Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

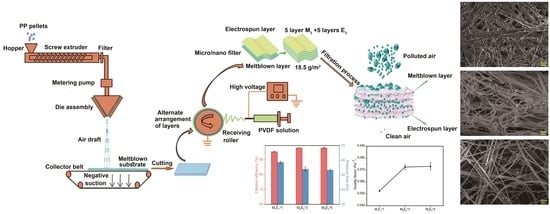

2.2. Sample Preparation

2.2.1. Preparation of Meltblown

2.2.2. Preparation of Laminated Filter

2.3. Structure Design

2.4. Characterization

2.5. Filtration Performance

3. Results and Discussion

3.1. Morphology of Laminated Micro/Nano Filter

3.2. Chemical Characterization

3.3. Hydrophobicity

3.4. Pore Size and Porosity

3.5. Filtration Properties

3.6. Loading Performance and Storage Stability

3.7. Filtration Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grobéty, B.; Gieré, R.; Dietze, V.; Stille, P. Airborne Particles in the Urban Environment. Elements 2010, 6, 229–234. [Google Scholar] [CrossRef]

- Song, J.; Liu, Z.; Li, Z.; Wu, H. Continuous production and properties of mutil-level nanofiber air filters by blow spinning. RSC Adv. 2020, 10, 19615–19620. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, S.; Liu, L.; Yu, J.; Ding, B. High-Performance PM0.3 Air Filters Using Self-Polarized Electret Nanofiber/Nets. Adv. Funct. Mater. 2020, 30, 1909554.1–1909554.8. [Google Scholar] [CrossRef]

- Hu, M.; Yin, L.; Low, N.; Ji, D.; Liu, Y.; Yao, J.; Zhong, Z.; Xing, W. Zeolitic-imidazolate-framework filled hierarchical porous nanofiber membrane for air cleaning. J. Membr. Sci. 2020, 594, 117467. [Google Scholar] [CrossRef]

- Brook, R.D.; Rajagopalan, S.; Pope, C.A., III; Brook, J.R.; Bhatnagar, A.; Diez-Roux, A.V.; Holguin, F.; Hong, Y.; Luepker, R.V.; Mittleman, M.A.; et al. Particulate Matter Air Pollution and Cardiovascular Disease: An update to the scientific statement from the american heart association. Circulation 2010, 121, 2331–2378. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Dey, S.; Smith, K.R. Ambient PM2.5 exposure and expected premature mortality to 2100 in India under climate change scenarios. Nat. Commun. 2018, 9, 318. [Google Scholar] [CrossRef]

- Xu, X.; Nie, S.; Ding, H.; Hou, F.F. Environmental pollution and kidney diseases. Nat. Rev. Nephrol. 2018, 14, 313–324. [Google Scholar] [CrossRef]

- Ardkapan, S.R.; Johnson, M.S.; Yazdi, S.; Afshari, A.; Bergsøe, N.C. Filtration efficiency of an electrostatic fibrous filter: Studying filtration dependency on ultrafine particle exposure and composition. J. Aerosol Sci. 2014, 72, 14–20. [Google Scholar] [CrossRef]

- Xiao, H.; Song, Y.; Chen, G. Correlation between charge decay and solvent effect for melt-blown polypropylene electret filter fabrics. J. Electrost. 2014, 72, 311–314. [Google Scholar] [CrossRef]

- Zhang, H.F.; Liu, N.; Zeng, Q.R.; Liu, J.X.; Zhang, X.; Ge, M.Z.; Zhang, W.; Li, S.Y.; Fu, Y.J.; Zhang, Y. Design of Polypropylene Electret Melt Blown Nonwovens with Superior Filtration Efficiency Stability through Thermally Stimulated Charging. Polymers 2020, 12, 2341. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Y.; Hua, T.; Jiang, P.; Yin, X.; Yu, J.; Ding, B. Cleanable Air Filter Transferring Moisture and Effectively Capturing PM2.5. Small 2017, 13, 1603306. [Google Scholar] [CrossRef] [PubMed]

- Campos, R.K.; Jin, J.; Rafael, G.H.; Zhao, M.; Liao, L.; Simmons, G.; Chu, S.; Weaver, S.C.; Chiu, W.; Cui, Y. Decontamination of SARS-CoV-2 and Other RNA Viruses from N95 Level Meltblown Polypropylene Fabric Using Heat under Different Humidities. ACS Nano 2020, 14, 14017–14025. [Google Scholar] [CrossRef] [PubMed]

- Kilic, A.; Shim, E.; Yeom, B.Y.; Pourdeyhimi, B. Improving electret properties of PP filaments with barium titanate. J. Electrost. 2013, 71, 41–47. [Google Scholar] [CrossRef]

