Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells

Abstract

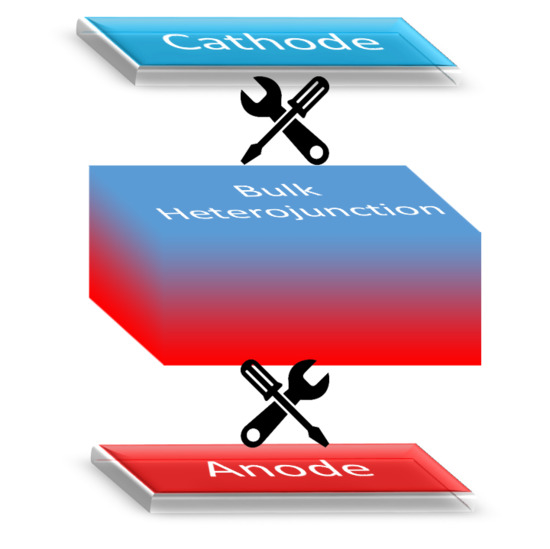

:1. Introduction

2. Polymer-Based Interfacial Layers

2.1. Poly(3,4-ethylenedioxythiophene)s and Polyaniline Derivatives

2.2. Water/Alcohol Soluble Conjugated Polymers

3. Small Molecules

4. Fullerenes and Derivatives

5. Graphene Oxide and Its Derivatives

6. Metal Oxide

7. Other Interfacial Layer Materials

8. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Coakley, K.M.; McGehee, M.D. Conjugated polymer photovoltaic cells. Chem. Mater. 2004, 16, 4533–4542. [Google Scholar] [CrossRef]

- Günes, S.; Neugebauer, H.; Sariciftci, N.S. Conjugated polymer-based organic solar cells. Chem. Rev. 2007, 107, 1324–1338. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Facchetti, A.; Marks, T.J. Imide- and amide-functionalized polymer semiconductors. Chem. Rev. 2014, 114, 8943–9021. [Google Scholar] [CrossRef] [PubMed]

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Krebs, F.C.; Gevorgyan, S.A.; Alstrup, J. A roll-to-roll process to flexible polymer solar cells: Model studies, manufacture and operational stability studies. J. Mater. Chem. 2009, 19, 5442–5451. [Google Scholar] [CrossRef]

- Søndergaard, R.R.; Hösel, M.; Krebs, F.C. Roll-to-roll fabrication of large area functional organic materials. J. Polym. Sci. B Polym. Phys. 2013, 51, 16–34. [Google Scholar] [CrossRef]

- Zhou, N.; Buchholz, D.B.; Zhu, G.; Yu, X.; Lin, H.; Facchetti, A.; Marks, T.J.; Chang, R.P.H. Ultraflexible polymer solar cells using amorphous zinc–indium–tin oxide transparent electrodes. Adv. Mater. 2014, 26, 1098–1104. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; He, Z.; Cheng, X.; Qin, D.; Yun, M.; Wang, M.; Huang, X.; Wu, J.; Wu, H.; Cao, Y. Flexible polymer solar cells with power conversion efficiency of 8.7%. J. Mater. Chem. C 2014, 2, 5077–5082. [Google Scholar] [CrossRef]

- Coughlin, J.E.; Henson, Z.B.; Welch, G.C.; Bazan, G.C. Design and synthesis of molecular donors for solution-processed high-efficiency organic solar cells. Acc. Chem. Res. 2013, 47, 257–270. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Wan, X.; Long, G. High performance photovoltaic applications using solution-processed small molecules. Acc. Chem. Res. 2013, 46, 2645–2655. [Google Scholar] [CrossRef] [PubMed]

- Harschneck, T.; Zhou, N.; Manley, E.F.; Lou, S.J.; Yu, X.; Butler, M.R.; Timalsina, A.; Turrisi, R.; Ratner, M.A.; Chen, L.X.; et al. Substantial photovoltaic response and morphology tuning in benzo[1,2-b:6,5-b′]dithiophene (bBDT) molecular donors. Chem. Commun. 2014, 50, 4099–4101. [Google Scholar] [CrossRef]

- Liang, Y.; Yu, L. A new class of semiconducting polymers for bulk heterojunction solar cells with exceptionally high performance. Acc. Chem. Res. 2010, 43, 1227–1236. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.; Zhang, S.; Huo, L.; Zhang, M.; Hou, J. Molecular design toward highly efficient photovoltaic polymers based on two-dimensional conjugated benzodithiophene. Acc. Chem. Res. 2014, 47, 1595–1603. [Google Scholar] [CrossRef] [PubMed]

- Zhou, N.; Lin, H.; Lou, S.J.; Yu, X.; Guo, P.; Manley, E.F.; Loser, S.; Hartnett, P.; Huang, H.; Wasielewski, M.R.; et al. Morphology-performance relationships in high-efficiency all-polymer solar cells. Adv. Energy Mater. 2014, 4. [Google Scholar] [CrossRef]

- Guo, X.; Zhou, N.; Lou, S.J.; Hennek, J.W.; Ponce Ortiz, R.; Butler, M.R.; Boudreault, P.-L.T.; Strzalka, J.; Morin, P.-O.; Leclerc, M.; et al. Bithiopheneimide–dithienosilole/dithienogermole copolymers for efficient solar cells: Information from structure–property–device performance correlations and comparison to thieno[3,4-c]pyrrole-4,6-dione analogues. J. Am. Chem. Soc. 2012, 134, 18427–18439. [Google Scholar] [CrossRef] [PubMed]

