The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Characterization

2.3.1. Mechanical Properties

2.3.2. Thermal Properties

2.3.3. Dynamic Mechanical Thermal Analysis (DMTA)

2.3.4. Spectroscopic Analysis

2.3.5. Microscopic Characterization

2.3.6. Static Water Contact Angle Measurements

2.3.7. Disintegration under Composting Conditions

3. Results and Discussion

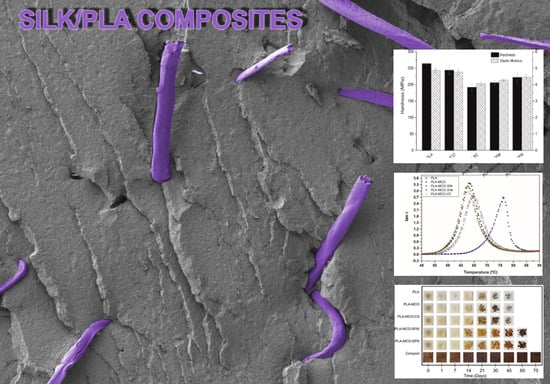

3.1. Mechanical Properties

3.2. Thermal Properties

3.3. Dynamic Mechanical Thermal Analysis (DMTA)

3.4. Spectroscopic Analysis

3.5. Microscopic Characterization

3.6. Water Contact Angle Measurements

3.7. Disintegration under Composting Conditions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, P.; Li, C.; Bai, Y.; Dong, S.; Xian, G.; Vedernikov, A.; Akhatov, I.; Safonov, A.; Yue, Q. Durability study on the interlaminar shear behavior of glass-fibre reinforced polypropylene (GFRPP) bars for marine applications. Constr. Build. Mater. 2022, 349, 128694. [Google Scholar] [CrossRef]

- Minchenkov, K.; Vedernikov, A.; Kuzminova, Y.; Gusev, S.; Sulimov, A.; Gulyaev, A.; Kreslavskaya, A.; Prosyanoy, I.; Xian, G.; Akhatov, I.; et al. Effects of the quality of pre-consolidated materials on the mechanical properties and morphology of thermoplastic pultruded flat laminates. Compos. Commun. 2022, 35, 101281. [Google Scholar] [CrossRef]

- Vedernikov, A.; Minchenkov, K.; Gusev, S.; Sulimov, A.; Zhou, P.; Li, C.; Xian, G.; Akhatov, I.; Safonov, A. Effects of the Pre-Consolidated Materials Manufacturing Method on the Mechanical Properties of Pultruded Thermoplastic Composites. Polymers 2022, 14, 2246. [Google Scholar] [CrossRef] [PubMed]

- Bioplastics Market Development Update 2021. European Bioplastics Association. Berlin, Germany. Available online: https://docs.european-bioplastics.org/publications/market_data/Report_Bioplastics_Market_Data_2021_short_version.pdf (accessed on 17 November 2022).

- Lomwongsopon, P.; Varrone, C. Contribution of Fermentation Technology to Building Blocks for Renewable Plastics. Fermentation 2022, 8, 47. [Google Scholar] [CrossRef]

- Luzi, F.; Dominici, F.; Armentano, I.; Fortunati, E.; Burgos, N.; Fiori, S.; Jiménez, A.; Kenny, J.M.; Torre, L. Combined effect of cellulose nanocrystals, carvacrol and oligomeric lactic acid in PLA_PHB polymeric films. Carbohydr. Polym. 2019, 223, 115131. [Google Scholar] [CrossRef]

- Balart, J.F.; Montanes, N.; Fombuena, V.; Boronat, T.; Sánchez-Nacher, L. Disintegration in Compost Conditions and Water Uptake of Green Composites from Poly(Lactic Acid) and Hazelnut Shell Flour. J. Polym. Environ. 2017, 26, 701–715. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Carbonell-Verdu, A.; Arrieta, M.P.; López-Martínez, J.; Samper, M. Improvement of PLA film ductility by plasticization with epoxidized karanja oil. Polym. Degrad. Stab. 2020, 179, 109259. [Google Scholar] [CrossRef]

- Ferri, J.M.; Samper, M.D.; García-Sanoguera, D.; Reig, M.J.; Fenollar, O.; Balart, R. Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly(lactic acid). J. Mater. Sci. 2016, 51, 5356–5366. [Google Scholar] [CrossRef]

