Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber

Abstract

:1. Introduction

2. Materials and Methods

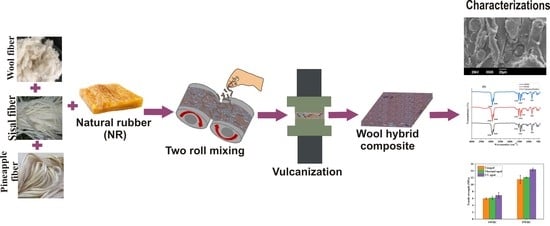

2.1. Preparation of the SWHC and PWHC

2.2. Analysis of the Physico-Mechanical Properties of the Composites

2.3. FTIR, SEM, TGA, and the Aging Analysis of the Composites

3. Results and Discussion

3.1. Cure Characteristics

3.2. Tensile and Tear Properties

3.3. Moisture Absorption and the Hardness Properties

3.4. FTIR Analysis

3.5. SEM Analysis

3.6. Thermogravimetric Analysis

3.7. Solvent Diffusion

3.8. Accelerated Thermal and UV Aging

3.9. Biodegradation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shekar, H.S.S.; Ramachandra, M. Green Composites: A Review. Mater. Today Proc. 2018, 5, 2518–2526. [Google Scholar] [CrossRef]

- Mitra, B.C. Environment Friendly Composite Materials: Biocomposites and Green Composites. Def. Sci. J. 2014, 64, 244–261. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-Friendly Bio-Composites Using Natural Rubber (NR) Matrices and Natural Fibre Reinforcements. Chem. Manuf. Appl. Nat. Rubber 2014, 249–283. [Google Scholar] [CrossRef]

- Li, Y.; Mai, Y.; Ye, L. Sisal Fibre and Its Composites: A Review of Recent Developments Im Pa Us As Do Me Us Ex On As. Compos. Sci. Technol. 2000, 60, 2037–2055. [Google Scholar]

- Jose, S.; Das, R.; Mustafa, I.; Karmakar, S.; Basu, G. Potentiality of Indian Pineapple Leaf Fibre for Apparels. J. Nat. Fibres 2019, 16, 536–544. [Google Scholar] [CrossRef]

- Salleh, S.; Majid, R.A.; Yahya, W.J.; Abd Kadir, H.; Chan AF, E.; Munthoub, D.I.; Rusman, R. Composite Paper from an Agricultural Waste of Bagasse Sugarcane and Pineapple Leaf Fibre: A Novel Random and Multilayer Hybrid Fibre Reinforced Composite Paper. Nord. Pulp Pap. Res. J. 2021, 36, 475–490. [Google Scholar] [CrossRef]

- Arib, R.M.N.; Sapuan, S.M.; Hamdan, M.A.M.M.; Paridah, M.T.; Zaman, H.M.D.K. A Literature Review of Pineapple Fibre Reinforced Polymer Composites. Polym. Polym. Compos. 2004, 12, 341–348. [Google Scholar] [CrossRef]

- Kumar, A.; Prince, L.L.; Jose, S. Sustainable Wool Production in India; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; ISBN 9780081020425. [Google Scholar]

- Conzatti, L.; Giunco, F.; Stagnaro, P.; Patrucco, A.; Tonin, C.; Marano, C.; Rink, M.; Marsano, E. Wool Fibres Functionalised with a Silane-Based Coupling Agent for Reinforced Polypropylene Composites. Compos. Part A Appl. Sci. Manuf. 2014, 61, 51–59. [Google Scholar] [CrossRef]

- Bharath, K.N.; Pasha, M.; Nizamuddin, B.A. Characterization of Natural Fibre (Sheep Wool)-Reinforced Polymer-Matrix Composites at Different Operating Conditions. J. Ind. Text. 2016, 45, 730–751. [Google Scholar] [CrossRef]

- Kim, N.K.; Lin, R.J.T.; Bhattacharyya, D. Effects of Wool Fibres, Ammonium Polyphosphate and Polymer Viscosity on the Flammability and Mechanical Performance of PP/Wool Composites. Polym. Degrad. Stab. 2015, 119, 167–177. [Google Scholar] [CrossRef]

- Sivasubramanian, P.; Mayandi, K.; Santulli, C.; Alavudeen, A.; Rajini, N. Effect of Fibre Length on Curing and Mechanical Behavior of Pineapple Leaf Fibre (PALF) Reinforced Natural Rubber Composites. J. Nat. Fibres 2020, 19, 4326–4337. [Google Scholar] [CrossRef]