- Kilic, A.; Shim, E.; Pourdeyhimi, B. Electrostatic Capture Efficiency Enhancement of Polypropylene Electret Filters with Barium Titanate. Aerosol Sci. Technol. 2015, 49, 666–673. [Google Scholar] [CrossRef]

- Han, M.-C.; He, H.-W.; Kong, W.-K.; Dong, K.; Wang, B.-Y.; Yan, X.; Wang, L.-M.; Ning, X. High-performance Electret and Antibacterial Polypropylene Meltblown Nonwoven Materials Doped with Boehmite and ZnO Nanoparticles for Air Filtration. Fibers Polym. 2022, 23, 1947–1955. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, H.; Gong, H.; Zhang, X.; Wang, Y.X.; Jin, X.Y. Polyethylene/Polypropylene Bicomponent Spunbond Air Filtration Materials Containing Magnesium Stearate for Efficient Fine Particle Capture. ACS Appl. Mater. Interfaces 2019, 11, 40592–40601. [Google Scholar] [CrossRef]

- Liu, H.; Liu, L.; Yu, J.; Yin, X.; Ding, B. High-efficiency and super-breathable air filters based on biomimetic ultrathin nanofiber networks. Compos. Commun. 2020, 22, 100493. [Google Scholar] [CrossRef]

- Lin, S.N.; Fu, X.W.; Luo, M.; Zhong, W.-H. Tailoring bimodal protein fabrics for enhanced air filtration performance. Sep. Purif. Technol. 2022, 290, 120913. [Google Scholar] [CrossRef]

- Chen, R.; Zhang, H.; Wang, M.; Zhang, X.; Gan, Z. Thermoplastic Polyurethane Nanofiber Membrane Based Air Filters for Efficient Removal of Ultrafine Particulate Matter PM0.1. ACS Appl. Nano Mater. 2020, 4, 182–189. [Google Scholar] [CrossRef]

- Kanafchian, M.; Valizadeh, M.; Haghi, A.K. Prediction of nanofiber diameter for improvements in incorporation of multilayer electrospun nanofibers. Korean J. Chem. Eng. 2011, 28, 751–755. [Google Scholar] [CrossRef]

- Lakshmanan, A.; Gavali, D.S.; Venkataprasanna, K.; Thapa, R.; Sarkar, D. Low-Basis Weight Polyacrylonitrile/Polyvinylpyrrolidone Blend Nanofiber Membranes for Efficient Particulate Matter Capture. ACS Appl. Polym. Mater. 2022, 4, 3971–3981. [Google Scholar] [CrossRef]

- Lou, L.-H.; Qin, X.-H.; Zhang, H. Preparation and study of low-resistance polyacrylonitrile nano membranes for gas filtration. Text. Res. J. 2016, 87, 208–215. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, X.; Teng, D.; Zhao, T.; Li, Y.; Zeng, Y. Multi-layered micro/nanofibrous nonwovens for functional face mask filter. Nano Res. 2022, 15, 7549–7558. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Qian, X.; Zhang, H.; Wang, L.; Zou, C.; Cui, Y. Preparing micro/nano-fibrous filters for effective PM 2.5 under low filtration resistance. Chem. Eng. Sci. 2020, 217, 115523. [Google Scholar] [CrossRef]

- Yao, Z.; Xia, M.; Xiong, Z.; Wu, Y.; Cheng, P.; Cheng, Q.; Xu, J.; Wang, D.; Liu, K. A Hierarchical Structure of Flower-Like Zinc Oxide and Poly(Vinyl Alcohol-co-Ethylene) Nanofiber Hybrid Membranes for High-Performance Air Filters. ACS Omega 2022, 7, 3030–3036. [Google Scholar] [CrossRef]

- Li, X.; Wang, C.; Huang, X.; Zhang, T.; Wang, X.; Min, M.; Wang, L.; Huang, H.; Hsiao, B.S. Anionic Surfactant-Triggered Steiner Geometrical Poly(vinylidene fluoride) Nanofiber/Nanonet Air Filter for Efficient Particulate Matter Removal. ACS Appl. Mater. Interfaces 2018, 10, 42891–42904. [Google Scholar] [CrossRef] [PubMed]

- Moon, J.; Bui, T.T.; Jang, S.; Ji, S.; Park, J.T.; Kim, M.-G. A highly efficient nanofibrous air filter membrane fabricated using electrospun amphiphilic PVDF-g-POEM double comb copolymer. Sep. Purif. Technol. 2021, 279, 119625. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Shao, W.; Wang, L.; Cui, C.; Gao, Y.; Jin, Y.; Yu, H.; Han, P.; Liu, F.; He, J. High-performance anti-haze window screen based on multiscale structured polyvinylidene fluoride nanofibers. J. Colloid Interface Sci. 2022, 607, 711–719. [Google Scholar] [CrossRef]

