A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of TEMPO-Treated BC Film

3. Characterization

3.1. Field Emission Scanning Electron Microscopy (FESEM) Observation

3.2. Film Transmittance

3.3. Fourier-Transform Infrared Spectroscopy (FTIR)

3.4. Thermal Resistance

3.5. Tensile Properties

3.6. X-Ray Diffraction

3.7. Electrical Properties

3.8. Statistical Analysis

4. Results and Discussions

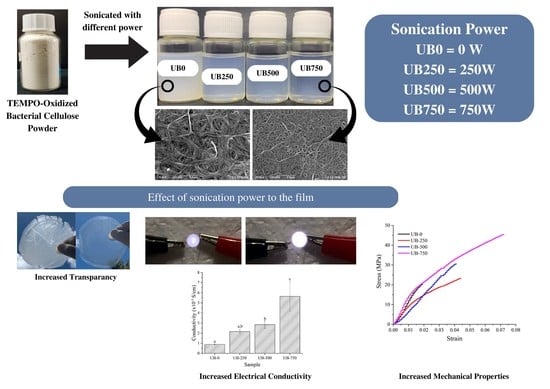

4.1. BC Powder, Suspension, a Film Appearance, and Transmittance Value

4.2. FESEM Morphology

4.3. FTIR Spectra

4.4. Thermal Properties

4.5. Tensile Properties

4.6. X-ray Diffraction

4.7. Electrical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhushan, I.; Singh, V.K.; Tripathi, D.K. Nanomaterial and Enviromental Biotechnology; Springer: Cham, Switzerland, 2020; ISBN 9783030345433. [Google Scholar]

- Abral, H.; Ikhsan, M.; Rahmadiawan, D.; Handayani, D.; Sandrawati, N.; Sugiarti, E.; Novi, A. Anti-UV, Antibacterial, Strong, and High Thermal Resistant Polyvinyl Alcohol/Uncaria Gambir Extract Biocomposite Film. J. Mater. Res. Technol. 2022, 17, 2193–2202. [Google Scholar] [CrossRef]

- Morena, A.G.; Roncero, M.B.; Valenzuela, S.V.; Valls, C.; Vidal, T.; Pastor, F.I.J.; Diaz, P.; Martínez, J. Laccase/TEMPO-Mediated Bacterial Cellulose Functionalization: Production of Paper-Silver Nanoparticles Composite with Antimicrobial Activity. Cellulose 2019, 26, 8655–8668. [Google Scholar] [CrossRef]

- Yusuf, Y.; Handoko, F. Synthesis and Physicochemical Properties of Poly(Vinyl) Alcohol Nanocomposites Reinforced with Nanocrystalline Cellulose from Tea (Camellia Sinensis) Waste. Materials 2021, 14, 7154. [Google Scholar]

- Wu, K.; Wu, H.; Wang, R.; Yan, X.; Sun, W.; Liu, Y.; Kuang, Y. Industrial Crops & Products The Use of Cellulose Fiber from Office Waste Paper to Improve the Thermal Insulation-Related Property of Konjac Glucomannan / Starch Aerogel. Ind. Crops Prod. 2022, 177, 114424. [Google Scholar] [CrossRef]

- Lay, M.; González, I.; Tarrés, J.A.; Pellicer, N.; Ngun, K. High Electrical and Electrochemical Properties in Bacterial Cellulose/Polypyrrole Membranes. Eur. Polym. J. 2017, 91, 1–9. [Google Scholar] [CrossRef]

- Liu, X.; Huang, K.; Lin, X.; Li, H.; Tao, T.; Wu, Q.; Zheng, Q.; Huang, L.; Ni, Y.; Chen, L.; et al. Transparent and Conductive Cellulose Film by Controllably Growing Aluminum Doped Zinc Oxide on Regenerated Cellulose Film. Cellulose 2020, 27, 4847–4855. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, G.; Li, R.; Zhao, K.; Shen, J.; Tian, J.; He, M. Facile Preparation of Highly Transparent Conducting Nanopaper with Electrical Robustness. ACS Sustain. Chem. Eng. 2020, 8, 5132–5139. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, S.; Wang, X.; Huang, Y.; Yu, W. Preparation of Ultra-Conductive Bamboo Cellulose Fiber via a Facile Pretreatment. Appl. Surf. Sci. 2022, 575, 151700. [Google Scholar] [CrossRef]

