A New Stress-Based Formulation for Modeling Notched Fiber-Reinforced Laminates

Abstract

:1. Introduction

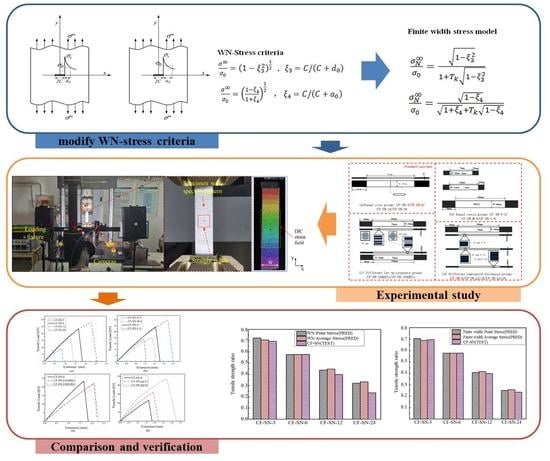

2. Theoretical Stress Analysis

2.1. Stress Concentration Factor

2.2. WN Stress Criteria

2.3. Finite-Width Stress Model

3. Experiment

3.1. Materials and Geometry of Specimens

3.2. Testing

4. Results and Discussion

4.1. Load–Displacement Curves

4.2. Comparison of Average Failure Strain

4.3. Characteristics of Notched Fiber-Reinforced Specimens

4.4. Analysis of Progressive Failure through Strain Distribution

4.5. Failure Characteristic Analysis

5. Characteristic Length and Predictive Models

5.1. Calculation of Characteristic Length

5.2. Prediction Based upon WN Stress Criteria

5.3. Prediction Based upon Finite-Width Stress Criteria

5.4. Reliability of the Finite-Width Stress Criterion and Discussion

- (1)

- Explore the mechanical behavior of the notch failure of other polymer fiber laminates and improve the theoretical prediction model.

- (2)

- Explore the mechanical properties of non-orthogonal composite laminates and improve the theoretical prediction model.

- (3)

- Investigate the mechanical properties of non-central notched composite laminates and establish a suitable theoretical model.

- (4)

- Study the patch repair methods, patch types, and mechanical properties of the patched composite laminates.

6. Conclusions

- (1)

- The quasi-static tensile behavior of carbon-fiber-reinforced plastic (CFRP) composites knitted with plain weave depend on the fiber strength in two weaving directions. The failure modes presented in the test are fairly close to brittle fracturing.

- (2)

- The fracture behavior of the specimen relies on the lay-up angle (fiber direction) and layer thickness, while the notch size has a less significant effect on the failure mode.

- (3)

- The finite-width stress criteria are found to be suitable for notched fiber-reinforced laminate specimens with both an infinite width and a finite width, and the size effect of the specimen almost does not affect the prediction results of the tensile strength when using the proposed formulations.

- (4)

- The finite-width stress criteria exhibited fairly good applicability. They can accurately predict the strength of the same kinds of specimens (e.g., the same materials, same lay-up type, and same lay-up thickness) after testing the standard specimen (the specimen used to decide the characteristic length). It can be well-applied to all kinds of fiber rei-forced composites and has great significance for the study of the strength of fiber rei-forced composites.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Notation List

