Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Materials Preparation

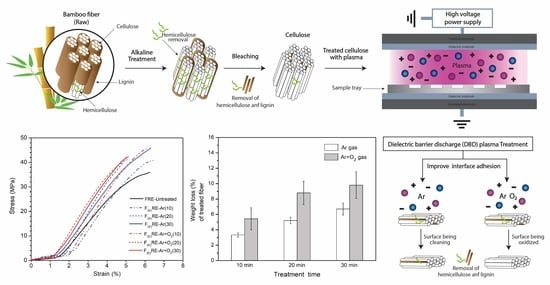

2.3. Preparation of Cellulose from Bamboo

2.4. Chemical Constituents Analysis

2.5. Plasma Treatment Process

2.6. Fourier Transform-Infrared Spectroscopy (FTIR)

2.7. X-ray Photoelectron Spectroscopy (XPS)

2.8. X-ray Diffraction Spectroscopy (XRD)

2.9. Scanning Electron Microscopy (SEM)

2.10. Brunauer–Emmett–Teller (BET)

2.11. Mechanical Properties

2.12. Statistical Analysis

3. Results and Discussion

3.1. Chemical Constituents of Extracted BFs

3.2. Morphology of Extracted BFs

3.3. Analysis of Reactive Radical Species via Optical Emission Spectroscopy

3.4. Analysis of Functional Groups via FTIR

3.5. Determination of Element Composition and Chemical Bonds

3.6. The Crystallinity Property

3.7. Comprehensive Weight Loss Percentage

3.8. Morphology of Treated BFs

3.9. BET Specific Surface Area

3.10. Mechanical Properties

3.11. The Effect of Plasma Treatment on the Fiber Surface on the Energy Absorption Property of the FRE Composite Samples

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rao, J.; Bao, L.; Wang, B.; Fan, M.; Feo, L. Plasma surface modification and bonding enhancement for bamboo composites. Compos. Part B Eng. 2018, 138, 157–167. [Google Scholar] [CrossRef]

- Chaiwong, C.; Rachtanapun, P.; Wongchaiya, P.; Auras, R.; Boonyawan, D. Effect of plasma treatment on hydrophobicity and barrier property of polylactic acid. Surf. Coat. Technol. 2010, 204, 2933–2939. [Google Scholar] [CrossRef]

- Felekoglu, B.; Tosun, K.; Baradan, B. A comparative study on the flexural performance of plasma treated polypropylene fiber reinforced cementitious composites. J. Mater. Process. Technol. 2009, 209, 5133–5144. [Google Scholar] [CrossRef]

- Zille, A.; Oliveira, F.R.; Souto, A.P. Plasma Treatment in Textile Industry. Plasma Process. Polym. 2015, 12, 98–131. [Google Scholar] [CrossRef] [Green Version]

- Jinkarn, T.; Thawornwiriyanan, S.; Boonyawan, D.; Rachtanapun, P.; Sane, S. Effects of Treatment Time by Sulfur Hexafluoride (SF6) Plasma on Barrier and Mechanical Properties of Paperboard. Packag. Technol. Sci. 2012, 25, 19–30. [Google Scholar] [CrossRef]

- Peran, J.; Ražić, S. Application of atmospheric pressure plasma technology for textile surface modification. Text. Res. J. 2019, 90, 1174–1197. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Y.; Zhang, Y.; Li, Y.; Tang, Y.; Huang, Y. Deposition of thin films on glass fiber fabrics by atmospheric pressure plasma jet. Surf. Coat. Technol. 2020, 404, 126498. [Google Scholar] [CrossRef]

- Liu, W.; Chen, T.; Xie, T.; Lai, F.; Qiu, R. Oxygen plasma treatment of bamboo fibers (BF) and its effects on the static and dynamic mechanical properties of BF-unsaturated polyester composites. Holzforschung 2015, 69, 449–455. [Google Scholar] [CrossRef]

- Putra, A.E.E.; Renreng, I.; Arsyad, H.; Bakri, B. Investigating the effects of liquid-plasma treatment on tensile strength of coir fibers and interfacial fiber-matrix adhesion of composites. Compos. Part B Eng. 2020, 183, 107722. [Google Scholar] [CrossRef]

