Multilayer Packaging in a Circular Economy

Abstract

:1. Introduction

2. Multilayer Packaging: State of the Art

2.1. Structure of Multilayer Packaging

2.2. Current End-of-Life Situation for Multilayer Packaging

2.3. Recycling of Multilayer Materials

3. Materials and Methods

3.1. Samples

3.2. FTIR–ATR Analysis

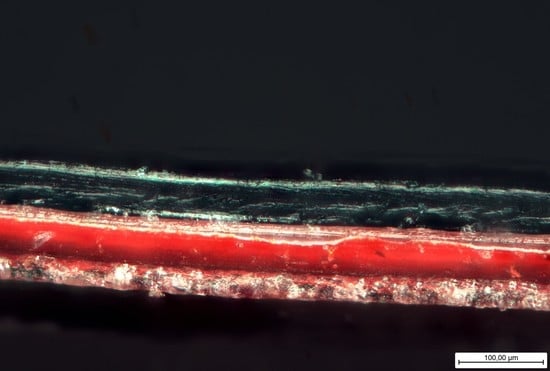

3.3. Microscopy Analysis

4. Research Results and Discussion

4.1. Analysis of the IR Sample

4.2. Extrapolated Original Sample, Data Validation, and Recycling Approaches

4.3. Depth Analysis of the ML Sample

4.3.1. Number of Layers, Total Thickness, and Outer and Inner Layer Polymer Combinations

4.3.2. Analysis of the Packaging Regarding Packaging Type and Storage Conditions

4.3.3. Analysis of the Packaging with Respect to Packaged Goods

4.3.4. Discussion of the ML Sample

4.3.5. Limitations of the Study

5. Outlook

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lindner, C.; Hoffmann, O. Analyse/Beschreibung der Derzeitigen Situation der Stofflichen und Energetischen Verwertung von Kunststoffabfällen in Deutschland. 2015. Available online: https://docplayer.org/24614382-Endbericht-analyse-beschreibung-der-derzeitigen-situation-der-stofflichen-und-energetischen-verwertung-von-kunststoffabfaellen-in-deutschland.html (accessed on 3 February 2021).

- Conversio GmbH. Stoffstrombild der Kunststoffe in Deutschland 2019: Kurzfassung; Conversio: Mainaschaff, Germany, 2020; Available online: https://www.vci.de/ergaenzende-downloads/kurzfassung-stoffstrombild-kunststoffe-2019.pdf (accessed on 2 May 2021).

- Mellen, D.; Becker, T. Kunststoffe. In Praxishandbuch der Kreislauf- und Rohstoffwirtschaft; Kurth, P., Oexle, A., Faulstich, M., Eds.; Springer Fachmedien: Wiesbaden, Germany, 2018; pp. 327–345. ISBN 978-3-658-17044-8. [Google Scholar]

- Schüler, K. Aufkommen und Verwertung von Verpackungsabfällen in Deutschland im Jahr 2017 Abschlussbericht; GVM: Mainz, Germany, 2019; Available online: https://www.umweltbundesamt.de/publikationen/aufkommen-verwertung-von-verpackungsabfaellen-in-12 (accessed on 3 February 2021).

- Industrievereinigung Kunststoffverpackungen e.V. Sustainability Report, 2018; Industrievereinigung Kunststoffverpackungen e.V.: Bad Homburg vor der Höhe, Germany, 2018; Available online: http://kunststoffverpackungen.de/wp-content/uploads/2019/09/Sustainability-Report-2018 (accessed on 3 February 2021).

- Dilkes-Hoffman, L.S.; Pratt, S.; Laycock, B.; Ashworth, P.; Lant, P.A. Public attitudes towards plastics. Resour. Conserv. Recycl. 2019, 147, 227–235. [Google Scholar] [CrossRef]

- Pauer, E.; Tacker, M.; Gabriel, V.; Krauter, V. Sustainability of flexible multilayer packaging: Environmental impacts and recyclability of packaging for bacon in block. Clean. Environ. Syst. 2020, 1, 100001. [Google Scholar] [CrossRef]

- Bundesministerium für Umwelt, Naturschutz, Nukleare Sicherheit und Verbraucherschutz. Bundesgesetzblatt Teil I Nr. 45/Gesetz über das Inverkehrbringen, die Rücknahme und die hochwertige Verwertung von Verpackungen (Verpackungsgesetz–VerpackG); Bundesministerium für Umwelt, Naturschutz, Nukleare Sicherheit und Verbraucherschutz: Bonn, Germany, 2017. [Google Scholar]

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018; Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:2df5d1d2-fac7-11e7-b8f5-01aa75ed71a1.0001.02/DOC_1&format=PDF (accessed on 14 April 2022).

- Blomsma, F.; Brennan, G. The Emergence of Circular Economy: A New Framing Around Prolonging Resource Productivity. J. Ind. Ecol. 2017, 21, 603–614. [Google Scholar] [CrossRef]

- Johansen, M.R.; Christensen, T.B.; Ramos, T.M.; Syberg, K. A review of the plastic value chain from a circular economy perspective. J. Environ. Manag. 2022, 302, 113975. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Rethinking the Future of Plastics; MacArthur Foundation: Cowes, UK, 2016. [Google Scholar]

- Roux, M.; Varrone, C. Assessing the Economic Viability of the Plastic Biorefinery Concept and Its Contribution to a More Circular Plastic Sector. Polymers 2021, 13, 3883. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Faraca, G.; Astrup, T. Plastic waste from recycling centres: Characterisation and evaluation of plastic recyclability. Waste Manag. 2019, 95, 388–398. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. The New Plastics Economy: Catalysing Action. 2017. Available online: https://emf.thirdlight.com/link/u3k3oq221d37-h2ohow/@/preview/1?o (accessed on 10 April 2022).