- Borysiuk, P.; Boruszewski, P.; Auriga, R.; Danecki, L.; Auriga, A.; Rybak, K.; Nowacka, M. Influence of a bark-filler on the properties of PLA biocomposites. J. Mater. Sci. 2021, 56, 9196–9208. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; López, J. On the Use of PLA-PHB Blends for Sustainable Food Packaging Applications. Materials 2017, 10, 1008. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Su, S.; Kopitzky, R.; Tolga, S.; Kabasci, S. Polylactide (PLA) and Its Blends with Poly(butylene succinate) (PBS): A Brief Review. Polymers 2019, 11, 1193. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeng, J.-B.; Li, K.-A.; Du, A.-K. Compatibilization strategies in poly(lactic acid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Bocqué, M.; Voirin, C.; Lapinte, V.; Caillol, S.; Robin, J.-J. Petro-based and bio-based plasticizers: Chemical structures to plasticizing properties. J. Polym. Sci. Part A Polym. Chem. 2015, 54, 11–33. [Google Scholar] [CrossRef]

- Omar, A.A.; Hanafi, M.H.M.; Razak, N.H.; Ibrahim, A.; Razak, N.A.A. A Best-Evidence Review of Bio-Based Plasticizer and the Effects on the Mechanical Properties of PLA. Chem. Eng. Trans. 2021, 89, 241–246. [Google Scholar] [CrossRef]

- Beltrán, F.R.; Gaspar, G.; Chomachayi, M.D.; Jalali-Arani, A.; Lozano-Pérez, A.A.; Cenis, J.L.; de la Orden, M.U.; Pérez, E.; Urreaga, J.M.M. Influence of addition of organic fillers on the properties of mechanically recycled PLA. Environ. Sci. Pollut. Res. 2020, 28, 24291–24304. [Google Scholar] [CrossRef]

- Aworinde, A.K.; Adeosun, S.O.; Oyawale, F.A.; Akinlabi, E.T.; Akinlabi, S. Comparative effects of organic and inorganic bio-fillers on the hydrophobicity of polylactic acid. Results Eng. 2020, 5, 100098. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A.; Gulino, E.; Alaimo, G.; Morreale, M. Green Composites Based on PLA and Agricultural or Marine Waste Prepared by FDM. Polymers 2021, 13, 1361. [Google Scholar] [CrossRef]

- Al-Mulla, E.A.J.; Ibrahim, N.A.B.; Shameli, K.; Bin Ahmad, M.; Yunus, W.M.Z.W. Effect of epoxidized palm oil on the mechanical and morphological properties of a PLA–PCL blend. Res. Chem. Intermed. 2013, 40, 689–698. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly(lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Samper, M.D.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Balart, R. Plasticization effect of epoxidized cottonseed oil (ECSO) on poly(lactic acid). Ind. Crop. Prod. 2017, 104, 278–286. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polym. Int. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Thakur, S.; Cisneros-Lopez, E.O.; Pin, J.-M.; Misra, M.; Mohanty, A.K. Green Toughness Modifier from Downstream Corn Oil in Improving Poly(lactic acid) Performance. ACS Appl. Polym. Mater. 2019, 1, 3396–3406. [Google Scholar] [CrossRef]

- Payne, A.R. Effect of dispersion on the dynamic properties of filler-loaded rubbers. J. Appl. Polym. Sci. 1965, 9, 2273–2284. [Google Scholar] [CrossRef]

- Chomachayi, M.D.; Jalali-Arani, A.; Urreaga, J.M. A Comparison of the Effect of Silk Fibroin Nanoparticles and Microfibers on the Reprocessing and Biodegradability of PLA/PCL Blends. J. Polym. Environ. 2021, 29, 2585–2597. [Google Scholar] [CrossRef]

- Beltrán, F.; Arrieta, M.; Antón, D.E.; Lozano-Pérez, A.; Cenis, J.; Gaspar, G.; de la Orden, M.; Urreaga, J.M. Effect of Yerba Mate and Silk Fibroin Nanoparticles on the Migration Properties in Ethanolic Food Simulants and Composting Disintegrability of Recycled PLA Nanocomposites. Polymers 2021, 13, 1925. [Google Scholar] [CrossRef]

- Omenetto, F.G.; Kaplan, D.L. New Opportunities for an Ancient Material. Science 2010, 329, 528–531. [Google Scholar] [CrossRef] [Green Version]

- Rockwood, D.N.; Preda, R.C.; Yücel, T.; Wang, X.; Lovett, M.L.; Kaplan, D.L. Materials fabrication from Bombyx mori silk fibroin. Nat. Protoc. 2011, 6, 1612–1631. [Google Scholar] [CrossRef] [Green Version]