- Sun, D. Chapter 2-Surface Modification of Natural Fibers Using Plasma Treatment. In Biodegradable Green Composite; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2016; pp. 18–39. [Google Scholar]

- Mengjin, W.U.; Lixia, J.I.A.; Suling, L.U.; Zhigang, Q.I.N.; Sainan, W.E.I.; Ruosi, Y.A.N. Interfacial performance of high-performance fiber-reinforced composites improved by cold plasma treatment: A review. Surf. Interfaces 2021, 24, 101077. [Google Scholar] [CrossRef]

- Pillai, R.R.; Thomas, V. Plasma Surface Engineering of Natural and Sustainable Polymeric Derivatives and Their Potential Applications. Polymers 2023, 15, 400. [Google Scholar] [CrossRef]

- Jia, H.; Chen, H.; Sheng, Y.; Meng, J.; Cui, S.; Kim, Y.R.; Huang, S.; Qin, H. Effect of laboratory aging on the stiffness and fatigue cracking of asphalt mixture containing bamboo fiber. J. Clean. Prod. 2022, 333, 130120. [Google Scholar] [CrossRef]

- Lu, Y.; Liang, Q.; Xue, L. Electroless nickel deposition on silane modified bamboo fabric through silver, copper or nickel activation. Surf. Coat. Technol. 2012, 206, 3639–3644. [Google Scholar] [CrossRef]

- Yamaguchi, H.; Fujii, T. Bamboo Fiber Reinforced Plastics. In Natural Fibers, Plastics and Composites; Wallenberger, F.T., Weston, N.E., Eds.; Springer: Boston, MA, USA, 2004; pp. 305–319. [Google Scholar]

- Noori, A.; Lu, Y.; Saffari, P.; Liu, J.; Ke, J. The effect of mercerization on thermal and mechanical properties of bamboo fibers as a biocomposite material: A review. Constr. Build. Mater. 2021, 279, 122519. [Google Scholar] [CrossRef]

- Lopes, M.D.M.; Pádua, M.d.S.; Carvalho, J.P.R.G.d.; Simonassi, N.T.; Lopez, F.P.D.; Colorado, H.A.; Vieira, C.M.F. Natural based polyurethane matrix composites reinforced with bamboo fiber waste for use as oriented strand board. J. Mater. Res. Technol. 2021, 12, 2317–2324. [Google Scholar] [CrossRef]

- Liu, D.; Song, J.; Anderson, D.; Chang, P.; Hua, Y. Bamboo fiber and its reinforced composites: Structure and properties. Cellulose 2012, 19, 1449–1480. [Google Scholar] [CrossRef]

- Hartono, R.; Iswanto, A.H.; Priadi, T.; Herawati, E.; Farizky, F.; Sutiawan, J.; Sumardi, I. Physical, Chemical, and Mechanical Properties of Six Bamboo from Sumatera Island Indonesia and Its Potential Applications for Composite Materials. Polymers 2022, 14, 4868. [Google Scholar] [CrossRef] [PubMed]

- Chitbanyong, K.; Pitiphatharaworachot, S.; Pisutpiched, S.; Khantayanuwong, S.; Puangsin, B. Characterization of Bamboo Nanocellulose Prepared by TEMPO-mediated Oxidation. Bioresources 2018, 13, 4440–4454. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Song, H.; Lin, L.; Zhuang, J.; Pang, C.; Liu, S. Microfibrillated cellulose from bamboo pulp and its properties. Biomass Bioenergy 2010, 39, 78–83. [Google Scholar] [CrossRef]

- Yu, D.; Jia, A.; Feng, C.; Liu, W.; Fu, T.; Qiu, R. Preparation and mechanical properties of asphalt mixtures reinforced by modified bamboo fibers. Constr. Build. Mater. 2021, 286, 122984. [Google Scholar] [CrossRef]

