Effect of Nanofibrillated Cellulose Content on the Temperature and Near Infrared Responses of Polyvinyl Butyral Nanofibers-Containing Bilayer Hydrogel System

Abstract

:1. Introduction

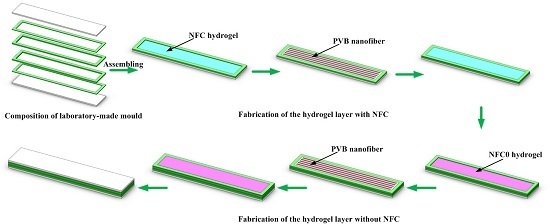

2. Experimental Section

2.1. Material

2.2. Synthesis of PNIPAm–NFC Hydrogel

2.3. Characteristics

2.3.1. Microstructure

2.3.2. Infrared Spectrum and Differential Scanning Calorimetry (DSC) Analysis

2.3.3. Tensile Stress-Strain Analysis

2.3.4. Temperature and Near Infrared Responses

3. Results and Discussion

3.1. Microstructure of PNIPAm–GO Hydrogel

3.2. FT-IR Spectra and DSC Analysis

3.3. Mechanical Properties

3.4. Microstructure and Responsive Characteristics of Bilayer Hydrogel System

3.4.1. Microstructure Characteristic

3.4.2. Temperature Responsive Properties

3.4.3. Near Infrared Responsive Characteristic

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Du, Z.S.; Hu, Y.; Gu, X.Y.; Hu, M.; Wang, C.Y. Poly (acrylamide) microgel-reinforced poly (acrylamide)/hectoritenanocomposite hydrogels. Colloids Surf. A 2016, 489, 1–8. [Google Scholar] [CrossRef]

- Li, C.P.; Mu, C.D.; Lin, W.; Ngai, T. Gelatin effects on the physicochemical and hemocompatible properties of gelatin/PAAm/laponite nanocomposite hydrogels. ACS Appl. Mater. Interfaces 2015, 7, 18732–18741. [Google Scholar] [CrossRef] [PubMed]

- Cheng, N.G.; Gopinath, A.; Wang, L.F.; Iagnemma, K.; Hosoi, A.E. Thermally tunable, self-healing composites for soft robotic applications. Macromol. Mater. Eng. 2014, 299, 1279–1284. [Google Scholar] [CrossRef]

- Bakarich, S.E.; Gorkin, R.; Naficy, S.; Gately, R.; Panhuis, M.I.H.; Spinks, G.M. 3D/4D printing hydrogel composites: A pathway to functional devices. MRS Adv. 2016, 1, 521–526. [Google Scholar] [CrossRef]

- Yao, C.; Liu, Z.; Yang, C.; Wang, W.; Ju, X.J.; Xie, R.; Chu, L.Y. Poly (N-isopropylacrylamide)–clay nanocomposite hydrogels with responsive bending property as temperature-controlled manipulators. Adv. Funct. Mater. 2015, 25, 2980–2991. [Google Scholar] [CrossRef]

- Zhang, E.Z.; Wang, T.; Hong, W.; Sun, W.X.; Liu, X.X.; Tong, Z. Infrared-driving actuation based on bilayer graphene oxide-poly (N-isopropylacrylamide) nanocomposite hydrogels. J. Mater. Chem. A 2014, 2, 15633–15639. [Google Scholar] [CrossRef]

- Wang, T.; Yang, Y.Q.; Sun, W.X.; Wang, C.Y.; Liu, X.X.; Tong, Z. Infrared radiation triggered detachable bio-adhesive hybrid hydrogels. J. Control. Release 2015, 213, e102–e103. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Huang, J.H.; Yang, Y.Q.; Zhang, E.Z.; Sun, W.X.; Tong, Z. Bioinspired smart actuator based on graphene oxide-polymer hybrid hydrogels. ACS Appl. Mater. Interfaces 2015, 7, 23423–23430. [Google Scholar] [CrossRef] [PubMed]

- Gladman, A.S.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–419. [Google Scholar] [CrossRef] [PubMed]

- Fujigaya, T.; Morimoto, T.; Niidome, Y.; Nakashima, N. NIR laser-driven reversible volume phase transition of single-walled carbon nanotube/poly (N-isopropylacrylamide) composite gels. Adv. Mater. 2008, 20, 3610–3614. [Google Scholar] [CrossRef]

- Lu, S.; Panchapakesan, B. Photomechanical responses of carbon nanotube/polymer actuators. Nanotechnology 2007, 18, 305502–305509. [Google Scholar] [CrossRef]

- Lo, C.W.; Zhu, D.F.; Jiang, H.R. An infrared-light responsive graphene-oxide incorporated poly (N-isopropylacrylamide) hydrogel nanocomposite. Soft Matter 2011, 7, 5604–5609. [Google Scholar] [CrossRef]

- Robinson, J.T.; Tabakman, S.M.; Liang, Y.; Wang, H.; Casalongue, H.S.; Vinh, D.; Dai, H.J. Ultrasmall Reduced Graphene Oxide with High Near-Infrared Absorbance for Photothermal Therapy. J. Am. Chem. Soc. 2011, 133, 6825–6831. [Google Scholar] [CrossRef] [PubMed]

