sarasua, J.-R. Crystallization Behavior and Mechanical Properties of Poly(ε-caprolactone) Reinforced with Barium Sulfate Submicron Particles. Materials 2021, 14, 2368. [Google Scholar] [CrossRef]

- Liu, F.; Mao, C.; Wu, S.; Wang, B.; Wu, C.; Hu, T.; Gong, X. Preparation and characterization of poly(ε-caprolactone)/Fe3O4 nanocomposites. Polym. Cryst. 2021, 4, 10196. [Google Scholar]

- Sousa, J.C.; Costa, A.R.M.; Lima, J.C.; Arruda, S.A.; Almeida, Y.M.B.; Canedo, E.L. Polycaprolactone (PCL)/alumina and PCL/niobium pentoxide composites: Rheology, crystallization, and mechanical properties. Polym. Compos. 2020, 41, 1265–1276. [Google Scholar] [CrossRef]

- Lv, Q.; Ying, Z.; Wu, D.; Wang, Z.; Zhang, M. Nucleation role of basalt fibers during crystallization of poly(ε-caprolactone) composites. Ind. Eng. Chem. Res. 2017, 56, 2746–2753. [Google Scholar] [CrossRef]

- Terzopoulou, Z.; Papageorgiou, D.G.; Papageorgiou, G.Z.; Bikiaris, D.N. Effect of surface functionalization of halloysite nanotubes on synthesis and thermal properties of poly(ε-caprolactone). J. Mater. Sci. 2018, 53, 6519–6541. [Google Scholar] [CrossRef]

- Mutua, F.N.; Lin, P.; Koech, J.K.; Wang, Y. Surface modification of hollow glass microspheres. Mater. Sci. Appl. 2012, 3, 856–860. [Google Scholar] [CrossRef] [Green Version]

- Canetti, M.; Bertini, F. Crystalline and supermolecular structure evolution of poly(ethylene terephthalate) during isothermal crystallization and annealing treatment by means of wide and small angle X-ray investigations. Eur. Polym. J. 2010, 46, 270–276. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change I. General theory. J. Chem. Phys. 1939, 7, 1103–1112. [Google Scholar] [CrossRef]

- Skoglund, P.; Fransson, A. Continuous Cooling and Isothermal Crystallization of Polycaprolactone. J. Appl. Polym. Sci. 1996, 61, 2455–2465. [Google Scholar] [CrossRef]

- Mucha, M.; Tylman, M.; Mucha, J. Crystallization kinetics of polycaprolactone in nanocomposites. Polimery 2015, 60, 686–692. [Google Scholar] [CrossRef]

- Schäfer, H.; Reul, L.T.A.; Souza, F.M.; Wellen, R.M.R.; Carvalho, L.H.; Koschek, K.; Canedo, E.L. Crystallization behavior of polycaprolactone/babassu compounds. J. Therm. Anal. Calorim. 2021, 143, 2963–2972. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Lin, X. Preparation and characterization of hollow glass microsphere reinforced poly(butylene succinate) composites. Mater. Des. 2013, 46, 902–909. [Google Scholar] [CrossRef]

- Hongsriphan, N.; Borkaew, K.; Peson, U.; Pumpruck, W. Thermoplastic composites between polybutylene succinate and recycled PET adding hollow glass microspheres. Int. J. Plast. Technol. 2018, 22, 312–325. [Google Scholar] [CrossRef]

- Petchwattana, N.; Naknaen, P.; Narupai, B. Crystallization behavior, mechanical, morphological and physical properties of poly(butelene succinate)/hollow glass microsphere composites: Particle size and density effects observations. J. Chem. Technol. Metall. 2020, 55, 324–334. [Google Scholar]

- Liu, F.; Wu, X.-F.; Guo, M.-Q.; Yang, Z.-Q.; Fan, H.-N.; Lu, H.-R.; Xu, X.-H. Phase structure, thermal, and mechanical properties of polypropylene/hollow glass microsphere composites modified with maleated poly(ethylene-octene). J. Macromol. Sci. Part B 2012, 51, 1449–1462. [Google Scholar] [CrossRef]

- Gogoi, R.; Kumar, N.; Mireja, S.; Ravindranath, S.S.; Manik, G.; Sinha, S. Effect of hollow glass microspheres on the morphology, rheology and crystallinity of short bamboo fiber-reinforced hybrid polypropylene composite. JOM 2019, 71, 548–558. [Google Scholar] [CrossRef]

- Malinowski, R.; Janczak, K.; Rytlewski, P.; Raszkowska-Kaczor, A.; Moraczewski, K.; Zuk, T. Influence of glass microspheres on selected properties of polylactide composites. Compos. Part B 2015, 76, 13–19. [Google Scholar] [CrossRef]

- Dobreva, A.; Gutzow, I. Activity of substrates in the catalyzed nucleation of glass-forming melts. I. Theory. J. Non Cryst. Solids. 1993, 162, 1–12. [Google Scholar] [CrossRef]