- Hartnett, P.E.; Timalsina, A.; Matte, H.S.S.R.; Zhou, N.; Guo, X.; Zhao, W.; Facchetti, A.; Chang, R.P.H.; Hersam, M.C.; Wasielewski, M.R.; et al. Slip-stacked perylenediimides as an alternative strategy for high efficiency nonfullerene acceptors in organic photovoltaics. J. Am. Chem. Soc. 2014, 136, 16345–16356. [Google Scholar] [CrossRef] [PubMed]

- Thompson, B.C.; Fréchet, J.M.J. Polymer–fullerene composite solar cells. Angew. Chem. Int. Ed. 2008, 47, 58–77. [Google Scholar] [CrossRef]

- Yu, G.; Gao, J.; Hummelen, J.C.; Wudl, F.; Heeger, A.J. Polymer photovoltaic cells-enhanced efficiencies via a network of internal donor-acceptor heterojunctions. Science 1995, 270, 1789–1791. [Google Scholar] [CrossRef]

- Halls, J.J.M.; Walsh, C.A.; Greenham, N.C.; Marseglia, E.A.; Friend, R.H.; Moratti, S.C.; Holmes, A.B. Efficient photodiodes from interpenetrating polymer networks. Nature 1995, 376, 498–500. [Google Scholar] [CrossRef]

- Cheng, Y.-J.; Yang, S.-H.; Hsu, C.-S. Synthesis of conjugated polymers for organic solar cell applications. Chem. Rev. 2009, 109, 5868–5923. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Watson, M.D. Pyromellitic diimide-based donor–acceptor poly(phenylene ethynylene)s. Macromolecules 2011, 44, 6711–6716. [Google Scholar] [CrossRef]

- Peet, J.; Heeger, A.J.; Bazan, G.C. “Plastic” solar cells: Self-assembly of bulk heterojunction nanomaterials by spontaneous phase separation. Acc. Chem. Res. 2009, 42, 1700–1708. [Google Scholar] [CrossRef] [PubMed]

- Guo, X.; Zhou, N.; Lou, S.J.; Smith, J.; Tice, D.B.; Hennek, J.W.; Ortiz, R.P.; Navarrete, J.T.L.; Li, S.; Strzalka, J.; et al. Polymer solar cells with enhanced fill factors. Nat. Photon. 2013, 7, 825–833. [Google Scholar] [CrossRef]

- Xin, H.; Guo, X.; Ren, G.; Watson, M.D.; Jenekhe, S.A. Efficient phthalimide copolymer-based bulk heterojunction solar cells: How the processing additive influences nanoscale morphology and photovoltaic properties. Adv. Energy Mater. 2012, 2, 575–582. [Google Scholar] [CrossRef]

- You, J.; Dou, L.; Yoshimura, K.; Kato, T.; Ohya, K.; Moriarty, T.; Emery, K.; Chen, C.-C.; Gao, J.; Li, G.; et al. A polymer tandem solar cell with 10.6% power conversion efficiency. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef]

- He, Z.; Zhong, C.; Su, S.; Xu, M.; Wu, H.; Cao, Y. Enhanced power-conversion efficiency in polymer solar cells using an inverted device structure. Nat. Photon. 2012, 6, 591–595. [Google Scholar]

- Liu, Y.; Zhao, J.; Li, Z.; Mu, C.; Ma, W.; Hu, H.; Jiang, K.; Lin, H.; Ade, H.; Yan, H. Aggregation and morphology control enables multiple cases of high-efficiency polymer solar cells. Nat. Commun. 2014, 5. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.-D.; Cui, C.; Li, Y.-Q.; Zhou, L.; Ou, Q.-D.; Li, C.; Li, Y.; Tang, J.-X. Single-junction polymer solar cells exceeding 10% power conversion efficiency. Adv. Mater. 2014, 1035–1041. [Google Scholar]

- Huang, Y.; Kramer, E.J.; Heeger, A.J.; Bazan, G.C. Bulk heterojunction solar cells: Morphology and performance relationships. Chem. Rev. 2014, 114, 7006–7043. [Google Scholar] [CrossRef] [PubMed]

- Kearns, D.; Calvin, M. Photovoltaic effect and photoconductivity in laminated organic systems. J. Chem. Phys. 1958, 29, 950–951. [Google Scholar] [CrossRef]

- Tang, C.W. Two-layer organic photovoltaic cell. Appl. Phys. Lett. 1986, 48, 183–185. [Google Scholar] [CrossRef]

- Wei, G.; Xiao, X.; Wang, S.; Zimmerman, J.D.; Sun, K.; Diev, V.V.; Thompson, M.E.; Forrest, S.R. Arylamine-based squaraine donors for use in organic solar cells. Nano Lett. 2011, 11, 4261–4264. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Ma, L.; Li, Y.; Liu, Y.; Zhu, D.; Zhan, X. Small-molecule solar cells with fill factors up to 0.75 via a layer-by-layer solution process. Adv. Energy Mater. 2014, 4. [Google Scholar] [CrossRef]