- Fattahi Meyabadi, T.; Dadashian, F.; Mir Mohamad Sadeghi, G.; Ebrahimi Zanjani Asl, H. Spherical Cellulose Nanoparticles Preparation from Waste Cotton Using a Green Method. Powder. Technol. 2014, 261, 232–240. [Google Scholar] [CrossRef]

- Solahuddin, B.A. A Critical Review on Experimental Investigation and Finite Element Analysis on Structural Performance of Kenaf Fibre Reinforced Concrete. Structures 2022, 35, 1030–1061. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Abral, H.; Yesa, W.H.; Handayani, D.; Sandrawati, N.; Sugiarti, E.; Muslimin, A.N.; Sapuan, S.M.; Ilyas, R.A. White Ginger Nanocellulose as Effective Reinforcement and Antimicrobial Polyvinyl Alcohol / ZnO Hybrid Biocomposite Films Additive for Food Packaging Applications. J. Compos. Sci. 2022, 6, 316. [Google Scholar] [CrossRef]

- Shi, S.C.; Liu, G.T. Cellulose Nanocrystal Extraction from Rice Straw Using a Chlorine-Free Bleaching Process. Cellulose 2021, 28, 6147–6158. [Google Scholar] [CrossRef] [PubMed]

- Esa, F.; Tasirin, S.M.; Rahman, N.A. Overview of Bacterial Cellulose Production and Application. Ital. Oral Surg. 2014, 2, 113–119. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Tavakoli, J.; Tang, Y. Bacterial Cellulose Production, Properties and Applications with Different Culture Methods—A Review. Carbohydr. Polym. 2019, 219, 63–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ullah, H.; Wahid, F.; Santos, H.A.; Khan, T. Advances in Biomedical and Pharmaceutical Applications of Functional Bacterial Cellulose-Based Nanocomposites. Carbohydr. Polym. 2016, 150, 330–352. [Google Scholar] [CrossRef]

- Andriani, D.; Apriyana, A.Y.; Karina, M. The Optimization of Bacterial Cellulose Production and Its Applications: A Review. Cellulose 2020, 27, 6747–6766. [Google Scholar] [CrossRef]

- Gabilondo, N.; Alon, A.E. A Review of Bacterial Cellulose: Sustainable Production from Agricultural Waste and Applications in Various Fields. Cellulose 2021, 4, 8229–8253. [Google Scholar] [CrossRef]

- Troncoso, O.P.; Torres, F.G. Bacterial Cellulose—Graphene Based Nanocomposites. Int. J. Mol. Sci. 2020, 21, 6532. [Google Scholar] [CrossRef]

- Hosseini, H.; Kokabi, M.; Mousavi, S.M. Conductive Bacterial Cellulose/Multiwall Carbon Nanotubes Nanocomposite Aerogel as a Potentially Flexible Lightweight Strain Sensor. Carbohydr. Polym. 2018, 201, 228–235. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Aslfattahi, N.; Nasruddin, N.; Saidur, R.; Arifutzzaman, A.; Mohammed, H.A. MXene Based Palm Oil Methyl Ester as an Effective Heat Transfer Fluid. J. Nano Res. 2021, 68, 17–34. [Google Scholar] [CrossRef]

- Levanič, J.; Svedström, K.; Liljeström, V.; Šernek, M.; Osojnik Črnivec, I.G.; Poklar Ulrih, N.; Haapala, A. Cellulose Fiber and Nanofibril Characteristics in a Continuous Sono-Assisted Process for Production of TEMPO-Oxidized Nanofibrillated Cellulose. Cellulose 2022, 29, 9121–9142. [Google Scholar] [CrossRef]

- Rahmadiawan, D.; Fuadi, Z.; Kurniawan, R.; Abral, H.; Ilhamsyah, F.; Arafat, A.; Rifelino, R.; Syahri, B.; Indrawan, E. Tribological Properties of Aqueous Carboxymethyl Cellulose/Uncaria Gambir Extract as Novel Anti-Corrosion Water-Based Lubricant. Tribol. Ind. 2022, 44, 584–591. [Google Scholar] [CrossRef]

- Chen, W.; Yu, H.; Liu, Y.; Chen, P.; Zhang, M.; Hai, Y. Individualization of Cellulose Nanofibers from Wood Using High-Intensity Ultrasonication Combined with Chemical Pretreatments. Carbohydr. Polym. 2011, 83, 1804–1811. [Google Scholar] [CrossRef]