- Sassanelli, C.; Rosa, P.; Terzi, S. disassembly processes through simulation tools: A systematic literature review with a focus on printed circuit boards. J. Manuf. Syst. 2021, 60, 429–448. [Google Scholar] [CrossRef]

- Picuno, C.; Alassali, A.; Chong, Z.K.; Kuchta, K. Flows of post-consumer plastic packaging in Germany: An MFA-aided case study. Resour. Conserv. Recycl. 2021, 169, 105515. [Google Scholar] [CrossRef]

- Kaiser, K.; Schmid, M.; Schlummer, M. Recycling of Polymer-Based Multilayer Packaging: A Review. Recycling 2018, 3, 1. [Google Scholar] [CrossRef] [Green Version]

- Wani, A.A.; Singh, P.; Langowski, H.-C. Introduction: Food Packaging Materials. In Food Packing Materials: Testing & Quality Assurance; Singh, P., Wani, A.A., Langowski, H.-C., Eds.; CRC Press: Boca-Rotan, FL, USA, 2017; pp. 1–9. ISBN 978-1-4665-5994-3. [Google Scholar]

- Bishop, C.A.; Mount, E.M. Vacuum Metallizing for Flexible Packaging. In Multilayer Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 235–255. ISBN 9780323371001. [Google Scholar]

- Gesellschaft für Verpackungsmarktforschung. Entwicklung des Verpackungsverbrauchs Flexibler Kunststoffe nach Branchen: Auswertung des deutschen Marktes 2009, Prognose 2014; Gesellschaft für Verpackungsmarktforschung: Mainz, Germany, 2010. [Google Scholar]

- Tartakowski, Z. Recycling of packaging multilayer films: New materials for technical products. Resour. Conserv. Recycl. 2010, 55, 167–170. [Google Scholar] [CrossRef]

- Anukiruthika, T.; Sethupathy, P.; Wilson, A.; Kashampur, K.; Moses, J.A.; Anandharamakrishnan, C. Multilayer packaging: Advances in preparation techniques and emerging food applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 1156–1186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goulas, A. Overall migration from commercial coextruded food packaging multilayer films and plastics containers into official EU food simulants. Eur. Food Res. Technol. 2001, 212, 597–602. [Google Scholar] [CrossRef]

- Dixon, J. Packaging Materials: 9. Multilayer Packaging for Food and Beverages; ILSI Europe: Brussels, Belgium, 2011; ISBN 9789078637264. [Google Scholar]

- Butler, T.I.; Morris, B.A. PE-Based Multilayer Film Structures. In Multilayer Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 281–310. ISBN 9780323371001. [Google Scholar]

- Morris, B.A. The science and Technology of Flexible Packaging: Multilayer Films from Resin and Process to End Use; William Andrew: Norwich, NY, USA, 2017; ISBN 978-0-323-24273-8. [Google Scholar]

- Dahlbo, H.; Poliakova, V.; Mylläri, V.; Sahimaa, O.; Anderson, R. Recycling potential of post-consumer plastic packaging waste in Finland. Waste Manag. 2018, 71, 52–61. [Google Scholar] [CrossRef]

- Tarantili, P.A.; Kiose, V. Effect of accelerated aging on the structure and properties of monolayer and multilayer packaging films. J. Appl. Polym. Sci. 2008, 109, 674–682. [Google Scholar] [CrossRef]

- Bauer, A.-S.; Tacker, M.; Uysal-Unalan, I.; Cruz, R.M.S.; Varzakas, T.; Krauter, V. Recyclability and Redesign Challenges in Multilayer Flexible Food Packaging-A Review. Foods 2021, 10, 2702. [Google Scholar] [CrossRef]

- Horodytska, O.; Valdés, F.J.; Fullana, A. Plastic flexible films waste management-A state of art review. Waste Manag. 2018, 77, 413–425. [Google Scholar] [CrossRef]

- Riedl, F. Recyclingherausforderung Multi-Layer? Neuartiges Aufbereitungsverfahren bietet Lösungen. In Vorträge-Konferenzband zur 14. Recy & DepoTech-Konferenz: Tracer Based Sorting–Innovative Sorting Options for Post Consumer Products; Pomberger, R., Adam, J., Aldrian, A., Kranzinger, L., Lorber, K., Neuhold, S., Nigl, T., Pfandl, K., Sarc, R., Schwarz, T., et al., Eds.; Abfallverwertungstechnik & Abfallwirtschaft Eigenverlag: Leoben, Austria, 2018; pp. 269–274. ISBN 9783200058743. [Google Scholar]

- Deutsches Institut für Normung. Kennzeichnung von Packstoffen und Packmitteln-Packstoffe und Packmittel aus Kunststoff; DIN 6120:2019-03; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- Clauß, D. Abfallmenge und Abfallzusammensetzung. In Einführung in die Kreislaufwirtschaft; Kranert, M., Ed.; Springer Fachmedien: Wiesbaden, Germany, 2017; pp. 65–110. ISBN 978-3-8348-1837-9. [Google Scholar]

- Acerbi, F.; Sassanelli, C.; Terzi, S.; Taisch, M. A Systematic Literature Review on Data and Information Required for Circular Manufacturing Strategies Adoption. Sustainability 2021, 13, 2047. [Google Scholar] [CrossRef]

- Chiappetta Jabbour, C.J.; Fiorini, P.D.C.; Ndubisi, N.O.; Queiroz, M.M.; Piato, É.L. Digitally-enabled sustainable supply chains in the 21st century: A review and a research agenda. Sci. Total Environ. 2020, 725, 138177. [Google Scholar] [CrossRef]

