3D-Printed Polylactic Acid/Lignin Films with Great Mechanical Properties and Tunable Functionalities towards Superior UV-Shielding, Haze, and Antioxidant Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

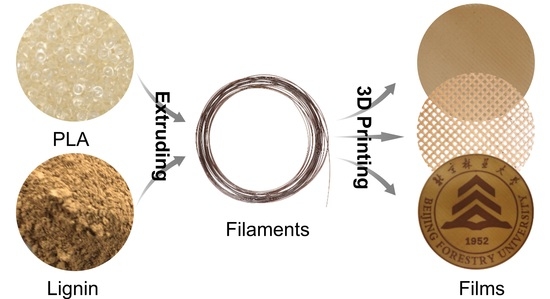

2.2. Preparation of P/L Filaments and 3D-Printed Film

2.3. Characterization

3. Results

3.1. P/L Filaments

3.2. 3D-Printed Films

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yong, H.; Liu, J. Active Packaging Films and Edible Coatings Based on Polyphenol-Rich Propolis Extract: A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2106–2145. [Google Scholar] [CrossRef]

- Li, D.; Lai, W.Y.; Zhang, Y.Z.; Huang, W. Printable Transparent Conductive Films for Flexible Electronics. Adv. Mater. 2018, 30, 1704738. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, W.; Deng, Y.; Fu, B.; Zhu, P.; Yu, Y.; Li, J.; Guo, J. Self-Powered Wearable Pressure Sensing System for Continuous Healthcare Monitoring Enabled by Flexible Thin-Film Thermoelectric Generator. Nano Energy 2020, 73, 104773. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Yuk, H.; Lu, B.; Lin, S.; Qu, K.; Xu, J.; Luo, J.; Zhao, X. 3D Printing of Conducting Polymers. Nat. Commun. 2020, 11, 1604. [Google Scholar] [CrossRef] [Green Version]

- Kumar Gupta, D.; Ali, M.H.; Ali, A.; Jain, P.; Anwer, M.K.; Iqbal, Z.; Mirza, M.A. 3D Printing Technology in Healthcare: Applications, Regulatory Understanding, IP Repository and Clinical Trial Status. J. Drug Target. 2022, 30, 131–150. [Google Scholar] [CrossRef]

- Lee, D.; Wu, G.Y. Parameters Affecting the Mechanical Properties of Three-Dimensional (3D) Printed Carbon Fiber-Reinforced Polylactide Composites. Polymers 2020, 12, 2456. [Google Scholar] [CrossRef]

- Yap, K.L.; Kong, I.; Abdul Kalam Saleena, L.; Pui, L.P. 3D Printed Gelatin Film with Garcinia Atroviridis Extract. J. Food Sci. Technol. 2022, 59, 4341–4351. [Google Scholar] [CrossRef]

- Wang, A.; Liu, J.; Shao, C.; Zhang, Y.; Chen, C. Electro-Assisted 3D Printing Multi-Layer PVDF/CaCl2 Composite Films and Sensors. Coatings 2022, 12, 820. [Google Scholar] [CrossRef]

- Yu, J.Y.; Kim, H.W.; Park, H.J. 131Customized Oral Mucosal Adhesive Film-Based Functional-Substance Delivery System Using Embedded 3D Printing Method. Food Hydrocoll. 2022, 131, 107762. [Google Scholar] [CrossRef]

- Schmidt, L.M.; dos Santos, J.; de Oliveira, T.V.; Funk, N.L.; Petzhold, C.L.; Benvenutti, E.V.; Deon, M.; Beck, R.C.R. Drug-Loaded Mesoporous Silica on Carboxymethyl Cellulose Hydrogel: Development of Innovative 3D Printed Hydrophilic Films. Int. J. Pharm. 2022, 620, 121750. [Google Scholar] [CrossRef]

- Mayakrishnan, V.; Mohamed, J.K.; Selvaraj, N.; SenthilKumar, D.; Annadurai, S. Effect of Nano-Biochar on Mechanical, Barrier and Mulching Properties of 3D Printed Thermoplastic Polyurethane Film. Polym. Bull. 2022, 80, 6725–6747. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, C.; Song, I.O.; Lee, B.J.; Kang, C.Y.; Park, J.B. Investigation of Patient-Centric 3D-Printed Orodispersible Films Containing Amorphous Aripiprazole. Pharmaceuticals 2022, 15, 895. [Google Scholar] [CrossRef]

- Qin, M.; Chen, C.; Song, B.; Shen, M.; Cao, W.; Yang, H.; Zeng, G.; Gong, J. A Review of Biodegradable Plastics to Biodegradable Microplastics: Another Ecological Threat to Soil Environments? J. Clean. Prod. 2021, 312, 127816. [Google Scholar] [CrossRef]