- Abral, H.; Ariksa, J.; Mahardika, M.; Handayani, D.; Aminah, I.; Sandrawati, N.; Pratama, A.B.; Fajri, N.; Sapuan, S.M.; Ilyas, R.A. Transparent and Antimicrobial Cellulose FIlm from Ginger Nanofiber. Food Hydrocoll. 2020, 98, 105266. [Google Scholar] [CrossRef]

- Qiu, J.; Li, M.; Ding, M.; Yao, J. Cellulose Tailored Semiconductors for Advanced Photocatalysis. Renew. Sustain. Energy Rev. 2022, 154, 111820. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, S.; Wang, B.; Yao, J.; Wang, H. TEMPO-Oxidized Bacterial Cellulose Nanofibers-Supported Gold Nanoparticles with Superior Catalytic Properties. Carbohydr. Polym. 2017, 160, 34–42. [Google Scholar] [CrossRef]

- Do Nascimento, E.S.; Pereira, A.L.S.; de Barros, M.O.; de Barroso, M.K.A.; Lima, H.L.S.; de Borges, M.F.; de Feitosa, J.P.A.; de Azeredo, H.M.C.; de Rosa, M.F. TEMPO Oxidation and High-Speed Blending as a Combined Approach to Disassemble Bacterial Cellulose. Cellulose 2019, 26, 2291–2302. [Google Scholar] [CrossRef]

- Pham, T.T.H.; Vadanan, S.V.; Lim, S. Enhanced Rheological Properties and Conductivity of Bacterial Cellulose Hydrogels and Aerogels through Complexation with Metal Ions and PEDOT/PSS. Cellulose 2020, 27, 8075–8086. [Google Scholar] [CrossRef]

- Fuadi, Z.; Rahmadiawan, D.; Kurniawan, R.; Mulana, F.; Abral, H. Effect of Graphene Nanoplatelets on Tribological Properties of Bacterial Cellulose/Polyolester Oil. Mech. Eng. 2022, 8, 810847. [Google Scholar] [CrossRef]

- Huang, C.; Ji, H.; Yang, Y.; Guo, B.; Luo, L.; Meng, Z.; Fan, L.; Xu, J. TEMPO-Oxidized Bacterial Cellulose Nanofiber Membranes as High-Performance Separators for Lithium-Ion Batteries. Carbohydr. Polym. 2020, 230, 115570. [Google Scholar] [CrossRef]

- Lv, P.; Zhou, H.; Zhao, M.; Li, D.; Lu, K.; Wang, D.; Huang, J.; Cai, Y.; Lucia, L.A.; Wei, Q. Highly Flexible, Transparent, and Conductive Silver Nanowire-Attached Bacterial Cellulose Conductors. Cellulose 2018, 25, 3189–3196. [Google Scholar] [CrossRef]

- Xu, Z.; Yan, P.; Li, H.; Liu, K.; Liu, X.; Jia, S.; Zhang, Z.C. Active Cp*Iridium(III) Complex with Ortho-Hydroxyl Group Functionalized Bipyridine Ligand Containing an Electron-Donating Group for the Production of Diketone from 5-HMF. ACS Catal 2016, 6, 3784–3788. [Google Scholar] [CrossRef]

- El-Saied, H.; Basta, A.H.; Gobran, R.H. Research Progress in Friendly Environmental Technology for the Production of Cellulose Products (Bacterial Cellulose and Its Application). Polym. Plast. Technol. Eng. 2004, 43, 797–820. [Google Scholar] [CrossRef]

- French, A.D. Idealized Powder Diffraction Patterns for Cellulose Polymorphs. Cellulose 2014, 21, 885–896. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.J.; Martin, A.E.; Conrad, M. Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1958, 29, 786–794. [Google Scholar] [CrossRef]

- Dilamian, M.; Noroozi, B. A Combined Homogenization-High Intensity Ultrasonication Process for Individualizaion of Cellulose Micro-Nano Fibers from Rice Straw. Cellulose 2019, 26, 5831–5849. [Google Scholar] [CrossRef]

- Zheng, X.; Huang, F.; Chen, L.; Huang, L.; Cao, S.; Ma, X. Preparation of Transparent Film via Cellulose Regeneration: Correlations between Ionic Liquid and Film Properties. Carbohydr. Polym. 2019, 203, 214–218. [Google Scholar] [CrossRef]