- Chen, M.; Jiang, J.; Feng, S.; Low, Z.-X.; Zhong, Z.; Xing, W. Graphene oxide functionalized polyvinylidene fluoride nanofibrous membranes for efficient particulate matter removal. J. Membr. Sci. 2021, 635, 119463. [Google Scholar] [CrossRef]

- Mandal, D.; Kim, K.J.; Lee, J.S. Simple Synthesis of Palladium Nanoparticles, β-Phase Formation, and the Control of Chain and Dipole Orientations in Palladium-Doped Poly(vinylidene fluoride) Thin Films. Langmuir 2012, 28, 10310–10317. [Google Scholar] [CrossRef]

- Zaarour, B.; Zhang, W.; Zhu, L.; Jin, X.Y.; Huang, C. Maneuvering surface structures of polyvinylidene fluoride nanofibers by controlling solvent systems and polymer concentration. Text. Res. J. 2018, 89, 2406–2422. [Google Scholar] [CrossRef]

- Kang, G.D.; Cao, Y.M. Application and modification of poly(vinylidene fluoride) (PVDF) membranes—A review. J. Membr. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Fan, Q.; Liang, W.; Fan, T.-T.; Li, X.; Yan, S.-Y.; Yu, M.; Ning, X.; Long, Y.-Z. Polyvinylidene fluoride composite nanofibrous filter for high-efficiency PM2.5 capture. Compos. Commun. 2020, 22, 100533. [Google Scholar] [CrossRef]

- Triwulandari, E.; Ghozali, M.; Sondari, D.; Septiyanti, M.; Sampora, Y.; Meliana, Y.; Fahmiati, S.; Restu, W.K.; Haryono, A. Effect of lignin on mechanical, biodegradability, morphology, and thermal properties of polypropylene/polylactic acid/lignin biocomposite. Plast. Rubber Compos. 2018, 48, 82–92. [Google Scholar] [CrossRef]

- Lao, W.; Li, G.; Zhou, Q.; Qin, T. Quantitative Analysis of Biomass in Three Types of Wood-Plastic Composites by FTIR Spectroscopy. Bioresources 2014, 9, 6073–6086. [Google Scholar] [CrossRef]

- Kumar, S.; Verma, V.; Walia, R. Magnetization and thickness dependent microwave attenuation behaviour of Ferrite-PANI composites and embedded composite-fabrics prepared by in situ polymerization. AIP Adv. 2021, 11, 015106. [Google Scholar] [CrossRef]

- Ismail, A.M.; Ramadan, R.; El-Masry, M.M. The role of nanoparticles inclusion in monitoring the physical properties of PVDF. J. Aust. Ceram. Soc. 2023. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. A simple and eco-friendly route for fabricating iron-based coating on metal mesh for efficient oil/water separation. Sep. Purif. Technol. 2019, 226, 31–38. [Google Scholar] [CrossRef]

- Peng, F.; Ma, W.; Zhang, Y.; Chen, Y.; Qi, H.; Zhang, C. Fabrication of laminated composite filter with nonwoven fabrics for oil/water separation. J. Text. Inst. 2022, 1–9. [Google Scholar] [CrossRef]

- Leung, W.W.-F.; Hung, C.-H.; Yuen, P.-T. Effect of face velocity, nanofiber packing density and thickness on filtration performance of filters with nanofibers coated on a substrate. Sep. Purif. Technol. 2010, 71, 30–37. [Google Scholar] [CrossRef]

- Wang, N.; Si, Y.; Wang, N.; Sun, G.; El-Newehy, M.; Al-Deyab, S.S.; Ding, B. Multilevel structured polyacrylonitrile/silica nanofibrous membranes for high-performance air filtration. Sep. Purif. Technol. 2014, 126, 44–51. [Google Scholar] [CrossRef]

- Leung, W.W.-F.; Choy, H.-F. Transition from depth to surface filtration for a low-skin effect filter subject to continuous loading of nano-aerosols. Sep. Purif. Technol. 2018, 190, 202–210. [Google Scholar] [CrossRef]

- Whitaker, S. Flow in porous media I: A theoretical derivation of Darcy’s law. Transp. Porous Media 1986, 1, 3–25. [Google Scholar] [CrossRef]

- Tang, M.; Thompson, D.; Chang, D.Q.; Chen, S.C.; Pui, D.Y. Filtration efficiency and loading characteristics of PM2.5 through commercial electret filter media. Sep. Purif. Technol. 2018, 195, 101–109. [Google Scholar] [CrossRef]