- Guo, X.; Marks, T.J. Plastic solar cells with engineered interfaces. Proc. SPIE 2013, 2013. [Google Scholar] [CrossRef]

- Po, R.; Carbonera, C.; Bernardi, A.; Camaioni, N. The role of buffer layers in polymer solar cells. Energy Environ. Sci. 2011, 4, 285–310. [Google Scholar] [CrossRef]

- Steim, R.; Kogler, F.R.; Brabec, C.J. Interface materials for organic solar cells. J. Mater. Chem. 2010, 20, 2499–2512. [Google Scholar] [CrossRef]

- Lai, T.-H.; Tsang, S.-W.; Manders, J.R.; Chen, S.; So, F. Properties of interlayer for organic photovoltaics. Mater. Today 2013, 16, 424–432. [Google Scholar] [CrossRef]

- Park, S.H.; Roy, A.; Beaupre, S.; Cho, S.; Coates, N.; Moon, J.S.; Moses, D.; Leclerc, M.; Lee, K.; Heeger, A.J. Bulk heterojunction solar cells with internal quantum efficiency approaching 100%. Nat. Photon. 2009, 3, 297–302. [Google Scholar] [CrossRef]

- Li, X.; Choy, W.C.H.; Huo, L.; Xie, F.; Sha, W.E.I.; Ding, B.; Guo, X.; Li, Y.; Hou, J.; You, J.; et al. Dual plasmonic nanostructures for high performance inverted organic solar cells. Adv. Mater. 2012, 24, 3046–3052. [Google Scholar] [CrossRef] [PubMed]

- Xie, F.-X.; Choy, W.C.H.; Sha, W.E.I.; Zhang, D.; Zhang, S.; Li, X.; Leung, C.-W.; Hou, J. Enhanced charge extraction in organic solar cells through electron accumulation effects induced by metal nanoparticles. Energy Environ. Sci. 2013, 6, 3372–3379. [Google Scholar] [CrossRef]

- Xiao, Z.; Yuan, Y.; Yang, B.; VanDerslice, J.; Chen, J.; Dyck, O.; Duscher, G.; Huang, J. Universal formation of compositionally graded bulk heterojunction for efficiency enhancement in organic photovoltaics. Adv. Mater. 2014, 26, 3068–3075. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, M.; Norrman, K.; Gevorgyan, S.A.; Tromholt, T.; Andreasen, B.; Krebs, F.C. Stability of polymer solar cells. Adv. Mater. 2012, 24, 580–612. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Fuentes-Hernandez, C.; Shim, J.; Meyer, J.; Giordano, A.J.; Li, H.; Winget, P.; Papadopoulos, T.; Cheun, H.; Kim, J.; et al. A universal method to produce low-work function electrodes for organic electronics. Science 2012, 336, 327–332. [Google Scholar] [CrossRef] [PubMed]

- Reese, M.O.; Morfa, A.J.; White, M.S.; Kopidakis, N.; Shaheen, S.E.; Rumbles, G.; Ginley, D.S. Pathways for the degradation of organic photovoltaic P3HT:PCBM based devices. Sol. Energy Mater. Sol. Cells 2008, 92, 746–752. [Google Scholar] [CrossRef]

- Zhou, N.; Guo, X.; Ortiz, R.P.; Li, S.; Zhang, S.; Chang, R.P.H.; Facchetti, A.; Marks, T.J. Bithiophene imide and benzodithiophene copolymers for efficient inverted polymer solar cells. Adv. Mater. 2012, 24, 2242–2248. [Google Scholar] [CrossRef] [PubMed]

- Gomez, E.D.; Loo, Y.-L. Engineering the organic semiconductor-electrode interface in polymer solar cells. J. Mater. Chem. 2010, 20, 6604–6611. [Google Scholar] [CrossRef]

- Roman, L.S.; Mammo, W.; Pettersson, L.A.A.; Andersson, M.R.; Inganäs, O. High quantum efficiency polythiophene. Adv. Mater. 1998, 10, 774–777. [Google Scholar] [CrossRef]

- Scott, J.C.; Malliaras, G.G.; Chen, W.D.; Breach, J.-C.; Salem, J.R.; Brock, P.J.; Sachs, S.B.; Chidsey, C.E.D. Hole limited recombination in polymer light-emitting diodes. Appl. Phys. Lett. 1999, 74, 1510–1512. [Google Scholar] [CrossRef]

- Aernouts, T.; Geens, W.; Poortmans, J.; Heremans, P.; Borghs, S.; Mertens, R. Extraction of bulk and contact components of the series resistance in organic bulk donor-acceptor-heterojunctions. Thin Solid Films 2002, 403–404, 297–301. [Google Scholar] [CrossRef]

- Frohne, H.; Müller, D.C.; Meerholz, K. Continuously variable hole injection in organic light emitting diodes. ChemPhysChem 2002, 3, 707–711. [Google Scholar] [CrossRef] [PubMed]

- Frohne, H.; Shaheen, S.E.; Brabec, C.J.; Müller, D.C.; Sariciftci, N.S.; Meerholz, K. Influence of the anodic work function on the performance of organic solar cells. ChemPhysChem 2002, 3, 795–799. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Chu, C.-W.; Shrotriya, V.; Huang, J.; Yang, Y. Efficient inverted polymer solar cells. Appl. Phys. Lett. 2006, 88. [Google Scholar] [CrossRef]