- Ozen, E.; Kiziltas, A.; Erbas Kiziltas, E.; Gardner, D. Natural Fiber Blend-Nylon 6 Composites. Polym. Compos. 2013, 34, 544–553. [Google Scholar] [CrossRef]

- Ding, R.; He, X.; Hu, Y.; Yan, J.; Lu, J.; Shi, S.Q.; Han, G.; Cheng, W. Uniform grafting of amino-functionalized multi-walled carbon nanotubes on the surface of oxidized bamboo fiber to enhance the interfacial strength with epoxy resin. Appl. Surf. Sci. 2022, 603, 154480. [Google Scholar] [CrossRef]

- Legras, A.; Kondor, A.; Heitzmann, M.T.; Truss, R.W. Inverse gas chromatography for natural fibre characterisation: Identification of the critical parameters to determine the Brunauer–Emmett–Teller specific surface area. J. Chromatogr. A 2015, 1425, 273–279. [Google Scholar] [CrossRef] [Green Version]

- Reddy, R.A.; Yoganandam, K.; Mohanavel, V. Effect of chemical treatment on natural fiber for use in fiber reinforced composites —Review. Mater. Today Proc. 2020, 33, 2996–2999. [Google Scholar] [CrossRef]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Mohit, H.; Arul Mozhi Selvan, V. A comprehensive review on surface modification, structure interface and bonding mechanism of plant cellulose fiber reinforced polymer based composites. Compos. Interfaces 2018, 25, 629–667. [Google Scholar] [CrossRef]

- Fournaud, B.; Rossignol, S.; Tatibouët, J.-M.; Thollon, S. Spherical pellets of BaTiO3 and Ba0.67Sr0.33TiO3 perovskite-type compounds made by a sol–gel oil drop process for non-thermal plasma applications. J. Mater. Process. Technol. 2009, 209, 2515–2521. [Google Scholar] [CrossRef]

- Radetić, M.; Jovančić, P.; Puač, N.; Petrović, Z. Environmental impact of plasma application to textiles. J. Phys. Conf. Ser. 2007, 71, 012017. [Google Scholar] [CrossRef] [Green Version]

- Xi, M.; Li, Y.-L.; Shang, S.-y.; Li, D.-H.; Yin, Y.-X.; Dai, X.-Y. Surface modification of aramid fiber by air DBD plasma at atmospheric pressure with continuous on-line processing. Surf. Coat. Technol. 2008, 202, 6029–6033. [Google Scholar] [CrossRef]

- Ngo, H.-T.; Hong, K.; Nguyen, T.-B. Surface Modification by the DBD Plasma to Improve the Flame-Retardant Treatment for Dyed Polyester Fabric. Polymers 2021, 13, 3011. [Google Scholar] [CrossRef]

- Ren, Y.; Ding, Z.; Wang, C.; Zang, C.; Zhang, Y.; Xu, L. Influence of DBD plasma pretreatment on the deposition of chitosan onto UHMWPE fiber surfaces for improvement of adhesion and dyeing properties. Appl. Surf. Sci. 2017, 396, 1571–1579. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Van Vlierberghe, S.; Dubruel, P.; Leys, C.; Gengembre, L.; Schacht, E.; Payen, E. Deposition of polymethyl methacrylate on polypropylene substrates using an atmospheric pressure dielectric barrier discharge. Prog. Org. Coat. 2009, 64, 230–237. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, S.K.; Ko, D.C.; Kim, D.J.; Kim, B.M. Evaluation of surface and bonding properties of cold rolled steel sheet pretreated by Ar/O2 atmospheric pressure plasma at room temperature. J. Mater. Process. Technol. 2009, 209, 4769–4775. [Google Scholar] [CrossRef]

- De Geyter, N.; Morent, R.; Leys, C.; Gengembre, L.; Payen, E. Treatment of polymer films with a dielectric barrier discharge in air, helium and argon at medium pressure. Surf. Coat. Technol. 2007, 201, 7066–7075. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patiño, W.; Cárdenas, J. Physical-mechanical properties of bamboo fibers-reinforced biocomposites: Influence of surface treatment of fibers. J. Build. Eng. 2019, 28, 101058. [Google Scholar] [CrossRef]