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Santibañez Gonzalez, E.D.R. Circular economy and big data analytics: A stakeholder perspective. Technol. Forecast. Soc. Chang. 2019, 144, 466–474. [Google Scholar] [CrossRef]

- Garcia, J.M.; Robertson, M.L. The future of plastics recycling. Science 2017, 358, 870–872. [Google Scholar] [CrossRef]

- Rosa, P.; Sassanelli, C.; Urbinati, A.; Chiaroni, D.; Terzi, S. Assessing relations between Circular Economy and Industry 4.0: A systematic literature review. Int. J. Prod. Res. 2020, 58, 1662–1687. [Google Scholar] [CrossRef] [Green Version]

- Sarc, R.; Hermann, R. Unternehmensbefragung zum Thema Abfallwirtschaft 4.0. In Vorträge-Konferenzband zur 14. Recy & DepoTech-Konferenz: Tracer Based Sorting–Innovative Sorting Options for Post Consumer Products; Pomberger, R., Adam, J., Aldrian, A., Kranzinger, L., Lorber, K., Neuhold, S., Nigl, T., Pfandl, K., Sarc, R., Schwarz, T., et al., Eds.; Abfallverwertungstechnik & Abfallwirtschaft Eigenverlag: Leoben, Austria, 2018; pp. 805–812. ISBN 9783200058743. [Google Scholar]

- Sarc, R.; Curtis, A.; Khodier, K.; Koinegg, J.; Ortner, M. Digitale Abfallwirtschaft. In Vorträge-Konferenzband zur 14. Recy & DepoTech-Konferenz: Tracer Based Sorting–Innovative Sorting Options for Post Consumer Products; Pomberger, R., Adam, J., Aldrian, A., Kranzinger, L., Lorber, K., Neuhold, S., Nigl, T., Pfandl, K., Sarc, R., Schwarz, T., et al., Eds.; Abfallverwertungstechnik & Abfallwirtschaft Eigenverlag: Leoben, Austria, 2018; pp. 793–798. ISBN 9783200058743. [Google Scholar]

- Sarc, R.; Pomberger, R. „ReWaste4.0“–Abfallwirtschaftliches Kompetenzzentrum am AVAW der Montanuniversität Leoben. Osterr. Wasser Abfallwirtsch. 2022, 74, 39–50. [Google Scholar] [CrossRef]

- Rocca, R.; Rosa, P.; Sassanelli, C.; Fumagalli, L.; Terzi, S. Integrating Virtual Reality and Digital Twin in Circular Economy Practices: A Laboratory Application Case. Sustainability 2020, 12, 2286. [Google Scholar] [CrossRef] [Green Version]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Schmidt, J.; Auer, M.; Moesslein, J.; Wendler, P.; Wiethoff, S.; Lang-Koetz, C.; Woidasky, J. Challenges and Solutions for Plastic Packaging in a Circular Economy. Chem. Ing. Tech. 2021, 9, 105. [Google Scholar] [CrossRef]

- Langhe, D.; Ponting, M. Coextrusion Processing of Multilayered Films. In Manufacturing and Novel Applications of Multilayer Polymer Films; Ponting, M., Langhe, D., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 16–45. ISBN 9780323371254. [Google Scholar]

- Häsänen, E. Composition Analysis and Compatibilization of Post-Consumer Recycled Multilayer Plastic Films. Master’s Thesis, Tampere University of Technology, Tampere, Finland, 2016. [Google Scholar]

- Franz, R. Migration of plastic constituents. In Plastic Packaging Materials for Food: Barrier Function, Mass Transport, Quality Assurance, and Legislation; Piringer, O.-G., Baner, A.L., Eds.; Wiley-VCH Verlag GmbH: Weinheim, Germany, 2000; pp. 287–357. ISBN 9783527613281. [Google Scholar]

- Ajitha, A.R.; Aswathi, M.K.; Maria, H.J.; Izdebska, J.; Thomas, S. Multilayer Polymer Films. In Multicomponent Polymeric Materials; Kim, C.-k., Thomas, S., Saha, P., Eds.; Springer: Dordrecht, The Netherlands, 2016; pp. 229–258. ISBN 9789401773232. [Google Scholar]

- Gutoff, E.B.; Cohen, E.D. Water- and Solvent-Based Coating Technology. In Multilayer Flexible Packaging; Elsevier: Amsterdam, The Netherlands, 2016; pp. 205–234. ISBN 9780323371001. [Google Scholar]

- Mariam, M. Charakterisierung von Verbundfolien zur Evaluierunng von Recycling Potentialen. Ph.D. Thesis, Technische Universität Wien, Vienna, Austria, 2020. [Google Scholar]

- Barlow, C.Y.; Morgan, D.C. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- European Commission. Plastics: Reuse, Recycling and Marine Litter: Final Report; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-93917-4. [Google Scholar]

- Woidasky, J. Plastics Recycling. In Ullmann’s Encyclopedia of Industrial Chemistry; Wiley: Hoboken, NJ, USA, 2000; pp. 1–29. ISBN 9783527303854. [Google Scholar]

- Xiao, K.; Zatloukal, M. Multilayer Die Design and Film Structures. In Film Processing Advances; Kanai, T., Campbell, G.A., Eds.; Hanser Publications: Munich, Germany, 2014; pp. 68–102. ISBN 9781569905364. [Google Scholar]

- Vera, P.; Canellas, E.; Nerín, C. Compounds responsible for off-odors in several samples composed by polypropylene, polyethylene, paper and cardboard used as food packaging materials. Food Chem. 2020, 309, 125792. [Google Scholar] [CrossRef]

- Ashter, S.A. Matching Material Characteristics to Commercial Thermoforming. In Thermoforming of Single and Multilayer Laminates; Elsevier: Amsterdam, The Netherlands, 2014; pp. 193–209. ISBN 9781455731725. [Google Scholar]

- Goetz, W. Polyamide for Flexible Packaging Film. Available online: https://www.tappi.org/content/enewsletters/eplace/2004/10-2goetz.pdf (accessed on 18 February 2021).