- Dobreva, A.; Gutzow, I. Activity of substrates in the catalyzed nucleation of glass-forming melts. II. Experimental evidence. J. Non Cryst. Solids 1993, 162, 13–25. [Google Scholar] [CrossRef]

| Sample | PCL/Glass Microspheres (wt/wt) |

|---|---|

| PCL | 100/0 |

| PCL–HGM10 | 90/10 |

| PCL–HGM15 | 85/15 |

| PCL–HGM20 | 80/20 |

| PCL–HGM25 | 75/25 |

| PCL–HGMf10 | 90/10 |

| PCL–HGMf20 | 80/20 |

| Sample | Tc (°C) | |||||

|---|---|---|---|---|---|---|

| 42 | 43 | 44 | 45 | 46 | ||

| PCL | n | 3.8 | 3.4 | 3.5 | 3.7 | 3.4 |

| K (min−1) | 1.2 × 10−3 | 7.0 × 10−4 | 1.6 × 10−4 | 1.6 × 10−5 | 1.8 × 10−5 | |

| PCL–HGM10 | n | 3.9 | 3.9 | 3.8 | 3.8 | 3.9 |

| K (min−1) | 1.6 × 10−2 | 2.2 × 10−3 | 1.1 × 10−3 | 2.3 × 10−4 | 2.5 × 10−5 | |

| n’ | 2.3 | 2.2 | 2.3 | 2.3 | 2.5 | |

| K’ (min−1) | 9.6 × 10−2 | 3.7 × 10−2 | 1.9 × 10−2 | 6.5 × 10−3 | 5.3 × 10−4 | |

| PCL–HGM15 | n | 3.7 | 3.9 | 3.8 | 3.9 | 3.9 |

| K (min−1) | 2.6 × 10−2 | 5.1 × 10−3 | 1.5 × 10−3 | 1.9 × 10−4 | 5.8 × 10−5 | |

| n’ | 2.3 | 2.5 | 2.0 | 2.5 | 2.5 | |

| K’ (min−1) | 1.2 × 10−1 | 4.1 × 10−2 | 3.6 × 10−2 | 5.0 × 10−3 | 2.3 × 10−3 | |

| PCL–HGM20 | n | 3.3 | 3.6 | 3.8 | 3.8 | 3.9 |

| K (min−1) | 4.3 × 10−2 | 8.0 × 10−3 | 2.3 × 10−3 | 6.0 × 10−4 | 7.2 × 10−5 | |

| n’ | 1.8 | 2.1 | 2.4 | 2.4 | 2.4 | |

| K’ (min−1) | 1.9 × 10−1 | 7.0× 10−1 | 2.6 × 10−2 | 9.7 × 10−3 | 3.0 × 10−3 | |

| PCL–HGM25 | n | 3.7 | 3.7 | 3.9 | 3.8 | 3.7 |

| K (min−1) | 5.8 × 10−2 | 1.2 × 10−2 | 1.8 × 10−3 | 6.3 × 10−4 | 1.0 × 10−4 | |

| n’ | 1.7 | 2.2 | 2.1 | 2.6 | 2.2 | |

| K’ (min−1) | 2.6 × 10−1 | 7.8 × 10−2 | 3.6 × 10−2 | 6.9 × 10−3 | 4.5 × 10−3 | |

| PCL–HGMf10 | n | 3.4 | 3.7 | 3.9 | 3.8 | 3.7 |

| K (min−1) | 2.1 × 10−1 | 4.5 × 10−2 | 9.2 × 10−3 | 1.7 × 10−4 | 3.5 × 10−4 | |

| n’ | 1.6 | 1.8 | 2.4 | 2.5 | 2.2 | |

| K’ (min−1) | 5.7 × 10−1 | 2.6× 10−1 | 6.2 × 10−2 | 1.7 × 10−2 | 1.0 × 10−2 | |

| PCL–HGMf20 | n | 3.2 | 3.5 | 3.5 | 3.6 | 3.6 |

| K (min−1) | 4.7 × 10−1 | 8.5 × 10−2 | 1.9 × 10−2 | 4.4 × 10−3 | 8.7 × 10−4 | |

| n’ | 1.5 | 2.1 | 2.0 | 2.2 | 1.9 | |

| K’ (min−1) | 8.1 × 10−1 | 2.4× 10−1 | 1.1× 10−1 | 4.2 × 10−2 | 2.7 × 10−2 | |

| Sample | Xc | Lp (nm) | L (nm) | tc (nm) | E (nm) |

|---|---|---|---|---|---|

| PCL iso 46 °C | 0.36 | 15.8 | 14.6 | 5.5 | 0.3 |

| PCL–HGM20 iso 46 °C | 0.27 | 16.0 | 15.8 | 4.5 | 0.5 |

| PCL–HGMf20 iso 46 °C | 0.28 | 15.8 | 15.0 | 3.8 | 0.4 |

| PCL fast cooled | 0.32 | 14.0 | 13.0 | 4.4 | 0.3 |

| PCL–HGM20 fast cooled | 0.25 | 14.3 | 14.7 | 3.6 | 0.4 |

| PCL–HGMf20 fast cooled | 0.26 | 14.7 | 14.8 | 2.8 | 0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vignali, A.; Utzeri, R.; Canetti, M.; Bertini, F. Crystallization Behavior of Poly(ε-Caprolactone)-Hollow Glass Microspheres Composites for Rotational Molding Technology. Polymers 2022, 14, 4326. https://doi.org/10.3390/polym14204326

Vignali A, Utzeri R, Canetti M, Bertini F. Crystallization Behavior of Poly(ε-Caprolactone)-Hollow Glass Microspheres Composites for Rotational Molding Technology. Polymers. 2022; 14(20):4326. https://doi.org/10.3390/polym14204326

Chicago/Turabian StyleVignali, Adriano, Roberto Utzeri, Maurizio Canetti, and Fabio Bertini. 2022. "Crystallization Behavior of Poly(ε-Caprolactone)-Hollow Glass Microspheres Composites for Rotational Molding Technology" Polymers 14, no. 20: 4326. https://doi.org/10.3390/polym14204326

APA StyleVignali, A., Utzeri, R., Canetti, M., & Bertini, F. (2022). Crystallization Behavior of Poly(ε-Caprolactone)-Hollow Glass Microspheres Composites for Rotational Molding Technology. Polymers, 14(20), 4326. https://doi.org/10.3390/polym14204326