- Kalia, S.; Thakur, K.; Celli, A.; Kiechel, M.A.; Schauer, C.L. Surface modification of plant fibers using environment friendly methods for their application in polymer composites, textile industry and antimicrobial activities: A review. J. Environ. Chem. Eng. 2013, 1, 97–112. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Wongchiaya, P.; Boonyawan, D. Effect of Sulphur Hexafluoride (SF 6) Plasma on Hydrophobicity of Methylcellulose Film. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2010; Volume 93, pp. 214–218. [Google Scholar]

- Berthomieu, C.; Hienerwadel, R. Fourier transform infrared (FTIR) spectroscopy. Photosynth. Res. 2009, 101, 157–170. [Google Scholar] [CrossRef]

- Ali, A.; Chiang, Y.W.; Santos, R.M. X-ray Diffraction Techniques for Mineral Characterization: A Review for Engineers of the Fundamentals, Applications, and Research Directions. Minerals 2022, 12, 205. [Google Scholar] [CrossRef]

- Magazzù, A.; Marcuello, C. Investigation of Soft Matter Nanomechanics by Atomic Force Microscopy and Optical Tweezers: A Comprehensive Review. Nanomaterials 2023, 13, 963. [Google Scholar] [CrossRef] [PubMed]

- Pacaphol, K.; Aht-Ong, D. Preparation of hemp nanofibers from agricultural waste by mechanical defibrillation in water. J. Clean. Prod. 2017, 142, 1283–1295. [Google Scholar] [CrossRef]

- Alamri, H.; Low, I.M. Mechanical properties and water absorption behaviour of recycled cellulose fibre reinforced epoxy composites. Polym. Test. 2012, 31, 620–628. [Google Scholar] [CrossRef]

- Xiaobo, L. Physical, Chemical, and Mechanical Properties of Bamboo and Its Utilization Potential for Fiberboard Manufacturing; Louisiana State University and Agricultural & Mechanical College: Pineville, LA, USA, 2004. [Google Scholar]

- Chen, W.; Yu, H.; Liu, Y. Preparation of millimeter-long cellulose I nanofibers with diameters of 30–80 nm from bamboo fibers. Carbohydr. Polym. 2011, 86, 453–461. [Google Scholar] [CrossRef]

- Liu, J.-R.; Xu, G.; Shi, X.-M.; Zhang, G.-J. Low temperature plasma promoting fibroblast proliferation by activating the NF-κB pathway and increasing cyclinD1 expression. Sci. Rep. 2017, 7, 11698. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Naz, M.; Shukrullah, S.; Rehman, S.; Khan, Y.; Al-Arainy, A.; Meer, R. Optical characterization of non-thermal plasma jet energy carriers for effective catalytic processing of industrial wastewaters. Sci. Rep. 2021, 11, 2896. [Google Scholar] [CrossRef]

- Rezaei, F.; Gorbanev, Y.; Chys, M.; Nikiforov, A.; Van Hulle, S.; Cos, P.; Bogaerts, A.; De Geyter, N. Investigation of plasma-induced chemistry in organic solutions for enhanced electrospun PLA nanofibers. Plasma Process. Polym. 2018, 15, e1700226. [Google Scholar] [CrossRef]

- Bozaci, E.; Sever, K.; Sarikanat, M.; Seki, Y.; Demir, A.; Özdoğan, E.; Tavman, I. Effects of the atmospheric plasma treatments on surface and mechanical properties of flax fiber and adhesion between fiber–matrix for composite materials. Compos. Part B Eng. 2013, 45, 565–572. [Google Scholar] [CrossRef]

- Dufay, M.; Jimenez, M.; Degoutin, S. Effect of Cold Plasma Treatment on Electrospun Nanofibers Properties: A Review. ACS Appl. Bio Mater. 2020, 3, 4696–4716. [Google Scholar] [CrossRef]

- Liu, Z.; Fei, B. Characteristics of Moso Bamboo with Chemical Pretreatment. In Sustainable Degradation of Lignocellulosic Biomass—Techniques, Applications and Commercialization; Intechopen: Rijeka, Croatia, 2013; pp. 1–14. [Google Scholar]

