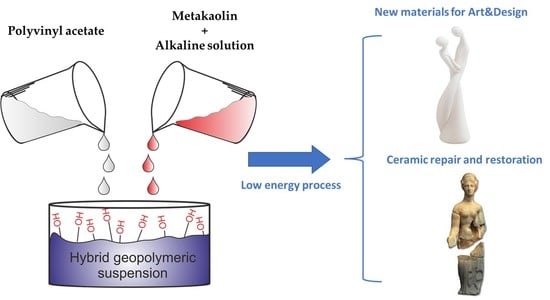

Sustainable Materials Based on Geopolymer–Polyvinyl Acetate Composites for Art and Design Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples’ Preparation

2.2.1. Neat Geopolymer (MK)

2.2.2. Geopolymer Composites’ (MK-PVAc-5; MK-PVAc-10; MK-PDMS-5 and MK-PDMS-10) Preparation

2.2.3. Curing Treatments

2.3. Sample Characterization

2.3.1. Thermogravimetric Analysis

2.3.2. X-ray Diffraction Characterization

2.3.3. Morphological Characterization

2.3.4. Physical and Mechanical Properties

3. Results and Discussion

3.1. Thermogravimetric Analysis

3.2. X-ray Diffraction Characterization

3.3. Morphological Characterization

3.4. Physical and Mechanical Properties

3.5. Applications in the Field of the Creative Industry and Cultural Heritage

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ozga, I.; Ghedini, N.; Giosuè, C.; Sabbioni, C.; Tittarelli, F.; Bonazza, A. Assessment of air pollutant sources in the deposit on monuments by multivariate analysis. Sci. Total Environ. 2014, 490, 776–784. [Google Scholar] [CrossRef] [PubMed]

- Hanzlícek, T.; Steinerová, M.; Straka, P.; Perná, I.; Siegl, P.; Švarcová, T. Reinforcement of the terracotta sculpture by geopolymer composite. Mater. Des. 2009, 30, 3229–3234. [Google Scholar] [CrossRef]

- Occhipinti, R.; Stroscio, A.; Finocchiaro, C.; Fugazzotto, M.; Leonelli, C.; José Lo Faro, M.; Megna, B.; Barone, G.; Mazzoleni, P. Alkali activated materials using pumice from the Aeolian Islands (Sicily, Italy) and their potentiality for cultural heritage applications: Preliminary study. Constr. Build. Mater. 2020, 259, 120391. [Google Scholar] [CrossRef]

- Eken, E.; Tascı, B.; Gustafsson, C. An evaluation of decision-making process on maintenance of built cultural heritage: The case of Visby, Sweden. Cities 2019, 94, 24–32. [Google Scholar] [CrossRef]

- Morkunaite, Z.; Podvezko, V.; Zavadskas, E.K.; Bausys, R. Contractor selection for renovation of cultural heritage buildings by PROMETHEE metho. Arch. Civ. Mech. Eng. 2019, 19, 1056–1071. [Google Scholar] [CrossRef]

- Ielo, I.; Galletta, M.; Rando, G.; Sfameni, S.; Cardiano, P.; Sabatino, G.; Drommi, D.; Rosace, G.; Plutino, M. Design, synthesis and characterization of hybrid coatings suitable for geopolymeric-based supports for the restoration of cultural heritage. In IOP Conference Series: Materials Science and Engineering; Functional Materials for Cultural Heritage (Fun4Heritage); IOP Publishing: Matera, Italy, 2019. [Google Scholar]

- Valluzzi, M.R.; Modena, C.; de Felice, G. Current practice and open issues in strengthen-ing historical buildings with composites. Mater. Struct. 2014, 47, 1971–1985. [Google Scholar] [CrossRef]

- Castillo, H.; Collado, H.; Droguett, T.; Vesely, M.; Garrido, P.; Palma, S. State of the art of geopolymers: A review. e-Polymers 2022, 22, 108–124. [Google Scholar] [CrossRef]