- Wu, C.N.; Cheng, K.C. Strong, Thermal-Stable, Flexible, and Transparent Films by Self-Assembled TEMPO-Oxidized Bacterial Cellulose Nanofibers. Cellulose 2017, 24, 269–283. [Google Scholar] [CrossRef]

- Wang, S.; Li, T.; Chen, C.; Kong, W.; Zhu, S.; Dai, J.; Diaz, A.J.; Hitz, E.; Solares, S.D.; Li, T.; et al. Transparent, Anisotropic Biofilm with Aligned Bacterial Cellulose Nanofibers. Adv. Funct. Mater. 2018, 28, 1707491. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Y.; Zhu, S.; Xu, L.; Jia, C.; Dai, J.; Song, J.; Yao, Y.; Wang, Y.; Li, Y.; et al. Anisotropic, Transparent Films with Aligned Cellulose Nanofibers. Adv. Mater. 2017, 29, 1606284. [Google Scholar] [CrossRef]

- Ono, Y.; Takeuchi, M.; Kimura, S.; Puangsin, B.; Wu, C.-N.; Isogai, A. Structures, Molar Mass Distributions, and Morphologies of TEMPO-Oxidized Bacterial Cellulose Fibrils. Cellulose 2022, 29, 4977–4992. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, Y.; Ma, D.; Ahmed, S.; Qin, W.; Liu, Y. Effects of Ultrasonication Duration and Graphene Oxide and Nano-Zinc Oxide Contents on the Properties of Polyvinyl Alcohol Nanocomposites. Ultrason. Sonochem. 2019, 59, 104731. [Google Scholar] [CrossRef]

- Zhang, C.; Yang, Z.; Shi, J.; Zou, X.; Zhai, X.; Huang, X.; Li, Z.; Holmes, M.; Daglia, M.; Xiao, J. Physical Properties and Bioactivities of Chitosan / Gelatin-Based Films Loaded with Tannic Acid and Its Application on the Preservation of Fresh-Cut Apples. LWT 2021, 144, 111223. [Google Scholar] [CrossRef]

- Abral, H.; Lawrensius, V.; Handayani, D.; Sugiarti, E. Preparation of Nano-Sized Particles from Bacterial Cellulose Using Ultrasonication and Their Characterization. Carbohydr. Polym. 2018, 191, 161–167. [Google Scholar] [CrossRef] [PubMed]

- Syafri, E.; Sudirman; Mashadi; Yulianti, E.; Deswita; Asrofi, M.; Abral, H.; Sapuan, S.M.; Ilyas, R.A.; Fudholi, A. Effect of Sonication Time on the Thermal Stability, Moisture Absorption, and Biodegradation of Water Hyacinth (Eichhornia Crassipes) Nanocellulose-Filled Bengkuang (Pachyrhizus Erosus) Starch Biocomposites. J. Mater. Res. Technol. 2019, 8, 6223–6231. [Google Scholar] [CrossRef]

- Asrofi, M.; Abral, H.; Kurnia, Y.; Sapuan, S.M.; Kim, H. Effect of Duration of Sonication during Gelatinization on Properties of Tapioca Starch Water Hyacinth Fiber Biocomposite. Int. J. Biol. Macromol. 2018, 108, 167–176. [Google Scholar] [CrossRef]

- Atta, O.M.; Manan, S.; Ul-Islam, M.; Ahmed, A.A.Q.; Ullah, M.W.; Yang, G. Silver Decorated Bacterial Cellulose Nanocomposites as Antimicrobial Food Packaging Materials. ES Food Agrofor. 2021, 6, 12–26. [Google Scholar] [CrossRef]

- Udoetok, I.A.; Wilson, L.D.; Headley, J.V. Ultra-Sonication Assisted Cross-Linking of Cellulose Polymers. Ultrason. Sonochem. 2018, 42, 567–576. [Google Scholar] [CrossRef]

- Lu, Q.; Tang, L.; Lin, F.; Wang, S.; Chen, Y.; Chen, X.; Huang, B. Preparation and Characterization of Cellulose Nanocrystals via Ultrasonication-Assisted FeCl3-Catalyzed Hydrolysis. Cellulose 2014, 21, 3497–3506. [Google Scholar] [CrossRef]

- Gayathri, G.; Srinikethan, G. Bacterial Cellulose Production by K. Saccharivorans BC1 Strain Using Crude Distillery Effluent as Cheap and Cost Effective Nutrient Medium. Int. J. Biol. Macromol. 2019, 138, 950–957. [Google Scholar] [CrossRef]