- Suriyatem, R.; Auras, R.A.; Rachtanapun, C.; Rachtanapun, P. Biodegradable Rice Starch/Carboxymethyl Chitosan Films with Added Propolis Extract for Potential Use as Active Food Packaging. Polymers 2018, 10, 954. [Google Scholar] [CrossRef] [Green Version]

- Suriyatem, R.; Auras, R.A.; Rachtanapun, P. Improvement of mechanical properties and thermal stability of biodegradable rice starch–based films blended with carboxymethyl chitosan. Ind. Crops Prod. 2018, 122, 37–48. [Google Scholar] [CrossRef]

- Suriyatem, R.; Auras, R.A.; Rachtanapun, P. Utilization of Carboxymethyl Cellulose from Durian Rind Agricultural Waste to Improve Physical Properties and Stability of Rice Starch-Based Film. J. Polym. Environ. 2019, 27, 286–298. [Google Scholar] [CrossRef]

- Yu, X.; Fan, K.; Wang, K.; Jiang, J.; Peng, X.; Yang, H.; Wang, M. Physicochemical Variation of the Main Components during Wild Pretreatment Process Based on the Concept of the Whole Utilization of Bamboo. Energies 2021, 14, 6857. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Marcovich, N.E.; Aranguren, M.I. 4-Characterization of Fiber Surface Treatments in Natural Fiber Composites by Infrared and Raman Spectroscopy. In Interface Engineering of Natural Fibre Composites for Maximum Performance; Zafeiropoulos, N.E., Ed.; Woodhead Publishing: Cambridge, UK, 2011; pp. 117–145. [Google Scholar]

- Leksawasdi, N.; Chaiyaso, T.; Rachtanapun, P.; Thanakkasaranee, S.; Jantrawut, P.; Ruksiriwanich, W.; Seesuriyachan, P.; Phimolsiripol, Y.; Techapun, C.; Sommano, S.R.; et al. Corn starch reactive blending with latex from natural rubber using Na+ ions augmented carboxymethyl cellulose as a crosslinking agent. Sci. Rep. 2021, 11, 19250. [Google Scholar] [CrossRef] [PubMed]

- Suriyatem, R.; Noikang, N.; Kankam, T.; Jantanasakulwong, K.; Leksawasdi, N.; Phimolsiripol, Y.; Insomphun, C.; Seesuriyachan, P.; Chaiyaso, T.; Jantrawut, P.; et al. Physical Properties of Carboxymethyl Cellulose from Palm Bunch and Bagasse Agricultural Wastes: Effect of Delignification with Hydrogen Peroxide. Polymers 2020, 12, 1505. [Google Scholar] [CrossRef]

- Camargo, L.A.; Pereira, S.C.; Correa, A.C.; Farinas, C.S.; Marconcini, J.M.; Mattoso, L.H.C. Feasibility of Manufacturing Cellulose Nanocrystals from the Solid Residues of Second-Generation Ethanol Production from Sugarcane Bagasse. BioEnergy Res. 2016, 9, 894–906. [Google Scholar] [CrossRef]

- Da Silva, C.C.; de Faria Lima, A.; Moreto, J.A.; Dantas, S.; Alves Henrique, M.; Pasquini, D.; Cipriano Rangel, E.; Scarmínio, J.; Gelamo, R.V. Influence of plasma treatment on the physical and chemical properties of sisal fibers and environmental application in adsorption of methylene blue. Mater. Today Commun. 2020, 23, 101140. [Google Scholar] [CrossRef]

- Guignard, M.I.; Campagne, C.; Giraud, S.; Brebu, M.; Vrinceanu, N.; Cioca, L.-I. Functionalization of a bamboo knitted fabric using air plasma treatment for the improvement of microcapsules embedding. J. Text. Inst. 2014, 106, 119–132. [Google Scholar] [CrossRef]

- Li, B.; Li, J.; Zhou, X.; Zhang, J.; Li, T.; Du, G. Study of Gliding Arc Plasma Treatment for Bamboo-Culm Surface Modification. Forests 2019, 10, 1086. [Google Scholar] [CrossRef] [Green Version]