- Provis, J.L. Green concrete or red herring?—future of alkali-activated materials. Adv. Appl. Ceram. 2014, 113, 472–477. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers: Ceramic-like inorganic polymers. J. Ceram. Sci. Technol. 2017, 8, 335–350. [Google Scholar]

- Jihui, Z. Eco-friendly geopolymer materials: A review of performance improvement, potential application and sustainability assessment. J. Clean. Prod. 2021, 307, 127085. [Google Scholar]

- Roviello, G.; Chianese, E.; Ferone, C.; Ricciotti, L.; Roviello, V.; Cioffi, R.; Tarallo, O. Hybrid geopolymeric foams for the removal of metallic ions from aqueous waste solutions. Materials 2019, 12, 4091. [Google Scholar] [CrossRef] [PubMed]

- Geraldes, C.F.M.; Lima, A.M.; Delgado-Rodrigues, J.; Mimoso, J.M.; Pereira, S.R.M. Geopolymers as potential repair material in tiles conservation. Appl. Phys. A 2016, 122, 197. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 3rd ed.; Institut-Géopolymér: Saint-Quentin, France, 2008. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Institut Geopolymère: Saint-Quentin, France, 2020. [Google Scholar]

- Ricciotti, L.; Occhicone, A.; Ferone, C.; Cioffi, R.; Tarallo, O.; Roviello, G. Development of Geopolymer-Based Materials with Ceramic Waste for Artistic and Restoration Applications. Materials 2022, 15, 8600. [Google Scholar] [CrossRef] [PubMed]

- Dal Pozzo, A.; Carabba, L.; Bignozzi, M.C.; Tugnoli, A. Life cycle assessment of a geopolymer mixture for fireproofing applications. Int. J. Life Cycle Assess 2019, 48, 1743–1757. [Google Scholar] [CrossRef]

- Provis, J.L.; Duxson, P.; van Deventer, J.S.J. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7. [Google Scholar] [CrossRef]

- Occhicone, A.; Vukčević, M.; Bosković, I.; Mingione, S.; Ferone, C. Alkali-Activated Red Mud and Construction and Demolition Waste-Based Components: Characterization and Environmental Assessment. Materials 2022, 15, 1617. [Google Scholar] [CrossRef] [PubMed]

- Phoo-ngernkham, T.; Phiangphimai, C.; Intarabut, D.; Hanjitsuwan, S.; Damrongwiriyanupap, N.; Li, L.; Chindaprasirt, P. Low cost and sustainable repair material made from alkali-activated high-calcium fly ash with calcium carbide residue. Constr. Build. Mater. 2020, 247, 118543. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef]

- Libo, Y.; Bohumil, K.; Liang, H. A review of recent research on the use of cellulosic fibres, their fibre fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B Eng. 2016, 92, 94–132. [Google Scholar]

- Faiz, U.A.S. Review of mechanical properties of short fibre reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49. [Google Scholar]

- Gupta, R.; Bhardwaj, P.; Deshmukh, K.; Mishra, D.; Prasad, M.; Amritphale, S. Development and Characterization of Inorganic-Organic (Si-O-Al) Hybrid Geopolymeric Precursors via Solid State Method. Silicon 2019, 11, 221–232. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Cioffi, R.; Tarallo, O. Synthesis and Characterization of Novel Epoxy Geopolymer Hybrid Composites. Materials 2013, 6, 3943–3962. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roviello, G.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Tarallo, O. Fire resistant melamine based organic-geopolymer hybrid composites. Cem. Concr. Compos. 2015, 59, 89–99. [Google Scholar] [CrossRef]

- Ricciotti, L.; Occhicone, A.; Petrillo, A.; Ferone, C.; Cioffi, R.; Roviello, G. Geopolymer-based hybrid foams: Lightweight materials from a sustainable production process. J. Clean. Prod. 2020, 250, 119588. [Google Scholar] [CrossRef]

