Factors for Consideration in an Open-Flame Test for Assessing Fire Blocking Performance of Barrier Fabrics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

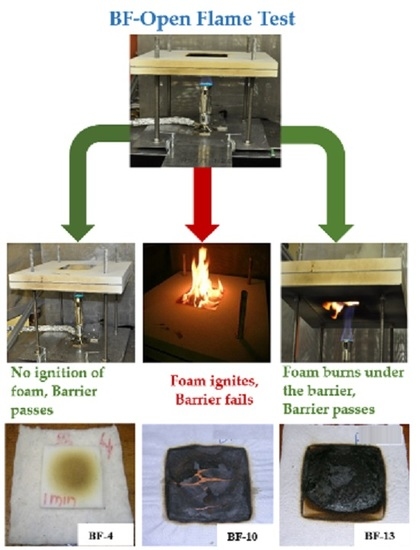

2.2. BF-Open Flame Test

2.3. Temperature and Heat Transfer Measurements

3. Results and Discussion

3.1. General Experimental Observations during BF-Open Flame Test

3.1.1. Thermally Insulating Barriers

3.1.2. Impermeable or Barriers with Low Gas Permeability

3.1.3. Thermally Thin, Permeable Barriers

3.2. Heat Flux Measurements on the Unexposed Side of BFs

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Troitzsch, J.H. Fires, statistics, ignition sources, and passive fire protection measures. J. Fire Sci. 2016, 34, 171–198. [Google Scholar] [CrossRef]

- Hall, J.R. Estimating fires when a product is the primary fuel but not the first fuel, with an application to upholstered furniture. Fire Technol. 2015, 51, 381–391. [Google Scholar] [CrossRef]

- State of California Department of Consumer Affairs. Technical Bulletin TB-117: Requirements, Test Procedure, and Apparatus for Testing and Flame Retardancy of Filling Materials and Fabrics; Bureau of Home Furnishings, Department of Consumer Affairs, State of California: North Highlands, CA, USA, 1977.

- California Senate Bill No. 1019, Chapter 862, Approved by Governor on September 30, 2014. Available online: https://leginfo.legislature.ca.gov/faces/billNavClient.xhtml?bill_id=201320140SB1019 (accessed on 22 February 2016).

- Alaee, M.; Wenning, R.J. The Significance of Brominated Flame Retardants in the Environment: Current Understanding, Issues and Challenges. Chemosphere 2002, 46, 579–796. [Google Scholar] [CrossRef]

- Letcher, R.; Behnisch, P. The State-of-Science and Trends of BFRs in the Environment. Environ. Int. 2003, 29, 663–886. [Google Scholar] [CrossRef]

- Babrauskas, V.; Blum, A.; Daley, R.; Birnbaum, L. Flame Retardants in Furniture Foam: Benefits and Risks. Fire Saf. Sci. 2011, 10, 265–278. [Google Scholar] [CrossRef]

- Hawthorne, M. Toxic Roulette: Flame Retardants Get a Pass from Regulators with Little Assessment of Potential Health Risks; Chicago Tribune: Chicago, IL, USA; Available online: http://www.pulitzer.org/files/finalists/2013/chictrib2013/chictrib05.pdf (accessed on 26 January 2016).

- Governor Brown Directs State Agencies to Revise Flammability Standards. Office of the Governor: Sacramento, CA, USA, 2012. Available online: http://gov.ca.gov/news.php?id=17598 (accessed on 4 February 2016).

- State of California Department of Consumer Affairs. Technical Bulletin Cal-117–2013: Requirements, Test Procedure and Apparatus for Testing the Smolder Resistance of Materials Used in Upholstered Furniture; Bureau of Electronic and Appliance Repair Home Furnishings and Thermal Insulation: Sacramento, CA, USA, 2013.

- Gann, R.G. The Challenge of Realizing Low Flammability Home Furnishing. In Interflam 2013, Proceedings of the Thirteenth International Conference, Windsor, UK, 24–26 June 2013; Interscience Communications: Greenwich, UK, 2013. [Google Scholar]

- Damant, G.H.; Nurbakhsh, S. Heat release tests of mattresses and bedding systems. J. Fire Sci. 1992, 10, 386–410. [Google Scholar] [CrossRef]

- Damant, G.H. Use of barriers and fire blocking layers to comply with full-scale fire tests for furnishings. J. Fire Sci. 1996, 14, 3–25. [Google Scholar] [CrossRef]

- State of California Department of Consumer Affairs. Technical Bulletin Cal-117–2013: Proposed Open Flame Test for Barrier Materials; Bureau of Electronic and Appliance Repair Home Furnishings and Thermal Insulation: Sacramento, CA, USA, 2013.