- Vizireanu, S.; Panaitescu, D.M.; Nicolae, C.A.; Frone, A.N.; Chiulan, I.; Ionita, M.D.; Satulu, V.; Carpen, L.G.; Petrescu, S.; Birjega, R.; et al. Cellulose defibrillation and functionalization by plasma in liquid treatment. Sci. Rep. 2018, 8, 15473. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rosa, S.M.L.; Rehman, N.; de Miranda, M.I.G.; Nachtigall, S.M.B.; Bica, C.I.D. Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr. Polym. 2012, 87, 1131–1138. [Google Scholar] [CrossRef] [Green Version]

- Jamali, A.; Evans, P.D. Etching of wood surfaces by glow discharge plasma. Wood Sci. Technol. 2011, 45, 169–182. [Google Scholar] [CrossRef]

- Kan, C.W.; Yuen, C.W.M. Surface characterisation of low temperature plasma-treated wool fibre. J. Mater. Process. Technol. 2006, 178, 52–60. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of Interfacial Adhesion Condition on Characterization of Plant-Fiber-Reinforced Polymer Composites: A Review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef]

- Papanicolaou, G.C.; Theocaris, P.S.; Spathis, G.D. Adhesion efficiency between phases in fibre-reinforced polymers by means of the concept of boundary interphase. Colloid Polym. Sci. 1980, 258, 1231–1237. [Google Scholar] [CrossRef]

- Ren, Z.; Guo, R.; Bi, H.; Jia, X.; Xu, M.; Cai, L. Interfacial Adhesion of Polylactic Acid on Cellulose Surface: A Molecular Dynamics Study. ACS Appl. Mater. Interfaces 2020, 12, 3236–3244. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.; Tao, X.; Yuen, C.; Yeung, K. Topographical Study of Low Temperature Plasma Treated Flax Fibers. Text. Res. J. 2000, 70, 886–893. [Google Scholar] [CrossRef]

- Teklal, F.; Djebbar, A.; Allaoui, S.; Hivet, G.; Joliff, Y.; Kacimi, B. A review of analytical models to describe pull-out behavior-Fiber/matrix adhesion. Compos. Struct. 2018, 201, 791–815. [Google Scholar] [CrossRef]

- Rachtanapun, P.; Boonyawan, D.; Auras, R.A.; Kasi, G. Effect of Water-Resistant Properties of Kraft Paper (KP) Using Sulfur Hexafluoride (SF6) Plasma Coating. Polymers 2022, 14, 3796. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

- Hh, M.; Hanoon, A.; Al Zand, A.; Abdulhameed, A.; Al-Sulttani, A. Torsional Strengthening of Reinforced Concrete Beams with Externally-Bonded Fibre Reinforced Polymer: An Energy Absorption Evaluation. Civ. Eng. J. 2020, 6, 69–85. [Google Scholar] [CrossRef]

- Wang, K.; Xie, X.; Wang, J.; Zhao, A.; Peng, Y.; Rao, Y. Effects of infill characteristics and strain rate on the deformation and failure properties of additively manufactured polyamide-based composite structures. Results Phys. 2020, 18, 103346. [Google Scholar] [CrossRef]

| Conditions | Ar Gas Flow Rate (L/min) | O2 Gas Flow Rate (L/min) | Treatment Time (min) |

|---|---|---|---|

| Untreated | - | - | - |

| Ar 10 min | 8 | - | 10 |

| Ar 20 min | 8 | - | 20 |

| Ar 30 min | 8 | - | 30 |

| Ar + O2 10 min | 8 | 10 | 10 |

| Ar + O2 20 min | 8 | 10 | 20 |

| Ar + O2 30 min | 8 | 10 | 30 |

| Treatments | Composition (wt/wt%) | |

|---|---|---|

| Fiber | Epoxy Resin | |

| FRE-Untreated | 5 | 95 |

| F(tr)RE-Ar (10) | 5 | 95 |

| F(tr)RE-Ar (20) | 5 | 95 |

| F(tr)RE-Ar (30) | 5 | 95 |

| F(tr)RE-Ar + O2 (10) | 5 | 95 |

| F(tr)RE-Ar + O2 (20) | 5 | 95 |

| F(tr)RE-Ar + O2 (30) | 5 | 95 |

| Holocellulose (%) | Alpha-Cellulose (%) | Linin (%) | Extractive (%) | Ash (%) |

