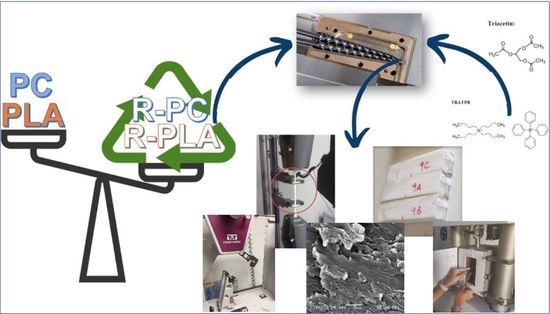

Upcycling of Poly(Lactic Acid) by Reactive Extrusion with Recycled Polycarbonate: Morphological and Mechanical Properties of Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Processing

2.3. Testing Methodologies

3. Results

3.1. Comparison PLA/R-PLA and PC/R-PC

3.1.1. Torque Analysis

3.1.2. Mechanical Properties

3.2. Blend Characterizations

3.2.1. Torque Analysis

3.2.2. Morphological Structure and the Mechanical Results

3.2.3. DMTA Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Muñoz Meneses, R.A.; Cabrera-Papamija, G.; Machuca-Martínez, F.; Rodríguez, L.A.; Diosa, J.E.; Mosquera-Vargas, E. Plastic recycling and their use as raw material for the synthesis of carbonaceous materials. Heliyon 2022, 8, e09028. [Google Scholar] [CrossRef]

- Mazur-Wierzbicka, E. Circular economy: Advancement of European Union countries. Environ. Sci. Eur. 2021, 33, 111. [Google Scholar] [CrossRef]

- Kumar, R.; Verma, A.; Shome, A.; Sinha, R.; Sinha, S.; Jha, P.K.; Kumar, R.; Kumar, P.; Shubham; Das, S.; et al. Impacts of Plastic Pollution on Ecosystem Services, Sustainable Development Goals, and Need to Focus on Circular Economy and Policy Interventions. Sustainability 2021, 13, 9963. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naser, A.Z.; Deiab, I.; Defersha, F.; Yang, S. Expanding Poly(lactic acid) (PLA) and Polyhydroxyalkanoates (PHAs) Applications: A Review on Modifications and Effects. Polymers 2021, 13, 4271. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Zhang, L.; Xiong, Z.; Tang, Z.; Zhang, R.; Zhu, J. Research progress in the heat resistance, toughening and filling modification of PLA. Sci. China Chem. 2016, 59, 1355–1368. [Google Scholar] [CrossRef]

- Zhao, X.; Hu, H.; Wang, X.; Yu, X.; Zhou, W.; Peng, S. Super tough poly(lactic acid) blends: A comprehensive review. RSC Adv. 2020, 10, 13316–13368. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, H.; Zhang, J. Research progress in toughening modification of poly(lactic acid). J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1051–1083. [Google Scholar] [CrossRef]

- Lin, L.; Deng, C.; Wang, Y. Improving the impact property and heat-resistance of PLA/PC blends through coupling molecular chains at the interface. Polym. Adv. Technol. 2015, 26, 1247–1258. [Google Scholar] [CrossRef]

- Yuryev, Y.; Mohanty, A.K.; Misra, M. Novel biocomposites from biobased PC/PLA blend matrix system for durable applications. Compos. Part B Eng. 2017, 130, 158–166. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misra, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Zeng, J.-B.; Li, K.-A.; Du, A.-K. Compatibilization strategies in poly(lactic acid)-based blends. RSC Adv. 2015, 5, 32546–32565. [Google Scholar] [CrossRef]

- Srithep, Y.; Rungseesantivanon, W.; Hararak, B.; Suchiva, K. Processing and characterization of poly(lactic acid) blended with polycarbonate and chain extender. J. Polym. Eng. 2014, 34, 665–672. [Google Scholar] [CrossRef]

- Wang, Y.; Chiao, S.M.; Lai, M.-T.; Yang, S.-Y. The role of polycarbonate molecular weight in the poly(L-lactide) blends compatibilized with poly(butylene succinate-co-L-lactate). Polym. Eng. Sci. 2013, 53, 1171–1180. [Google Scholar] [CrossRef]

- Chen, Y.; Zeng, G.S.; Jiang, P.; Lu, W.; Huang, W.L. Study on the Thermal and Rheological Properties of Reactive Blending PC/PLA/EVA Blends. Appl. Mech. Mater. 2011, 79, 282–287. [Google Scholar] [CrossRef]

- Ikehara, T.; Nishikawa, Y.; Nishi, T. Evidence for the formation of interpenetrated spherulites in poly(butylene succinate-co-butylene carbonate)/poly(l-lactic acid) blends investigated by atomic force microscopy. Polymer 2003, 44, 6657–6661. [Google Scholar] [CrossRef]