- Craig, C.L.; Riekel, C. Comparative architecture of silks, fibrous proteins and their encoding genes in insects and spiders. Comp. Biochem. Physiol. Part B Biochem. Mol. Biol. 2002, 133, 493–507. [Google Scholar] [CrossRef]

- Altman, G.H.; Diaz, F.; Jakuba, C.; Calabro, T.; Horan, R.L.; Chen, J.; Lu, H.; Richmond, J.; Kaplan, D.L. Silk-based biomaterials. Biomaterials 2003, 24, 401–416. [Google Scholar] [CrossRef]

- Perez-Nakai, A.; Lerma-Canto, A.; Domingez-Candela, I.; Garcia-Garcia, D.; Ferri, J.; Fombuena, V. Comparative Study of the Properties of Plasticized Polylactic Acid with Maleinized Hemp Seed Oil and a Novel Maleinized Brazil Nut Seed Oil. Polymers 2021, 13, 2376. [Google Scholar] [CrossRef] [PubMed]

- Sempere-Torregrosa, J.; Ferri, J.M.; de la Rosa-Ramírez, H.; Pavon, C.; Samper, M.D. Effect of Epoxidized and Maleinized Corn Oil on Properties of Polylactic Acid (PLA) and Polyhydroxybutyrate (PHB) Blend. Polymers 2022, 14, 4205. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez-Nogales, A.; Lozano-Pérez, A.; Aznar-Cervantes, S.; Algieri, F.; Garrido-Mesa, J.; Vezza, T.; Utrilla, M.; Cenis, J.; Rodríguez-Cabezas, M.; Gálvez, J. Effect of aqueous and particulate silk fibroin in a rat model of experimental colitis. Int. J. Pharm. 2016, 511, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Carissimi, G.; Lozano-Pérez, A.A.; Montalbán, M.G.; Aznar-Cervantes, S.D.; Cenis, J.L.; Víllora, G. Revealing the Influence of the Degumming Process in the Properties of Silk Fibroin Nanoparticles. Polymers 2019, 11, 2045. [Google Scholar] [CrossRef] [Green Version]

- Ajisawa, A. Dissolution of Silk Fibroin with Calcium Chloride/Ethanol Aqueous Solution. J. Sericultural Sci. Jpn. 1998, 67, 91–94. [Google Scholar] [CrossRef]

- ISO 527-1:2019; Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 179-1:2010; Plastics—Determination of Charpy Impact Properties Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2010.

- ISO 527-3:2018; Plastics—Determination of Tensile Properties—Test Conditions for Films and Sheets. International Organization for Standardization: Geneva, Switzerland, 2018.

- ISO 178:2011; International Standards Organization Plastics-Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 179-2:2020; Plastics—Determination of Charpy Impact Properties—Part 2: Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- ISO 20200:2015; International Organization for Standardization Plastics—Determination of the Degree of Disintegration of Plastic Materials under Simulated Composting Conditions in a Laboratory-Scale Test. International Organization for Standardization: Geneva, Switzerland, 2015.

- Arrieta, M.P.; Castro-Lopez, M.D.M.; Rayón, E.; Barral-Losada, L.F.; López-Vilariño, J.M.; López, J.; González-Rodríguez, M.V. Plasticized Poly(lactic acid)–Poly(hydroxybutyrate) (PLA–PHB) Blends Incorporated with Catechin Intended for Active Food-Packaging Applications. J. Agric. Food Chem. 2014, 62, 10170–10180. [Google Scholar] [CrossRef]

- Rayón, E.; Arrieta, M.; Pasíes, T.; López, J.; Jordá, J. Enhancing the mechanical features of clay surfaces by the absorption of nano-SiO2 particles in aqueous media. Case of study on Bronze Age clay objects. Cem. Concr. Compos. 2018, 93, 107–117. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sánchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, F.; Gough, C.R.; Hu, X. Tunable microphase-regulated silk fibroin/poly (lactic acid) biocomposite materials generated from ionic liquids. Int. J. Biol. Macromol. 2022, 197, 55–67. [Google Scholar] [CrossRef]

- Dominguez-Candela, I.; Ferri, J.M.; Cardona, S.C.; Lora, J.; Fombuena, V. Dual Plasticizer/Thermal Stabilizer Effect of Epoxidized Chia Seed Oil (Salvia hispanica L.) to Improve Ductility and Thermal Properties of Poly(Lactic Acid). Polymers 2021, 13, 1283. [Google Scholar] [CrossRef]

