1. Introduction

Paper is a non-woven fibrous cellulose based material, which is formed by an interaction of individual fibers to form a network with a complex hierarchy and porosity. The large fraction of this network consists of pulp fibers, which have been subjected to a variety of treatments depending on the envisaged application for the final paper products. During these treatments in pulping and papermaking processes, cellulosic microparticles are formed, the so-called fines. Fines are defined as the fine cellulosic particles, which are able to pass through a 200 mesh screen (equivalent hole diameter 76 μm) of a conventional laboratory fractionation device (SCAN-CM 66:05). There are two major types of fiber fines, namely primary and secondary fines. Primary fines are generated during pulping and bleaching, where they are removed from the cell wall matrix by harsh chemical and mechanical treatment. As a consequence of their origin (i.e., compound middle lamella, ray cells, parenchyma cells), primary fines exhibit a flake-like structure with only minor shares of fibrillar material [

1,

2]. In contrast, secondary fines are generated during the refining of pulp. In this case, a mechanical treatment partially induces fibrillation of cell wall fractions, resulting in the formation of a fibrillated material that has microscopic dimensions [

3,

4]. Both types of fines are usually present in a papermaking furnish. However, due to their differences in morphology and chemistry, which is also dependent on the type of the pulping process, they have a different impact on paper quality and product performance [

2,

5,

6]. Particularly the large aspect ratio, surface area, and bonding ability of secondary fines enhance the mechanical strength of papers, while having a negative influence on dewatering in the forming section of a paper machine. Primary fines mainly affect the optical properties of the final papers [

2,

7,

8], but also have a negative effect on dewatering, and in some cases also on mechanical paper properties. Because of their large specific surface area in comparison to pulp fibers, fines also consume a high proportion of chemical additives used in pulp and paper production.

Fines usually are an inevitable, but undefined part of papermaking furnishes. Although in principle their effects on paper properties, being it sheet densification, strength improvement, deterioration of dewatering, etc. are known, their impact is often difficult to quantify. The partly negative effects of fines on process performance and paper properties are also a motivation to consider the removal of fines from papermaking furnishes.

There are two major issues when it comes to the fines fraction in papers. The first is related to the analysis of the distribution of the types of fines in papermaking furnishes and in paper, which is not a straightforward task [

9]. The second is related to the isolation of the fines from paper pulps, which involves laborious separation steps (e.g., screening, centrifugation, etc.), resulting in suspensions with dry weight contents of 0.1 wt % and below [

10,

11,

12,

13,

14]. Consequently, the removal of water to obtain higher dry weight contents is a major challenge. In contrast to microfibrillated celluloses (MFCs), which recently entered into the market, pulp fines so far are not commercially available. This is certainly associated with the above-mentioned problems in analysis and production/separation, as well as a lack of detailed investigations on their properties.

In the production of MFCs, various kinds of mechanical treatments are applied, such as high pressure homogenization, microfluidization, grinding, cryo-crushing, steamexplosion, and high intensity ultrasonfication, as summarized in a review by Osong et al. [

15]. All these techniques require a significantly higher energy input of up to 30,000 kWh/t when compared to conventional refining [

15]. Depending on the applied technique a more or less homogeneous MFC material is produced. In a microfluidizer, for example, the material has to undergo several homogenization passes to achieve a homogeneous fibrillation. Fibrillation is improved by chemical or enzymatical pretreatment to reduce energy consumption [

16], but pretreatment and multiple passes are a cost factor in MFC production. In conventional refining, fibrillar (secondary) fines are produced at much lower energy levels than in MFC production. These fines, however, have to be separated from the remaining fibers in order to use it as a MFC substitute. Microfribrillation is directly related to the gap-clearance of the refiners, which is rather high in conventional refining when compared to super grinders, and thus tends to produce a coarser material. MFC is defined to have a length between 0.5 to 100 µm, and a width from 10 to 100 nm [

15]. Since fines are defined as the particles passing through a 200 mesh screen, they contain also larger particles. For example, primary fines having a flake-like structure show dimensions of up to 350 µm × 25 µm in the fines fraction [

17].

