A Hyper-Viscoelastic Constitutive Model for Polyurea under Uniaxial Compressive Loading

Abstract

:1. Introduction

- (i)

- To describe the hyperelastic behavior of polyuea at low strain rates, and choose a more accurate model between three-parameter Mooney-Rivlin model and the third Ogden model based on quasi-static compression experimental data.

- (ii)

- To describe the viscoelastic behavior of polyuea at high strain rates, and choose a more accurate model between the SLS model and the K-BKZ model based on the SHPB experimental data.

- (iii)

- To combine the two models chosen from the previous two steps to yield the constitutive model for polyurea.

2. Materials and Methods

2.1. Speicmens Preparation

2.2. Experimental

2.2.1. Quasi-Static Experiment

2.2.2. SHPB Experiment

3. Analysis

3.1. Hyperelasticity

3.1.1. Mooney-Rivlin Theory

3.1.2. Ogden Theory

3.2. Viscoelasticity

3.2.1. SLS Theory

3.2.2. K-BKZ Theory

4. Results and Discussion

4.1. Properties of Polyurea

4.2. Curves Fitting

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Grujicic, M.; Bell, W.C.; Pandurangan, B.; He, T. Blast-wave impact-mitigation capability of polyurea when used as helmet suspension-pad material. Mater. Des. 2010, 31, 4050–4065. [Google Scholar] [CrossRef]

- Raman, S.N.; Ngo, T.; Mendis, P.; Pham, T. Elastomeric polymers for retrofitting of reinforced concrete structures against the explosive effects of blast. Adv. Mater. Sci. Eng. 2012, 2012. [Google Scholar] [CrossRef]

- Knox, K.J.; Hammons, M.I.; Lewis, T.T.; Porter, J.R. Polymer Material for Structural Retrofit; Force Protection Branch, Air Expeditionary Forces Technology Division, Air Force Research Laboratory: Tyndall AFB, FL, USA, 2000. [Google Scholar]

- Bahei-El-Din, Y.A.; Dvorak, G.J.; Fredricksen, O.J. A blast-tolerant sandwich plate design with a polyurea interlayer. Int. J. Solids Struct. 2006, 43, 7644–7658. [Google Scholar] [CrossRef]

- Tekalur, S.A.; Shukla, A.; Shivakumar, K. Blast resistance of polyurea based layered composite materials. Compos. Struct. 2008, 84, 271–281. [Google Scholar] [CrossRef]

- Ackland, K.; Anderson, C.; Ngo, T.D. Deformation of polyurea-coated steel plates under localised blast loading. Int. J. Impact Eng. 2013, 51, 13–22. [Google Scholar] [CrossRef]

- Xue, L.; Mock, W.; Belytschko, T. Penetration of DH-36 steel plates with and without polyurea coating. Mech. Mater. 2010, 42, 981–1003. [Google Scholar] [CrossRef]

- Mohotti, D.; Ngo, T.; Mendis, P.; Raman, S.N. Polyurea coated composite aluminium plates subjected to high velocity projectile impact. Mater. Des. 2013, 52, 1–16. [Google Scholar] [CrossRef]

- Amirkhizi, A.V.; Isaacs, J.; Mcgee, J.; Nemat-Nasser, S. An experimentally-based viscoelastic constitutive model for polyurea, including pressure and temperature effects. Philos. Mag. 2006, 86, 5847–5866. [Google Scholar] [CrossRef]

- Yi, J.; Boyce, M.C.; Lee, G.F.; Balizer, E. Large deformation rate-dependent stress-strain behavior of polyurea and polyurethanes. Polymer 2006, 47, 319–329. [Google Scholar] [CrossRef]

- Xu, J.; Li, Y.B.; Ge, D.Y.; Liu, B.H.; Zhu, M.Y. Experimental investigation on constitutive behavior of PVB under impact loading. Int. J. Impact Eng. 2011, 38, 106–114. [Google Scholar] [CrossRef]

- Gamonpilas, C.; McCuiston, R. A non-linear viscoelastic material constitutive model for polyurea. Polymer 2012, 53, 3655–3658. [Google Scholar] [CrossRef]

- Li, C.Y.; Lua, J. A hyper-viscoelastic constitutive model for polyurea. Mater. Lett. 2009, 63, 877–880. [Google Scholar] [CrossRef]

- El Sayed, T.; Mock, W.; Mota, A.; Fraternali, F.; Ortiz, M. Computational assessment of ballistic impact on a high strength structural steel/polyurea composite plate. Comput. Mech. 2009, 43, 525–534. [Google Scholar] [CrossRef]

- Roland, C.M.; Fragiadakis, D.; Gamache, R.M. Elastomer-steel laminate armor. Compos. Struct. 2010, 92, 1059–1064. [Google Scholar] [CrossRef]