- Roviello, G.; Menna, C.; Tarallo, O.; Ricciotti, L.; Ferone, C.; Colangelo, F.; Asprone, D.; Di Maggio, R.; Cappelletto, E.; Prota, A.; et al. Preparation, structure and properties of hybrid materials based on geopolymers and polysiloxanes. Mater. Des. 2015, 87, 82–94. [Google Scholar] [CrossRef]

- Roviello, G.; Ricciotti, L.; Molino, A.J.; Menna, C.; Ferone, C.; Cioffi, R.; Tarallo, O. Hybrid Geopolymers from Fly Ash and Polysiloxanes. Molecules 2019, 24, 3510. [Google Scholar] [CrossRef] [Green Version]

- Ebnesajjad, S. Bookbinding and the Conservation of Books: A Dictionary of Descriptive Terminology. In Adhesives Technology Handbook, 2nd ed; William Andrew: Norwich, NY, USA, 2008. [Google Scholar]

- Geddes, K. Polyvinyl and Ethylene–Vinyl Acetates. In Handbook of Adhesive Technology, 2nd ed; Marcel Dekker, Inc.: New York, NY, USA, 2003; pp. 712–722. [Google Scholar]

- Jović, M.; Buhin, Z.; Krobot, I.; Lučić Blagojević, S. Analysis of the Environmental Sustainability of the Adhesive Technology. Kem. Ind. 2011, 60, 269–276. [Google Scholar]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Liew, Y.M.; Kamarudin, H.; Mustafa Al Bakri, A.M.; Luqman, M.; Khairul Nizar, I.; Ruzaidi, C.M.; Heah, C.Y. Processing and characterization of calcined kaolin cement powder. Constr. Build. Mater. 2012, 30, 794–802. [Google Scholar] [CrossRef]

- San Cristóbal, A.G.; Castelló, R.; Martín Luengo, M.A.; Vizcayno, C. Zeolites prepared from calcined and mechanically modified kaolins: A comparative study. Appl. Clay Sci. 2010, 49, 239–246. [Google Scholar] [CrossRef]

- Aruldass, S.; Mathivanan, V.; Mohamed, A.R.; Tye, C.T. Factors affecting hydrolysis of polyvinyl acetate to polyvinyl alcohol. J. Env. Chem. Eng. 2019, 7, 103238. [Google Scholar] [CrossRef]

- Xu, F.; Zeng, W.; Li, D. Recent advance in alkoxysilane-based consolidants for stone. Progr. Org. Coat. 2019, 127, 45–54. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, J. Synthesis of TEOS/PDMS-OH/CTAB composite coating material as a new stone consolidant formulation. Constr. Build. Mater. 2016, 122, 90–94. [Google Scholar] [CrossRef]

- Zornoza-Indart, A.; Lopez-Arce, P.; Leal, N.; Simão, J.; Zoghlami, K. Consolidation of a Tunisian bioclastic calcarenite: From conventional ethyl silicate products to nanostructured and nanoparticle based consolidants. Constr. Build. Mater. 2016, 188, 150. [Google Scholar] [CrossRef]

- Zornoza-Indart, A.; Lopez-Arce, P. Silica nanoparticles (SiO2): Influence of relative humidity in stone consolidation. J. Cult. Herit. 2016, 18, 258–270. [Google Scholar] [CrossRef]

- Fierascu, I.; Fierascu, R.C.; Ion, R.M.; Radovici, C. Synthesized apatitic materials for artefacts protection against biodeterioration. Rom. J. Mater. 2014, 44, 292–297. [Google Scholar]

- Fierascu, I.; Fierascu, R.C.; Somoghi, R.; Ion, R.M.; Moanta, A.; Avramescu, S.M.; Damian, C.M.; Ditu, L.M. Tuned apatitic materials: Synthesis, characterization and potential antimicrobial applications. Appl. Surf. Sci. 2018, 438, 127–135. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Moundoulas, P.; Aggelakopoulou, E.; Anagnostopoulou, S. Optimization of compatible restoration mortars for the earthquake protection of Hagia Sophia. J. Cult. Herit. 2013, 14S, 147–152. [Google Scholar] [CrossRef]