- Marsh, K.; Bugusu, B. Food packaging–Roles, materials, and environmental issues. J. Food Sci. 2007, 72, R39–R55. [Google Scholar] [CrossRef]

- Fereydoon, M.; Ebnesajjad, S. Development of High-Barrier Film for Food Packaging. In Plastic Films in Food Packaging; Elsevier: Amsterdam, The Netherlands, 2013; pp. 71–92. ISBN 9781455731121. [Google Scholar]

- Becker, W.; Sachsenheimer, K.; Klemenz, M. Detection of Black Plastics in the Middle Infrared Spectrum (MIR) Using Photon Up-Conversion Technique for Polymer Recycling Purposes. Polymers 2017, 9, 435. [Google Scholar] [CrossRef] [Green Version]

- Burns, D.A.; Ciurczak, E.W. Handbook of Near-Infrared Analysis; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9780429123016. [Google Scholar]

- Habich, U.; Beel, H. Modifizierung von Recyclingverfahren durch sensorbasierte Sortierung. In Recycling und Rohstoffe; Thomé-Kozmiensky, K.J., Goldmann, D., Eds.; TK Verlag: Neuruppin, Germany, 2014; pp. 471–482. ISBN 978-3-944310-09-1. [Google Scholar]

- de Biasio, M.; Arnold, T.; McGunnigle, G.; Leitner, R.; Balthasar, D.; Rehrmann, V. Detecting and discriminating PE and PP polymers for plastics recycling using NIR imaging spectroscopy. In Proceedings of the SPIE Defense, Security, and Sensing, Thermosense XXXII, Orlando, FL, USA, 5 April 2010; Dinwiddie, R.B., Safai, M., Eds.; SPIE: Bellingham, WA, USA, 2010; Volume 7661. [Google Scholar]

- Küppers, B.; Vollprecht, D.; Pomberger, R. Einfluss von Verschmutzungen auf die sensorgestützte Sortierung. In Vorträge-Konferenzband zur 14. Recy & DepoTech-Konferenz: Tracer Based Sorting–Innovative Sorting Options for Post Consumer Products; Pomberger, R., Adam, J., Aldrian, A., Kranzinger, L., Lorber, K., Neuhold, S., Nigl, T., Pfandl, K., Sarc, R., Schwarz, T., et al., Eds.; Abfallverwertungstechnik & Abfallwirtschaft Eigenverlag: Leoben, Austria, 2018; pp. 111–118. ISBN 9783200058743. [Google Scholar]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kusch, A.; Gasde, J.; Deregowski, C.; Woidasky, J.; Lang-Koetz, C.; Viere, T. Sorting and Recycling of Lightweight Packaging in Germany—Climate Impacts and Options for Increasing Circularity Using Tracer-Based-Sorting. Mater. Circ. Econ. 2021, 3, 125. [Google Scholar] [CrossRef]

- Brunner, S.; Fomin, P.; Zhelondz, D.; Kargel, C. Investigation of algorithms for the reliable classification of fluorescently labeled plastics. In Proceedings of the 2012 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Graz, Austria, 13–16 May 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1659–1664, ISBN 978-1-4577-1772-7. [Google Scholar]

- Nonclercq, A. Mapping Flexible Packaging in a Circular Economy [F.I.A.C.E]: Final Report; Delft University of Technology: Delft, The Netherlands, 2016. [Google Scholar]

- Briedis, R.; Syversen, F. Plastic Packaging Recyclability in a Nordic Context; Nordic Council of Ministers: Copenhagen, Denmark, 2019; ISBN 9789289362399. [Google Scholar]

- Christiani, J.; Beckamp, S. Was können die mechanische Aufbereitung von Kunststoffen und das werkstoffliche Recycling leisten. In Energie aus Abfall; Thiel, S., Thomé-Kozmiensky, E., Quicker, P., Gosten, A., Eds.; Thomé-Kozmiensky Verlag GmbH: Neuruppin, Germany, 2020; pp. 139–152. ISBN 9783944310503. [Google Scholar]

- Hahladakis, J.N.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity. Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef] [PubMed]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Use of Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- DerGrünePunkt. Produktspezifikation 03/2018 Fraktions-Nr. 325. Available online: https://www.gruener-punkt.de/fileadmin/Dateien/Downloads/PDFs/spezifikationen/325_PET-Flaschen_-_transparent.pdf (accessed on 10 March 2021).

- DerGrünePunkt. Produktspezifikation 03/2018 Fraktions-Nr. 310-1. Available online: https://www.gruener-punkt.de/fileadmin/Dateien/Downloads/PDFs/spezifikationen/310-1_Kunststoff-Folien.pdf (accessed on 19 January 2022).