- Kim, Y.; Ballantyne, A.M.; Nelson, J.; Bradley, D.D.C. Effects of thickness and thermal annealing of the PEDOT:PSS layer on the performance of polymer solar cells. Org. Electron. 2009, 10, 205–209. [Google Scholar] [CrossRef]

- De Jong, M.P.; van Ijzendoorn, L.J.; de Voigt, M.J.A. Stability of the interface between indium-tin-oxide and poly(3,4-ethylenedioxythiophene)/poly(styrenesulfonate) in polymer light-emitting diodes. Appl. Phys. Lett. 2000, 77, 2255–2257. [Google Scholar] [CrossRef]

- Kim, H.; Nam, S.; Lee, H.; Woo, S.; Ha, C.-S.; Ree, M.; Kim, Y. Influence of controlled acidity of hole-collecting buffer layers on the performance and lifetime of polymer:fullerene solar cells. J. Phys. Chem. C 2011, 115, 13502–13510. [Google Scholar] [CrossRef]

- Meng, Y.; Hu, Z.; Ai, N.; Jiang, Z.; Wang, J.; Peng, J.; Cao, Y. Improving the stability of bulk heterojunction solar cells by incorporating pH-neutral PEDOT:PSS as the hole transport layer. ACS Appl. Mater. Interfaces 2014, 6, 5122–5129. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Zhao, B.; He, Z.; Zhao, X.; Wang, H.; Yang, S.; Wu, H.; Cao, Y. High-efficiency ITO-free polymer solar cells using highly conductive PEDOT:PSS/surfactant bilayer transparent anodes. Energy Environ. Sci. 2013, 6, 1956–1964. [Google Scholar] [CrossRef]

- Mengistie, D.A.; Ibrahem, M.A.; Wang, P.-C.; Chu, C.-W. Highly conductive PEDOT:PSS treated with formic acid for ito-free polymer solar cells. ACS Appl. Mater. Interfaces 2014, 6, 2292–2299. [Google Scholar] [CrossRef] [PubMed]

- Choi, M.-R.; Han, T.-H.; Lim, K.-G.; Woo, S.-H.; Huh, D.H.; Lee, T.-W. Soluble self-doped conducting polymer compositions with tunable work function as hole injection/extraction layers in organic optoelectronics. Angew. Chem. Int. Ed. 2011, 50, 6274–6277. [Google Scholar] [CrossRef]

- Lee, T.W.; Chung, Y.; Kwon, O.; Park, J.J. Self-organized gradient hole injection to improve the performance of polymer electroluminescent devices. Adv. Funct. Mater. 2007, 17, 390–396. [Google Scholar] [CrossRef]

- Wu, H.; Huang, F.; Mo, Y.; Yang, W.; Wang, D.; Peng, J.; Cao, Y. Efficient electron injection from a bilayer cathode consisting of aluminum and alcohol-/water-soluble conjugated polymers. Adv. Mater. 2004, 16, 1826–1830. [Google Scholar] [CrossRef]

- Duan, C.; Zhang, K.; Zhong, C.; Huang, F.; Cao, Y. Recent advances in water/alcohol-soluble π-conjugated materials: New materials and growing applications in solar cells. Chem. Soc. Rev. 2013, 42, 9071–9104. [Google Scholar] [CrossRef] [PubMed]

- He, Z.; Zhong, C.; Huang, X.; Wong, W.-Y.; Wu, H.; Chen, L.; Su, S.; Cao, Y. Simultaneous enhancement of open-circuit voltage, short-circuit current density, and fill factor in polymer solar cells. Adv. Mater. 2011, 23, 4636–4643. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Wu, H.; He, C.; Li, A.; Yang, W.; Cao, Y. Enhanced open-circuit voltage in polymer solar cells. Appl. Phys. Lett. 2009, 95. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Xie, Z.; Qin, C.; Qu, Y.; Geng, Y.; Wang, L. Enhanced charge collection in polymer photovoltaic cells by using an ethanol-soluble conjugated polyfluorene as cathode buffer layer. Sol. Energy Mater. Sol. Cells 2009, 93, 604–608. [Google Scholar] [CrossRef]

- Na, S.-I.; Oh, S.-H.; Kim, S.-S.; Kim, D.-Y. Efficient organic solar cells with polyfluorene derivatives as a cathode interfacial layer. Org. Electron. 2009, 10, 496–500. [Google Scholar] [CrossRef]

- He, C.; Zhong, C.; Wu, H.; Yang, R.; Yang, W.; Huang, F.; Bazan, G.C.; Cao, Y. Origin of the enhanced open-circuit voltage in polymer solar cells via interfacial modification using conjugated polyelectrolytes. J. Mater. Chem. 2010, 20, 2617–2622. [Google Scholar] [CrossRef]

- Seo, J.H.; Gutacker, A.; Sun, Y.; Wu, H.; Huang, F.; Cao, Y.; Scherf, U.; Heeger, A.J.; Bazan, G.C. Improved high-efficiency organic solar cells via incorporation of a conjugated polyelectrolyte interlayer. J. Am. Chem. Soc. 2011, 133, 8416–8419. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.H.; Gutacker, A.; Walker, B.; Cho, S.; Garcia, A.; Yang, R.; Nguyen, T.-Q.; Heeger, A.J.; Bazan, G.C. Improved injection in n-type organic transistors with conjugated polyelectrolytes. J. Am. Chem. Soc. 2009, 131, 18220–18221. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Zhang, Y.; Seifter, J.; Collins, S.D.; Luo, C.; Bazan, G.C.; Nguyen, T.-Q.; Heeger, A.J. High-efficiency polymer solar cells enhanced by solvent treatment. Adv. Mater. 2013, 25, 1646–1652. [Google Scholar] [CrossRef] [PubMed]