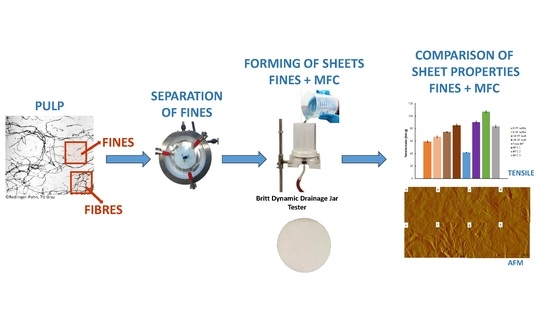

In this paper, we attempt to address the challenge of fines separation by first introducing an elegant method to upscale the production/separation method for fines to kg scale, then we investigate the sheet formation using different types of fines, and finally compare their performance to commercially available MFC products.

2. Materials and Methods

All tests have been performed using primary and secondary fines, separated from never-dried, unbleached softwood kraft pulp (a mixture of spruce and pine), never-dried, bleached sulfite pulp (spruce), as well as mechanical pulp fines from never-dried, bleached pressure ground wood (spruce). Furthermore, two commercially available microfibrillated cellulose samples, and one experimental MFC grade from an institution, that does not want to be disclosed, were used. The analyzed samples are summarized in

Table 1.

2.1. Separation and Thickening of Fines

In order to separate the fines from the pulp, a purpose-built laboratory pressure screen was employed. This newly designed device is capable of separating fines from pulps in kilogram scale [

10].

Figure 1 depicts the pressure screen used in the present study.

In the first step of fines separation, the pulp was diluted with water to a consistency of 0.5 to 1 wt %, and stirred for about 10 min. This suspension was pumped through the pressure screen (PS), whose main element is a perforated strainer with hole diameters of 100 μm. Larger particles will not pass the strainer, and are transferred back to the feed tank. The fines fraction that is able to pass the strainer is collected in a separate barrel. Due to the low solid content of the fines suspension (0.02%,) a subsequent thickening step is needed. For this task, a laboratory flotation cell, which can be directly connected to the PS, is implemented. The flotation cell developed at the Institute of Paper, Pulp and Fibre Technology (Graz, Austria) is shown in

Figure 2.

The fines suspension is pumped from the feed barrel to the flotation cell. Air is injected into the suspension with a needle positioned directly before the pump (see

Figure 2, magnification right). The air flow can be adjusted by an air control valve. Shear forces inside the pump lead to the collapse of the air bubbles, and finally to the dissolution of air. Due to a pressure drop, controlled with a pressure relief valve, the air is released in the form of fine bubbles (Ø ~ 60 μm). The fines, attached to the air bubbles, rise to the surface of the water layer in the flotation cell and can be collected in the collection pan. Using this method, the solid content can be increased by up to 4% [

10]. In contrast to other flotation methods, a major advantage here is to avoid the use of any chemicals in the course of the applied flotation process.

2.2. Lignin Content and Morphological Properties of Fines and MFC

For each of the materials, the κ-number, as an indication for the lignin content of a certain pulp or pulp fraction, was determined according to ISO 302:2015. An approximation of the mass fraction of lignin can be obtained by multiplying the κ-number by 0.15 [

18].

The morphological properties of the fines, as well as of the microfibrillated cellulose are determined using the L & W Fiber Tester Plus (ABB, Mannheim, Germany). Morphological features of even small cellulosic microparticles can be detected (resolution: 3.3 μm/pixel). The size measurement was carried out on the fines fraction obtained using the pressure screen, MFC samples were measured without fractionation. No size definition criteria of the instrument were applied. For each test, a dry sample (0.1 g) is diluted with 150 mL of deionized water. A minimum of 100.000 particles was detected. For each sample, two replicates have been performed. The results of these measurements are expressed as the average circle equivalent diameter (CED

q2, Equation (1)), which in terms of irregularly formed particles, can be used instead of the length weighted average particle length [

4]. The CED is the diameter of a circle CED

i of equivalent area than the projection area A

i of the particle (Equation (2)). For an illustration of the differences between these samples additional images using a conventional transmission light microscope (Leica 301–371.010) were captured. Details regarding this method are described in [

4].

2.3. Fines and MFC Sheet Formation

In order to prepare handsheets from pure fines and MFC, a vacuum filtration method is used. A defined amount of fines or MFC (0.24 g, dry weight) is diluted with deionized water to reach a solid content of 0.2 wt %. This suspension is stirred at 450 rpm for at least 2 h. After stirring, the sheets are formed by vacuum filtration using a Britt Dynamic Drainage Jar (Frank PTI, Birkenau, Germany). The setup used for sheet forming is shown in

Figure 3.