| C | Half-length of the straight notch size. |

| W | Width of specimen. |

| Far-field tensile load. | |

| The finite-width stress concentration coefficient (SCF). | |

| Stress concentration coefficient. | |

| Finite-width correction coefficient. | |

| Plane stiffness matrix. | |

| M | A parameter for calculating . |

| Characteristic length of the average stress criterion. | |

| Characteristic length of the point stress criterion. | |

| Stress ahead of the crack tip; y is the distance to crack. | |

| Failure stress of a corresponding non-notched plate. | |

| Stress intensity factor of mode I fracture. | |

| T | T stress. |

| A parameter for calculating T. | |

| CF-SN-2C | |

| CF | Carbon-fiber-reinforced composite. |

| SN | Straight notch. |

| CF-SN-S/M/L-2C | |

| S | Adjustments of specimen size: 100 mm × 18 mm. |

| M | Adjustments of specimen size: 200 mm × 24 mm. |

| L | Adjustments of specimen size: 300 mm × 48 mm. |

| CF-SN-[ABAB]s | |

| A | 0°/90° layer. |

| B | +45°/−45° layer. |

| s | Symmetrical distribution. |

| CF-SN-plyn | |

| n | Total layer number. |

References

- Salleh, Z.; Berhan, M.N.; Hyie, K.M.; Taib, Y.M.; Kalam, A.; Roselina, N.R.N. Open hole tensile properties of kenaf composite and kenaf/fibreglass hybrid composite laminates. Procedia Eng. 2013, 68, 399–404. [Google Scholar] [CrossRef] [Green Version]

- Castanié, B.; Achard, V.; Chirol, C. Effect of milled notches on the strength of open hole, filled holes, single and double lap shear CFRP tension coupons. Compos. Struct. 2020, 254, 112872. [Google Scholar] [CrossRef]

- Gao, X.; Yu, G.; Xue, J.; Song, Y. Failure analysis of C/SiC composites plate with a hole by the PFA and DIC method. Ceram. Int. 2017, 43, 5255–5266. [Google Scholar] [CrossRef]

- Khechai, A.; Tati, A.; Guerira, B.; Guettala, A.; Mohite, P. Strength degradation and stress analysis of composite plates with circular, square and rectangular notches using digital image correlation. Compos. Struct. 2018, 185, 699–715. [Google Scholar] [CrossRef]

- Mohammed, Y.; Hassan, M.K.; El-Ainin, H.A.; Hashem, A.M. Size effect analysis of openhole glass fiber composite laminate using two-parameter cohesive laws. Acta Mech. 2015, 226, 1027–1044. [Google Scholar] [CrossRef]

- Panin, S.V.; Burkov, M.V.; Byakov, A.V.; Lyubutin, P.S.; Khizhnyak, S.A. Staging of a localized deformation during tension of specimens of a carbon-carbon composite material with holes of different diameters according to acoustic-emission, surface-deformation mapping, and strain-gauging data. Russ. J. Nondestruct. Test. 2012, 48, 598–608. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Stress concentration factors in tubular X-connections retrofitted with FRP under compressive load. Ocean. Eng. 2021, 229, 108562. [Google Scholar] [CrossRef]

- Arifin, A.M.T.; Abdullah, S.; Rafiquzzaman, M.; Zulkifli, R.; Wahab, D.A. Failure characterisation in polymer matrix composite for un-notched and notched (open-hole) specimens under tension condition. Fibers Polym. 2014, 15, 1729–1738. [Google Scholar] [CrossRef]

- Johnson, S.; Kang, L.; Akil, H.M. Mechanical behavior of jute hybrid bio-composites. Compos. Part B Eng. 2016, 91, 83–93. [Google Scholar] [CrossRef] [Green Version]

- Cunningham, D.; Harries, K.A.; Bell, A.J. Open-hole tension capacity of pultruded GFRP having staggered hole arrangement. Eng. Struct. 2015, 95, 8–15. [Google Scholar] [CrossRef]

- Xu, X.; Wisnom, M.R.; Mahadik, Y.; Hallett, S.R. An experimental investigation into size effects in quasi-isotropic carbon/epoxy laminates with sharp and blunt notches. Compos. Sci. Technol. 2014, 100, 220–227. [Google Scholar] [CrossRef] [Green Version]

- Xu, X.; Wisnom, M.R.; Li, X.; Hallett, S.R. A numerical investigation into size effects in centre-notched quasi-isotropic carbon/epoxy laminates. Compos. Sci. Technol. 2015, 111, 32–39. [Google Scholar] [CrossRef] [Green Version]