| Compound | Metakaolin | Sodium Silicate |

|---|---|---|

| SiO2 | 52.2 | 27.40 |

| Al2O3 | 45.1 | - |

| Na2O | 0.22 | 8.15 |

| K2O | 0.15 | - |

| TiO2 | 1.75 | - |

| Fe2O3 | 0.42 | - |

| CaO | 0.04 | - |

| MgO | 0.04 | - |

| P2O5 | 0.08 | - |

| H2O | - | 64.42 |

| Materials (Weight %) | MK | MK-PVAc-5 | MK-PVAc-10 | MK-PDMS-5 | MK-PDMS-10 |

|---|---|---|---|---|---|

| Metakaolin | 37.5 | 35.7 | 33.7 | 35.7 | 33.7 |

| NaOH | 7.2 | 6.8 | 6.5 | 6.8 | 6.5 |

| Sodium silicate | 55.3 | 52.5 | 49.8 | 52.5 | 49.8 |

| Polyvinyl acetate | - | 5.0 | 10.0 | - | - |

| Polydimethylsiloxane oligomers | - | - | - | 5.0 | 10 |

| Samples | Wts (°C) 1 | Wte (°C) 2 | R (Weight %) 3 |

|---|---|---|---|

| MK | 30 | 300 | 84 |

| MK-PVAc-10 | 30 | 720 | 78 |

| MK-PDMS-10 | 30 | 500 | 75 |

| Sample | Bulk Density (g/cm3) | Water Absorption (%) |

|---|---|---|

| MK | 1.35 ± 0.03 | 33.8 ± 0.4 |

| MK-PVAc-5 | 1.23 ± 0.01 | 31.9 ± 0.1 |

| MK-PVAc-10 | 1.16 ± 0.01 | 34.6 ± 0.1 |

| MK-PDMS-5 | 1.32 ± 0.01 | 8.6 ± 0.1 |

| MK-PDMS-10 | 1.29 ± 0.01 | 6.5 ± 0.1 |

| Sample | E (GPa) | σf (MPa) | σc (MPa) |

|---|---|---|---|

| MK | 7.5 ± 0.3 | 2 ± 1 | 40 ± 5 |

| MK-PVAc-5 | 6.2 ± 0.8 | 2.7 ± 0.2 | 42 ± 5 |

| MK-PVAc-10 | 5.1 ± 0.2 | 2.6 ± 0.2 | 38 ± 2 |

| MK-PDMS-5 | 5.8 ± 0.2 | 1.1 ± 0.4 | 42 ± 2 |

| MK-PDMS-10 | 4.9 ± 0.2 | 0.7 ± 0.1 | 37 ± 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ricciotti, L.; Occhicone, A.; Manzi, S.; Saccani, A.; Ferone, C.; Tarallo, O.; Roviello, G. Sustainable Materials Based on Geopolymer–Polyvinyl Acetate Composites for Art and Design Applications. Polymers 2022, 14, 5461. https://doi.org/10.3390/polym14245461

Ricciotti L, Occhicone A, Manzi S, Saccani A, Ferone C, Tarallo O, Roviello G. Sustainable Materials Based on Geopolymer–Polyvinyl Acetate Composites for Art and Design Applications. Polymers. 2022; 14(24):5461. https://doi.org/10.3390/polym14245461

Chicago/Turabian StyleRicciotti, Laura, Alessio Occhicone, Stefania Manzi, Andrea Saccani, Claudio Ferone, Oreste Tarallo, and Giuseppina Roviello. 2022. "Sustainable Materials Based on Geopolymer–Polyvinyl Acetate Composites for Art and Design Applications" Polymers 14, no. 24: 5461. https://doi.org/10.3390/polym14245461

APA StyleRicciotti, L., Occhicone, A., Manzi, S., Saccani, A., Ferone, C., Tarallo, O., & Roviello, G. (2022). Sustainable Materials Based on Geopolymer–Polyvinyl Acetate Composites for Art and Design Applications. Polymers, 14(24), 5461. https://doi.org/10.3390/polym14245461