- Nazaré, S.; Davis, R.D. A Review of Fire Blocking Technologies for Soft Furnishings. Fire Sci. Rev. 2012, 1, 1–23. [Google Scholar] [CrossRef]

- Nazaré, S.; Pitts, W.M.; Flynn, S.; Shields, J.; Davis, R.D. Evaluating fire blocking performance of barrier fabrics. Fire Mater. 2014, 38, 695–716. [Google Scholar] [CrossRef]

- Nazaré, S.; Pitts, W.M.; Matko, S.; Davis, R.D. Evaluating Smoldering Behavior of Barrier Fabrics. J. Fire Sci. 2014, 32, 539–562. [Google Scholar] [CrossRef]

- ASTM. ASTM D7140-07: Standard Test Method to Measure Heat Transfer through Textile Thermal Barrier Materials; ASTM International: West Conshohocken, PA, USA, 2007. [Google Scholar]

- Ohlemiller, T.; Shields, J. One- and two-sided burning of thermally thin materials. Fire Mater. 1993, 17, 103–110. [Google Scholar] [CrossRef]

- Shields, T.J.; Silock, G.W.; Murray, J.J. Evaluating ignition data using the flux time product. Fire Mater. 1994, 18, 243–254. [Google Scholar] [CrossRef]

- Taylor, B.N.; Kuyatt, C.E. NIST Technical Note 1297: Guidelines for Evaluating and Expressing the Uncertainty of NIST Measurement Results; NIST: Gaithersburg, MD, USA, 1994.

- JCGM 100:2008: Evaluation of Measurement Data—Guide to the Expression of Uncertainty in Measurement. Available online: http://www.bipm.org/utils/common/documents/jcgm/JCGM_100_2008_E.pdf (accessed on 19 May 2016).

- Eiseman, J.H. A study of laboratory Bunsen burner for natural gas. J. Res. Stand. 1949, 42, 541–556. [Google Scholar] [CrossRef]

- Ravey, M.; Pearce, E.M. Flexible polyurethane foam. I. Thermal decomposition of a polyether-based, water-blown commercial type of flexible polyurethane foam. J. Appl. Polym. Sci. 1997, 63, 47–74. [Google Scholar] [CrossRef]

- Rogers, F.E.; Ohlemiller, T. Smolder characteristic of flexible polyurethane foams. J. Fire Flammabl. 1980, 11, 32–44. [Google Scholar]

- Bustamante, V.L.; Rogaume, T.; Guillaume, E.; Rein, G.; Torero, J.L. Analysis of principal gas products during combustion of polyether polyurethane foam at different irradiance levels. Fire Saf. J. 2009, 44, 933–940. [Google Scholar] [CrossRef]

- Drysdale, D. An Introduction to Fire Dynamics, 2nd ed.; Wiley: Chichester, UK, 1998. [Google Scholar]

- Tse, S.D.; Carlo, A.; Nde-Pello, F.; Miyasaka, K. Controlling mechanisms in the transition from smoldering to flaming of flexible polyurethane foam. Symp. Int. Combust. 1996, 26, 1505–1513. [Google Scholar] [CrossRef]

- Eggestad, J.; Johnsen, A.C. Effects of interliners on the ignitability of upholstered furniture. J. Fire Sci. 1987, 5, 152–161. [Google Scholar] [CrossRef]

- Damant, G.H. Cigarette ignition of upholstered furniture. J. Fire Sci. 1995, 3, 337–349. [Google Scholar] [CrossRef]

- Gandhi, S.; Spivak, S.M. A survey of upholstered furniture fabrics and implications for furniture flammability. J. Fire Sci. 1994, 12, 284–312. [Google Scholar] [CrossRef]

- Hightower, T.M.; Olivares, R.A.; Philippidis, D. Thermal Capacitance (Slug) Calorimeter Theory including Heat Losses and other Decaying Processes. In Proceedings of the Thermal and Fluids Analysis Workshop (TFAWS) 2008, San Jose, CA, USA, 18–22 August 2008; National Aeronautics and Space Administration: Washington, DC, USA, 2008. Available online: http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20090008662.pdf (accessed on 1 August 2016). [Google Scholar]

- Filipczak, R.; Lyon, R.E. DOT/FAA/AR-TN00/38: Heat Flux Measurements in the Ohio State University Rate of Heat Release Apparatus; Federal Aviation Administration, Airport and Aircraft Safety Research and Development Division: Atlantic, NJ, USA, 2000.

