Latent Recycling Potential of Multilayer Films in Austrian Waste Management

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Description

2.2. Hand Sorting Analysis of a 2D Fraction from a Packaging Sorting Plant

2.3. FTIR-ATR Measurements of the Specimens

2.4. Assessment of Recycling Potential of Mono- and Multilayer Packaging Films

3. Results and Discussion

3.1. Occurrence of Multilayer Material in the Waste Stream

3.2. Material Composition of Monolayer and Multilayer Materials

3.3. Contribution of Monolayer and Multilayer Films in Waste Generation

3.4. Influence of Improved Multilayer Recycling on the Circular Economy

3.4.1. Scenario 1: Current Situation

3.4.2. Scenario 2: New Technologies

3.4.3. Scenario 3: Zero Incineration of Flexible Packaging Derived from SCW

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- PlasticsEurope. Plastics—The Facts 2016; PlasticsEurope—Association of Plastics Manufacturers: Brussels, Belgium, 2016; Available online: https://plasticseurope.org/wp-content/uploads/2021/10/2016-Plastic-the-facts.pdf (accessed on 15 February 2022).

- Consultic. Produktion, Verarbeitung und Verwertung von Kunststoffen in Deutschland 2015 (Production, Processing and Recycling of Plastics in Germany); Consultic Marketing & Industrieberatung GmbH: Rückersdorf, Germany, 2016; Available online: https://plasticker.de/docs/news/Consultic-Studie%202015%20Kurzfassung.pdf (accessed on 15 February 2022).

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Bilewicz, M. Analysis of structure and properties of multilayer polymer foil. In IOP Conference Series: Materials Science and Engineering, Proceeding of the 6th International Conference on Recent Trends in Structural Materials (COMAT 2020), Pilsen, Czech Republic, 30 November–4 December 2020; IOP Publishing: Bristol, UK, 2021. [Google Scholar] [CrossRef]

- Barlow, C.Y.; Morgan, D.C. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- Van Eygen, E.; Laner, D.; Fellner, J. Circular economy of plastic packaging: Current practice and perspectives in Austria. Waste Manag. 2018, 72, 55–64. [Google Scholar] [CrossRef] [PubMed]

- Tartakowski, Z. Recycling of packaging multilayer films: New materials for technical products. Resour. Conserv. Recycl. 2010, 55, 167–170. [Google Scholar] [CrossRef]

- Pfaendner, R.; Herbst, H.; Hoffmann, K.; Sitek, F. Recycling and restabilization of polymers for high quality applications. An Overview. Macromol. Mater. Eng. 1995, 232, 193–227. [Google Scholar] [CrossRef]

- Pilz, H.; Brandt, B.; Fehringer, R. The Impact of Plastics on Life Cycle Energy Consumption and Greenhouse Gas Emissions in Europe. Summary Report, June 2010. Denkstatt GmbH. Retrieved 02.02.2022. Available online: https://plasticseurope.org/knowledge-hub/the-impact-of-plastics-on-life-cycle-energy-consumption-and-greenhouse-gas-emissions-in-europe/ (accessed on 15 February 2022).

- Villanueva, A.; Eder, P. End-Of-Waste Criteria for Waste Plastic for Conversion: Technical Proposals; Final Report; Publications Office of the European Union: Luxembourg, 2014; ISBN 978-92-79-40944-8. [Google Scholar] [CrossRef]

- Waste Framework Directive. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2018 on Waste and Repealing Certain Directives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:32008L0098 (accessed on 15 February 2022).

- Schwarzböck, T.; Van Eygen, E.; Rechberger, H.; Fellner, J. Determining the amount of waste plastics in the feed of Austrian waste-to-energy facilities. Waste Manag. Res. 2017, 35, 207–216. [Google Scholar] [CrossRef] [PubMed]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies: Tables and Charts, 3rd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2001. [Google Scholar]

- Mecozzi, M.; Pietroletti, M.; Monakhova, Y. FTIR Spectroscopy Supported by Statistical Techniques for the Structural Characterization of Plastic Debris in the Marine Environment: Application to Monitoring Studies. Mar. Pollut. Bull. 2016, 106, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Jung, M.R.; Horgen, F.D.; Orski, S.V.; Rodriguez, V.; Beers, K.L.; Balazs, G.H.; Jones, T.T.; Work, T.M.; Brignac, K.C.; Royer, S.-J.; et al. Lynch, Validation of ATR FT-IR to identify polymers of plastic marine debris, including those ingested by marine organisms. Mar. Pollut. Bull. 2018, 127, 704–716. [Google Scholar] [CrossRef] [PubMed]

- Schlögl, S. State of the Art of Plastic Packaging Sorting Plants and Potentials of Sensor-Based Material Flow Monitoring. Master’s Thesis, University of Leoben, Leoben, Austria, 2021. Available online: https://pure.unileoben.ac.at/portal/files/6479484/AC16189306.pdf (accessed on 2 March 2022).

