Developing a Biodegradable Film for Packaging with Lignocellulosic Materials from the Amazonian Biodiversity

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

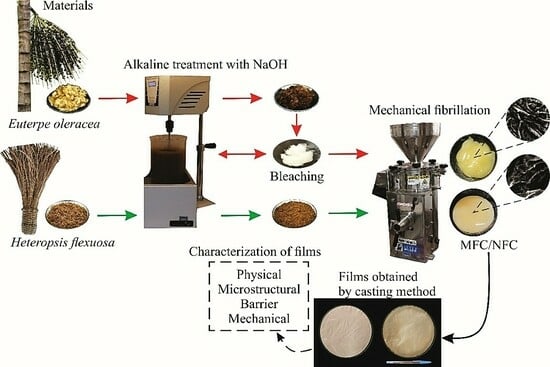

2.2. Fiber Treatment

2.3. Chemical Composition of Fibers

2.4. Production of Cellulose Micro/Nanofibrils (MFC/NFC)

2.5. Energy Consumption

2.6. Microstructural Analysis of MFC/NFC

2.7. Suspension Stability

2.8. Production of MFC/NFC films

2.9. Physical Properties of the Films

2.10. Barrier to Water Vapor

2.11. Test of Grease Resistance

2.12. Mechanical Properties of the Films

2.13. Statistical Analyzes

3. Results and Discussion

3.1. Chemical Composition of the Fibers

3.2. Energy Consumption

3.3. Microstructural Analysis of MFC/NFC

3.4. Suspension Stability

3.5. Physical Properties of the Films

3.6. Test of Grease Resistance

3.7. Mechanical Properties of the Films

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dias, M.C.; Zidanes, U.L.; Mascarenhas, A.R.P.; Setter, C.; Scatolino, M.V.; Martins, M.A.; Mori, F.A.; Belgacem, M.N.; Tonoli, G.H.D.; Ferreira, S.R. Mandacaru cactus as a source of nanofibrillated cellulose for nanopaper production. Int. J. Biol. Macromol. 2023, 235, 123850. [Google Scholar] [CrossRef]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7. [Google Scholar] [CrossRef]

- de Souza Fonseca, A.; Panthapulakkal, S.; Konar, S.K.; Sain, M.; Bufalino, L.; Raabe, J.; Tonoli, G.H.D. Improving cellulose nanofibrillation of non-wood fiber using alkaline and bleaching pre-treatments. Ind. Crops Prod. 2019, 131, 203–212. [Google Scholar] [CrossRef]

- Bhutto, A.W.; Qureshi, K.; Harijan, K.; Abro, R.; Abbas, T.; Bazmi, A.A.; Karim, S.; Yu, G. Insight into progress in pre-treatment of lignocellulosic biomass. Energy 2017, 122, 724–745. [Google Scholar] [CrossRef]

- Oliveira, D.N.; Claro, P.I.; Freitas, R.R.; Martins, M.A.; Souza, T.M.; Silva, B.M.; Mendes, L.M.; Bufalino, L. Enhancement of the Amazonian Açaí Waste Fibers through Variations of Alkali Pretreatment Parameters. Chem. Biodivers. 2019, 16, e1900275. [Google Scholar] [CrossRef]

- Guimarães, M.R.G.; Scatolino, M.V.; Martins MAFerreira, S.R.; Mendes, L.M.; Lima, J.T.; Guimarães Junior, M.; Tonoli, G.H.D. Bio-based films/nanopapers from lignocellulosic wastes for production of added-value micro-/nanomaterials. Environ. Sci. Pollut. Res. 2022, 29, 8665–8683. [Google Scholar] [CrossRef]

- Guimarães Junior, M.; Teixeira, F.G.; Tonoli, G.H.D. Effect of the nano-fibrillation of bamboo pulp on the thermal, structural, mechanical and physical properties of nanocomposites based on starch/poly (vinyl alcohol) blend. Cellulose 2018, 25, 1823–1849. [Google Scholar] [CrossRef]

- Lago, R.C.; Oliveira, A.L.M.; Dias, M.C.; Carvalho, E.E.N.; Tonoli, G.H.D.; Boas, E.V.D.B.V. Obtaining cellulosic nanofibrils from oat straw for biocomposite reinforcement: Mechanical and barrier properties. Ind. Crops Prod. 2020, 148, 112264. [Google Scholar] [CrossRef]