- Yang, T.; Wang, M.; Duan, C.; Hu, X.; Huang, L.; Peng, J.; Huang, F.; Gong, X. Inverted polymer solar cells with 8.4% efficiency by conjugated polyelectrolyte. Energy Environ. Sci. 2012, 5, 8208–8214. [Google Scholar] [CrossRef]

- Cheng, Y.-J.; Hsieh, C.-H.; He, Y.; Hsu, C.-S.; Li, Y. Combination of indene-C60 bis-adduct and cross-linked fullerene interlayer leading to highly efficient inverted polymer solar cells. J. Am. Chem. Soc. 2010, 132, 17381–17383. [Google Scholar] [CrossRef] [PubMed]

- Woo, S.; Kim, H.W.; Kim, H.; Yi, Y.; Lyu, H.-K.; Kim, Y. 8.9% Single-stack inverted polymer solar cells with electron-rich polymer nanolayer-modified inorganic electron-collecting buffer layers. Adv. Energy Mater. 2014, 4. [Google Scholar] [CrossRef]

- Yang, D.; Fu, P.; Zhang, F.; Wang, N.; Zhang, J.; Li, C. High efficiency inverted polymer solar cells with room-temperature titanium oxide/polyethylenimine films as electron transport layers. J. Mater. Chem. A 2014, 2, 17281–17285. [Google Scholar] [CrossRef]

- Pho, T.V.; Kim, H.; Seo, J.H.; Heeger, A.J.; Wudl, F. Quinacridone-based electron transport layers for enhanced performance in bulk-heterojunction solar cells. Adv. Funct. Mater. 2011, 21, 4338–4341. [Google Scholar] [CrossRef]

- Lu, K.; Yuan, J.; Peng, J.; Huang, X.; Cui, L.; Jiang, Z.; Wang, H.-Q.; Ma, W. New solution-processable small molecules as hole-transporting layer in efficient polymer solar cells. J. Mater. Chem. A 2013, 1, 14253–14261. [Google Scholar] [CrossRef]

- Chen, D.; Zhou, H.; Liu, M.; Zhao, W.-M.; Su, S.-J.; Cao, Y. Novel cathode interlayers based on neutral alcohol-soluble small molecules with a triphenylamine core featuring polar phosphonate side chains for high-performance polymer light-emitting and photovoltaic devices. Macromol. Rapid Commun. 2013, 34, 595–603. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Wu, Y.; Bao, Q.; Gao, F.; Fang, J. Morphological control for highly efficient inverted polymer solar cells via the backbone design of cathode interlayer materials. Adv. Energy Mater. 2014, 4. [Google Scholar] [CrossRef]

- Tan, W.-Y.; Wang, R.; Li, M.; Liu, G.; Chen, P.; Li, X.-C.; Lu, S.-M.; Zhu, H.L.; Peng, Q.-M.; Zhu, X.-H.; et al. Lending triarylphosphine oxide to phenanthroline: A facile approach to high-performance organic small-molecule cathode interfacial material for organic photovoltaics utilizing air-stable cathodes. Adv. Funct. Mater. 2014, 24, 6540–6547. [Google Scholar] [CrossRef]

- Zhang, Z.-G.; Qi, B.; Jin, Z.; Chi, D.; Qi, Z.; Li, Y.; Wang, J. Perylene diimides: A thickness-insensitive cathode interlayer for high performance polymer solar cells. Energy Environ. Sci. 2014, 7, 1966–1973. [Google Scholar] [CrossRef]

- Cheng, X.; Sun, S.; Chen, Y.; Gao, Y.; Ai, L.; Jia, T.; Li, F.; Wang, Y. A water-soluble metallophthalocyanine derivative as a cathode interlayer for highly efficient polymer solar cells. J. Mater. Chem. A 2014, 2014. [Google Scholar] [CrossRef]

- Wei, Q.; Nishizawa, T.; Tajima, K.; Hashimoto, K. Self-organized buffer layers in organic solar cells. Adv. Mater. 2008, 20, 2211–2216. [Google Scholar] [CrossRef]

- Wei, Q.; Tajima, K.; Tong, Y.; Ye, S.; Hashimoto, K. Surface-segregated monolayers: A new type of ordered monolayer for surface modification of organic semiconductors. J. Am. Chem. Soc. 2009, 131, 17597–17604. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Sun, L.; Zhang, X.; Bao, X.; Zheng, W.; Yang, R. Easily-accessible fullerenol as a cathode buffer layer for inverted organic photovoltaic devices. RSC Adv. 2014, 4, 25886–25891. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Wu, Y.; Min, C.; Fang, J. High performance polymer solar cells with a polar fullerene derivative as the cathode buffer layer. J. Mater. Chem. A 2013, 1, 12413–12416. [Google Scholar] [CrossRef]