- O’Higgins, R.M.; McCarthy, M.A.; McCarthy, C.T. Comparison of open hole tension characteristics of high strength glass and carbon fibre-reinforced composite materials. Compos. Sci. Technol. 2008, 68, 2770–2778. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.-l.; Yu, Y.; Wang, H. Peridynamic analytical method for progressive damage in notched composite laminates. Peridynamic analytical method for progressive damage in notched composite laminates. Compos. Struct. 2014, 108, 801–810. [Google Scholar] [CrossRef]

- Ridha, M.; Wang, C.H.; Chen, B.Y.; Tay, T.E. Modelling complex progressive failure in notched composite laminates with varying sizes and stacking sequences. Modelling complex progressive failure in notched composite laminates with varying sizes and stacking sequences. Compos. Part A Appl. Sci. Manuf. 2014, 58, 16–23. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Hallett, S.R. The role of delamination in strength, failure mechanism and hole size effect in open hole tensile tests on quasi-isotropic laminates. Compos. Part A Appl. Sci. Manuf. 2009, 40, 335–342. [Google Scholar] [CrossRef]

- Erçin, G.H.; Camanho, P.P.; Xavier, J.; Catalanotti, G.; Mahdi, S.; Linde, P. Size effects on the tensile and compressive failure of notched composite laminates. Compos. Struct. 2013, 96, 736–744. [Google Scholar] [CrossRef]

- Caminero, M.A.; Lopez-Pedrosa, M.; Pinna, C.; Soutis, C. Damage monitoring and analysis of composite laminates with an open hole and adhesively bonded repairs using digital image correlation. Compos. Part B Eng. 2013, 53, 76–91. [Google Scholar] [CrossRef]

- Bo, L.; University, N.M. Application of Fiber Reinforced Resin Composites in Sports Equipment. Plast. Sci. Technol. 2017, 45, 66–69. [Google Scholar]

- Camanho, P.P.; Erçin, G.H.; Catalanotti, G.; Mahdi, S.; Linde, P. A finite fracture mechanics model for the prediction of the open-hole strength of composite laminates. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1219–1225. [Google Scholar] [CrossRef] [Green Version]

- Meneghetti, G.; Rigon, D.; Gennari, C. An analysis of defects influence on axial fatigue strength of maraging steel specimens produced by additive manufacturing. Int. J. Fatigue 2019, 118, 54–64. [Google Scholar] [CrossRef]

- Sun, G.; Wang, L.; Chen, D.; Luo, Q. Tensile performance of basalt fiber composites with open circular holes and straight notches. Int. J. Mech. Sci. 2020, 176, 105517. [Google Scholar] [CrossRef]

- Wallner, C.; Almeida, S.F.M.; Kassapoglou, C. Modified Whitney-Nuismer criteria for prediction of notched strength of composite laminates. In Proceedings of the 31st Congress of International Council of the Aeronautical Sciences, Belo Horizonte, Brazil, 9–14 September 2018. [Google Scholar]

- Wallner, C.; Almeida, S.F.M.; Kassapoglou, C. Novel criteria for strength predictions of open-hole composite laminates for preliminary design. Compos. Struct. 2019, 229, 111409. [Google Scholar] [CrossRef]

- Moure, M.M.; Herrero-Cuenca, J.; García-Castillo, S.K.; Barbero, E. Design tool to predict the open-hole failure strength of composite laminates subjected to in-plane loads. Compos. Struct. 2020, 238, 111970. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Rezaei, S.; Ruan, H.; Reinicke, T. Fracture behavior of anisotropic 3D-printed parts: Experiments and numerical simulations. J. Mater. Res. Technol. 2022, 19, 1260–1270. [Google Scholar] [CrossRef]

- Sharma, A.; Mukhopadhyay, T.; Kushvaha, V. Experimental data-driven uncertainty quantification for the dynamic fracture toughness of particulate polymer composites. Eng. Fract. Mech. 2022, 273, 108724. [Google Scholar] [CrossRef]

- Yuan, L.; Shan, H.; Yang, Z.; Peng, F. The Application and Prospect of Composite Materials in UAV. Fiber Glass 2017, 6, 30–36. [Google Scholar]

- Whitney, J.M.; Nuismer, R.J. Stress Fracture Criteria for Laminated Composites Containing Stress Concentrations; Sage Publications: Thousand Oaks, CA, USA, 2016; Volume 8. [Google Scholar]

- ASTM D5766; Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates. ASTM International: West Conshohocken, PA, USA, 2011.