- Ehrenstein, G.W. Polymer Werkstoffe: Struktur Eigenschaften Anwendung, 3. Auflage; Hanser Verlag: München, Germany, 2011; ISBN 978-3-446-42283-4. [Google Scholar]

- Bonnet, M. Kunststoffe in der Ingenieuranwendung: Verstehen und Zuverlässig Auswählen, 1. Aufl.; Vieweg + Teubner Verlag/GWV Fachverlage: Wiesbaden, Germany, 2009; ISBN 9783834803498. [Google Scholar]

- Jönkkäri, I.; Poliakova, V.; Mylläri, V.; Anderson, R.; Andersson, M.; Vuorinen, J. Compounding and characterization of recycled multilayer plastic films. J. Appl. Polym. Sci. 2020, 137, 49101. [Google Scholar] [CrossRef]

- Nickel, W. Recycling-Handbuch; Springer: Berlin/Heidelberg, Germany, 1996; ISBN 978-3-642-95769-7. [Google Scholar]

- Pilz, H.; Brandt, B.; Fehringer, R. The Impact of Plastics on Life Cycle Energy Consumption and Greenhouse Gas Emissions in Europe; PlasticsEurope: Vienna, Austria, 2010. [Google Scholar]

- Knappe, F.; Reinhardt, J.; Kauertz, B.; Oetjen-Dehne, R.; Buschow, N.; Ritthoff, M.; Wilts, H.; Lehmann, M. Technische Potenzialanalyse zur Steigerung des Kunststoffrecyclings und des Rezyklateinsatzes; Wuppertal Institut für Klima, Umwelt, Energie: Wuppertal, Germany, 2021. [Google Scholar]

- Elsner, P.; Müller-Kirschbaum, T.; Schweitzer, K.; Wolf, R.; Seiler, E.; Désilets, P.; Detsch, R.; Dornack, C.; Ferber, J.; Fleck, C.; et al. Kunststoffverpackungen im Geschlossenen Kreislauf–Potenziale, Bedingungen, Herausforderungen; Acatech: Munich, Germany, 2021. [Google Scholar]

- Berg, H.; Kulinna, R.; Stöcker, C.; Guth-Orlowski, S.; Thiermann, R.; Porepp, N. Overcoming Information Asymmetry in the Plastics Value Chain with Digital Product Passports; Wuppertal Institut für Klima, Umwelt, Energie: Wuppertal, Germany, 2022; Available online: https://epub.wupperinst.org/frontdoor/index/index/docId/7940 (accessed on 14 April 2022).

- Salmenperä, H.; Pitkänen, K.; Kautto, P.; Saikku, L. Critical factors for enhancing the circular economy in waste management. J. Clean. Prod. 2021, 280, 124339. [Google Scholar] [CrossRef]

- Balwada, J.; Samaiya, S.; Mishra, R.P. Packaging Plastic Waste Management for a Circular Economy and Identifying a better Waste Collection System using Analytical Hierarchy Process (AHP). Procedia CIRP 2021, 98, 270–275. [Google Scholar] [CrossRef]

- European Commission. Closing the Loop–An EU Action Plan for the Circular Economy; European Commission: Brussels, Belgium, 2015; Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:8a8ef5e8-99a0-11e5-b3b7-01aa75ed71a1.0012.02/DOC_1&format=PDF (accessed on 14 April 2022).

- CEFLEX. Designing for a Circular Economy: Recyclability of Polyolefin-Based Flexible Packaging. 2020. Available online: https://guidelines.ceflex.eu/resources/ (accessed on 27 January 2022).

- Woidasky, J.; Schmidt, J.; Auer, M.; Sander, I.; Schau, A.; Moesslein, J.; Wendler, P.; Kirchenbauer, D.; Wacker, D.; Gao, G.; et al. Photoluminescent Tracer Effects on Thermoplastic Polymer Recycling. In Advances in Polymer Processing 2020; Hopmann, C., Dahlmann, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–13. ISBN 978-3-662-60808-1. [Google Scholar]

- Brunner, S.; Fomin, P.; Kargel, C. Automated sorting of polymer flakes: Fluorescence labeling and development of a measurement system prototype. Waste Manag. 2015, 38, 49–60. [Google Scholar] [CrossRef]

- Ahmad, S.R. A new technology for automatic identification and sorting of plastics for recycling. Environ. Technol. 2004, 25, 1143–1149. [Google Scholar] [CrossRef]

- AIM-European Brands Association. Pioneering Digital Watermarks for Accurate Sorting and High Quality Recycling–HolyGrail 2.0. Available online: https://www.aim.be/priorities/digital-watermarks/ (accessed on 16 April 2021).

- Meys, R.; Frick, F.; Westhues, S.; Sternberg, A.; Klankermayer, J.; Bardow, A. Towards a circular economy for plastic packaging wastes–The environmental potential of chemical recycling. Resour. Conserv. Recycl. 2020, 162, 105010. [Google Scholar] [CrossRef]

- Agulla, K. Circular Packaging–Bau einer Industriellen Demonstrationsanlage für das Recycling von Kunststoffverpackungen; Fraunhofer IVV, 14 January 2019. Available online: https://www.ivv.fraunhofer.de/de/presseinformationen/circular-packaging.html (accessed on 26 January 2022).

- CreaCycle GmbH. CreaSolv® Demonstrationsanlage für Kunststoff Verpackungsabfälle–Lober. 2018. Available online: https://www.creacycle.de/de/creasolv-werke/circular-packaging-2018.html (accessed on 26 January 2022).

- Schlummer, M.; Fell, T.; Mäurer, A.; Altnau, G. Die Rolle der Chemie beim Recycling: Physikalisches und chemisches Kunststoffrecycling im Vergleich. Kunststoffe 2020, 6, 51–54. [Google Scholar]

- Vollmer, I.; Jenks, M.J.F.; Roelands, M.C.P.; White, R.J.; Harmelen, T.; Wild, P.; Laan, G.P.; Meirer, F.; Keurentjes, J.T.F.; Weckhuysen, B.M. Die nächste Generation des Recyclings–neues Leben für Kunststoffmüll. Angew. Chem. 2020, 132, 15524–15548. [Google Scholar] [CrossRef]

- Lovis, F.; Seibt, H.; Kernbaum, S. Method and Apparatus for Recycling Packaging Material. U.S. Patent No. 10,682,788, 16 June 2020. [Google Scholar]

- Wohnig, K.; Kaina, M.; Fleig, M.; Hanel, H. Solvent and Method for Dissolving at Least Two Plastics from a Solid within a Suspension. Patent No. DE.102.016.015.199.A1, 21 June 2018. [Google Scholar]

- Saperatec GmbH. Homepage: Applications. Available online: https://www.saperatec.de/en/technology.html (accessed on 19 January 2022).