| Description | ASTM 7140 | BF-open flame test |

|---|---|---|

| Test specimen | 133 mm × 133 mm | 250 mm × 250 mm |

| Exposed specimen area | 76 mm × 76 mm | 127 mm × 127 mm |

| Burner | Meker burner 38 mm diameter, 1.2 mm orifice size | Meker burner 38 mm diameter, 1.2 mm orifice size |

| Gas | Natural gas/propane | Butane |

| Gas flow rate | Not specified | 500 ± 10 mL/min |

| Distance between specimen and burner | 50 ± 1.6 mm | 100 mm |

| Flame application time | 60 s | 60 s |

| Heat flux of flame exposure | 46 kW/m2 | Not specified |

| ID | Fiber blend | Structure | FR system | Thickness (mm) | Area density § (g/m2) | Bulk density (g/cm3) | Air permeability (m/s) |

|---|---|---|---|---|---|---|---|

| BF-1 | Flame retarded (FR) rayon/polyester | Highloft | Passive | 4.1 ± 0.1 | 155 | 0.038 | 2.8 ± 0.2 |

| BF-2 | Highloft | Passive | 6.7 ± 0.2 | 230 | 0.034 | 2.0 ± 0.1 | |

| BF-3 | Needle punched | Passive | 7.8 ± 0.6 | 240 | 0.031 | 2.3 ± 0.1 | |

| BF-4 | Boric acid treated cotton/FR rayon/polyester | Needle punched/Stratified | Passive | 5.7 ± 0.1 | 230 | 0.040 | 2.2 ± 0.2 |

| BF-5 | Boric acid treated cotton | Needle punched | Passive | 6.9 ± 0.8 | 230 | 0.033 | 1.3 ± 0.1 |

| BF-8 | FR rayon/polyester | Needle punched nonwoven | Passive | 4.3 ± 0.1 | 237 | 0.055 | 2.2 ± 0.1 |

| BF-9 | FR rayon/polyester | Needle punched nonwoven | Passive | 2.2 ± 0.1 | 240 | 0.109 | 1.5 ± 0.1 |

| BF-10 | FR polyester/FR rayon | Stitchbond | Active | 0.7 ± 0.1 | 165 | 0.236 | 1.1 ± 0.1 |

| BF-13 | Glass fiber core/FR acrylic fiber (core spun yarn) | Knitted | Active | 1.4 ± 0.1 | 165 | 0.118 | 1.9 ± 0.1 |

| BF-15 | Glass fiber core/FR acrylic fiber | Woven | Active | 0.5 ± 0.1 | 170 | 0.340 | 2.1 ± 0.1 |

| BF-16 | FR rayon/glass fiber/Poly Lactic Acid (PLA) fiber | Nonwoven | Active | 2.9 ± 0.1 | 290 | 0.097 | 1.9 ± 0.2 |

| BF-17 | Glass filaments | Woven | Passive | 0.2 ± 0.1 | 150 | 0.750 | 0 |

| BF-20 | Para-aramid/melamine | Woven | Passive | 0.77 ± 0.02 | 264 | 0.343 | 0.2 ± 0.1 |

| BF-21 | Para-aramid | Nonwoven | Passive | 0.67 ± 0.02 | 69 | 0.103 | 2.1 ± 0.1 |

| BF-22 | Meta-aramid/Para-aramid | Woven/non-woven composite | Passive | 1.61 ± 0.11 | 267 | 0.166 | 0.9 ± 0.1 |

| BF-23 | Cotton/glass fiber | Knit/backcoated | Active/Passive | 1.5 ± 0.1 | 284 | 0.189 | 0 |

| BF-24 | Polyester | Nonwoven batting | Passive | 8.13 ± 1.1 | 165 | 0.020 | 7.6 ± 0.2 |

| ID | Structure | 12.7 mm (1/2″) thick foam | 25.4 mm (1″) thick foam | |||

|---|---|---|---|---|---|---|

| Pass/Fail | Comments | Ignition of FPUF | Time to ignition (s) | Comments | ||

| BF-1 | Highloft | Fail | Foam ignites due to hole/crack formation in the BF | Yes | 40 | Foam ignites due to hole/crack formation in the BF |

| BF-2 | Highloft | Pass | Dome formation | Yes | 120 | Foam ignites due to hole/crack formation in the BF |

| BF-3 | Highloft | Pass | Dome formation | No | - | Dome formation |

| BF-4 | Needle punched nonwoven | Pass | Dome formation | No | - | Dome formation |

| BF-5 | Needle punched nonwoven | Pass | Dome formation | No | - | Dome formation |

| BF-8 | Needle punched flat | Pass | Dome formation | No | - | Dome structure collapses due to formation of hole in the FPUF |

| BF-9 | Needle punched flat | Pass | Dome formation | No | - | Dome structure collapses due to formation of hole in the FPUF |

| BF-10 | Stitchbond | Fail | Foam ignites due to hole/crack formation in the BF | Yes | 130 | Foam ignites due to hole/crack formation in the BF |