- Zhang, Z.-G.; Li, H.; Qi, B.; Chi, D.; Jin, Z.; Qi, Z.; Hou, J.; Li, Y.; Wang, J. Amine group functionalized fullerene derivatives as cathode buffer layers for high performance polymer solar cells. J. Mater. Chem. A 2013, 1, 9624–9629. [Google Scholar] [CrossRef]

- Page, Z.A.; Liu, Y.; Duzhko, V.V.; Russell, T.P.; Emrick, T. Fulleropyrrolidine interlayers: Tailoring electrodes to raise organic solar cell efficiency. Science 2014, 346, 441–444. [Google Scholar] [CrossRef] [PubMed]

- Cho, N.; Li, C.-Z.; Yip, H.-L.; Jen, A.K.Y. In situ doping and crosslinking of fullerenes to form efficient and robust electron-transporting layers for polymer solar cells. Energy Environ. Sci. 2014, 7, 638–643. [Google Scholar] [CrossRef]

- Li, C.-Z.; Chang, C.-Y.; Zang, Y.; Ju, H.-X.; Chueh, C.-C.; Liang, P.-W.; Cho, N.; Ginger, D.S.; Jen, A.K.Y. Suppressed charge recombination in inverted organic photovoltaics via enhanced charge extraction by using a conductive fullerene electron transport layer. Adv. Mater. 2014, 26, 6262–6267. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Durstock, M.; Dai, L. Graphene oxide derivatives as hole- and electron-extraction layers for high-performance polymer solar cells. Energy Environ. Sci. 2014, 7, 1297–1306. [Google Scholar] [CrossRef]

- Li, S.-S.; Tu, K.-H.; Lin, C.-C.; Chen, C.-W.; Chhowalla, M. Solution-processable graphene oxide as an efficient hole transport layer in polymer solar cells. Acs Nano 2010, 4, 3169–3174. [Google Scholar] [CrossRef] [PubMed]

- Murray, I.P.; Lou, S.J.; Cote, L.J.; Loser, S.; Kadleck, C.J.; Xu, T.; Szarko, J.M.; Rolczynski, B.S.; Johns, J.E.; Huang, J.; et al. Graphene oxide interlayers for robust, high-efficiency organic photovoltaics. J. Phys. Chem. Lett. 2011, 2, 3006–3012. [Google Scholar] [CrossRef]

- Smith, C.T.G.; Rhodes, R.W.; Beliatis, M.J.; Jayawardena Imalka, K.D.J.; Rozanski, L.J.; Mills, C.A.; Silva, S.R.P. Graphene oxide hole transport layers for large area, high efficiency organic solar cells. Appl. Phys. Lett. 2014, 105. [Google Scholar] [CrossRef]

- Stratakis, E.; Savva, K.; Konios, D.; Petridis, C.; Kymakis, E. Improving the efficiency of organic photovoltaics by tuning the work function of graphene oxide hole transporting layers. Nanoscale 2014, 6, 6925–6931. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.; Zhou, L.; Yu, W.; Zhang, J.; Li, C. Work-function-tunable chlorinated graphene oxide as an anode interface layer in high-efficiency polymer solar cells. Adv. Energy Mater. 2014, 2014. [Google Scholar] [CrossRef]

- Kim, S.-H.; Lee, C.-H.; Yun, J.-M.; Noh, Y.-J.; Kim, S.-S.; Lee, S.; Jo, S.M.; Joh, H.-I.; Na, S.-I. Fluorine-functionalized and simultaneously reduced graphene oxide as a novel hole transporting layer for highly efficient and stable organic photovoltaic cells. Nanoscale 2014, 6, 7183–7187. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Xue, Y.; Dai, L. Sulfated graphene oxide as a hole-extraction layer in high-performance polymer solar cells. J. Phys. Chem. Lett. 2012, 3, 1928–1933. [Google Scholar] [CrossRef]

- Kakavelakis, G.; Konios, D.; Stratakis, E.; Kymakis, E. Enhancement of the efficiency and stability of organic photovoltaic devices via the addition of a lithium-neutralized graphene oxide electron-transporting layer. Chem. Mater. 2014, 20, 5988–5993. [Google Scholar] [CrossRef]

- Jayawardena, K.D.G.I.; Rhodes, R.; Gandhi, K.K.; Prabhath, M.R.R.; Dabera, G.D.M.R.; Beliatis, M.J.; Rozanski, L.J.; Henley, S.J.; Silva, S.R.P. Solution processed reduced graphene oxide/metal oxide hybrid electron transport layers for highly efficient polymer solar cells. J. Mater. Chem. A 2013, 1, 9922–9927. [Google Scholar] [CrossRef] [Green Version]

- Small, C.E.; Chen, S.; Subbiah, J.; Amb, C.M.; Tsang, S.-W.; Lai, T.-H.; Reynolds, J.R.; So, F. High-efficiency inverted dithienogermole-thienopyrrolodione-based polymer solar cells. Nat. Photon. 2012, 6, 115–120. [Google Scholar] [CrossRef]

- Wang, D.H.; Kim, J.K.; Seo, J.H.; Park, I.; Hong, B.H.; Park, J.H.; Heeger, A.J. Transferable graphene oxide by stamping nanotechnology: Electron-transport layer for efficient bulk-heterojunction solar cells. Angew. Chem. Int. Ed. 2013, 52, 2874–2880. [Google Scholar] [CrossRef]