|---|---|---|---|---|

| 73.10 ± 0.21 | 41.67 ± 0.35 | 28.88 ± 0.14 | 3.17 ± 0.07 | 2.04 ± 0.08 |

| Treatments | Compositions (%) a,b | O/C | |

|---|---|---|---|

| C | O | ||

| Untreated | 61.16 | 38.84 | 0.64 |

| Ar 10 min | 60.36 | 39.64 | 0.66 |

| Ar 20 min | 58.48 | 41.52 | 0.71 |

| Ar 30 min | 58.17 | 41.83 | 0.72 |

| Ar + O2 10 min | 57.61 | 42.39 | 0.74 |

| Ar + O2 20 min | 56.18 | 43.52 | 0.77 |

| Ar + O2 30 min | 55.12 | 44.88 | 0.81 |

| Type of Gas | Treatment Time (min) | BET Surface Area (m2/g) |

|---|---|---|

| Untreated | - | 0.99 a |

| Ar | 10 min | 3.04 ab |

| Ar | 20 min | 3.96 abc |

| Ar | 30 min | 7.38 cd |

| Ar + O2 | 10 min | 5.68 bcd |

| Ar + O2 | 20 min | 8.86 d |

| Ar + O2 | 30 min | 15.36 e |

| Sample | Tensile Strength (MPa) * | Elongation (%) * | Energy Absorption (MPa·mm/mm) * |

|---|---|---|---|

| FRE-untreated | 36.94 ± 0.46 a | 6.02 ± 0.49 ab | 98.25 ± 11.78 a |

| F(tr)RE-Ar 10 min | 39.80 ± 0.72 ab | 6.77 ± 0.74 a | 116.76 ± 15.65 ab |

| F(tr)RE-Ar 20 min | 42.12 ± 1.11 bc | 4.97 ± 0.45 b | 100.30 ± 13.73 ab |

| F(tr)RE-Ar 30 min | 46.30 ± 0.29 d | 6.33 ± 0.21 ab | 129.22 ± 5.28 b |

| F(tr)RE-Ar + O2 10 min | 45.19 ± 0.67 cd | 5.92 ± 0.23 ab | 116.38 ± 2.84 ab |

| F(tr)RE-Ar + O2 20 min | 40.95 ± 1.53 ab | 5.09 ± 0.22 b | 107.54 ± 7.94 ab |

| F(tr)RE-Ar + O2 30 min | 42.66 ± 0.59 bcd | 5.12 ± 0.17 b | 98.24 ± 4.43 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sawangrat, C.; Thipchai, P.; Kaewapai, K.; Jantanasakulwong, K.; Suhr, J.; Wattanachai, P.; Rachtanapun, P. Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment. Polymers 2023, 15, 1711. https://doi.org/10.3390/polym15071711

Sawangrat C, Thipchai P, Kaewapai K, Jantanasakulwong K, Suhr J, Wattanachai P, Rachtanapun P. Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment. Polymers. 2023; 15(7):1711. https://doi.org/10.3390/polym15071711

Chicago/Turabian StyleSawangrat, Choncharoen, Parichat Thipchai, Kannikar Kaewapai, Kittisak Jantanasakulwong, Jonghwan Suhr, Pitiwat Wattanachai, and Pornchai Rachtanapun. 2023. "Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment" Polymers 15, no. 7: 1711. https://doi.org/10.3390/polym15071711

APA StyleSawangrat, C., Thipchai, P., Kaewapai, K., Jantanasakulwong, K., Suhr, J., Wattanachai, P., & Rachtanapun, P. (2023). Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment. Polymers, 15(7), 1711. https://doi.org/10.3390/polym15071711