- Scatolino, M.V.; Bufalino, L.; Dias, M.C.; Mendes, L.M.; Silva, M.S.; Tonoli, G.H.D. Copaiba oil and vegetal tannin as functionalizing agents for açai nanofibril films: Valorization of forest wastes from Amazonia. Environ. Sci. Pollut. Res. 2022, 29, 66422–66437. [Google Scholar] [CrossRef]

- Leitner, J.; Hinterstoisser, B.; Wastyn, M.; Keckes, J.; Gindl, W. Sugar beet cellulose nanofibril-reinforced composites. Cellulose 2007, 14, 419–425. [Google Scholar] [CrossRef]

- Yan, C.; Yin, Y.; Zhang, S.; Luo, G.; Xu, Y.; Liu, L.; Luo, J.; Zhou, X. Fabrication and characterization of sunflower oil-in-water emulsions stabilized with sunflower stem pith cellulose nanofibril. Int. J. Biol. Macromol. 2023, 224, 919–926. [Google Scholar] [CrossRef]

- Santos, F.S.; Ramos, K.S.; Brum, G.G.G.; Gaia, I.A.; Pereira, S.S.P.; Vieira, A.L. Chagas disease and its transmission by açaí: A bibliographic review. Braz. J. Health Rev. D 2019, 2, 2128–2144. Available online: https://ojs.brazilianjournals.com.br/ojs/index.php/BJHR/article/view/1595 (accessed on 15 June 2022).

- Braga, D.G.; Abreu, J.L.L.D.; Silva, M.G.D.; Souza, T.M.D.; Dias, M.C.; Tonoli, G.H.D.; Oliveira Neto, C.F.; Claro, P.I.C.; Gomes, L.G.; Bufalino, L. Cellulose nanostructured films from pretreated açaí mesocarp fibers: Physical, barrier, and tensile performance. Cerne 2021, 27, e-102783. [Google Scholar] [CrossRef]

- Shanley, P.; Medina, G. Fruit Trees and Useful Plants in Amazonian Life; CIFOR, Embrapa Amazônia Oriental, Imazon: Belém, Brazil, 2005; Available online: http://www.fao.org/docrep/015/i2360e/i2360e.pdf (accessed on 20 April 2023).

- Hoffman, B. Biology and Use of Nibbi Heteropsis Flexuosa (ARACEAE) the Source of an Aerial Root Fiber Product in Guyana. Master’s Thesis, Florida International University, Miami, FL, USA, 1997. [Google Scholar]

- Cunha, J.D.S.C.; Nascimento, L.F.C.; Luz, F.S.; Garcia Filho, F.F.C.; Oliveira, M.S.; Monteiro, S.N. Titica Vine Fiber (Heteropsis flexuosa): A Hidden Amazon Fiber with Potential Applications as Reinforcement in Polymer Matrix Composites. J. Compos. Sci. 2022, 6, 251. [Google Scholar] [CrossRef]

- Aguado, R.; Lourenço, A.F.; Ferreira, P.J.; Tijero, A. The relevance of the pretreatment on the chemical modification of cellulosic fibers. Cellulose 2019, 26, 5925–5936. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry—TAPPI. Solvent Extractives of Wood and Pulp T 204 om-97; TAPPI: Norcross, GA, USA, 2007. [Google Scholar]

- Technical Association of the Pulp and Paper Industry—TAPPI. Acid-Insoluble Lignin in Wood Pulp, T 222 om-02; TAPPI: Norcross, GA, USA, 2002. [Google Scholar]

- Browning, B.L. The Chemistry of Wood; Interscience: Warrenvile, IL, USA, 1963; 689p. [Google Scholar]

- Kennedy, F.; Phillips, G.O.; Willians, P.A. Wood and Cellulosics, Industrial Utilization, Biotechnology, Structure and Properties; Ellis Horwood: New York, NY, USA, 1987. [Google Scholar]

- Technical Association of the Pulp and Paper Industry—TAPPI. Ash in Wood Pulp Paper Paperboard: Combustion at 525 °C. T 211 om-02; TAPPI: Norcross, GA, USA, 2002. [Google Scholar]

