Microscopic Imaging Technology Assisted Dynamic Monitoring and Restoration of Micron-Level Cracks in the Painted Layer of Terracotta Warriors and Horses of the Western Han Dynasty

Abstract

:1. Introduction

2. Status of Preservation

3. Equipment and Methods

3.1. Preparation of Simulated Painted Pottery

3.2. Chromatic Aberration Test

3.3. Adhesion Test

3.4. Contact Angle Test

3.5. Scanning Electron Microscope

3.6. Thermal Stability Properties

3.7. Equipment

3.8. Methods

4. Results and Discussion

4.1. Chromatic Aberration and Adhesion Changes

4.2. Hydrophobic Performance

4.3. Scanning Electron Microscopy (SEM) Analysis

4.4. Thermal Stability

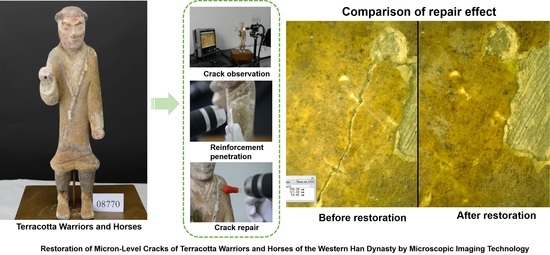

4.5. Monitoring of the Restoration Process: A Case Study of the Painted Terracotta Warriors of the Western Han Dynasty

4.5.1. Locating the Cracks

4.5.2. Evaluation and Measurement of the Crack Development

4.5.3. Penetration of the Adhesive Agent

4.5.4. Pressing the Cracks in the Painted Layer

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Paranoid B72 | ethyl methacrylate/methyl acrylate copolymer |

| ZB-F600 | ZB-F600 water-borne FEVE |

| 2D | two-dimensional |

| 3D | three-dimensional |

| SEM | scanning electronic microscopy |

| TG | thermogravimetric analysis |

| DTG | derivative thermogravimetry |

References

- Liu, X.H. Rare treasure-colored command pottery from western dynasty. Silk Road 1999, 4, 6–18. [Google Scholar]

- Zhang, M.D. An example of Han cavalry in the main battle--The terra cotta warriors of the han dynasty tomb in Yangjiawan, Xianyang. Relics Mus. 1992, 6, 22–25. [Google Scholar]

- Hou, Y.B.; Ma, Y.N.; Li, K.; Chen, B.; Shi, N.; Yang, W.Z.; Zhang, S.C.; Qi, Z.A.; Zheng, C.Y.; Sun, Z. Brief report on archaeological excavation of the pit outside m3 of hanyang ling eastern burial tomb. Archaeol. Cult. Relics 2021, 5, 22–39. [Google Scholar]

- Liu, H.; Jiao, N.F. Study on the animal remains in the no. 14 external pit of hanyang ling imperial cemetery. Archaeol. Cult. Relics 2019, 1, 120–128. [Google Scholar]

- Zhang, J.J. Brief account of the sculpture art of the painted terra-cotta warriors of the western han dynasty in xuzhou. Sculpture 2001, 1, 38–39. [Google Scholar]

- Cheng, Y.N. A preliminary study on the exhibition of qin history. Relics Mus. 2015, 1, 75–79. [Google Scholar]

- Cheng, X.P.; Zhang, J.Y. A review on the diseases and mechanism of pottery painting. Archaeol. Luoyang 2020, 1, 91–95. [Google Scholar]

- Wang, W.; Duan, Y.; Wu, F. The Microbial Deterioration and Occurrence Mechanism of Relocated Wall Paintings of the Tiantishan Grottoes. In Proceedings of the 4rd International Conference on Science and Engineering in Arts, Heritage, and Archaeology, London, UK, 4–6 June 2018. [Google Scholar] [CrossRef]

- Chelazzi, D.; Chevalier, A.; Pizzorusso, G.; Giorgi, R.; Menu, M.; Baglioni, P. Characterization and degradation of poly(vinyl acetate)-based adhesives for canvas paintings. Polym. Degrad. Stab. 2014, 107, 314–320. [Google Scholar] [CrossRef]

- Pintus, V.; Wei, S.; Schreiner, M. Accelerated UV ageing studies of acrylic, alkyd, and polyvinyl acetate paints: Influence of inorganic pigments. Microchem. J. 2016, 124, 949–961. [Google Scholar] [CrossRef]

- Wei, S.; Pintus, V.; Schreiner, M. Photochemical degradation study of polyvinyl acetate paints used in artworks by Py-GC/MS. J. Anal. Appl. Pyrolysis 2012, 97, 158–163. [Google Scholar] [CrossRef] [Green Version]

