Comparative Study of Flax and Pineapple Leaf Fiber Reinforced Poly(butylene succinate): Effect of Fiber Content on Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

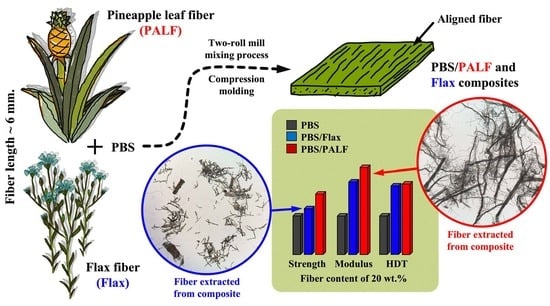

2.2. Composite Prepreg Preparation

2.3. Compressed Sheet Preparation

2.4. Characterizations

2.4.1. Fibers’ Chemical Composition

2.4.2. X-ray Diffraction

2.4.3. Scanning Electron Microscopy (SEM)

2.4.4. Thermal Properties

2.4.5. Mechanical Properties

3. Results

3.1. PALF and Flax Characteristics

3.1.1. Fiber Composition and Structure

3.1.2. Scanning Electron Microscopy (SEM)

3.1.3. Prepreg Appearance

3.2. Mechanical Properties of Composites

3.2.1. Flexural Properties

3.2.2. Impact Properties

3.3. Thermal Properties

3.3.1. DSC

3.3.2. HDT

3.4. Fracture Surfaces

4. Discussion

4.1. Matrix Orientation via Pole Figures

4.2. Reinforcing Fiber in the Matrix

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hong, W.Y. A techno-economic review on carbon capture, utilisation and storage systems for achieving a net-zero CO2 emissions future. Carbon Capture Sci. Technol. 2022, 3, 100044. [Google Scholar] [CrossRef]

- Liu, E.; Lu, X.; Wang, D. A Systematic Review of Carbon Capture, Utilization and Storage: Status, Progress and Challenges. Energies 2023, 16, 2865. [Google Scholar] [CrossRef]

- George, J.; Ivens, J.; Verpoest, I. Mechanical properties of flax fibre reinforced epoxy composites. Angew. Makromol. Chem. 1999, 272, 41–45. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of Natural Fibers and their Application as Reinforcing Material in Polymer Composites—A Review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Baley, C.; Gomina, M.; Breard, J.; Bourmaud, A.; Davies, P. Variability of mechanical properties of flax fibres for composite reinforcement. A review. Ind. Crop Prod. 2020, 145, 111984. [Google Scholar] [CrossRef]

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376. [Google Scholar] [CrossRef]

- Nabi Saheb, D.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Biagiotti, J.; Puglia, D.; Kenny, J.M. A review on natural fibre-based composites—Part I: Structure, processing and properties of vegetable fibres. J. Nat. Fibers 2004, 1, 37–68. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A review on natural fibre-based composites—Part II: Application of natural reinforcements in composite materials for automotive industry. J. Nat. Fibers 2004, 1, 23–65. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical treatments of natural fiber for use in natural fiber-reinforced composites: A review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Pil, L.; Bensadoun, F.; Pariset, J.; Verpoest, I. Why are designers fascinated by flax and hemp fibre composites? Compos. Part A Appl. 2016, 83, 193–205. [Google Scholar] [CrossRef]

- Baley, C.; Bourmaud, A.; Davies, P. Eighty years of composites reinforced by flax fibres: A historical review. Compos. Part A Appl. Sci. Manuf. 2021, 144, 106333. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Flax fibre and its composites—A review. Compos. B Eng. 2014, 56, 296–317. [Google Scholar] [CrossRef]

- Baley, C.; Le Duigou, A.; Morvan, C.; Bourmaud, A. Tensile properties of flax fibers. In Handbook of Properties of Textile and Technical Fibres, 2nd ed.; Bunsell, A.R., Ed.; Elsevier: Kidlington, UK, 2018; pp. 275–300. [Google Scholar]

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol. Mater. Eng. 2004, 289, 955–974. [Google Scholar] [CrossRef]