- Mendonça, M.; Dias, M.C.; Martins, C.C.N.; Durães, A.F.S.; Damásio, R.A.P.; Tonoli, G.H.D. Alkaline pretreatment facilitate mechanical fibrillation of unbleached cellulose pulps for obtaining of cellulose micro/nanofibrils (MFC). J. Nat. Fibers 2022, 19, 13385–13400. [Google Scholar] [CrossRef]

- Mascarenhas, A.R.P.; Scatolino, M.V.; Dias, M.C.; Martins, M.A.; Melo, R.R.; Damásio, R.A.P.; Mendonça, M.C.; Tonoli, G.H.D. Fibers pre-treatments with sodium silicate affect the properties of suspensions, films, and quality index of cellulose micro/nanofibrils. Nord. Pulp Pap. Res. J. 2022, 37, 534–552. [Google Scholar] [CrossRef]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; Dezonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 529. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry—TAPPI. Thickness (Caliper) Of Paper, Paperboard And Combined Board, T 411 om-15. Phys. Prop. Comm. Process Prod. Qual. Div. 2015, 2013, 3–6. [Google Scholar]

- Technical Association of the Pulp and Paper Industry—TAPPI. Grammage of Paper and Paperboard (Weight per Unit Area) (Revision of T 410 om-08); TAPPI: Norcross, GA, USA, 2013. [Google Scholar]

- Desmaisons, J.; Boutonnet, E.; Rueff, M.; Dufresne, A.; Bras, J. A new quality index for benchmarking of different cellulose nanofibrils. Carbohydr. Polym. 2017, 174, 318–329. [Google Scholar] [CrossRef]

- ASTM E96; Standard Test Methods for Water Vapor Transmission of Materials. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2016.

- Technical Association of the Pulp and Paper Industry—TAPPI. Grease Resistance Test for Paper and Paperboard, T 559 cm-12; TAPPI: Norcross, GA, USA, 2012. [Google Scholar]

- ASTM D882-12; Standard Test Methods for Tensile Properties of Thin Plastic Sheeting. American Society for Testing and Materials—ASTM: West Conshohocken, PA, USA, 2018.

- Dias, M.C.; Mendonça, M.C.; Damásio, R.A.; Zidanes, U.L.; Mori, F.A.; Ferreira, S.R.; Tonoli, G.H. Influence of hemicellulose content of Eucalyptus and Pinus fibers on the grinding process for obtaining cellulose micro/nanofibrils. Holzforschung 2019, 73, 1035–1046. [Google Scholar] [CrossRef]

- Coutts, R.S.P.; Warden, P.G. Sisal pulp reinforced cement mortar. Cem. Concr. Compos. 1992, 14, 17–21. [Google Scholar] [CrossRef]

- Naidjonoka, P.; Hernandez, M.A.; Pálsson, G.K.; Heinrich, F.; Stålbrand, H.; Nylander, T. On the interaction of softwood hemicellulose with cellulose surfaces in relation to molecular structure and physicochemical properties of hemicellulose. Soft Matter 2020, 16, 7063–7076. [Google Scholar] [CrossRef]

- Wang, C.; Yang, J.; Wen, J.; Bian, J.; Li, M.; Peng, F.; Sun, R. Structure and distribution changes of Eucalyptus hemicelluloses during hydrothermal and alkaline pretreatments. Int. J. Biol. Macromol. 2019, 133, 514–521. [Google Scholar] [CrossRef]

- Lahtinen, P.; Liukkonen, S.; Pere, J.; Sneck, A.; Kangas, H. A comparative study of fibrillated fibers from different mechanical and chemical pulps. BioResources 2014, 9, 2115–2127. [Google Scholar] [CrossRef]

- Morais, M.L.C. Systematics and Ecology of Heteropsis Kunth (Araceae Juss.) with Special Emphasis on Species Occurring in the Adolpho Ducke Forest Reserve, Manaus—Amazonas, Brasil. Ph.D. Thesis, INPA/UFAM, Manaus, Brazil, 2008; 206p. [Google Scholar]