- Abdelsayed, V.; Moussa, S.; Hassan, H.M.; Aluri, H.S.; Collinson, M.M.; El-Shall, M.S. Photothermal Deoxygenation of Graphite Oxide with Laser Excitation in Solution and Graphene-Aided Increase in Water Temperature. J. Phys. Chem. Lett. 2010, 1, 2804–2809. [Google Scholar] [CrossRef]

- Acik, M.; Lee, G.; Mattevi, C.; Chhowalla, M.; Cho, K.; Chabal, Y.J. Unusual infrared-absorption mechanism in thermally reduced graphene oxide. Nat. Mater. 2010, 9, 840–845. [Google Scholar] [CrossRef] [PubMed]

- Niu, C.J.; Meng, J.S.; Wang, X.P.; Han, C.H.; Yan, M.Y.; Zhao, K.N.; Xu, X.M.; Ren, W.H.; Zhao, Y.L.; Xu, L.; et al. General synthesis of complex nanotubes by gradient electrospinning and controlled pyrolysis. Nat. Commun. 2015, 6, 7402–7410. [Google Scholar] [CrossRef] [PubMed]

- Pant, H.R.; Baek, W.; Nam, K.T.; Seo, Y.A.; Oh, H.J.; Kim, H.Y. Fabrication of polymeric microfibers containing rice-like oligomeric hydrogel nanoparticles on their surface: A novel strategy in the electrospinning process. Mater. Lett. 2011, 65, 1441–1444. [Google Scholar] [CrossRef]

- Esmaeili, A.; Haseli, M. Electrospinning of thermoplastic carboxymethyl cellulose/poly (ethylene oxide) nanofibers for use in drug-release systems. Mater. Sci. Eng. C 2017, 77, 1117–1127. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Zhang, R.; Sun, Y.; Lin, D.D.; Sun, Z.Q.; Pan, W.; Downs, P. Biomimetic nanofiber patterns with controlled wettability. Soft Matter 2008, 4, 2429–2433. [Google Scholar] [CrossRef]

- Wang, E.; Desai, M.S.; Lee, S.W. Light-controlled graphene-elastin composite hydrogel actuators. Nano Lett. 2013, 13, 2826–2830. [Google Scholar] [CrossRef] [PubMed]

- Jiang, W.T.; Niu, D.; Liu, H.Z.; Wang, C.H.; Zhao, T.T.; Yin, L.; Shi, Y.S.; Chen, B.D.; Ding, Y.C.; Lu, B.H. Photoresponsive soft-robotic platform: biomimetic fabrication and remote actuation. Adv. Funct. Mater. 2014, 24, 7598–7604. [Google Scholar] [CrossRef]

| Sample | NIPAm (g) | GO (mg) | NFC (mg) | XLG (g) | KPS (mg) | TEMED (μL) | H2O (mL) |

|---|---|---|---|---|---|---|---|

| NFC0 | 2.26 | 20 | 0 | 0.693 | 20 | 27 | 20 |

| NFC1–PVB | 2.26 | 20 | 20 | 0.693 | 20 | 27 | 20 |

| NFC2–PVB | 2.26 | 20 | 40 | 0.693 | 20 | 27 | 20 |

| NFC3–PVB | 2.26 | 20 | 60 | 0.693 | 20 | 27 | 20 |

| Sample | Stress (KPa) | Strain (%) | Modulus (Pa) |

|---|---|---|---|

| NFC0 | 12.9 ± 3.6 | 994.8 ±87.1 | 13.2 ± 4.8 |

| NFC1–PVB | 22.1 ± 2.1 | 735.6 ±40.7 | 30.2 ± 4.5 |

| NFC2–PVB | 23.1 ± 3.5 | 688.6 ± 45.6 | 33.9 ± 7.3 |

| NFC3–PVB | 24.0 ± 2.5 | 502.3 ± 45.3 | 48.3 ± 9.4 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Q.; Ning, L.; Liang, Y.; Zhang, Z.; Ren, L. Effect of Nanofibrillated Cellulose Content on the Temperature and Near Infrared Responses of Polyvinyl Butyral Nanofibers-Containing Bilayer Hydrogel System. Polymers 2017, 9, 270. https://doi.org/10.3390/polym9070270

Zhao Q, Ning L, Liang Y, Zhang Z, Ren L. Effect of Nanofibrillated Cellulose Content on the Temperature and Near Infrared Responses of Polyvinyl Butyral Nanofibers-Containing Bilayer Hydrogel System. Polymers. 2017; 9(7):270. https://doi.org/10.3390/polym9070270

Chicago/Turabian StyleZhao, Qian, Luping Ning, Yunhong Liang, Zhihui Zhang, and Luquan Ren. 2017. "Effect of Nanofibrillated Cellulose Content on the Temperature and Near Infrared Responses of Polyvinyl Butyral Nanofibers-Containing Bilayer Hydrogel System" Polymers 9, no. 7: 270. https://doi.org/10.3390/polym9070270

APA StyleZhao, Q., Ning, L., Liang, Y., Zhang, Z., & Ren, L. (2017). Effect of Nanofibrillated Cellulose Content on the Temperature and Near Infrared Responses of Polyvinyl Butyral Nanofibers-Containing Bilayer Hydrogel System. Polymers, 9(7), 270. https://doi.org/10.3390/polym9070270