- Awerbuch, J.; Madhukar, M.S. Notched Strength of Composite Laminates: Predictions and Experiments—A Review. J. Reinf. Plast. Compos. 2016, 4, 3–159. [Google Scholar] [CrossRef]

- Cornetti, P.; Pugno, N.; Carpinteri, A.; Taylor, D. Finite fracture mechanics: A coupled stress and energy failure criterion. Eng. Fract. Mech. 2006, 73, 2021–2033. [Google Scholar] [CrossRef]

- Tan, S.C. Laminated Composites Containing an Elliptical Opening. I. Approximate Stress Analyses and Fracture Models. J. Compos. Mater. 1987, 21, 925–948. [Google Scholar] [CrossRef]

- Potter, K.; Khan, B.; Wisnom, M.; Bell, T.; Stevens, J. Variability, fibre waviness and misalignment in the determination of the properties of composite materials and structures. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1343–1354. [Google Scholar] [CrossRef]

- Ouinas, D.; Bouiadjra, B.; Serier, B.; SaidBekkouche, M. Comparison of the effectiveness of boron/epoxy and graphite/epoxy patches for repaired cracks emanating from a semicircular notch edge. Compos. Struct. 2007, 80, 514–522. [Google Scholar] [CrossRef]

- Weißgraeber, P.; Leguillon, D.; Becker, W. A review of Finite Fracture Mechanics: Crack initiation at singular and non-singular stress raisers. Arch. Appl. Mech. 2015, 86, 375–401. [Google Scholar] [CrossRef]

- Ghasemi, A.R.; Tabatabaeian, A.; Asghari, B. Application of slitting method to characterize the effects of thermal fatigue, lay-up arrangement and MWCNTs on the residual stresses of laminated composites. Mech. Mater. 2019, 134, 185–192. [Google Scholar] [CrossRef]

- Bhanuprakash, L.; Parasuram, S.; Varghese, S. Experimental investigation on graphene oxides coated carbon fibre/epoxy hybrid composites: Mechanical and electrical properties. Compos. Sci. Technol. 2019, 179, 134–144. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-08; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- Buttlar, W.G.; Hill, B.C.; Kim, Y.R.; Kutay, M.E.; Millien, A.; Montepara, A.; Paulino, G.H.; Petit, C.; Pop, I.C.; Romeo, E.; et al. Digital image correlation techniques to investigate strain fields and cracking phenomena in asphalt materials. Mater. Struct. 2014, 47, 1373–1390. [Google Scholar] [CrossRef]

- Wang, Z.; Jin, X.; Li, Q.; Sun, G. On crashworthiness design of hybrid metal-composite structures. Int. J. Mech. Sci. 2020, 171, 105380. [Google Scholar] [CrossRef]

- Huo, X.; Liu, H.; Luo, Q.; Sun, G.; Li, Q. On low-velocity impact response of foam-core sandwich panels. Int. J. Mech. Sci. 2020, 181, 105681. [Google Scholar] [CrossRef]

- Zheng, G.; He, Z.; Wang, K.; Liu, X.; Luo, Q.; Li, Q.; Sun, G. On failure mechanisms in CFRP/Al adhesive joints after hygrothermal aging degradation following by mechanical tests. Thin-Walled Struct. 2020, 158, 107184. [Google Scholar] [CrossRef]

- Wu, X.; Fuller, J.D.; Longana, M.L.; Wisnom, M.R. Reduced notch sensitivity in pseudoductile CFRP thin ply angle-ply laminates with central 0° plies. Compos. Part A Appl. Sci. Manuf. 2018, 111, 62–72. [Google Scholar] [CrossRef]