- Wardhono, E.Y.; Kanani, N.; Alfirano, A. A Simple Process of Isolation Microcrystalline Cellulose Using Ultrasonic Irradiation. J. Dispers. Sci. Technol. 2020, 41, 1217–1226. [Google Scholar] [CrossRef]

- Qu, R.; Tang, M.; Wang, Y.; Li, D.; Wang, L. TEMPO-Oxidized Cellulose Fibers from Wheat Straw: Effect of Ultrasonic Pretreatment and Concentration on Structure and Rheological Properties of Suspensions. Carbohydr. Polym. 2021, 255, 117386. [Google Scholar] [CrossRef] [PubMed]

- Epp, J. X-ray Diffraction (XRD) Techniques for Materials Characterization; Elsevier Ltd: Amsterdam, The Netherlands, 2016; ISBN 9780081000571. [Google Scholar]

- Izumi, A.; Kakara, T.; Otsuki, M.W.; Shudo, Y.; Koganezawa, T.; Shibayama, M. In Situ Residual Stress Analysis in a Phenolic Resin and Copper Composite Material during Curing. Polymer 2019, 182, 121857. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, T.J. Mechanics of Strong and Tough Cellulose Nanopaper. Appl. Mech. Rev. 2019, 71, 040801. [Google Scholar] [CrossRef]

- Abdel-karim, A.M.; Salama, A.H.; Hassan, M.L. Electrical Conductivity and Dielectric Properties of Nanofibrillated Cellulose Thin Films from Bagasse. J. Phys. Org. Chem. 2018, 31, e3851. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, X.; Shen, Y.; Yoshino, K.; Feng, W. A Mechanically Strong, Flexible and Conductive Film Based on Bacterial Cellulose/Graphene Nanocomposite. Carbohydr. Polym. 2012, 87, 644–649. [Google Scholar] [CrossRef]

- Paximada, P.; Dimitrakopoulou, E.A.; Tsouko, E.; Koutinas, A.A.; Fasseas, C.; Mandala, I.G. Structural Modification of Bacterial Cellulose Fibrils under Ultrasonic Irradiation. Carbohydr. Polym. 2016, 150, 5–12. [Google Scholar] [CrossRef]

| Samples | Transmittance (%) at 650 nm | CI (%) of (200) Plane | d-Spacing (Å) of (200) Plane |

|---|---|---|---|

| UB-0 | 20.7 | 86.8 | 3.92 |

| UB-250 | 49.3 | 88.3 | 3.95 |

| UB-500 | 53.9 | 89.0 | 3.89 |

| UB-750 | 56.6 | 86.2 | 3.85 |

| Samples | Tmax (°C) | Latent Heat of Fusion (J/g) |

|---|---|---|

| UB-0 | 301.3 | 532.79 |

| UB-250 | 276.2 | 385.83 |

| UB-500 | 288.9 | 433.26 |

| UB-750 | 214.7 | 501.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahmadiawan, D.; Abral, H.; Kotodeli, R.A.; Sugiarti, E.; Muslimin, A.N.; Admi, R.I.; Arafat, A.; Kim, H.-J.; Sapuan, S.M.; Kosasih, E.A. A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power. Polymers 2023, 15, 643. https://doi.org/10.3390/polym15030643

Rahmadiawan D, Abral H, Kotodeli RA, Sugiarti E, Muslimin AN, Admi RI, Arafat A, Kim H-J, Sapuan SM, Kosasih EA. A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power. Polymers. 2023; 15(3):643. https://doi.org/10.3390/polym15030643

Chicago/Turabian StyleRahmadiawan, Dieter, Hairul Abral, Rafi Alzues Kotodeli, Eni Sugiarti, Ahmad Novi Muslimin, Ratna Isnanita Admi, Andril Arafat, Hyun-Joong Kim, S.M. Sapuan, and Engkos Achmad Kosasih. 2023. "A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power" Polymers 15, no. 3: 643. https://doi.org/10.3390/polym15030643

APA StyleRahmadiawan, D., Abral, H., Kotodeli, R. A., Sugiarti, E., Muslimin, A. N., Admi, R. I., Arafat, A., Kim, H. -J., Sapuan, S. M., & Kosasih, E. A. (2023). A Novel Highly Conductive, Transparent, and Strong Pure-Cellulose Film from TEMPO-Oxidized Bacterial Cellulose by Increasing Sonication Power. Polymers, 15(3), 643. https://doi.org/10.3390/polym15030643