- Haider, T.P.; Völker, C.; Kramm, J.; Landfester, K.; Wurm, F.R. Kunststoffe Der Zukunft? Der Einfluss von Bioabbaubaren Polymeren Auf Umwelt Und Gesellschaft. Angew. Chem. 2019, 131, 50–63. [Google Scholar] [CrossRef]

- Hong, S.H.; Park, J.H.; Kim, O.Y.; Hwang, S.H. Preparation of Chemically Modified Lignin-Reinforced Pla Biocomposites and Their 3D Printing Performance. Polymers 2021, 13, 667. [Google Scholar] [CrossRef]

- Wasti, S.; Triggs, E.; Farag, R.; Auad, M.; Adhikari, S.; Bajwa, D.; Li, M.; Ragauskas, A.J. Influence of Plasticizers on Thermal and Mechanical Properties of Biocomposite Filaments Made from Lignin and Polylactic Acid for 3D Printing. Compos. Part B Eng. 2021, 205, 108483. [Google Scholar] [CrossRef]

- Tanase-Opedal, M.; Espinosa, E.; Rodríguez, A.; Chinga-Carrasco, G. Lignin: A Biopolymer from Forestry Biomass for Biocomposites and 3D Printing. Materials 2019, 12, 3006. [Google Scholar] [CrossRef] [Green Version]

- Domínguez-Robles, J.; Martin, N.K.; Fong, M.L.; Stewart, S.A.; Irwin, N.J.; Rial-Hermida, M.I.; Donnelly, R.F.; Larrañeta, E. Antioxidant Pla Composites Containing Lignin for 3D Printing Applications: A Potential Material for Healthcare Applications. Pharmaceutics 2019, 11, 165. [Google Scholar] [CrossRef] [Green Version]

- Mimini, V.; Sykacek, E.; Hashim, S.N.A.; Holzweber, J.; Hettegger, H.; Fackler, K.; Potthast, A.; Mundigler, N.; Rosenau, T. Compatibility of Kraft Lignin, Organosolv Lignin and Lignosulfonate With PLA in 3D Printing. J. Wood Chem. Technol. 2019, 39, 14–30. [Google Scholar] [CrossRef]

- Fang, C.; Zhang, Y.; Qi, S.; Liao, Y.; Li, Y.; Wang, P. Influence of Structural Design on Mechanical and Thermal Properties of Jute Reinforced Polylactic Acid (PLA) Laminated Composites. Cellulose 2020, 27, 9397–9407. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3d Printing Applications of Pla Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Li, Y.D.; Zeng, J.B. Progress in Toughening Poly(Lactic Acid) with Renewable Polymers. Polym. Rev. 2017, 57, 557–593. [Google Scholar] [CrossRef]

- Shi, S.; Dai, M.; Tao, X.; Wu, F.; Sun, J.; Chen, Y. 3D Printed Polylactic Acid/Graphene Nanocomposites with Tailored Multifunctionality towards Superior Thermal Management and High-Efficient Electromagnetic Interference Shielding. Chem. Eng. J. 2022, 450, 138248. [Google Scholar] [CrossRef]

- Al Zahmi, S.; Alhammadi, S.; Elhassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef]

- Sun, Y.; Zheng, Z.; Wang, Y.; Yang, B.; Wang, J.; Mu, W. PLA Composites Reinforced with Rice Residues or Glass Fiber—A Review of Mechanical Properties, Thermal Properties, and Biodegradation Properties. J. Polym. Res. 2022, 29, 422. [Google Scholar] [CrossRef]

- López-Camacho, A.; Magaña-García, D.; Grande, M.J.; Carazo-Álvarez, D.; La Rubia, M.D. Preliminary Study of the Bactericide Properties of Biodegradable Polymers (PLA) with Metal Additives for 3D Printing Applications. Bioengineering 2023, 10, 297. [Google Scholar] [CrossRef]

- Agaliotis, E.M.; Ake-Concha, B.D.; May-Pat, A.; Morales-Arias, J.P.; Bernal, C.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Proust, G.; Koh-Dzul, J.F.; Carrillo, J.G.; et al. Tensile Behavior of 3D Printed Polylactic Acid (PLA) Based Composites Reinforced with Natural Fiber. Polymers 2022, 14, 3976. [Google Scholar] [CrossRef]

- Ebers, L.S.; Arya, A.; Bowland, C.C.; Glasser, W.G.; Chmely, S.C.; Naskar, A.K.; Laborie, M.P. 3D Printing of Lignin: Challenges, Opportunities and Roads Onward. Biopolymers 2021, 112, e23431. [Google Scholar] [CrossRef]

- Căpraru, A.-M.; Popa, V.I.; Măluţan, T.; Lisă, G. Contribution to the modification and characterization of different types of lignins. Cellul. Chem. Technol. 2009, 43, 409–418. [Google Scholar]