- Sarva, S.S.; Deschanel, S.; Boyce, M.C.; Chen, W.N. Stress-strain behavior of a polyurea and a polyurethane from low to high strain rates. Polymer 2007, 48, 2208–2213. [Google Scholar] [CrossRef]

- Naz, S.; Sweeney, J.; Coates, P.D. Analysis of the essential work of fracture method as applied to UHMWPE. J. Mater. Sci. 2010, 45, 448–459. [Google Scholar] [CrossRef]

- Shim, J.; Mohr, D. Rate dependent finite strain constitutive model of polyurea. Int. J. Plast. 2011, 27, 868–886. [Google Scholar] [CrossRef]

- Shim, J.; Mohr, D. Using split Hopkinson pressure bars to perform large strain compression tests on polyurea at low, intermediate and high strain rates. Int. J. Impact Eng. 2009, 36, 1116–1127. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Zhou, B. A quartz-crystal-embedded split Hopkinson pressure bar for soft materials. Exp. Mech. 2000, 40, 1–6. [Google Scholar] [CrossRef]

- Nie, X.; Song, B.; Ge, Y.; Chen, W.W.; Weerasooriya, T. Dynamic tensile testing of soft materials. Exp. Mech. 2009, 49, 451–458. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, B.; Forrestal, M.J. A split Hopkinson bar technique for low-impedance materials. Exp. Mech. 1999, 39, 81–85. [Google Scholar] [CrossRef]

- Gray III, G.T.; Blumenthal, W.R. Split-Hopkinson pressure bar testing of soft materials. ASM Int. 2000, 8, 488–496. [Google Scholar]

- Sawas, O.; Brar, N.S.; Brockman, R.A. Dynamic characterization of compliant materials using an all-polymeric split Hopkinson bar. Exp. Mech. 1998, 38, 204–210. [Google Scholar] [CrossRef]

- Zhao, H.; Gary, G.; Klepaczko, J.R. On the use of a viscoelastic split Hopkinson pressure bar. Int. J. Impact Eng. 1997, 19, 319–330. [Google Scholar] [CrossRef]

- Doman, D.A.; Cronin, D.S.; Salisbury, C.P. Characterization of polyurethane rubber at high deformation rates. Exp. Mech. 2006, 46, 367–376. [Google Scholar] [CrossRef]

- Johnson, T.P. M.; Sarva, S.S.; Socrate, S. Comparison of low impedance split-hopkinson pressure bar techniques in the characterization of polyurea. Exp. Mech. 2010, 50, 931–940. [Google Scholar] [CrossRef]

- Knauss, W.G. Nonlinear, Time-Dependent Constitution of Engineering Polymers; University of California: SanDiego, CA, USA, 1995. [Google Scholar]

- Davies, E.D. H.; Hunter, S.C. The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J. Mech. Phys. Solid 1963, 11, 155–179. [Google Scholar] [CrossRef]

- Ravichandran, G.; Subhash, G. Critical-appraisal of limiting strain rates for compression testing of ceramics in a split hopkinson pressure bar. J. Am. Ceram. Soc. 1994, 77, 263–267. [Google Scholar] [CrossRef]

- Mooney, M. A theory of large elastic deformations. J. Appl. Phys. 1940, 11, 582–592. [Google Scholar] [CrossRef]

- Rivlin, R.S. Large elastic deformations of isotropic materials. IV. Further developments of the general theory. Philos. Trans. R. Soc. Lond. A Math. Phys. Sci. 1948, 241, 379–397. [Google Scholar] [CrossRef]

- Brown, R. Physical Testing of Rubber, 3rd ed.; Springer Science & Business Media: London, UK, 1996. [Google Scholar]

- Yang, L.M.; Shim, V.P. W.; Lim, C.T. A visco-hyperelastic approach to modelling the constitutive behaviour of rubber. Int. J. Impact Eng. 2000, 24, 545–560. [Google Scholar] [CrossRef]

- Ogden, R.W. Large deformation isotropic elasticity-on the correlation of theory and experiment for incompressible rubber like solids. Proc. R. Soc. Lond. A. Math. Phys. Sci. 1972, 326, 565–584. [Google Scholar] [CrossRef]

- Almagableh, A.; Mantena, P.R.; Alostaz, A. Creep and stress relaxation modeling of vinyl ester nanocomposites reinforced by nanoclay and graphite platelets. J. Appl. Polym. Sci. 2010, 115, 1635–1641. [Google Scholar] [CrossRef]

- Bernstein, B.; Kearsley, A.E.; Zapas, J.L. A study of stress relaxation with finite strain. Rubber Chem. Technol. 1965, 38, 76–89. [Google Scholar] [CrossRef]

- Lockett, F.J. Nonlinear Viscoelastic Solids; Academic Press: New York, NY, USA, 1972. [Google Scholar]

- Truesdell, C.; Noll, W. The Non-Linear Field Theories of Mechanics/Die Nicht-Linearen Feldtheorien der Mechanik. In Encyclopedia of Physics/Handbuch der Physik; Springer: Heidelberg, Germany, 1965; p. 1. [Google Scholar]