- Purecycle. News-Seite. Available online: https://purecycle.com/2021/11/purecycle-technologies-provides-third-quarter-2021-update/ (accessed on 26 January 2022).

- Walker, T.W.; Frelka, N.; Shen, Z.; Chew, A.K.; Banick, J.; Grey, S.; Kim, M.S.; Dumesic, J.A.; van Lehn, R.C.; Huber, G.W. Recycling of multilayer plastic packaging materials by solvent-targeted recovery and precipitation. Sci. Adv. 2020, 6, eaba7599. [Google Scholar] [CrossRef] [PubMed]

- Georgiopoulou, I.; Pappa, G.D.; Vouyiouka, S.N.; Magoulas, K. Recycling of post-consumer multilayer Tetra Pak® packaging with the Selective Dissolution-Precipitation process. Resour. Conserv. Recycl. 2021, 165, 105268. [Google Scholar] [CrossRef]

- BASF. Chemical Recycling of Plastic Waste. Available online: https://www.basf.com/global/de/who-we-are/sustainability/we-drive-sustainable-solutions/circular-economy/mass-balance-approach/chemcycling.html (accessed on 21 January 2022).

- Garbo. Homepage. Available online: https://garbo.it/en/chempet/ (accessed on 21 January 2022).

- Kaiser, K.M.A. Recycling of multilayer packaging using a reversible cross-linking adhesive. J. Appl. Polym. Sci. 2020, 137, 49230. [Google Scholar] [CrossRef] [Green Version]

- Engel, D.W.; Dalton, A.C.; Anderson, K.K.; Sivaramakrishnan, C.; Lansing, C. Development of Technology Readiness Level (TRL) Metrics and Risk Measures. 2012. Available online: https://www.osti.gov/biblio/1067968 (accessed on 26 January 2022).

- European Commission. A New Method for Separation Full Recovery of Multilayer Packaging Waste to Create High Value Materials—LAMPACK. Available online: https://cordis.europa.eu/project/id/736010 (accessed on 22 February 2021).

- Schmidt, J.; Auer, M. Analyse von Leichtverpackungsabfällen aus deutschen Haushalten. In Markerbasiertes Sortier und Recyclingsystem für Kunststoffverpackungen: Schlussbericht des BMBF-Forschungsvorhabens “MaReK”. Förderkennzeichen: 033R195A bis E; Technische Informationsbibliothek: Pforzheim, Germany, 2021; in press. [Google Scholar]

- Berndt, D.; Sellschopf, L. Packstoffe, Packmittel und Packhilfsmittel. In Grundlagen der Verpackung: Leitfaden für die Fächerübergreifende Verpackungsausbildung, 1. Aufl.; Kaßmann, M., Ed.; Beuth: Berlin, Germany, 2011; pp. 19–96. ISBN 978-3410204923. [Google Scholar]

- Duale Systeme Deutschland. Neue Mülltrennungsstudie: Die Deutschen Brauchen Nachhilfe im Mülltrennen; Köln, Germany, 2020; Available online: https://www.muelltrennung-wirkt.de/neue-muelltrennungsstudie-die-deutschen-brauchen-nachhilfe-im-muelltrennen/ (accessed on 9 April 2021).

- Conversio GmbH. Material Flow Analysis Plastics in Germany 2019; Conversio: Mainaschaff, Germany. 2020. Available online: https://www.bkv-gmbh.de/files/bkv-neu/studien/Summary_Material_Flow_Analysis_Plastics_Germany_2019_EN.pdf (accessed on 8 June 2021).

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263. [Google Scholar] [CrossRef]

- Partridge, C.; Medda, F. Opportunities for chemical recycling to benefit from waste policy changes in the United Kingdom. Resour. Conserv. Recycl. X 2019, 3, 100011. [Google Scholar] [CrossRef]

- Baldt, T. Robotersortierlösung von ZenRobotics. In Vorträge-Konferenzband zur 14. Recy & DepoTech-Konferenz: Tracer Based Sorting–Innovative Sorting Options for Post Consumer Products; Pomberger, R., Adam, J., Aldrian, A., Kranzinger, L., Lorber, K., Neuhold, S., Nigl, T., Pfandl, K., Sarc, R., Schwarz, T., et al., Eds.; Abfallverwertungstechnik & Abfallwirtschaft Eigenverlag: Leoben, Austria, 2018; pp. 695–700. ISBN 9783200058743. [Google Scholar]

- ZenRobotics. Fast Picker: High-Speed Robot for Maximizing Material Recovery. Available online: https://zenrobotics.com/solutions/fast-picker/ (accessed on 5 May 2021).

- Machinex. SamurAI. Available online: https://www.machinexrecycling.com/samurai/ (accessed on 5 May 2021).

- Steinert. UniSort PR EVO 5.0: NIR-Sortieraggregat mit Hyper Spectral Imaging-Kameratechnik. State of the Art–Kamerabasierte NIR-Technologie für Noch bessere Sortierergebnisse. Available online: https://steinertglobal.com/de/magnete-sensorsortierer/sensorsortierung/nir-sortiersysteme/unisort-pr/ (accessed on 5 May 2021).