- Lu, X.; Gu, X.; Shi, Y. A Review on Lignin Antioxidants: Their Sources, Isolations, Antioxidant Activities and Various Applications. Int. J. Biol. Macromol. 2022, 210, 716–741. [Google Scholar] [CrossRef]

- Sadeghifar, H.; Ragauskas, A. Lignin as a UV Light Blocker-a Review. Polymers 2020, 12, 1134. [Google Scholar] [CrossRef]

- Makri, S.P.; Xanthopoulou, E.; Klonos, P.A.; Grigoropoulos, A.; Kyritsis, A.; Tsachouridis, K.; Anastasiou, A.; Deligkiozi, I.; Nikolaidis, N.; Bikiaris, D.N. Effect of Micro- and Nano-Lignin on the Thermal, Mechanical, and Antioxidant Properties of Biobased PLA–Lignin Composite Films. Polymers 2022, 14, 5274. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Khoja, S. Brittleness and Toughness of Polymers and Other Materials. Mater. Lett. 2015, 159, 478–480. [Google Scholar] [CrossRef]

- Song, Y.; Chen, S.; Chen, Y.; Xu, Y.; Xu, F. Biodegradable and Transparent Films with Tunable UV-Blocking Property from Lignocellulosic Waste by a Top-down Approach. Cellulose 2021, 28, 8629–8640. [Google Scholar] [CrossRef]

- Cavallo, E.; He, X.; Luzi, F.; Dominici, F.; Cerrutti, P.; Bernal, C.; Foresti, M.L.; Torre, L.; Puglia, D. UV Protective, Antioxidant, Antibacterial and Compostable Polylactic Acid Composites Containing Pristine and Chemically Modified Lignin Nanoparticles. Molecules 2020, 26, 126. [Google Scholar] [CrossRef]

- Kai, D.; Zhang, K.; Jiang, L.; Wong, H.Z.; Li, Z.; Zhang, Z.; Loh, X.J. Sustainable and Antioxidant Lignin-Polyester Copolymers and Nanofibers for Potential Healthcare Applications. ACS Sustain. Chem. Eng. 2017, 5, 6016–6025. [Google Scholar] [CrossRef]

- Mohan, D.; Bakir, A.N.; Sajab, M.S.; Bakarudin, S.B.; Mansor, N.N.; Roslan, R.; Kaco, H. Homogeneous Distribution of Lignin/Graphene Fillers with Enhanced Interlayer Adhesion for 3D Printing Filament. Polym. Compos. 2021, 42, 2408–2421. [Google Scholar] [CrossRef]

- Jacucci, G.; Schertel, L.; Zhang, Y.; Yang, H.; Vignolini, S. Light Management with Natural Materials: From Whiteness to Transparency. Adv. Mater. 2021, 33, 2001215. [Google Scholar] [CrossRef]

- Liang, R.; Yang, X.; Yew, P.Y.M.; Sugiarto, S.; Zhu, Q.; Zhao, J.; Loh, X.J.; Zheng, L.; Kai, D. PLA-Lignin Nanofibers as Antioxidant Biomaterials for Cartilage Regeneration and Osteoarthritis Treatment. J. Nanobiotechnol. 2022, 20, 327. [Google Scholar] [CrossRef]

- Tracey, C.T.; Predeina, A.L.; Krivoshapkina, E.F.; Kumacheva, E. A 3D Printing Approach to Intelligent Food Packaging. Trends Food Sci. Technol. 2022, 127, 87–98. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, H.; He, Y.; Li, H.; You, T.; Xu, F. 3D-Printed Polylactic Acid/Lignin Films with Great Mechanical Properties and Tunable Functionalities towards Superior UV-Shielding, Haze, and Antioxidant Properties. Polymers 2023, 15, 2806. https://doi.org/10.3390/polym15132806

Ye H, He Y, Li H, You T, Xu F. 3D-Printed Polylactic Acid/Lignin Films with Great Mechanical Properties and Tunable Functionalities towards Superior UV-Shielding, Haze, and Antioxidant Properties. Polymers. 2023; 15(13):2806. https://doi.org/10.3390/polym15132806

Chicago/Turabian StyleYe, Haichuan, Yuan He, Haichao Li, Tingting You, and Feng Xu. 2023. "3D-Printed Polylactic Acid/Lignin Films with Great Mechanical Properties and Tunable Functionalities towards Superior UV-Shielding, Haze, and Antioxidant Properties" Polymers 15, no. 13: 2806. https://doi.org/10.3390/polym15132806

APA StyleYe, H., He, Y., Li, H., You, T., & Xu, F. (2023). 3D-Printed Polylactic Acid/Lignin Films with Great Mechanical Properties and Tunable Functionalities towards Superior UV-Shielding, Haze, and Antioxidant Properties. Polymers, 15(13), 2806. https://doi.org/10.3390/polym15132806