- Friedrich, K.; Koinig, G.; Fritz, T.; Pomberger, R.; Vollprecht, D. Sensor-Based and Robot Sorting Processes and Their Role in Achieving European Recycling Goals—A Review. Correspondence: [email protected], Chair of Waste Processing Technology and Waste Management, Department of Environmental and Energy Process Engineering, University of Leoben, Leoben, Styria, Austria. 2022; manuscript in preparation. [Google Scholar]

- Schmidt, J.; Auer, M.; Moesslein, J.; Wendler, P.; Wiethoff, S.; Lang-Koetz, C.; Woidasky, J. Challenges and Solutions for Plastic Packaging in a Circular Economy. Chem. Ing. Tech. 2021, 93, 1751–1762. [Google Scholar] [CrossRef]

| Category 1 | Category 2 | Example/Packaging of: |

|---|---|---|

| Primary food packaging | Bakery products Coffee Dairy Dry food Fresh produce Frozen food/convenience Household packaging Meat Snack metallised Snack uncoated | Bread, rolls, pastry Coffee bags Sliced cheese, yoghurt lids Rice, noodles, cereal Fruit and vegetables Frozen vegetables, Zip-bags, cling film Sausages, steak, cold cuts Chocolate Bars, Granola Bars |

| Secondary food packaging | Beverage | Wrapping of six-packs |

| Primary product packaging | Construction/workshop Dry pet food Garden Household products Sanitary products Toys Wet pet food | Cement, Tools, oil Soil, mulch, bark chips, Clothes, toner Toilet paper, kitchen roll interlocking (plastic) brick |

| Secondary product packaging | Gift wrapping | Wrapping paper, ribbons, |

| Bags | Generic bags | Transparent single-use bags |

| Foils | Generic foils | Pieces of foil |

| Wavenumber [cm−1] | Comment |

|---|---|

| 2914, 2850 | Stretching vibrations of CH2 |

| 1471 | Bending vibrations of CH2 |

| 717 | Rocking vibrations of CH2 |

| Wavenumber [cm−1] | Comment |

|---|---|

| 3295, 3070 | Stretching vibration of NH |

| 3000–2840 | Stretching vibrations of CH2 |

| 1633 | Vibration of C=O |

| 1534 | Bending vibration of NH, stretching vibration of CN |

| 1462 | Bending vibration of CH2 |

| 1368 | Deformation vibration of CH2 |

| 1260 | Bending vibration of NH, stretching vibration of CN |

| 730 | Rocking vibrations of CH2 |

| Wavenumber [cm−1] | Comment |

|---|---|

| 2959, 2916, 2868, 2837 | Stretching vibrations (symmetrical and asymmetrical) of CH2 and CH3 |

| 1452, 1376 | Bending vibrations of CH2 and CH3 |

| 1167 | Rocking vibrations of CH3, bending vibrations of CH, stretching vibrations of C-C |

| 998, | Rocking vibrations of CH3, bending vibrations of CH3, bending vibrations of CH |

| 972 | Stretching vibration of C-C, rocking vibrations of CH3 |

| 841, 732 | Rocking vibration of CH2, stretching vibrations of C– CH3 |

| 809 | Rocking vibration of CH2, stretching vibrations of C-C, stretching vibrations of C-CH |

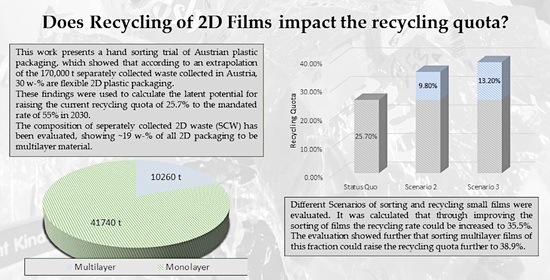

| Scenario 1 | Scenario 2 | Scenario 3 | ||||

|---|---|---|---|---|---|---|

| Monolayer | Multilayer | Monolayer | Multilayer | Monolayer | Multilayer | |

| Recycling | 24 wt% | 100 wt% | 100 wt% | 100 wt% | ||

| Incineration | 76 wt% | 100 wt% | ||||

| Scenario | Scenario 1: Current Situation | Scenario 2: Mechanical Recycling of Monolayer Films Derived from SCW | Scenario 3: Zero Incineration of Flexible Packaging Derived from SCW |

|---|---|---|---|

| Total Amount of Waste | 300,000 t | 300,000 t | 300,000 t |

| Sum of Small Films | 69,000 t | 69,000 t | 69,000 t |

| Chemical/Solvent-Based Recycling | 0 t | 0 t | 10,260 t |

| Energy Recovery | 56,720 t | 28,260 t | 17,000 t |

| Mechanical Recycling | 12,280 t | 41,740 t | 41,740 t |

| Sum of Recycled Small Films | 12,280 t | 41,740 t | 52,000 t |

| Total Recycling | 77,000 t | 106,460 t | 116,720 t |

| Recycling Quota | 25.7% | 35.5% | 38.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koinig, G.; Rutrecht, B.; Friedrich, K.; Barretta, C.; Vollprecht, D. Latent Recycling Potential of Multilayer Films in Austrian Waste Management. Polymers 2022, 14, 1553. https://doi.org/10.3390/polym14081553

Koinig G, Rutrecht B, Friedrich K, Barretta C, Vollprecht D. Latent Recycling Potential of Multilayer Films in Austrian Waste Management. Polymers. 2022; 14(8):1553. https://doi.org/10.3390/polym14081553

Chicago/Turabian StyleKoinig, Gerald, Bettina Rutrecht, Karl Friedrich, Chiara Barretta, and Daniel Vollprecht. 2022. "Latent Recycling Potential of Multilayer Films in Austrian Waste Management" Polymers 14, no. 8: 1553. https://doi.org/10.3390/polym14081553

APA StyleKoinig, G., Rutrecht, B., Friedrich, K., Barretta, C., & Vollprecht, D. (2022). Latent Recycling Potential of Multilayer Films in Austrian Waste Management. Polymers, 14(8), 1553. https://doi.org/10.3390/polym14081553