The Britt Dynamic Drainage Jar is equipped with a supporting plate, a 500-mesh screen (hole diameter 20 μm), two filter papers, and a nitrocellulose membrane (DAWP29325 from Merck Chemicals and Life Science GesmbH, Darmstadt, Germany) with a pore size of 0.65 μm. The major advantage of using the Britt Dynamic Drainage Jar as compared to a Büchner funnel is to improve the fines and MFC sheet formation. In particular, the sandwich-like setup prevents the loss of fine cellulosic material. After the filtration step, the membrane with the fines/MFC sheet on top is pre-dried in a Rapid-Köthen sheet dryer (Frank PTI, Birkenau, Germany) for about 20 s at 93 °C under vacuum. Then, the membrane is peeled off, and the neat fines/MFC sheets are dried for 10 min in the Rapid-Köthen sheet dryer. The sheets are then stored in a climate room at 23 °C and 50% RH for least 12 h prior to testing.

2.4. Sheet Testing

Air permeability (Bendtsen method, ISO 5636-3:2013), thickness, and apparent density (DIN EN ISO 534:2011) were determined in order to get structural information of the sheets. Mechanical properties such as the modulus of elasticity, breaking load, and strain to failure of the sheets were measured using the Z010 tensile tester from Zwick Roell (Ulm, Germany). For tensile testing, a testing speed of 5 mm/min, a free clamping length of 50 mm, and strip width of 15 mm were used; eight to ten strips per sample were tested.

The surface roughness of the sheets was determined using the Bruker DekTak XT surface profiler (Bruker Nano Surfaces Division, Tucson, AZ, USA). The needle scanning the sheets had a tip radius of 12.5 μm, and a scan force of 0.03 mN. The length of the line scan was set to 2 mm.

For the atomic force microscopy (AFM) measurements, a Veeco Multimode Quadrax MM AFM (Bruker; Billerica, MA, USA) was used. The images were recorded in the tapping mode (non-contact mode), and silicon cantilevers (NCH-VS1-W, NanoWorld AG, Neuchatel, Switzerland) were used with an average spring constant of 42 N/m (Force Constant), and a resonance frequency of 281–296 kHz (Coating: none). All measurements were performed at room temperature and under an ambient atmosphere. In addition, the surface of the handsheets was investigated using low voltage scanning electron microscopy (LVSEM) with the high resolution scanning electron microscope Zeiss Ultra 55 (Zeiss, Oberkochen, Germany), and the Everhart–Thornley detector (ETD) [

19]. A beam energy of 0.65 keV was used.

In order to determine the static contact angle, as well as the surface free energy of the sheets, a DSA100 (Krüss GmbH, Hamburg, Germany) equipped with a T1E CCD camera (Newton, NJ, USA) and the DSA1 v 1.90 software (Krüss GmbH, Hamburg, Germany) was used. 3 μL droplets of Milli-Q water and diiodomethane were deposited on the surface of the sheets, and after 2 s an image was taken. Ten replicates were performed. The contact angle was calculated according to the Young-Laplace equation. The surface free energy was calculated according to the Owens-Wendt-Rabel-Kaelble (OWRK) method.

4. Conclusions

Sheet properties of primary and secondary pulp fines from different sources were compared to MFC sheets, together with the use of novel equipment for fines separation in the kg scale from paper pulps. The MFC samples tend to form the densest and smoothest sheets, also achieving the highest strength. Sheets from secondary fines from unbleached kraft pulp exhibit structural and mechanical properties coming close to MFC. The known differences between kraft and sulfite pulps on the fiber level are also observable at the level of fines from these pulps. Sheets formed from mechanical pulp fines exhibit a coarser surface, show the lowest apparent density, and significantly lower stress-strain values. Hydrophilicity of the fines sheets is mainly depending on the chemical composition, with higher lignin content imparting a more hydrophobic character.

Because of their wide spectrum of properties depending on pulp type and their similar character to coarser MFC grades, fiber fines as a by-product of the paper and pulp industry might find applications in various fields where presently the use of MFC grades is evaluated.