- Abdel-Hakim, A.; El-Wakil, A.E.A.A.; El-Mogy, S.; Halim, S. Effect of Fibre Coating on the Mechanical Performance, Water Absorption and Biodegradability of Sisal Fibre/Natural Rubber Composite. Polym. Int. 2021, 70, 1356–1366. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical Properties Evaluation of Sisal Fibre Reinforced Polymer Composites: A Review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/Synthetic Fibre Reinforced Polymer Hybrid Composites: A Review. Carbohydr. Polym. 2011, 86, 1–18. [Google Scholar] [CrossRef]

- Siakeng, R.; Jawaid, M.; Asim, M.; Saba, N.; Sanjay, M.R.; Siengchin, S.; Fouad, H. Alkali Treated Coir/Pineapple Leaf Fibres Reinforced Pla Hybrid Composites: Evaluation of Mechanical, Morphological, Thermal and Physical Properties. Express Polym. Lett. 2020, 14, 717–730. [Google Scholar] [CrossRef]

- Veerasimman, A.; Shanmugam, V.; Rajendran, S.; Johnson, D.J.; Subbiah, A.; Koilpichai, J.; Marimuthu, U. Thermal Properties of Natural Fibre Sisal Based Hybrid Composites—A Brief Review. J. Nat. Fibres 2021, 19, 4696–4706. [Google Scholar] [CrossRef]

- Kaliyathan, A.V.; Rane, A.V.; Jackson, S.; Thomas, S. Analysis of Diffusion Characteristics for Aromatic Solvents through Carbon Black Filled Natural Rubber/ Butadiene Rubber Blends. Polym. Compos. 2021, 42, 375–396. [Google Scholar] [CrossRef]

- Yakubu, M.K.; Gumel, M.S.; Umar, A.; Metelerkamp, R. Physico-Mechanical Effects of Surface-Modified Sorgum Stalk Powder on Reinforced Rubber. J. Reinf. Plast. Compos. 2010, 29, 2855–2868. [Google Scholar] [CrossRef]

- Palanisamy, S.; Mayandi, K.; Palaniappan, M.; Alavudeen, A. Mechanical Properties of Phormium Tenax Reinforced Natural. Fibers 2021, 9, 11. [Google Scholar]

- Surya, I.; Khosman, H. The Compounds of Montmorillonite-Filled Natural Rubber: Cure Rate Index, Swelling and Hardness Properties. AIP Conf. Proc. 2020, 2237, 020076. [Google Scholar] [CrossRef]

- Jose, S.; Thomas, S.; Jibin, K.P.; Sisanth, K.S.; Kadam, V.; Shakyawar, D.B. Surface Modification of Wool Fabric Using Sodium Lignosulfonate and Subsequent Improvement in the Interfacial Adhesion of Natural Rubber Latex in the Wool/Rubber Composites. Ind. Crops Prod. 2022, 177, 114489. [Google Scholar] [CrossRef]

- John, M.J.; Varughese, K.T.; Thomas, S. Green Composites from Natural Fibres and Natural Rubber: Effect of Fibre Ratio on Mechanical and Swelling Characteristics. J. Nat. Fibres 2008, 5, 47–60. [Google Scholar] [CrossRef]

- Surya, I.; Sukeksi, L.; Hayeemasae, N. Studies on Cure Index, Swelling Behaviour, Tensile and Thermooxidative Properties of Natural Rubber Compounds in the Presence of Alkanolamide. IOP Conf. Ser. Mater. Sci. Eng. 2018, 309, 012060. [Google Scholar] [CrossRef]

- Setyadewi, N.M.; Indrajati, I.N.; Darmawan, N. Mechanical Properties and Curing Characteristics of Shape Memory Natural Rubber. IOP Conf. Ser. Mater. Sci. Eng. 2019, 541, 012012. [Google Scholar]

- Ismail, H.; Edyham, M.R.; Wirjosentono, B. Bamboo Fibre Filled Natural Rubber Composites: The Effects of Filler Loading and Bonding Agent. Polym. Test. 2002, 21, 139–144. [Google Scholar] [CrossRef]

- Aguele, F.O.; Madufor, C.I.; Adekunle, K.F. Comparative Study of Physical Properties of Polymer Composites Reinforced with Uncarbonised and Carbonised Coir. Open J. Polym. Chem. 2014, 4, 73–82. [Google Scholar] [CrossRef] [Green Version]