- Sun, F.; Li, J.; He, Z.; Li, Y.; Wang, R.; Xu, H. Gelatin microsphere-based protection treatment for polychromic relics. Mater. Lett. 2021, 282, 128619. [Google Scholar] [CrossRef]

- Ntelia, E.; Karapanagiotis, I. Superhydrophobic Paraloid B72. Prog. Org. Coat. 2020, 139, 105224. [Google Scholar] [CrossRef]

- Milanesi, C.; Baldi, F.; Borin, S.; Brusetti, L.; Ciampolini, F.; Iacopini, F.; Cresti, M. Deterioration of medieval painting in the chapel of the Holy Nail, Siena (Italy) partially treated with Paraloid B72. Int. Biodeterior. Biodegrad. 2009, 63, 844–850. [Google Scholar] [CrossRef]

- Vaz, M.F.; Pires, J.; Carvalho, A.P. Effect of the impregnation treatment with Par-aloid B-72 on the properties of old Portuguese ceramic tiles. J. Cult. Herit. 2008, 9, 269–276. [Google Scholar] [CrossRef]

- Kotlík, P.; Doubravová, K.; Horálek, J.; Kubáč, L.; Akrman, J. Acrylic copolymer coatings for protection against UV rays. J. Cult. Herit. 2014, 15, 44–48. [Google Scholar] [CrossRef]

- Cultrone, G.; Madkour, F. Evaluation of the effectiveness of treatment products in improving the quality of ceramics used in new and historical buildings. J. Cult. Herit. 2013, 14, 304–310. [Google Scholar] [CrossRef]

- Piccinini, F.; Levi, M.; Turri, S. Photoactive sol−gel hybridcoatings from modified fluorocarbon polymers and amorphous titania. Prog. Org. Coat. 2013, 76, 1265–1272. [Google Scholar] [CrossRef]

- Lopez, A.B.; Bohórquez, S.J.; Meeuwisse, M.; Mestach, D.; dea Cal, J.C.; Asua, J.M. Self-matting waterborne fluoropolymers. Prog. Org. Coat. 2018, 116, 57–69. [Google Scholar] [CrossRef]

- Fu, P.; Teri, G.L.; Li, J.; Li, J.X.; Li, Y.H.; Yang, H. Investigation of ancient architectural painting from the Taidong tomb in the western qing tombs, hebei, china. Coatings 2020, 10, 688. [Google Scholar] [CrossRef]

- Qi, Y.; Jia, Z.; Zhou, Y.; Wang, Y.; Zhao, G.; Chao, X.; Xing, H.; Li, Y. Application of ethylene oxide gas and argon gas mixture system method for scale deacidif zSZication of cellulose-based cultural heritage collections. Coatings 2021, 11, 973. [Google Scholar] [CrossRef]

- Fu, P.; Teri, G.L.; Li, J.X.; Huo, Y.J.; Yang, H.; Li, Y.H. Analysis of an ancient architectural painting from the Jiangxue palace in the imperial museum, Beijing, China. Anal. Lett. 2020, 54, 684–697. [Google Scholar] [CrossRef]

- LLiu, Z.-F.; Zhang, H.; Zhou, W.-H.; Hao, S.-C.; Zhou, Z.; Qi, X.-K.; Shi, J.-L. Pigment identification on an undated Chinese painting by non-destructive analysis. Vib. Spectrosc. 2019, 101, 28–33. [Google Scholar] [CrossRef]

- Su, B.M.; Jiang, D.Q.; Ma, X.S.; Fan, Z.X.; Zhao, L.Y. Application in synthesized methods of deformation monitoring of the ruins of ancient Jiaohe city. Dunhuang Res. 2007, 5, 39–44. [Google Scholar]

- Wang, W.F.; Li, Z.X.; Ma, Z.F.; Fu, Y.X.; Liu, T.; Yang, T.; Fan, Z.; Li, S. The conservation technology of the seriously damaged wall paintings locates at the ancient cultural sites in tibetan. Dunhuang Res. 2005, 4, 24–29. [Google Scholar]

- Lan, D.S.; Rong, B.; Xia, Y.; Zhou, T.; Wang, D.F. Reattachment of paint and restoration of qin polychrome terra-cotta warriors. Sci. Conserv. Archaeol. 2016, 28, 60–66. [Google Scholar] [CrossRef]

- Ma, Z.Z.; Wang, L.Q.; Vaclav, P. The influence of the photothermal aging exerting on the gc-ms identification of the common proteinaceous binding media in polychromy artworks. J. Northwest Univ. 2020, 50, 595–605. [Google Scholar] [CrossRef]