- Arib, R.M.N.; Sapuan, S.M.; Hamdan, M.A.M.M.; Paridah, M.T.; Zaman, H.M.D.K. A literature review of pineapple fibre reinforced polymer composites. Polym. Polym. Compos. 2004, 12, 341–348. [Google Scholar] [CrossRef]

- Kengkhetkit, N.; Amornsakchai, T. Utilisation of pineapple leaf waste for plastic reinforcement: 1. A novel extraction method for short pineapple leaf fiber. Ind. Crops. Prod. 2012, 40, 55–61. [Google Scholar] [CrossRef]

- Asim, M.; Abdan, K.; Jawaid, M.; Nasir, M.; Dashtizadeh, Z.; Ishak, M.R.; Hoque, M.E.; Deng, Y. A review on pineapple leaves fibre and its composites. Inter. J. Polym. Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fibre (PALF) reinforced polymer composites. Compos. B. Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Nopparut, A.; Amornsakchai, T. Influence of pineapple leaf fiber and it’s surface treatment on molecular orientation in, and mechanical properties of, injection molded nylon composites. Polym. Test. 2016, 52, 141–149. [Google Scholar] [CrossRef]

- Kalapakdee, A.; Amornsakchai, T. Mechanical properties of preferentially aligned short pineapple leaf fiber reinforced thermoplastic elastomer: Effects of fiber content and matrix orientation. Polym. Test. 2014, 37, 36–44. [Google Scholar] [CrossRef]

- Surajarusarn, B.; Hajjar-Garreau, S.; Schrodj, G.; Mougin, K.; Amornsakchai, T. Comparative study of pineapple leaf microfiber and aramid fiber reinforced natural rubbers using dynamic mechanical analysis. Polym. Test. 2020, 82, 106289. [Google Scholar] [CrossRef]

- Surajarusarn, B.; Traiperm, P.; Amornsakchai, T. Revisiting the morphology, microstructure, and properties of cellulose fiber from pineapple leaf so as to expand its utilization. Sains Malays. 2019, 48, 145–154. [Google Scholar] [CrossRef]

- Straumit, I.; Vandepitte, D.; Wevers, M.; Lomov, S.V. Identification of the flax fibre modulus based on an impregnated quasi-unidirectional fibre bundle test and X-ray computed tomography. Compos. Sci. Technol. 2017, 151, 124–130. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef] [PubMed]

- Mochane, M.J.; Magagula, S.I.; Sefadi, J.S.; Mokhena, T.C. A Review on Green Composites Based on Natural Fiber-Reinforced Polybutylene Succinate (PBS). Polymers 2021, 13, 1200. [Google Scholar] [CrossRef] [PubMed]

- New High Biocontent Biopolymers. Available online: https://plasticsengineering.wordpress.com/2015/09/03/new-high-biocontent-biopolymers (accessed on 8 August 2023).

- Bianchi, S.; Marchese, P.; Vannini, M.; Sisti, L.; Tassoni, A.; Ferri, M.; Mallegni, N.; Cinelli, P.; Celli, A. Evaluation of the activity of natural phenolic antioxidants, extracted from industrial coffee residues, on the stability of poly(1,4-butylene succinate) formulations. J. Appl. Polym. Sci. 2023, 140, e53878. [Google Scholar] [CrossRef]

- European Flax: Environmentally Responsible. Available online: https://allianceflaxlinenhemp.eu/en/european-flax-environmentally-responsible (accessed on 24 August 2023).

- Lintex. Available online: http://www.dehondtcomposites.com/en/products/lintex/ (accessed on 24 August 2023).

- Kengkhetkit, N.; Amornsakchai, T. Effect of matrix orientation and fiber content on the properties of uniaxial pineapple leaf fiber—Polypropylene composites. KGK-Kaut. Gummi. Kunst. 2020, 73, 44–50. [Google Scholar]

- Updegraff, D.M. Semimicro determination of cellulose inbiological materials. Anal. Biochem. 1969, 32, 420–424. [Google Scholar] [CrossRef]

- Wise, L.E.; Murphy, M.; Adieco, A.A.D. A chlorite holocellulose, its fractionation and bearing on summative wood analysis and studies on the hemicelluloses. Pap. Trade J. 1946, 122, 35–43. [Google Scholar]