- Carpinteri, A.; Ingraffea, A.R. Fracture Mechanics of Concrete: Material Characterization and Testing: Material Characterization and Testing; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Bažant, Z.P.; Pijaudier-Cabot, G. Nonlocal continuum damage, localization instability and convergence. J. Appl. Mech. 1988, 55, 287–293. [Google Scholar] [CrossRef]

| No. | Size | Thickness (mm) | Crack Length 2C (mm) | Ply Angle and Sequence |

|---|---|---|---|---|

| CF-SN-3 | 2 | 3 | [0°/90°]8 | |

| CF-SN-6 | 2 | 6 | [0°/90°]8 | |

| CF-SN-12 | 2 | 12 | [0°/90°]8 | |

| CF-SN-24 | 2 | 24 | [0°/90°]8 | |

| CF-SN-S-3 | 2 | 3 | [0°/90°]8 | |

| CF-SN-M-4 | 2 | 4 | [0°/90°]8 | |

| CF-SN-L-8 | 2 | 8 | [0°/90°]8 | |

| CF-SN-[ABAB]s | 2 | 6 | [(0°/90°)/±45°]2S | |

| CF-SN-[AABB]s | 2 | 6 | [(0°/90°)/(0°/90°)/±45°/±45°]S | |

| CF-SN-ply12 | 3 | 6 | [0°/90°]12 | |

| CF-SN-ply16 | 4 | 6 | [0°/90°]16 |

| Specimens | Peak Load Ratio | Notch Sensitivity | Specimens | Peak Load Ratio | Notch Sensitivity |

|---|---|---|---|---|---|

| CF-SN-3 | 0.69457 | 1.43974 | CF-SN-S-3 | 0.72896 | 1.37182 |

| CF-SN-6 | 0.57672 | 1.73394 | CF-SN-M-4 | 0.66023 | 1.51462 |

| CF-SN-12 | 0.39746 | 2.51598 | CF-SN-6 | 0.57672 | 1.73394 |

| CF-SN-24 | 0.23459 | 4.26276 | CF-SN-L-8 | 0.52393 | 1.90865 |

| CF-SN-[AABB]s | 0.64553 | 1.54911 | CF-SN-ply12 | 0.52111 | 1.91898 |

| CF-SN-[ABAB]s | 0.63808 | 1.56720 | CF-SN-ply16 | 0.50224 | 1.99108 |

| Name | |||||

|---|---|---|---|---|---|

| WN | |||||

| Equation size | 0.12 | 0.62 | 0.22 | 0.26 | |

| Equation ratio | 0.01 | 0.16 | 0.02 | 0.05 | |

| Finite | |||||

| Equation size | 0.06 | 0.36 | 0.10 | 0.14 | |

| Equation ratio | 0.02 | 0.21 | 0.02 | 0.06 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Wang, L.; Luo, Q.; Bai, Z.; Li, Q.; Hu, J. A New Stress-Based Formulation for Modeling Notched Fiber-Reinforced Laminates. Polymers 2022, 14, 5552. https://doi.org/10.3390/polym14245552

Liu X, Wang L, Luo Q, Bai Z, Li Q, Hu J. A New Stress-Based Formulation for Modeling Notched Fiber-Reinforced Laminates. Polymers. 2022; 14(24):5552. https://doi.org/10.3390/polym14245552

Chicago/Turabian StyleLiu, Xian, Linxin Wang, Quantian Luo, Zhonghao Bai, Qing Li, and Jian Hu. 2022. "A New Stress-Based Formulation for Modeling Notched Fiber-Reinforced Laminates" Polymers 14, no. 24: 5552. https://doi.org/10.3390/polym14245552

APA StyleLiu, X., Wang, L., Luo, Q., Bai, Z., Li, Q., & Hu, J. (2022). A New Stress-Based Formulation for Modeling Notched Fiber-Reinforced Laminates. Polymers, 14(24), 5552. https://doi.org/10.3390/polym14245552