- Chen, X.; Han, L.; Zhang, T.; Zhang, J. Influence of crystal polymorphism on crystallinity calculation of poly(l-lactic acid) by infrared spectroscopy. Vib. Spectrosc. 2014, 70, 1–5. [Google Scholar] [CrossRef]

- Zhang, J.; Duan, Y.; Sato, H.; Tsuji, H.; Noda, I.; Yan, S.; Ozaki, Y. Crystal Modifications and Thermal Behavior of Poly(l-lactic acid) Revealed by Infrared Spectroscopy. Macromolecules 2005, 38, 8012–8021. [Google Scholar] [CrossRef]

- Phan, Q.T.; Le, M.H.; Le, T.T.H.; Tran, T.H.H.; Xuan, P.N.; Ha, P.T. Characteristics and cytotoxicity of folate-modified curcumin-loaded PLA-PEG micellar nano systems with various PLA:PEG ratios. Int. J. Pharm. 2016, 507, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Cele, H.; Ojijo, V.; Chen, H.; Kumar, S.; Land, K.; Joubert, T.; de Villiers, M.; Ray, S. Effect of nanoclay on optical properties of PLA/clay composite films. Polym. Test. 2014, 36, 24–31. [Google Scholar] [CrossRef]

- Breslauer, D.N.; Kaplan, D.L. Silks: Properties and uses of natural and designed variants. Biopolymers 2012, 97, 319–321. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. The Effects of Process Engineering on the Performance of PLA and PHBV Blends. Macromol. Mater. Eng. 2011, 296, 719–728. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, Y.; Ren, W.; Zhang, Y.; Lin, H. Morphology, mechanical and optical properties of transparent BR/clay nanocomposites. Polym. Test. 2005, 24, 766–774. [Google Scholar] [CrossRef]

- Sionkowska, A.; Planecka, A. The influence of UV radiation on silk fibroin. Polym. Degrad. Stab. 2011, 96, 523–528. [Google Scholar] [CrossRef]

- Cai, K.; Yao, K.; Lin, S.; Yang, Z.; Li, X.; Xie, H.; Qing, T.; Gao, L. Poly(d,l-lactic acid) surfaces modified by silk fibroin: Effects on the culture of osteoblast in vitro. Biomaterials 2001, 23, 1153–1160. [Google Scholar] [CrossRef]

- Cai, K.; Yao, K.; Cui, Y.; Yang, Z.; Li, X.; Xie, H.; Qing, T.; Gao, L. Influence of different surface modification treatments on poly(d,l-lactic acid) with silk fibroin and their effects on the culture of osteoblast in vitro. Biomaterials 2001, 23, 1603–1611. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P. Biodegradability and biodegradation of poly(lactide). Appl. Microbiol. Biotechnol. 2006, 72, 244–251. [Google Scholar] [CrossRef] [PubMed]

- Seves, A.; Romanò, M.; Maifreni, T.; Sora, S.; Ciferri, O. The microbial degradation of silk: A laboratory investigation. Int. Biodeterior. Biodegrad. 1998, 42, 203–211. [Google Scholar] [CrossRef]

- Szostak-Kotowa, J. Biodeterioration of textiles. Int. Biodeterior. Biodegrad. 2004, 53, 165–170. [Google Scholar] [CrossRef]

- Auras, R.; Lim, L.T.; Selke, S.E.M.; Tsuji, H. Poly(Lactic Acid); Auras, R., Lim, L.-T., Selke, S.E.M., Tsuji, H., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010; ISBN 9780470649848. [Google Scholar]

- Hu, X.; Kaplan, A.D.; Cebe, P. Determining Beta-Sheet Crystallinity in Fibrous Proteins by Thermal Analysis and Infrared Spectroscopy. Macromolecules 2006, 39, 6161–6170. [Google Scholar] [CrossRef]

- Arrieta, M.; Fortunati, E.; Dominici, F.; Rayón, E.; López, J.; Kenny, J. PLA-PHB/cellulose based films: Mechanical, barrier and disintegration properties. Polym. Degrad. Stab. 2014, 107, 139–149. [Google Scholar] [CrossRef]

- Fortunati, E.; Armentano, I.; Iannoni, A.; Barbale, M.; Zaccheo, S.; Scavone, M.; Visai, L.; Kenny, J.M. New multifunctional poly(lactide acid) composites: Mechanical, antibacterial, and degradation properties. J. Appl. Polym. Sci. 2011, 124, 87–98. [Google Scholar] [CrossRef]

- ISO 660:2009; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. International Standard Organization: Geneva, Switzerland, 2010.