- Wagner, M.H. Network Theory of Polymer Melts. Rheol. Acta 1979, 18, 33–50. [Google Scholar] [CrossRef]

- Papanastasiou, A.C.; Scriven, L.E.; Macosko, C.W. An integral constitutive equation for mixed flows-viscoelastic characterization. J. Rheol. 1983, 27, 387–410. [Google Scholar] [CrossRef]

- Narimissa, E.; Gupta, R.K.; Kao, N. Shear and extensional rheological evaluation of polylactide-nanographite platelet nanocomposites through constitutive equations. Polym. Compos. 2013, 25. [Google Scholar]

- Osaki, K.; Ohta, S.; Fukuda, M.; Kurata, M. Nonlinear viscoelasticity of polystyrene solutions–stress development at start of steady shear-flow and an experimental check of some constitutive models. J. Polym. Sci. Pol. Phys. 1976, 14, 1701–1715. [Google Scholar] [CrossRef]

- Wang, L.L.; Yang, L.M. A class of nonlinear viscoelastic constitutive relations of solid polymeric materials. Prog. Impact Dyn. 1992, 88–116. [Google Scholar]

- Wang, L.L.; Huang, D.; Gan, S. Nonlinear viscoelastic constitutive relations and nonlinear viscoelastic wave propagation for polymers at high strain rates. In Constitutive Relation in High/Very High Stran Rate; Springer: Tokyo, Japan, 1996; pp. 137–146. [Google Scholar]

- Raman, S.N.; Ngo, T.; Lu, J.; Mendis, P. Experimental investigation on the tensile behavior of polyurea at high strain rates. Mater. Des. 2013, 50, 124–129. [Google Scholar] [CrossRef]

- Roland, C.M.; Twigg, J.N.; Vu, Y.; Mott, P.H. High strain rate mechanical behavior of polyurea. Polymer 2007, 48, 574–578. [Google Scholar] [CrossRef]

- Bogoslovov, R.B.; Roland, C.M.; Gamache, R.M. Impact-induced glass transition in elastomeric coatings. Appl. Phys. Lett. 2007, 90, 221910. [Google Scholar] [CrossRef]

| Parameters | Striker Bar | Incident Bar | Transmission Bar |

|---|---|---|---|

| Length L (mm) | 800 | 2,000 | 2,000 |

| Diameter Φ (mm) | 37 | 37 | 37 |

| Mass density ρ (kg/m3) | 2,810 | ||

| Young’s modulus (MPa) | 70,250 | ||

| Strain gauge location Lg (mm) (distance from gauge to specimen) | - | 1,100 | 1,100 |

| Stain Rate (s−1) | RMSE | |

|---|---|---|

| Mooney-Rivlin Model | Ogden Model | |

| 10−3 | 0.0166 | 0.0305 |

| 10−2 | 0.0371 | 0.0217 |

| 10−1 | 0.0573 | 0.0118 |

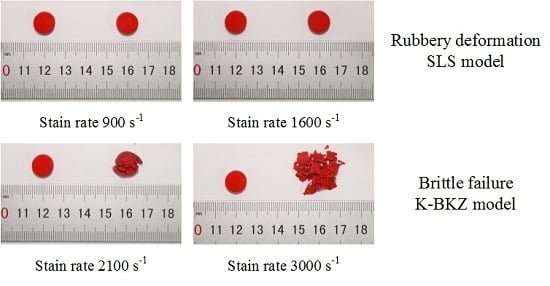

| SLS Model | K-BKZ Model | |

| 900 | 0.0033 | 0.0077 |

| 1600 | 0.0253 | 0.0816 |

| 2100 | 0.7501 | 0.1783 |

| 3000 | 0.9457 | 0.5687 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Y.; Liu, C.; Huang, G.; Li, W.; Feng, S. A Hyper-Viscoelastic Constitutive Model for Polyurea under Uniaxial Compressive Loading. Polymers 2016, 8, 133. https://doi.org/10.3390/polym8040133

Bai Y, Liu C, Huang G, Li W, Feng S. A Hyper-Viscoelastic Constitutive Model for Polyurea under Uniaxial Compressive Loading. Polymers. 2016; 8(4):133. https://doi.org/10.3390/polym8040133

Chicago/Turabian StyleBai, Yang, Chunmei Liu, Guangyan Huang, Wei Li, and Shunshan Feng. 2016. "A Hyper-Viscoelastic Constitutive Model for Polyurea under Uniaxial Compressive Loading" Polymers 8, no. 4: 133. https://doi.org/10.3390/polym8040133

APA StyleBai, Y., Liu, C., Huang, G., Li, W., & Feng, S. (2016). A Hyper-Viscoelastic Constitutive Model for Polyurea under Uniaxial Compressive Loading. Polymers, 8(4), 133. https://doi.org/10.3390/polym8040133