- van Velzen, U.T.; de Weert, L.; Molenveld, K. Flexible Laminates within the Circular Economy; Wageningen University & Research: Wageningen, The Netherlands, 2020. [Google Scholar]

| Layer | Function | Material |

|---|---|---|

| (1) Seal Layer (innermost layer) | Heat sealability (low melting temperature), inert against filling goods | (LLD, LD) PE, EVA, ionomers, (O)PP, (O)PA, (O)PET |

| Resistance against: | ||

| (2) Barrier Layer | Moisture | (LD, LLD, HD) PE; (O)PP, EVA, ionomers, PVDC, PET |

| Oil/grease | PET, HDPE, PA, Ionomers, EVOH, PVDC | |

| Water vapor | PP, HDPE, PELD, PVDC | |

| Aroma/flavor | PET, PA, EVOH, PVDC | |

| Oxygen | EVOH (standard), PA or PET (below standard), Aluminum (exceeding standard), PVDC, (biaxially oriented) PA, (oriented) PET, SiOx, or Al2O3 coatings | |

| Light | Aluminum, TiO2-filled polymers | |

| (3) Tie Layer | Combines two chemically incompatible materials | polyurethanes, acid/anhydride grafted polyolefins |

| (4) Structural layer | Provides shape: Toughness | PE, PET |

| Puncture resistance | HDPE, PA | |

| Stiffness | PP, PET, HDPE, LDPE, PA, EVA, Ionomers, EVOH | |

| Stability | PP, PET, PA, EVA, ionomers, EVOH | |

| (5) Outer layer | Provides printing surface and mechanical performance | PE or PET |

| (6) Coating (outermost layer facing environment) | Optional thin film to protect the printed material | Any specialized polymer |

| Polymer-Matrix | |||||||

|---|---|---|---|---|---|---|---|

| PE | PP | PET | PA | PS | PVC | ||

| Additive material | PE | 1 | 3–4 | 4 | 2–4 | 4 | 4 |

| PP | 2–4 | 1 | 4 | 2–4 | 4 | 4 | |

| PET | 4 | 4 | 1 | 3–4 | 4 | 4 | |

| PA | 4 | 4 | 3 | 1 | 3–4 | 4 | |

| PS | 4 | 4 | 3 | 3–4 | 1 | 4 | |

| PVC | 4 | 4 | 4 | 4 | 2–4 | 1 | |

| Procedure/Company | Raw material/Recovery | Capacity | * TRL | Current Status |

|---|---|---|---|---|

| Solvent-Based Recycling Processes | ||||

| CreaSolv® (Fraunhofer IVV) [94,95,96] | PE from post-consumer multilayer pouches | 1000 t/a | 7 | Pilot plant (2019) for recycling post-consumer multilayer pouches in Indonesia |

| PE and PP from, e.g., multilayer (post-consumer) consisting of PE/PA, PP/PET, and aluminum content | Truckload per day (approx. 5 m³ per day) | 5 | Construction of an industrial-scale pilot plant (2020) in Germany as part of the “Circular Packaging” project. | |

| Newcycling® (APK AG) [33,97,98,99] | PE/PA and aluminum from multilayer films (post-industrial) Separation of PE from PP | 8000 t/a | 7 | Operation of a pilot plant (2018) in Germany |

| Saperatec GmbH [98,100] | PET, PE, and aluminum from each other Paper, plastic, and aluminum (liquid cartons) | 18,000 t/a | 5–6 | Pilot plant currently under construction (completion 2023) |

| Purecycle (Procter & Gamble) [96,101] | PP from, e.g., food and liquid packaging | 48,000 t/a | 6 | Pilot plant currently under construction (completion end 2022) |

| Solvent-targeted recovery and precipitation [102] | PE, EVOH, and PET from each other | / | 1 | Release (solvent) of the target polymer from the composite system with subsequent precipitation and repetition for the next target polymer. |

| Recycling of post-consumer multilayer Tetra Pak® packaging with the selective dissolution–precipitation process [103] | LDPE from aluminum (Tetra Paks) | / | 1 | Separation through selective dissolution–precipitation process |

| Chemical recycling processes | ||||

| ChemCycling (BASF) [104] | Pyrolysis process enables recycling of post-consumer plastic waste (also multilayers) | / | 3–4 | / |

| ChemPET (Garbo) [105] | PET out of multilayer films (PET/PE/aluminum/PE) and multilayer trays (PET/PE/EVOH/PE) | 1000 t/a | 6 | Operation of a pilot plant using glycolysis (3 t/day) |

| Other approaches | ||||

| Recycling of multilayer packaging using a reversible crosslinking adhesive [106] | PE/PET, PET/aluminum, and PE/aluminum from each other | / | 1 | Modification of the packaging adhesives. Separation by heated solvent from dimethylsulfoxide |

| Packaging Type | Mass Share [%] |

|---|---|

| Unmarked (no recycling code) | 30.69 |

| 3-Composite paper/cardboard+metal+plastic | 10.97 |

| PP | 10.46 |

| Tinplate | 8.53 |

| PET | 8.46 |

| 2-Composite paper/cardboard+plastic | 6.77 |

| Paper/cardboard (no compound) | 5.71 |

| HDPE | 3.46 |

| LDPE | 3.14 |

| PS | 2.61 |

| Aluminum | 2.54 |

| 07-Other (recycling code) | 2.41 |

| 2-Composite aluminum+paper/cardboard | 1.57 |

| Remaining small parts | 1.27 |

| 2-Composite plastic+aluminum | 0.80 |

| Plastic+paper/cardboard unlaminated | 0.53 |

| PA | 0.02 |

| PLA | 0.02 |

| PVC | 0.02 |

| PMMA | 0.01 |

| Total | 100.00 |

| Packaging Type | IR Sample | ML Sample | Original Sample | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Count Share | Percentage Share [%] | |||||||||