- TAPPI UM 250. Acid-Soluble Lignin in Wood and Pulp; Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 1991. [Google Scholar]

- TAPPI T 222. Acid-Insoluble Lignin in Wood and Pulp; Technical Association of the Pulp and Paper Industry: Atlanta, GA, USA, 2002. [Google Scholar]

- Deng, Y.; Thomas, N.L. Blending Poly(butylene succinate) with Poly(lactic acid): Ductility and Phase Inversion Effects. Eur. Polym. J. 2015, 71, 534–546. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of chemical modifications of the pineapple leaf fiber surfaces on the interfacial and mechanical properties of laminated biocomposites. Compos. Interfaces 2008, 15, 169–191. [Google Scholar] [CrossRef]

- Gaba, E.W.; Asimeng, B.O.; Kaufmann, E.E.; Katu, S.K.; Foster, E.J.; Tiburu, E.K. Mechanical and Structural Characterization of Pineapple Leaf Fiber. Fibers 2021, 9, 51. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S. All-cellulose composite laminates prepared from pineapple leaf fibers treated with steam explosion and alkaline treatment. J. Reinf. Plast. Compos. 2017, 36, 073168441770492. [Google Scholar] [CrossRef]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Tantatherdtam, R.; Tran, T.; Chotineeranat, S.; Lee, B.H.; Sriroth, K.; Kim, H.J. Preparation and Characterization of Cassava Fiber-Based Polypropylene and Polybutylene Succinate Composites. Agric. Nat. Resour. 2009, 43, 245–251. [Google Scholar]

- Then, Y.Y.; Ibrahim, N.; Zainuddin, N.; Ariffin, H.; Yunus, W. Oil Palm Mesocarp Fiber as New Lignocellulosic Material for Fabrication of Polymer/Fiber Biocomposites. Int. J. Polym. Sci. 2013, 2013, 797452. [Google Scholar] [CrossRef]

- Frackowiak, S.; Ludwiczak, J.; Leluk, K. Man-Made and Natural Fibres as a Reinforcement in Fully Biodegradable Polymer Composites: A Concise Study. J. Polym. Environ. 2018, 26, 4360–4368. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A. Injection Molded Sustainable Biocomposites From Poly(butylene succinate) Bioplastic and Perennial Grass. ACS Sustain. Chem. Eng. 2015, 3, 2767–2776. [Google Scholar] [CrossRef]

- Nanni, A.; Cancelli, U.; Montevecchi, G.; Masino, F.; Messori, M.; Antonelli, A. Functionalization and use of grape stalks as poly(butylene succinate) (PBS) reinforcing fillers. Waste Manag. 2021, 126, 538–548. [Google Scholar] [CrossRef]

- Goh, K.L. Physical Properties of Fibres and Matrix. In Discontinuous-Fibre Reinforced Composites: Fundamentals of Stress Transfer and Fracture Mechanics; Springer: London, UK, 2017; pp. 21–74. [Google Scholar]

- Cosquer, R.; Pruvost, S.; Gouanvé, F. Improvement of Barrier Properties of Biodegradable Polybutylene Succinate/Graphene Nanoplatelets Nanocomposites Prepared by Melt Process. Membranes 2021, 11, 151. [Google Scholar] [CrossRef]

- Ihn, K.J.; Yoo, E.S.; Im, S.S. Structure and Morphology of Poly(tetramethylene succinate) Crystals. Macromolecules 1995, 28, 2460–2464. [Google Scholar] [CrossRef]

- Tanguy, M.; Bourmaud, A.; Beaugrand, J.; Gaudry, T.; Baley, C. Polypropylene reinforcement with flax or jute fibre; Influence of microstructure and constituents properties on the performance of composite. Compos. B Eng. 2018, 139, 64–74. [Google Scholar] [CrossRef]

- Berzin, F.; Amornsakchai, T.; Lemaitre, A.; Di Giuseppe, E.; Vergnes, B. Processing and properties of pineapple leaf fibers-polypropylene composites prepared by twin-screw extrusion. Polym. Compos. 2018, 39, 4115–4122. [Google Scholar] [CrossRef]