| BF-13 | Knitted | Pass | Dome structure collapses due to formation of hole in the FPUF | Yes | 186 | Foam ignites due to hole/crack formation in the BF |

| BF-15 | Woven | Pass | Dome structure collapses due to formation of hole in the FPUF | Yes | 165 | Foam ignites due to hole/crack formation in the BF |

| BF-16 | Nonwoven | Pass | Dome structure collapses due to formation of hole in the FPUF | No | - | Dome structure collapses due to formation of hole in the FPUF |

| BF-17 | Woven glass | Pass | No dome formation, FPUF forms liquid | No | - | No dome formation, FPUF forms liquid |

| BF-20 | Woven | Pass | Dome structure collapses due to formation of hole in the FPUF | No | Dome structure collapses due to formation of hole in the FPUF | |

| BF-21 | Nonwoven | Pass | Dome structure collapses due to formation of hole in the FPUF | Yes | 240 | Dome structure collapses due to formation of hole in the FPUF |

| BF-22 | Woven/nonwoven composite fabric | Pass | Dome structure collapses due to formation of hole in the FPUF | No | - | Dome structure collapses due to formation of hole in the FPUF |

| BF-23 | Knit/backcoated | Pass | No dome formation, FPUF forms liquid | No | - | No dome formation, FPUF forms liquid |

| BF-24 | Polyester batting | Fail | Foam ignites due to hole/crack formation in the BF | Yes | 4 | Foam ignites due to hole/crack formation in the BF |

| ID | Maximum heat flux at unexposed side of barrier at 60 s (kW/m2) | Total amount of heat transferred at 60 s (J/cm2) | Heat transfer factor (kJ/g) | Visual observations and comments |

|---|---|---|---|---|

| BF-1 | 17 ± 2 | 95 ± 12 | 61 | Thin, fragile char with hole formations |

| BF-2 | 8 ± 1 | 43 ± 1 | 21 | Thermally thick, insulating char |

| BF-3 | 6 ± 0.5 | 35 ± 3 | 15 | Thermally thick, insulating char |

| BF-4 | 7 ± 1 | 40 ± 2 | 18 | Thermally thick, insulating char |

| BF-5 | 5 ± 1 | 30 ± 1 | 13 | Thermally thick, insulating char |

| BF-8 | 13 ± 6 | 73 ± 4 | 31 | Undamaged char |

| BF-9 | 14 ± 2 | 76 ± 10 | 32 | Undamaged char |

| BF-10 | 15 ± 1 | 88 ± 4 | 53 | Thermally thin, cracked barrier |

| BF-13 | 29 ± 1 | 163 ± 4 | 99 | Thermally thin, permeable barrier |

| BF-15 * | 18 | 104 | 61 | Thermally thin, permeable barrier |

| BF-16 | 10 ± 0.3 | 58 ± 1 | 20 | Undamaged char |

| BF-17 | 17 ± 1 | 98 ± 2 | 65 | Undamaged char |

| BF-19 | 16 ± 1 | 93 ± 7 | 29 | Undamaged char |

| BF-20 | 13 ± 2 | 73 ±16 | 28 | Undamaged char |

| BF-21 | 15 ± 3 | 87 ± 15 | 126 | Undamaged char |

| BF-22 * | 9 | 52 | 19 | Undamaged char |

| BF-23 | 12 ± 1 | 69 ± 6 | 24 | Undamaged char |

| BF-24 | 33 ± 6 | 190 ± 33 | 115 | Barrier melts and exposes slug calorimeter to the flame |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nazaré, S.; Pitts, W.M.; Shields, J.; Davis, R. Factors for Consideration in an Open-Flame Test for Assessing Fire Blocking Performance of Barrier Fabrics. Polymers 2016, 8, 342. https://doi.org/10.3390/polym8090342

Nazaré S, Pitts WM, Shields J, Davis R. Factors for Consideration in an Open-Flame Test for Assessing Fire Blocking Performance of Barrier Fabrics. Polymers. 2016; 8(9):342. https://doi.org/10.3390/polym8090342

Chicago/Turabian StyleNazaré, Shonali, William M. Pitts, John Shields, and Rick Davis. 2016. "Factors for Consideration in an Open-Flame Test for Assessing Fire Blocking Performance of Barrier Fabrics" Polymers 8, no. 9: 342. https://doi.org/10.3390/polym8090342

APA StyleNazaré, S., Pitts, W. M., Shields, J., & Davis, R. (2016). Factors for Consideration in an Open-Flame Test for Assessing Fire Blocking Performance of Barrier Fabrics. Polymers, 8(9), 342. https://doi.org/10.3390/polym8090342