| Pouch | 498 | | | 41.85 | 135 | | | 45.61 | 7351 | | | 34.38 |

| Foil | 156 | | | 13.11 | 85 | | | 28.72 | 2466 | | | 11.53 |

| Tray | 301 | | | 25.29 | 56 | | | 18.92 | 2197 | | | 10.28 |

| Separate closure element | 3 | | | 0.25 | | | 1865 | | | 8.72 | ||

| Cup | 42 | | | 3.53 | | | 1477 | | | 6.91 | ||

| Bag | 105 | | | 8.82 | | | 1466 | | | 6.86 | ||

| Liquid packaging | 2 | | | 0.17 | | | 1027 | | | 4.80 | ||

| Bottle | 7 | | | 0.59 | | | 610 | | | 2.85 | ||

| Can | | | | | 530 | | | 2.48 | ||||

| Blister | 4 | | | 0.34 | | | 494 | | | 2.31 | ||

| Non-packaging items | 7 | | | 0.59 | | | 370 | | | 1.73 | ||

| Skin packaging | 36 | | | 3.03 | | | 355 | | | 1.66 | ||

| Tube | 3 | | | 0.25 | | | 250 | | | 1.17 | ||

| Net | 6 | | | 0.50 | | | 229 | | | 1.07 | ||

| Remaining small parts | | | | | 199 | | | 0.93 | ||||

| Folding box | | | | | 189 | | | 0.88 | ||||

| Other packaging element | 1 | | | 0.08 | | | 113 | | | 0.53 | ||

| Rigid foil | 17 | | | 1.43 | | | 98 | | | 0.46 | ||

| Filling material | 2 | | | 0.17 | | | 60 | | | 0.28 | ||

| Wrap packaging | | | | | 25 | | | 0.12 | ||||

| Screw-top jar | | | | | 9 | | | 0.04 | ||||

| * Stand-up pouch | | | 20 | | | 6.76 | | | ||||

| Total | 1190 | | | 100.00 | 296 | | | 100.00 | 21,380 | | | 100.00 |

| Packaging for | Pouch | Foil | Tray | Stand-Up Pouch | Total |

|---|---|---|---|---|---|

| Sliced cheese | 14 | 18 | 21 | 53 | |

| Sausages and cold cuts | 5 | 27 | 20 | 52 | |

| Baked goods | 21 | 4 | 1 | 26 | |

| Meat substitutes | 13 | 5 | 18 | ||

| Non-food items | 9 | 4 | 13 | ||

| Salty biscuits | 13 | 1 | 14 | ||

| Feta in brine | 12 | 12 | |||

| Mozzarella in brine | 12 | 12 | |||

| Nuts | 7 | 5 | 12 | ||

| Dry food | 11 | 11 | |||

| Coffee, tea, spices | 10 | 10 | |||

| Sweets | 8 | 8 | |||

| Preserves | 2 | 1 | 4 | 7 | |

| Ready meals | 1 | 3 | 2 | 6 | |

| Soft cheese | 2 | 3 | 1 | 6 | |

| Fresh meat + fish | 1 | 2 | 2 | 5 | |

| Granulates | 5 | 5 | |||

| Animal feed | 4 | 1 | 5 | ||

| Dried fruits | 3 | 2 | 5 | ||

| Minced meat | 2 | 2 | 4 | ||

| Hard cheese | 1 | 1 | 1 | 1 | 4 |

| Grated cheese | 4 | 4 | |||

| Vegetables | 2 | 2 | |||

| Butter | 1 | 1 | |||

| Rice pudding | 1 | 1 | |||

| Total | 135 | 85 | 56 | 20 | 296 |

| Material/Category | Result of the Recycling Code Labeling | Result after IR Analysis | Percentage Change |

|---|---|---|---|

| Mass Share [%] | |||

| PP | 11.34 | 25.55 | +125.30 |

| LDPE | 1.26 | 8.07 | +540.50 |

| PET | 3.53 | 6.89 | +95.20 |

| PS | 1.68 | 3.28 | +95.20 |

| PA | 0.25 | 1.18 | +372.00 |

| PVC | 0.34 | 2.35 | +591.20 |

| HDPE | 0.76 | 4.96 | +552.60 |

| Multilayer | * 4.79 | 43.19 | +801.70 |

| Unmarked (no recycling code) | 65.71 | 4.54 remain | −93.10 |

| 07-Other | 10.34 | not determinable | |

| Total | 100.00 | 100.00 | |

| Material Combinations | PET–LDPE | PA–LDPE | PP–PP | PP–LDPE | LDPE–LDPE | PET–PET | PET–PP |

|---|---|---|---|---|---|---|---|

| ML sample (wt%) | 38 | 15 | 14 | 8 | 6 | 5 | 3 |

| IR sample (wt%) | 51 | 23 | 3 | 5 | 2 | 3 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmidt, J.; Grau, L.; Auer, M.; Maletz, R.; Woidasky, J. Multilayer Packaging in a Circular Economy. Polymers 2022, 14, 1825. https://doi.org/10.3390/polym14091825

Schmidt J, Grau L, Auer M, Maletz R, Woidasky J. Multilayer Packaging in a Circular Economy. Polymers. 2022; 14(9):1825. https://doi.org/10.3390/polym14091825

Chicago/Turabian StyleSchmidt, Jannick, Laura Grau, Maximilian Auer, Roman Maletz, and Jörg Woidasky. 2022. "Multilayer Packaging in a Circular Economy" Polymers 14, no. 9: 1825. https://doi.org/10.3390/polym14091825

APA StyleSchmidt, J., Grau, L., Auer, M., Maletz, R., & Woidasky, J. (2022). Multilayer Packaging in a Circular Economy. Polymers, 14(9), 1825. https://doi.org/10.3390/polym14091825