- Ouarhim, W.; Essabir, H.; Bensalah, M.O.; Rodrigue, D.; Bouhfid, R.; Qaiss, A. el kacem Hybrid Composites and Intra-Ply Hybrid Composites Based on Jute and Glass Fibres: A Comparative Study on Moisture Absorption and Mechanical Properties. Mater. Today Commun. 2020, 22, 100861. [Google Scholar] [CrossRef]

- Rani, S.; Kadam, V.; Rose, N.M.; Jose, S.; Yadav, S.; Shakyawar, D.B. Wheat Starch, Gum Arabic and Chitosan Biopolymer Treatment of Wool Fabric for Improved Shrink Resistance Finishing. Int. J. Biol. Macromol. 2020, 163, 1044–1052. [Google Scholar] [CrossRef]

- Rani, S.; Kadam, V.; Rose, N.M.; Jose, S.; Shakyawar, D.B.; Yadav, S. Effect of Enzyme Treatment on Wool Fabric Properties and Dimensional Stability. Indian J. Fibre Text. Res. 2021, 46, 83–90. [Google Scholar] [CrossRef]

- Jose, S.; Shanmugam, N.; Das, S.; Kumar, A.; Pandit, P. Coating of Lightweight Wool Fabric with Nano Clay for Fire Retardancy. J. Text. Inst. 2019, 110, 764–770. [Google Scholar] [CrossRef]

- Basu, G.; Mishra, L.; Jose, S.; Samanta, A.K. Accelerated Retting Cum Softening of Coconut Fibre. Ind. Crops Prod. 2015, 77, 66–73. [Google Scholar] [CrossRef]

- Hazarika, D.; Gogoi, N.; Jose, S.; Das, R.; Basu, G. Exploration of Future Prospects of Indian Pineapple Leaf, an Agro Waste for Textile Application. J. Clean. Prod. 2017, 141, 580–586. [Google Scholar] [CrossRef]

- Singh, G.; Jose, S.; Kaur, D.; Soun, B. Extraction and Characterization of Corn Leaf Fibre. J. Nat. Fibres 2022, 19, 1581–1591. [Google Scholar] [CrossRef]

- Zhou, F.; Cheng, G.; Jiang, B. Effect of Silane Treatment on Microstructure of Sisal Fibres. Appl. Surf. Sci. 2014, 292, 806–812. [Google Scholar] [CrossRef]

- Mohan, S. Vibrational Spectra of Cis-1, 4-Polyisoprene. Arab. J. Sci. Eng. 2015, 29, 17–26. [Google Scholar]

- Hu, C.; Zhou, Y.; Zhang, T.; Jiang, T.; Zeng, G. Effect of Fibre Modified by Alkali/Polyvinyl Alcohol Coating Treatment on Properties of Sisal Fibre Plastic Composites. J. Reinf. Plast. Compos. 2020, 39, 880–889. [Google Scholar] [CrossRef]

- Ahmed, A.; Qayoum, A. Investigation on the Thermal Degradation, Moisture Absorption Characteristics and Antibacterial Behavior of Natural Insulation Materials. Mater. Renew. Sustain. Energy 2021, 10, 4. [Google Scholar] [CrossRef]

- Forouharshad, M.; Montazer, M.; Moghadam, M.B.; Saligheh, O. Flame Retardant Wool Using Zirconium Oxychloride in Various Acidic Media Optimized by RSM. Thermochim. Acta 2011, 516, 29–34. [Google Scholar] [CrossRef]

- Davies, P.J.; Horrocks, A.R.; Miraftab, M. Scanning Electron Microscopic Studies of Wool/Intumescent Char Formation. Polym. Int. 2000, 49, 1125–1132. [Google Scholar] [CrossRef]

- Sircar, A.K.; Lamond, T.G. Identification of Elastomer Blends by Thermal Analysis. Thermochim. Acta 1973, 7, 287–292. [Google Scholar]

- Li, S.D.; Peng, Z.; Kong, L.X.; Zhong, J.P. Thermal Degradation Kinetics and Morphology of Natural Rubber/Silica Nanocomposites. J. Nanosci. Nanotechnol. 2006, 6, 541–546. [Google Scholar] [CrossRef]

- Obasi, H.C.; Arukalam, I.O.; Nwanonenyi, S.C.; Eze, I.O.; Chiemenem, L.I.; Nwosu-Obieogu, K.; Opara, H. Mechanical and Transport Properties of Natural Rubber Reinforced with Piassava (Raphia Hookeri) Fibre Composites. J. Mater. Environ. Sci. 2019, 10, 119–131. [Google Scholar]