- Lee, J.M.; Mohd Ishak, Z.A.; Mat Taib, R.; Law, T.T.; Ahmad Thirmizir, M.Z. Mechanical, Thermal and Water Absorption Properties of Kenaf-Fiber-Based Polypropylene and Poly(Butylene Succinate) Composites. J. Polym. Environ. 2013, 21, 293–302. [Google Scholar] [CrossRef]

- Hao, X.; Zhou, H.; Mu, B.; Chen, L.; Guo, Q.; Yi, X.; Sun, L.; Wang, Q.; Ou, R. Effects of fiber geometry and orientation distribution on the anisotropy of mechanical properties, creep behavior, and thermal expansion of natural fiber/HDPE composites. Compos. B Eng. 2020, 185, 107778. [Google Scholar] [CrossRef]

- Goh, K.L. Appendix A: Convergence to Continuous-Fibre Composites. In Discontinuous-Fibre Reinforced Composites: Fundamentals of Stress Transfer and Fracture Mechanics; Springer: London, UK, 2017; pp. 185–186. [Google Scholar]

- Surajarusarn, B.; Thaiwattananon, S.; Thanawan, S.; Mougin, K.; Amornsakchai, T. Realising the Potential of Pineapple Leaf Fiber as Green and High-performance Reinforcement for Natural Rubber Composite with Liquid Functionalized Rubber. Fibers Polym. 2021, 22, 2543–2551. [Google Scholar] [CrossRef]

- Albrecht, K.; Osswald, T.; Baur, E.; Meier, T.; Wartzack, S.; Müssig, J. Fibre Length Reduction in Natural Fibre-Reinforced Polymers during Compounding and Injection Moulding—Experiments Versus Numerical Prediction of Fibre Breakage. J. Compos. Sci. 2018, 2, 20. [Google Scholar] [CrossRef]

| Chemical Constituent (%) | PALF | Flax |

|---|---|---|

| Cellulose (%) | 57.2 | 67.2 |

| Holocellulose (%) | 85.5 | 82.6 |

| Lignin (acid soluble) | 2.6 | 0.9 |

| Lignin (acid insoluble) | 7.8 | 6.5 |

| Sample | First Heating | Cooling | Second Heating | ||

|---|---|---|---|---|---|

| Tm (°C) | Xc (%) | Tc (°C) | Tm (°C) | Xc (%) | |

| PBS | 115.0 | 75.4 | 84.4 | 114.4 | 72.6 |

| 10PALF | 114.2 | 78.9 | 81.4 | 114.2 | 75.7 |

| 20PALF | 114.4 | 79.0 | 82.8 | 114.0 | 75.5 |

| 10Flax | 114.8 | 76.2 | 81.0 | 114.8 | 72.9 |

| 20Flax | 115.0 | 76.4 | 81.8 | 115.3 | 72.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amornsakchai, T.; Duangsuwan, S.; Mougin, K.; Goh, K.L. Comparative Study of Flax and Pineapple Leaf Fiber Reinforced Poly(butylene succinate): Effect of Fiber Content on Mechanical Properties. Polymers 2023, 15, 3691. https://doi.org/10.3390/polym15183691

Amornsakchai T, Duangsuwan S, Mougin K, Goh KL. Comparative Study of Flax and Pineapple Leaf Fiber Reinforced Poly(butylene succinate): Effect of Fiber Content on Mechanical Properties. Polymers. 2023; 15(18):3691. https://doi.org/10.3390/polym15183691

Chicago/Turabian StyleAmornsakchai, Taweechai, Sorn Duangsuwan, Karine Mougin, and Kheng Lim Goh. 2023. "Comparative Study of Flax and Pineapple Leaf Fiber Reinforced Poly(butylene succinate): Effect of Fiber Content on Mechanical Properties" Polymers 15, no. 18: 3691. https://doi.org/10.3390/polym15183691

APA StyleAmornsakchai, T., Duangsuwan, S., Mougin, K., & Goh, K. L. (2023). Comparative Study of Flax and Pineapple Leaf Fiber Reinforced Poly(butylene succinate): Effect of Fiber Content on Mechanical Properties. Polymers, 15(18), 3691. https://doi.org/10.3390/polym15183691