- Mirpoor, S.F.; Restaino, O.F.; Schiraldi, C.; Giosafatto, C.V.L.; Ruffo, F.; Porta, R. Lignin/carbohydrate complex isolated from Posidonia oceanica sea balls (egagropili): Characterization and antioxidant reinforcement of protein-based films. Int. J. Mol. Sci. 2021, 22, 9147. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Tayeb, P.; Joyce, M.; Tyagi, P.; Kehoe, M.; Dimic-Misic, K.; Pal, L. Rheology of nanocellulose-rich aqueous suspensions: A review. BioResources 2017, 12, 9556–9661. [Google Scholar] [CrossRef]

- Kim, J.; Bang, J.; Kim, Y.; Kim, J.C.; Hwang, S.W.; Yeo, H.; Choi, I.; Kwak, H.W. Eco-friendly alkaline lignin/cellulose nanofiber drying system for efficient redispersion behavior. Carbohydr. Polym. 2022, 282, 119122. [Google Scholar] [CrossRef]

- Butchosa, N.; Zhou, Q. Water redispersible cellulose nanofibrils adsorbed with carboxymethyl cellulose. Cellulose 2014, 21, 4349–4358. [Google Scholar] [CrossRef]

- Miettinen, A.; Chinga-Carrasco, G.; Kataja, M. Three-dimensional microstructural properties of nanofibrillated cellulose films. Int. J. Mol. Sci. 2014, 15, 6423–6440. [Google Scholar] [CrossRef]

- Li, W.; Wang, S.; Wang, W.; Qin, C.; Wu, M. Facile preparation of reactive hydrophobic cellulose nanofibril film for reducing water vapor permeability (WVP) in packaging applications. Cellulose 2019, 26, 3271–3284. [Google Scholar] [CrossRef]

- Stark, N.M. Opportunities for cellulose nanomaterials in packaging films: A review and future trends. J. Renew. Mater. 2016, 4, 313–326. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Tajvidi, M.; Bousfield, D. Paper-based oil barrier packaging using lignin-containing cellulose nanofibrils. Molecules 2020, 25, 1344. [Google Scholar] [CrossRef]

- Abbasi, H.; Fahim, H.; Mahboubi, M. Fabrication and characterization of composite film based on gelatina and electrospun cellulose acetate fibers incorporating essential oil. J. Food Meas. Charact. 2021, 15, 2108–2118. [Google Scholar] [CrossRef]

- Sahraee, S.; Milani, J.M.; Ghanbarzade, B.; Hamishekar, H. Effect of corn oil on physical, thermal, and antifungal properties of gelatin-based nanocomposite films containing nano chitin. LWT—Food Sci. Technol. 2017, 76, 33–39. [Google Scholar] [CrossRef]

- Oliveira, M.L.C.; Mirmehdi, S.; Scatolino, M.V.; Júnior, M.G.; Sanadi, A.R.; Damasio, R.A.P.; Tonoli, G.H.D. Effect of overlapping cellulose nanofibrils and nanoclay layers on mechanical and barrier properties of spray-coated papers. Cellulose 2022, 29, 1097–1113. [Google Scholar] [CrossRef]

- Mirzaei-Mohkam, A.; Garavand, F.; Dehnad, D.; Keramat, J.; Nasirpour, A. Physical, mechanical, thermal and structural characteristics of nanoencapsulated vitamin E loaded carboxymethyl cellulose films. Prog. Org. Coat. 2020, 138, 105383. [Google Scholar] [CrossRef]

- Spence, K.L.; Venditti, R.A.; Habibi, Y.; Rojas, O.J.; Pawlak, J.J. The effect of chemical composition on microfibrillar cellulose films from wood pulps: Mechanical processing and physical properties. Bioresour. Technol. 2010, 101, 5961–5968. [Google Scholar] [CrossRef]

- Rojo, E.; Peresin, M.S.; Sampson, W.W.; Hoeger, I.C.; Vartiainen, J.; Laine, J.; Rojas, O.J. Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem. 2015, 17, 1853–1866. [Google Scholar] [CrossRef]

| Score | Castor Oil | Toluene | n-Heptane |

|---|---|---|---|

| ---------------------------%------------------------- | |||

| 1 | 100 | 0 | 0 |

| 2 | 90 | 5 | 5 |

| 3 | 80 | 10 | 10 |

| 4 | 70 | 15 | 15 |

| 5 | 60 | 20 | 20 |

| 6 | 50 | 25 | 25 |

| 7 | 40 | 30 | 30 |

| 8 | 30 | 35 | 35 |

| 9 | 20 | 40 | 40 |

| 10 | 10 | 45 | 45 |

| 11 | 0 | 50 | 50 |

| 12 | 0 | 45 | 55 |

| Component | Euterpe oleracea (açaí) | Heteropsis flexuosa (titica) | * Commercial Eucalyptus Pulp | ||