- Wang, Y.; Chiao, S.M.; Hung, T.-F.; Yang, S.-Y. Improvement in toughness and heat resistance of poly(lactic acid)/polycarbonate blend through twin-screw blending: Influence of compatibilizer type. J. Appl. Polym. Sci. 2012, 125, E402–E412. [Google Scholar] [CrossRef]

- Liu, C.; Lin, S.; Zhou, C.; Yu, W. Influence of catalyst on transesterification between poly(lactic acid) and polycarbonate under flow field. Polymer 2013, 54, 310–319. [Google Scholar] [CrossRef]

- Tripathi, N.; Misra, M.; Mohanty, A.K. Durable Polylactic Acid (PLA)-Based Sustainable Engineered Blends and Biocomposites: Recent Developments, Challenges, and Opportunities. ACS Eng. Au 2021, 1, 7–38. [Google Scholar] [CrossRef]

- Pompe, G.; Häußler, L. Investigations of transesterification in PC/PBT melt blends and the proof of immiscibility of PC and PBT at completely suppressed transesterification. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2161–2168. [Google Scholar] [CrossRef]

- Ignatov, V.N.; Carraro, C.; Tartari, V.; Pippa, R.; Scapin, M.; Pilati, F.; Berti, C.; Toselli, M.; Fiorini, M. PET/PC blends and copolymers by one-step extrusion: 2. Influence of the initial polymer composition and type of catalyst. Polymer 1997, 38, 201–205. [Google Scholar] [CrossRef]

- Phuong, V.T.; Coltelli, M.-B.B.; Cinelli, P.; Cifelli, M.; Verstichel, S.; Lazzeri, A. Compatibilization and property enhancement of poly(lactic acid)/polycarbonate blends through triacetin-mediated interchange reactions in the melt. Polymer 2014, 55, 4498–4513. [Google Scholar] [CrossRef]

- Phuong, V.T.; Gigante, V.; Aliotta, L.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Reactively extruded ecocomposites based on poly(lactic acid)/bisphenol A polycarbonate blends reinforced with regenerated cellulose microfibers. Compos. Sci. Technol. 2017, 139, 127–137. [Google Scholar] [CrossRef]

- Aryan, V.; Maga, D.; Majgaonkar, P.; Hanich, R. Valorisation of polylactic acid (PLA) waste: A comparative life cycle assessment of various solvent-based chemical recycling technologies. Resour. Conserv. Recycl. 2021, 172, 105670. [Google Scholar] [CrossRef]

- Yarahmadi, N.; Jakubowicz, I.; Enebro, J. Polylactic acid and its blends with petroleum-based resins: Effects of reprocessing and recycling on properties. J. Appl. Polym. Sci. 2016, 133, 43196. [Google Scholar] [CrossRef]

- Freeland, B.; McCarthy, E.; Balakrishnan, R.; Fahy, S.; Boland, A.; Rochfort, K.D.; Dabros, M.; Marti, R.; Kelleher, S.M.; Gaughran, J. A Review of Polylactic Acid as a Replacement Material for Single-Use Laboratory Components. Materials 2022, 15, 2989. [Google Scholar] [CrossRef]

- Penco, M.; Lazzeri, A.; Phuong, V.T.; Cinelli, P. Copolymers Based on Polyester and Aromatic Polycarbonate. U.S. Patent 20140128540A1, 8 May 2014. [Google Scholar]

- Tejada-Oliveros, R.; Gomez-Caturla, J.; Sanchez-Nacher, L.; Montanes, N.; Quiles-Carrillo, L. Improved Toughness of Polylactide by Binary Blends with Polycarbonate with Glycidyl and Maleic Anhydride-Based Compatibilizers. Macromol. Mater. Eng. 2021, 306, 2100480. [Google Scholar] [CrossRef]

- Guessoum, M.; Chelghoum, N.; Haddaoui, N. Reactive Compatibilization of Poly(lactic acid) and Polycarbonate Blends Through Catalytic Transesterification Reactions. Int. J. Comput. Exp. Sci. Eng. 2019, 5, 65–68. [Google Scholar] [CrossRef] [Green Version]

- You, W.; Yu, W. Control of the dispersed-to-continuous transition in polymer blends by viscoelastic asymmetry. Polymer 2018, 134, 254–262. [Google Scholar] [CrossRef]

- Santi, C.R.; Hage, E.; Correa, C.A.; Vlachopoulos, J. Torque viscometry of molten polymers and composites. Appl. Rheol. 2009, 19, 13148. [Google Scholar] [CrossRef]

- Chiu, H.T.; Huang, J.K.; Kuo, M.T.; Huang, J.H. Characterisation of PC/ABS blend during 20 reprocessing cycles and subsequent functionality recovery by virgin additives. J. Polym. Res. 2018, 25, 124. [Google Scholar] [CrossRef]