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

| Code | PLA (wt.%) | MCO (wt.%) | CS (phr *) | SFM (phr) | SFN (phr) |

|---|---|---|---|---|---|

| PLA | 100 | - | - | - | - |

| PLA-MCO | 90 | 10 | - | - | - |

| PLA-MCO-CS | 90 | 10 | 0.5 | - | - |

| PLA-MCO-SFM | 90 | 10 | - | 0.5 | - |

| PLA-MCO-SFN | 90 | 10 | - | - | 0.5 |

| Formulation | Tensile Properties | Flexural Properties | Impact Resistance | ||

|---|---|---|---|---|---|

| Maximum Resistance (MPa) | Elongation at Break (%) | Maximum Resistance (MPa) | Flexural Modulus (MPa) | Charpy’s Impact Energy (kJ·m2) | |

| PLA | 62.4 ± 1.5 a | 1.7 ± 0.9 a | 102.3 ± 3.6 a | 2609 ± 119 a | 29.5 ± 5.5 a,b,c |

| PLA-MCO | 54.7 ± 1.3 b | 6.1 ± 2.1 a,c | 99.5 ± 2.3 a | 2314 ± 251 a | 26.4 ± 2.5 a,b,c |

| PLA-MCO-CS | 47.5 ± 1.8 c | 23.7 ± 4.7 b | 85.2 ± 2.8 b | 2652 ±206 a | 31.8 ± 5.6 b |

| PLA-MCO-SFM | 48.6 ± 2.6 c | 8.8 ± 1.8 c | 86.6 ± 3.1 b | 2536 ± 98 a | 31.3 ± 6.8 a,b,c |

| PLA-MCO-SFN | 52.0 ± 0.9 b | 10.8 ± 2.5 c | 84.9 ± 3.1 b | 2649 ± 147 a | 22.6 ± 4.3 c |

| DSC 1st Heating | TGA | |||||||

|---|---|---|---|---|---|---|---|---|

| Formulation | Tg (°C) | Tcc (°C) | ΔHcc (J·g−1) | Tm (°C) | ΔHm (J·g−1) | Xc (%) | T5% (°C) | Tmax (°C) |

| PLA | 62.4 | 110.1 | 23.1 | 148.4 | 23.6 | 0.6 | 305.0 | 339.6 |

| PLA-MCO | 62.3 | 106.0 | 17.1 | 152.0 | 18.5 | 1.7 | 326.3 | 358.3 |

| PLA-MCO-CS | 60.8 | 103.9 | 19.5 | 150.7 | 20.8 | 1.5 | 324.5 | 361.0 |

| PLA-MCO-SFM | 60.9 | 103.5 | 21.0 | 152.4 | 24.3 | 3.9 | 323.0 | 362.1 |

| PLA-MCO-SFN | 60.7 | 106.3 | 20.9 | 150.2 | 23.0 | 2.5 | 322.0 | 361.0 |

| Sample | PLA | PLA-MCO | PLA-MCO-CS | PLA-MCO-SFM | PLA-MCO-SFN |

|---|---|---|---|---|---|

| θC (°) | 75.0 ± 2.8 a | 82.6 ± 1.1 b | 81.6 ± 3.1 b | 68.7 ± 3.1 c | 84.0 ± 2.4 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferri, J.M.; Aldas, M.; Rayon, E.; Samper, M.D.; Lozano-Pérez, A.A. The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites. Polymers 2022, 14, 5016. https://doi.org/10.3390/polym14225016

Ferri JM, Aldas M, Rayon E, Samper MD, Lozano-Pérez AA. The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites. Polymers. 2022; 14(22):5016. https://doi.org/10.3390/polym14225016

Chicago/Turabian StyleFerri, José Miguel, Miguel Aldas, Emilio Rayon, Maria Dolores Samper, and Antonio Abel Lozano-Pérez. 2022. "The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites" Polymers 14, no. 22: 5016. https://doi.org/10.3390/polym14225016

APA StyleFerri, J. M., Aldas, M., Rayon, E., Samper, M. D., & Lozano-Pérez, A. A. (2022). The Influence of Different Sustainable Silk-Based Fillers on the Thermal and Mechanical Properties of Polylactic Acid Composites. Polymers, 14(22), 5016. https://doi.org/10.3390/polym14225016