- Arango, A.C.; Johnson, L.R.; Bliznyuk, V.N.; Schlesinger, Z.; Carter, S.A.; Hörhold, H.H. Efficient titanium oxide/conjugated polymer photovoltaics for solar energy conversion. Adv. Mater. 2000, 12, 1689–1692. [Google Scholar] [CrossRef]

- van Hal, P.A.; Wienk, M.M.; Kroon, J.M.; Verhees, W.J.H.; Slooff, L.H.; van Gennip, W.J.H.; Jonkheijm, P.; Janssen, R.A.J. Photoinduced electron transfer and photovoltaic response of a MDMO–PPV:TiO2 bulk-heterojunction. Adv. Mater. 2003, 15, 118–121. [Google Scholar] [CrossRef]

- Yeon Song, M.; Kim, K.-J.; Kim, D.Y. Enhancement of photovoltaic characteristics using a PEDOT interlayer in TiO2/MEHPPV heterojunction devices. Sol. Energy Mater. Sol. Cells 2005, 85, 31–39. [Google Scholar]

- Watanabe, A.; Kasuya, A. Effect of atmospheres on the open-circuit photovoltage of nanoporous TiO2/poly(3-hexylthiophene) heterojunction solar cell. Thin Solid Films 2005, 483, 358–366. [Google Scholar] [CrossRef]

- Kim, J.Y.; Kim, S.H.; Lee, H.H.; Lee, K.; Ma, W.; Gong, X.; Heeger, A.J. New architecture for high-efficiency polymer photovoltaic cells using solution-based titanium oxide as an optical spacer. Adv. Mater. 2006, 18, 572–576. [Google Scholar] [CrossRef]

- Park, M.-H.; Li, J.-H.; Kumar, A.; Li, G.; Yang, Y. Doping of the metal oxide nanostructure and its influence in organic electronics. Adv. Funct. Mater. 2009, 19, 1241–1246. [Google Scholar] [CrossRef]

- Roest, A.L.; Kelly, J.J.; Vanmaekelbergh, D.; Meulenkamp, E.A. Staircase in the electron mobility of a zno quantum dot assembly due to shell filling. Phys. Rev. Lett. 2002, 89, 036801. [Google Scholar] [CrossRef] [PubMed]

- Shirakawa, T.; Umeda, T.; Hashimoto, Y.; Fujii, A.; Yoshino, K. Effect of ZnO layer on characteristics of conducting polymer/C60 photovoltaic cell. J. Phys. D Appl. Phys. 2004, 37. [Google Scholar] [CrossRef]

- White, M.S.; Olson, D.C.; Shaheen, S.E.; Kopidakis, N.; Ginley, D.S. Inverted bulk-heterojunction organic photovoltaic device using a solution-derived ZnO underlayer. Appl. Phys. Lett. 2006, 89. [Google Scholar] [CrossRef]

- Amb, C.M.; Chen, S.; Graham, K.R.; Subbiah, J.; Small, C.E.; So, F.; Reynolds, J.R. Dithienogermole as a fused electron donor in bulk heterojunction solar cells. J. Am. Chem. Soc. 2011, 133, 10062–10065. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Small, C.E.; Amb, C.M.; Subbiah, J.; Lai, T.-H.; Tsang, S.-W.; Manders, J.R.; Reynolds, J.R.; So, F. Inverted polymer solar cells with reduced interface recombination. Adv. Energy Mater. 2012, 2, 1333–1337. [Google Scholar] [CrossRef]

- Sun, Y.; Seo, J.H.; Takacs, C.J.; Seifter, J.; Heeger, A.J. Inverted polymer solar cells integrated with a low-temperature-annealed sol-gel-derived zno film as an electron transport layer. Adv. Mater. 2011, 23, 1679–1683. [Google Scholar] [CrossRef] [PubMed]

- Hsieh, C.-H.; Cheng, Y.-J.; Li, P.-J.; Chen, C.-H.; Dubosc, M.; Liang, R.-M.; Hsu, C.-S. Highly efficient and stable inverted polymer solar cells integrated with a cross-linked fullerene material as an interlayer. J. Am. Chem. Soc. 2010, 132, 4887–4893. [Google Scholar] [CrossRef] [PubMed]

- Mrowec, S.; Grzesik, Z. Oxidation of nickel and transport properties of nickel oxide. J. Phys. Chem. Solids 2004, 65, 1651–1657. [Google Scholar] [CrossRef]

- Irwin, M.D.; Buchholz, D.B.; Hains, A.W.; Chang, R.P.H.; Marks, T.J. P-type semiconducting nickel oxide as an efficiency-enhancing anode interfacial layer in polymer bulk-heterojunction solar cells. Proc. Natl. Acad. Sci. USA 2008, 105, 2783–2787. [Google Scholar] [CrossRef]

- Irwin, M.D.; Servaites, J.D.; Buchholz, D.B.; Leever, B.J.; Liu, J.; Emery, J.D.; Zhang, M.; Song, J.-H.; Durstock, M.F.; Freeman, A.J.; et al. Structural and electrical functionality of nio interfacial films in bulk heterojunction organic solar cells. Chem. Mater. 2011, 23, 2218–2226. [Google Scholar] [CrossRef]