- Walsh, D.C.; Stenhouse, J.I.T. Parameters Affecting the Loading Behavior and Degradation of Electrically Active Filter Materials. Aerosol Sci. Technol. 1998, 29, 419–432. [Google Scholar] [CrossRef]

- Chang, D.-Q.; Tien, C.-Y.; Peng, C.-Y.; Tang, M.; Chen, S.-C. Development of composite filters with high efficiency, low pressure drop, and high holding capacity PM2.5 filtration. Sep. Purif. Technol. 2019, 212, 699–708. [Google Scholar] [CrossRef]

- Leung, W.W.-F.; Hau, C.W.-Y.; Choy, H.-F. Microfiber-nanofiber composite filter for high-efficiency and low pressure drop under nano-aerosol loading. Sep. Purif. Technol. 2018, 206, 26–38. [Google Scholar] [CrossRef]

- Wang, Q.; Lin, X.; Chen, D.-R. Effect of dust loading rate on the loading characteristics of high efficiency filter media. Powder Technol. 2016, 287, 20–28. [Google Scholar] [CrossRef]

- Ji, J.H.; Bae, G.N.; Kang, S.H.; Hwang, J. Effect of particle loading on the collection performance of an electret cabin air filter for submicron aerosols. J. Aerosol Sci. 2003, 34, 1493–1504. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, J.; Zhang, X.; Huang, C.; Zhang, Y.; Fu, Y.; Jin, X. Design of three-dimensional gradient nonwoven composites with robust dust holding capacity for air filtration. J. Appl. Polym. Sci. 2019, 136, 47827. [Google Scholar] [CrossRef]

- Kanaoka, C.; Hiragi, S.; Tanthapanichakoon, W. Stochastic simulation of the agglomerative deposition process of aerosol particles on an electret fiber. Powder Technol. 2001, 118, 97–106. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, J.; Zhang, H.; Hou, J.; Wang, Y.; Deng, C.; Huang, C.; Jin, X. Multi-Layered, Corona Charged Melt Blown Nonwovens as High Performance PM0.3 Air Filters. Polymers 2021, 13, 485. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Jung, S.; Park, H.; Kim, J. Bifunctional ZIF-8 Grown Webs for Advanced Filtration of Particulate and Gaseous Matters: Effect of Charging Process on the Electrostatic Capture of Nanoparticles and Sulfur Dioxide. ACS Appl. Mater. Interfaces 2021, 13, 50401–50410. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.-S.; Otani, Y. Removal of Nanoparticles from Gas Streams by Fibrous Filters: A Review. Ind. Eng. Chem. Res. 2013, 52, 5–17. [Google Scholar] [CrossRef]

- Tian, X.; Ou, Q.; Liu, J.; Liang, Y.; Pui, D.Y. Particle loading characteristics of a two-stage filtration system. Sep. Purif. Technol. 2019, 215, 351–359. [Google Scholar] [CrossRef]

- Sanyal, A.; Sinha-Ray, S. Ultrafine PVDF Nanofibers for Filtration of Air-Borne Particulate Matters: A Comprehensive Review. Polymers 2021, 13, 1864. [Google Scholar] [CrossRef]

| Sample | Number of Layers | Thickness (mm) | Base Weight (g/m2) (Microweb) (Nanoweb) | Total Base Weight (g/m2) | |

|---|---|---|---|---|---|

| M1E1*1 | 2 | 0.158 | 16.50 | 2.00 | 18.50 |

| M2E2*3 | 6 | 0.169 | 5.50*3 | 0.67*3 | 18.50 |

| M3E3*5 | 10 | 0.192 | 3.30*5 | 0.40*5 | 18.50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, W.; Qi, H.; Zhang, Y.; Lin, M.; Qiu, Y.; Zhang, C. Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal. Polymers 2023, 15, 1459. https://doi.org/10.3390/polym15061459

Ma W, Qi H, Zhang Y, Lin M, Qiu Y, Zhang C. Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal. Polymers. 2023; 15(6):1459. https://doi.org/10.3390/polym15061459

Chicago/Turabian StyleMa, Wenhua, Huan Qi, Yongmeng Zhang, Minggang Lin, Yiping Qiu, and Chuyang Zhang. 2023. "Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal" Polymers 15, no. 6: 1459. https://doi.org/10.3390/polym15061459

APA StyleMa, W., Qi, H., Zhang, Y., Lin, M., Qiu, Y., & Zhang, C. (2023). Fabrication of Laminated Micro/Nano Filter and Its Application for Inhalable PM Removal. Polymers, 15(6), 1459. https://doi.org/10.3390/polym15061459