- Abbås, K.B. Thermal degradation of bisphenol A polycarbonate. Polymer 1980, 21, 936–940. [Google Scholar] [CrossRef]

- Abbås, K.B. Degradational effects on bisphenol A polycarbonate extruded at high shear stresses. Polymer 1981, 22, 836–841. [Google Scholar] [CrossRef]

- Cuadri, A.A.; Martín-Alfonso, J.E. Thermal, thermo-oxidative and thermomechanical degradation of PLA: A comparative study based on rheological, chemical and thermal properties. Polym. Degrad. Stab. 2018, 150, 37–45. [Google Scholar] [CrossRef]

- Khademi, S.M.H.; Hemmati, F.; Aroon, M.A. An insight into different phenomena involved in continuous extrusion foaming of biodegradable poly(lactic acid)/expanded graphite nanocomposites. Int. J. Biol. Macromol. 2020, 157, 470–483. [Google Scholar] [CrossRef]

- Polidar, M.; Metzsch-Zilligen, E.; Pfaendner, R. Controlled and Accelerated Hydrolysis of Polylactide (PLA) through Pentaerythritol Phosphites with Acid Scavengers. Polymers 2022, 14, 4237. [Google Scholar] [CrossRef] [PubMed]

- Signori, F.; Coltelli, M.-B.; Bronco, S. Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym. Degrad. Stab. 2009, 94, 74–82. [Google Scholar] [CrossRef]

- Coltelli, M.-B.; Mallegni, N.; Rizzo, S.; Cinelli, P.; Lazzeri, A. Improved Impact Properties in Poly(lactic acid) (PLA) Blends Containing Cellulose Acetate (CA) Prepared by Reactive Extrusion. Materials 2019, 12, 270. [Google Scholar] [CrossRef] [Green Version]

- Coltelli, M.-B.; Toncelli, C.; Ciardelli, F.; Bronco, S. Compatible blends of biorelated polyesters through catalytic transesterification in the melt. Polym. Degrad. Stab. 2011, 96, 982–990. [Google Scholar] [CrossRef]

- Pérez, J.M.; Vilas, J.L.; Laza, J.M.; Arnáiz, S.; Mijangos, F.; Bilbao, E.; Rodríguez, M.; León, L.M. Effect of reprocessing and accelerated ageing on thermal and mechanical polycarbonate properties. J. Mater. Process. Technol. 2010, 210, 727–733. [Google Scholar] [CrossRef]

- Reich, M.J.; Woern, A.L.; Tanikella, N.G.; Pearce, J.M. Mechanical Properties and Applications of Recycled Polycarbonate Particle Material Extrusion-Based Additive Manufacturing. Materials 2019, 12, 1642. [Google Scholar] [CrossRef] [Green Version]

- Agüero, A.; Morcillo, M.d.C.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Lascano, D.; Torres-Giner, S.; Fenollar, O. Study of the Influence of the Reprocessing Cycles on the Final Properties of Polylactide Pieces Obtained by Injection Molding. Polymers 2019, 11, 1908. [Google Scholar] [CrossRef] [Green Version]

- Bi, F.-L.; Xi, Z.-H.; Zhao, L. Reaction Mechanisms and Kinetics of the Melt Transesterification of Bisphenol-A and Diphenyl Carbonate. Int. J. Chem. Kinet. 2018, 50, 188–203. [Google Scholar] [CrossRef]

- Sadiku-Agboola, O.; Sadiku, E.R.; Adegbola, A.T.; Biotidara, O.F. Rheological Properties of Polymers: Structure and Morphology of Molten Polymer Blends. Mater. Sci. Appl. 2011, 02, 30–41. [Google Scholar] [CrossRef] [Green Version]

- Willemse, R.C.; Posthuma de Boer, A.; van Dam, J.; Gotsis, A.D. Co-continuous morphologies in polymer blends: The influence of the interfacial tension. Polymer 1999, 40, 827–834. [Google Scholar] [CrossRef]

- Pötschke, P.; Paul, D.R. Formation of Co-continuous Structures in Melt-Mixed Immiscible Polymer Blends. J. Macromol. Sci. Part C 2003, 43, 87–141. [Google Scholar] [CrossRef]

- Yeo, L.Y.; Matar, O.K.; de Ortiz, E.S.P.; Hewitt, G.F. Phase Inversion and associated phenomena. Multiph. Sci. Technol. 2000, 12, 66. [Google Scholar] [CrossRef]

- Avgeropoulos, G.N.; Weissert, F.C.; Biddison, P.H.; Böhm, G.G.A. Heterogeneous Blends of Polymers. Rheology and Morphology. Rubber Chem. Technol. 1976, 49, 93–104. [Google Scholar] [CrossRef]