- Ratcliff, E.L.; Meyer, J.; Steirer, K.X.; Garcia, A.; Berry, J.J.; Ginley, D.S.; Olson, D.C.; Kahn, A.; Armstrong, N.R. Evidence for near-surface niooh species in solution-processed niox selective interlayer materials: Impact on energetics and the performance of polymer bulk heterojunction photovoltaics. Chem. Mater. 2011, 23, 4988–5000. [Google Scholar] [CrossRef]

- Steirer, K.X.; Ndione, P.F.; Widjonarko, N.E.; Lloyd, M.T.; Meyer, J.; Ratcliff, E.L.; Kahn, A.; Armstrong, N.R.; Curtis, C.J.; Ginley, D.S.; et al. Enhanced efficiency in plastic solar cells via energy matched solution processed niox interlayers. Adv. Energy Mater. 2011, 1, 813–820. [Google Scholar] [CrossRef]

- Manders, J.R.; Tsang, S.-W.; Hartel, M.J.; Lai, T.-H.; Chen, S.; Amb, C.M.; Reynolds, J.R.; So, F. Solution-processed nickel oxide hole transport layers in high efficiency polymer photovoltaic cells. Adv. Funct. Mater. 2013, 23, 2993–3001. [Google Scholar] [CrossRef]

- Song, C.K.; White, A.C.; Zeng, L.; Leever, B.J.; Clark, M.D.; Emery, J.D.; Lou, S.J.; Timalsina, A.; Chen, L.X.; Bedzyk, M.J.; et al. Systematic investigation of organic photovoltaic cell charge injection/performance modulation by dipolar organosilane interfacial layers. ACS Appl. Mater. Interfaces 2013, 5, 9224–9240. [Google Scholar] [CrossRef] [PubMed]

- Song, C.K.; Luck, K.A.; Zhou, N.; Zeng, L.; Heitzer, H.M.; Manley, E.F.; Goldman, S.; Chen, L.X.; Ratner, M.A.; Bedzyk, M.J.; et al. “Supersaturated” self-assembled charge-selective interfacial layers for organic solar cells. J .Am. Chem. Soc. 2014, 136, 17762–17773. [Google Scholar] [CrossRef] [PubMed]

- Motiei, L.; Yao, Y.; Choudhury, J.; Yan, H.; Marks, T.J.; Boom, M.E.V.D.; Facchetti, A. Self-propagating molecular assemblies as interlayers for efficient inverted bulk-heterojunction solar cells. J. Am. Chem. Soc. 2010, 132, 12528–12530. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Yan, L.; Zhou, Y.; Song, B.; Li, Y. Lowering the work function of ito by covalent surface grafting of aziridine: Application in inverted polymer solar cells. Adv. Mater. Interfaces 2015, 2. [Google Scholar] [CrossRef]

- Hains, A.W.; Liu, J.; Martinson, A.B.F.; Irwin, M.D.; Marks, T.J. Anode interfacial tuning via electron-blocking/hole-transport layers and indium tin oxide surface treatment in bulk-heterojunction organic photovoltaic cells. Adv. Funct. Mater. 2010, 20, 595–606. [Google Scholar] [CrossRef]

- Cho, N.; Yip, H.-L.; Davies, J.A.; Kazarinoff, P.D.; Zeigler, D.F.; Durban, M.M.; Segawa, Y.; O'Malley, K.M.; Luscombe, C.K.; Jen, A.K.Y. In-situ crosslinking and n-doping of semiconducting polymers and their application as efficient electron-transporting materials in inverted polymer solar cells. Adv. Energy Mater. 2011, 1, 1148–1153. [Google Scholar] [CrossRef]

- Moon, B.J.; Cho, S.; Lee, K.S.; Bae, S.; Lee, S.; Hwang, J.Y.; Angadi, B.; Yi, Y.; Park, M.; Son, D.I. Enhanced photovoltaic performance of inverted polymer solar cells utilizing multifunctional quantum-dot monolayers. Adv. Energy Mater. 2014, 5. [Google Scholar] [CrossRef]

- Yaacobi-Gross, N.; Treat, N.D.; Pattanasattayavong, P.; Faber, H.; Perumal, A.K.; Stingelin, N.; Bradley, D.D.C.; Stavrinou, P.N.; Heeney, M.; Anthopoulos, T.D. High-efficiency organic photovoltaic cells based on the solution-processable hole transporting interlayer copper thiocyanate (CuSCN) as a replacement for PEDOT:PSS. Adv. Energy Mater. 2014, 5. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, H.; Zhu, X.; Liang, Y.; Guo, X. Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells. Polymers 2015, 7, 333-372. https://doi.org/10.3390/polym7020333

Zeng H, Zhu X, Liang Y, Guo X. Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells. Polymers. 2015; 7(2):333-372. https://doi.org/10.3390/polym7020333

Chicago/Turabian StyleZeng, Hao, Xucheng Zhu, Yongye Liang, and Xugang Guo. 2015. "Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells" Polymers 7, no. 2: 333-372. https://doi.org/10.3390/polym7020333

APA StyleZeng, H., Zhu, X., Liang, Y., & Guo, X. (2015). Interfacial Layer Engineering for Performance Enhancement in Polymer Solar Cells. Polymers, 7(2), 333-372. https://doi.org/10.3390/polym7020333