- Wool, R.P. Properties of Triglyceride-Based Thermosets. Bio-Based Polym. Compos. 2005, 202–255. [Google Scholar] [CrossRef]

- Vinod, V.S.; Varghese, S.; Kuriakose, B. Degradation Behaviour of Natural Rubber-Aluminium Powder Composites: Effect of Heat, Ozone and High Energy Radiation. Polym. Degrad. Stab. 2002, 75, 405–412. [Google Scholar] [CrossRef]

- Gull, N.; Khan, S.M.; Islam, A.; Butt, M.T.Z.; Jamil, T. Modification of Polyaniline; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 9780128095515. [Google Scholar]

- Choi, S.S. Influence of Rubber Composition on Change of Crosslink Density of Rubber Vulcanizates with EV Cure System by Thermal Aging. J. Appl. Polym. Sci. 2000, 75, 1378–1384. [Google Scholar] [CrossRef]

- Ji, M.; Li, F.; Li, J.; Li, J.; Zhang, C.; Sun, K.; Guo, Z. Enhanced Mechanical Properties, Water Resistance, Thermal Stability, and Biodegradation of the Starch-Sisal Fi Bre Composites with Various Fi Llers. Mater. Des. 2021, 198, 109373. [Google Scholar] [CrossRef]

| Ingredients | SWHC (phr) | PWHC (phr) |

|---|---|---|

| Natural Rubber | 100 | 100 |

| Zinc Oxide | 5.0 | 5.0 |

| Stearic Acid | 2.5 | 2.5 |

| Wingstay L | 1.0 | 1.0 |

| CBS | 1.5 | 1.5 |

| Wool Fibre | 50 | 50 |

| Sisal Fibre | 50 | - |

| PALF | - | 50 |

| Sulphur | 2.5 | 2.5 |

| Sample Name | Maximum Torque (dNm) | Minimum Torque (dNm) | t90 (min) | ts2 (min) | Cure Rate Index (min−1) |

|---|---|---|---|---|---|

| SWHC | 38.36 | 0.76 | 5.12 | 2.29 | 35.34 |

| PWHC | 48.68 | 1.72 | 5.14 | 2.29 | 35.09 |

| Sample | Tensile Strength at Break (MPa) | Elongation at Break (%) | Young’s Modulus (MPa) | Tear Strength (N/mm) |

|---|---|---|---|---|

| SWHC | 6.09 (3.30) | 5.42 (8.85) | 169.3 (1.36) | 45.9 (6.48) |

| PWHC | 11.14 (7.08) | 4.49 (3.1) | 334 (3.00) | 85.0 (6.18) |

| Sample | Moisture Content (%) | Hardness (Shore A) | Areal Density (g/m²) | Relative Density (g/cm3) |

|---|---|---|---|---|

| PWHC | 5.90 | 91.56 | 2719.36 | 1.11 |

| SWHC | 6.57 | 91.30 | 2707.84 | 1.09 |

| Composite | Mc (g/mol) | Crosslink Density (g·mol/cc) |

|---|---|---|

| SWHC | 62,840.43 | 7.96 × 10−6 |

| PWHC | 65,247.92 | 7.66 ×10−6 |

| Sample | Weight Reduction (%) |

|---|---|

| SWHC | 2.43 (0.38) |

| PWHC | 2.34 (0.49) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jose, S.; Shanumon, P.S.; Paul, A.; Mathew, J.; Thomas, S. Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber. Polymers 2022, 14, 4882. https://doi.org/10.3390/polym14224882

Jose S, Shanumon PS, Paul A, Mathew J, Thomas S. Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber. Polymers. 2022; 14(22):4882. https://doi.org/10.3390/polym14224882

Chicago/Turabian StyleJose, Seiko, Puthenpurackal Shajimon Shanumon, Annmi Paul, Jessen Mathew, and Sabu Thomas. 2022. "Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber" Polymers 14, no. 22: 4882. https://doi.org/10.3390/polym14224882

APA StyleJose, S., Shanumon, P. S., Paul, A., Mathew, J., & Thomas, S. (2022). Physico-Mechanical, Thermal, Morphological, and Aging Characteristics of Green Hybrid Composites Prepared from Wool-Sisal and Wool-Palf with Natural Rubber. Polymers, 14(22), 4882. https://doi.org/10.3390/polym14224882