- Veenstra, H.; Verkooijen, P.C.J.; van Lent, B.J.J.; van Dam, J.; de Boer, A.P.; Nijhof, A.P.H.J. On the mechanical properties of co-continuous polymer blends: Experimental and modelling. Polymer 2000, 41, 1817–1826. [Google Scholar] [CrossRef]

- Gigante, V.; Canesi, I.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rubber toughening of Polylactic acid (PLA) with Poly(butylene adipate-co- terephthalate) (PBAT): Mechanical properties, fracture mechanics and analysis of brittle—Ductile behavior while varying temperature and test speed. Eur. Polym. J. 2019, 115, 125–137. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Acucella, O.; Signori, F.; Lazzeri, A. Thermal, mechanical and micromechanical analysis of PLA/PBAT/POE-g-GMA extruded ternary blends. Front. Mater. 2020, 7, 130. [Google Scholar] [CrossRef]

| Blend Name | PLA (wt. %) | PC (wt. %) | R-PLA (wt. %) | R-PC (wt. %) | TA (wt. %) | TBATPB (wt. %) |

|---|---|---|---|---|---|---|

| PLA | 100 | - | - | - | - | - |

| PC | - | 100 | - | - | - | - |

| R-PLA | - | - | 100 | - | - | - |

| R-PC | - | - | - | 100 | - | - |

| R-PLA60/R-PC40 | - | - | 60 | 40 | - | - |

| R-PLA60/R-PC40 + CATA | - | - | 56.8 | 38 | 5 | 0.2 |

| R-PLA40/R-PC60 | - | - | 40 | 60 | - | - |

| R-PLA40/R-PC60 + CATA | - | - | 38 | 56.8 | 5 | 0.2 |

| Polymer | Elastic Modulus (GPa) | Yield Stress (MPa) | Stress at Break (MPa) | Elongation at Break (%) | Charpy Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| PLA | 3.5 ± 0.3 | - | 67.3 ± 3.5 | 2.5 ± 0.4 | 2.9 ± 0.2 |

| R-PLA | 3.6 ± 0.2 | - | 65.1 ± 3.2 | 3.0 ± 0.6 | 2.7 ± 0.3 |

| PC | 2.2 ± 0.1 | 67.1 ± 0.8 | 63.1 ± 3.8 | 60.6 ± 3.2 | 10.9 ± 0.2 |

| R-PC | 2.3 ± 0.2 | 65.7 ± 1.6 | 54.8 ± 3.9 | 55.7 ± 4.5 | 9.4 ± 0.5 |

| Blend | Elastic Modulus (GPa) | Yield Stress (MPa) | Stress at Break (MPa) | Elongation at Break (%) | Charpy Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| R-PLA60/R-PC40 | 2.7 ± 0.4 | 61.1 ± 1.1 | 57.2 ± 2.0 | 63.9 ± 8.7 | 7.5 ± 1.9 |

| R-PLA60/R-PC40 + CATA | 3.0 ± 0.2 | - | 60.1 ± 0.7 | 4.0 ± 0.6 | 6.3 ± 0.2 |

| R-PLA40/R-PC60 | 3.2 ± 0.3 | - | 63.6 ± 2.8 | 3.5 ± 0.2 | 5.6 ± 0.8 |

| R-PLA40/R-PC60 + CATA | 3.4 ± 0.3 | 61.7 ± 1.5 | 66.4 ± 3.5 | 72.4 ± 9.5 | 4.6 ± 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gigante, V.; Aliotta, L.; Coltelli, M.-B.; Lazzeri, A. Upcycling of Poly(Lactic Acid) by Reactive Extrusion with Recycled Polycarbonate: Morphological and Mechanical Properties of Blends. Polymers 2022, 14, 5058. https://doi.org/10.3390/polym14235058

Gigante V, Aliotta L, Coltelli M-B, Lazzeri A. Upcycling of Poly(Lactic Acid) by Reactive Extrusion with Recycled Polycarbonate: Morphological and Mechanical Properties of Blends. Polymers. 2022; 14(23):5058. https://doi.org/10.3390/polym14235058

Chicago/Turabian StyleGigante, Vito, Laura Aliotta, Maria-Beatrice Coltelli, and Andrea Lazzeri. 2022. "Upcycling of Poly(Lactic Acid) by Reactive Extrusion with Recycled Polycarbonate: Morphological and Mechanical Properties of Blends" Polymers 14, no. 23: 5058. https://doi.org/10.3390/polym14235058

APA StyleGigante, V., Aliotta, L., Coltelli, M. -B., & Lazzeri, A. (2022). Upcycling of Poly(Lactic Acid) by Reactive Extrusion with Recycled Polycarbonate: Morphological and Mechanical Properties of Blends. Polymers, 14(23), 5058. https://doi.org/10.3390/polym14235058