|---|---|---|---|---|---|

| In Natura | Bleached | In Natura | Alkali-Treated | ||

| -----------------------------(%)----------------------------- | |||||

| Total extractives | 4.0 ± 0.2 | - | 5.9 ± 0.4 | 2.3 ± 0.1 | - |

| Insoluble lignin | 36.0 ± 0.6 | 17.0 ± 3.6 | 24.9 ± 1.7 | 15.4 ± 1.1 | 0.14 ± 1.1 |

| Holocellulose | 60.0 ± 2.0 | 81.0 ± 2.8 | 68.4 ± 1.4 | 80.6 ± 1.1 | 90.0 ± 1.1 |

| Cellulose | 34.0 ± 1.8 | 56.0 ± 0.2 | 42.0 ± 1.2 | 60.6 ± 2.2 | 76.0 ± 2.2 |

| Hemicelluloses | 26.0 ± 1.9 | 25.0 ± 0.1 | 26.4 ± 2.5 | 20.0 ± 1.8 | 14.0 ± 1.8 |

| Ash | 1.6 ± 0.2 | 0.3 ± 0.1 | 1.3 ± 0.1 | 1.6 ± 0.05 | 0.03 ± 0.01 |

| Raw Material | Thickness (µm) | Grammage (g/m2) | Apparent Density (g/cm3) | Porosity(%) |

|---|---|---|---|---|

| Euterpe oleracea | 43.0 ± 9.0 * b | 33.7 ± 1.9 b | 0.82 ± 0.15 a | 46.7 ± 3.0 b |

| Heteropsis flexuosa | 32.4 ± 1.7 a | 28.2 ± 2.5 a | 0.79 ± 0.05 a | 48.2 ± 3.4 b |

| Eucalyptus sp. | 31.0 ± 1.0 a | 35.5 ± 2.3 b | 1.16 ± 0.03 b | 24.7 ± 4.7 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, D.W.; Batista, F.G.; Scatolino, M.V.; Mascarenhas, A.R.P.; De Medeiros, D.T.; Tonoli, G.H.D.; Lazo, D.A.Á.; Caselli, F.d.T.R.; de Souza, T.M.; Alves Junior, F.T. Developing a Biodegradable Film for Packaging with Lignocellulosic Materials from the Amazonian Biodiversity. Polymers 2023, 15, 3646. https://doi.org/10.3390/polym15173646

Silva DW, Batista FG, Scatolino MV, Mascarenhas ARP, De Medeiros DT, Tonoli GHD, Lazo DAÁ, Caselli FdTR, de Souza TM, Alves Junior FT. Developing a Biodegradable Film for Packaging with Lignocellulosic Materials from the Amazonian Biodiversity. Polymers. 2023; 15(17):3646. https://doi.org/10.3390/polym15173646

Chicago/Turabian StyleSilva, Danillo Wisky, Felipe Gomes Batista, Mário Vanoli Scatolino, Adriano Reis Prazeres Mascarenhas, Dayane Targino De Medeiros, Gustavo Henrique Denzin Tonoli, Daniel Alberto Álvarez Lazo, Francisco de Tarso Ribeiro Caselli, Tiago Marcolino de Souza, and Francisco Tarcísio Alves Junior. 2023. "Developing a Biodegradable Film for Packaging with Lignocellulosic Materials from the Amazonian Biodiversity" Polymers 15, no. 17: 3646. https://doi.org/10.3390/polym15173646

APA StyleSilva, D. W., Batista, F. G., Scatolino, M. V., Mascarenhas, A. R. P., De Medeiros, D. T., Tonoli, G. H. D., Lazo, D. A. Á., Caselli, F. d. T. R., de Souza, T. M., & Alves Junior, F. T. (2023). Developing a Biodegradable Film for Packaging with Lignocellulosic Materials from the Amazonian Biodiversity. Polymers, 15(17), 3646. https://doi.org/10.3390/polym15173646