- Cauzzi, D.; Chiavari, G.; Montalbani, S.; Melucci, D.; Cam, D.; Ling, H. Spectroscopic and chromatographic studies of sculptural polychromy in the zhongshan grottoes (r.P.C.). J. Cult. Herit. 2013, 14, 70–75. [Google Scholar] [CrossRef]

- Wang, J.L.; Li, Y.H.; Feng, P.; Tong, G.G.; Jing, C. Micro Dynamic Monitoring Device for Micron-Level Cracks in Painted Layers of Pottery Cultural Relics. China Patent 201520878905.9, 6 April 2016. [Google Scholar]

- Li, Q.; Xi, S.; Zhang, X. Deacidification of paper relics by plasma technology. J. Cult. Herit. 2014, 15, 159–164. [Google Scholar] [CrossRef]

- Huang, J.; Liang, G.; Lu, G.; Zhang, J. Conservation of acidic papers using a dispersion of oleic acid-modified MgO nanoparticles in a non-polar solvent. J. Cult. Herit. 2018, 34, 61–68. [Google Scholar] [CrossRef]

- Li, Y.H.; Xiong, K.; Wang, Y.J.; Dou, J.J.; Wang, J.L. A Strengthening Agent for Crisp Powder Pottery Painted Cultural Relics. China Patent 201410190654.5, 17 June 2015. [Google Scholar]

- Wang, J.L.; Hu, L.Y.; Feng, P.; Tong, G.G.; Cao, J. Micro Dynamic Monitoring Device and Repair Method for Micron Cracks in Painted Layers of Pottery Cultural Relics. China Patent 201510749340.9, 30 December 2015. [Google Scholar]

- Balokhonov, R.R.; Romanova, V.A.; Schmauder, S. Computational analysis of deformation and fracture in a composite material on the mesoscale level. Comput. Mater. Sci. 2006, 37, 110–118. [Google Scholar] [CrossRef]

- Panin, V.E.; Goldstein, R.V.; Panin, S.V. Mesomechanics of multiple cracking of brittle coatings in a loaded solid. Int. J. Fract. 2008, 150, 37–53. [Google Scholar] [CrossRef]

| Sample | L* | a* | b* | ΔE* | Adhesion |

|---|---|---|---|---|---|

| Untreated-iron oxide red | 35.56 | 18.63 | 16.79 | Level 3 | |

| Treated-iron oxide red | 34.44 | 18.58 | 17.01 | 0.67 | Level 1 |

| Untreated-malachite green | 71.85 | −26.67 | 10.68 | Level 3 | |

| Treated-malachite green | 73.55 | −26.17 | 10.48 | 0.71 | Level 1 |

| Untreated-ultramarine | 35.41 | 6.99 | −42.83 | Level 4 | |

| Treated-ultramarine | 35.54 | 6.58 | −42.01 | 0.87 | Level 1 |

| Untreated-cinnabar | 47.95 | 40.83 | 22.53 | Level 3 | |

| Treated-cinnabar | 49.06 | 39.64 | 21.86 | 0.76 | Level 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Li, J.; Chao, X.; Chen, Y.; Huang, Y.; Mai, B.; Li, Y.; Cao, J. Microscopic Imaging Technology Assisted Dynamic Monitoring and Restoration of Micron-Level Cracks in the Painted Layer of Terracotta Warriors and Horses of the Western Han Dynasty. Polymers 2022, 14, 760. https://doi.org/10.3390/polym14040760

Wang J, Li J, Chao X, Chen Y, Huang Y, Mai B, Li Y, Cao J. Microscopic Imaging Technology Assisted Dynamic Monitoring and Restoration of Micron-Level Cracks in the Painted Layer of Terracotta Warriors and Horses of the Western Han Dynasty. Polymers. 2022; 14(4):760. https://doi.org/10.3390/polym14040760

Chicago/Turabian StyleWang, Juanli, Jiaxin Li, Xiaolian Chao, Youlu Chen, Yongsheng Huang, Bingjie Mai, Yuhu Li, and Jing Cao. 2022. "Microscopic Imaging Technology Assisted Dynamic Monitoring and Restoration of Micron-Level Cracks in the Painted Layer of Terracotta Warriors and Horses of the Western Han Dynasty" Polymers 14, no. 4: 760. https://doi.org/10.3390/polym14040760

APA StyleWang, J., Li, J., Chao, X., Chen, Y., Huang, Y., Mai, B., Li, Y., & Cao, J. (2022). Microscopic Imaging Technology Assisted Dynamic Monitoring and Restoration of Micron-Level Cracks in the Painted Layer of Terracotta Warriors and Horses of the Western Han Dynasty. Polymers, 14(4), 760. https://doi.org/10.3390/polym14040760