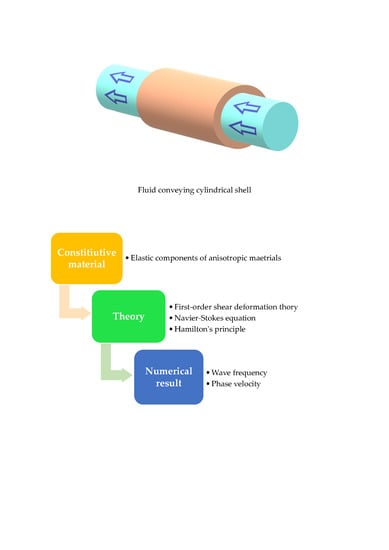

Propagation of Flexural Waves in Anisotropic Fluid-Conveying Cylindrical Shells

Abstract

:1. Introduction

2. Anisotropic Materials

3. First-Order Shear Deformation Shell Theory

4. Numerical Results

5. Conclusions

- Wave frequency and phase velocity of anisotropic cylindrical shells can be reduced by increasing flow velocity amount;

- There is a critical flow velocity that occurs for cylindrical shells at various wave numbers and it can be different for various radius to thickness ratios and different anisotropic materials;

- Hexagonal, trigonal, monoclinic, and triclinic materials experience the highest wave frequency, respectively;

- With an increase in radius to thickness ratio there is a decreasing effect on the value of wave frequency and phase velocity of anisotropic fluid-conveying cylindrical shells.

- Conducting wave propagation analysis of anisotropic fluid-conveying truncated conical shell;

- Performing wave propagation analysis of anisotropic joined conical–conical shells;

- Analyzing the wave propagation behavior of anisotropic joined conical–cylindrical–conical shells.

Author Contributions

Funding

Conflicts of Interest

References

- Sheng, G.; Wang, X. Thermomechanical vibration analysis of a functionally graded shell with flowing fluid. Eur. J. Mech. A Solids 2008, 27, 1075–1087. [Google Scholar] [CrossRef]

- Bagherizadeh, E.; Kiani, Y.; Eslami, M. Thermal buckling of functionally graded material cylindrical shells on elastic foundation. AIAA J. 2012, 50, 500–503. [Google Scholar] [CrossRef]

- Sofiyev, A.; Kuruoglu, N. Torsional vibration and buckling of the cylindrical shell with functionally graded coatings surrounded by an elastic medium. Compos. Part B Eng. 2013, 45, 1133–1142. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M.; Dimitri, R. Dynamic analysis of thick and thin elliptic shell structures made of laminated composite materials. Compos. Struct. 2015, 133, 278–299. [Google Scholar] [CrossRef]

- Tornabene, F.; Fantuzzi, N.; Bacciocchi, M. The GDQ method for the free vibration analysis of arbitrarily shaped laminated composite shells using a NURBS-based isogeometric approach. Compos. Struct. 2016, 154, 190–218. [Google Scholar] [CrossRef]

- Civalek, Ö. Discrete singular convolution method for the free vibration analysis of rotating shells with different material properties. Compos. Struct. 2017, 160, 267–279. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, D. Free vibration of functionally graded porous cylindrical shell using a sinusoidal shear deformation theory. Aerosp. Sci. Technol. 2017, 66, 83–91. [Google Scholar] [CrossRef]

- Pourasghar, A.; Moradi-Dastjerdi, R.; Yas, M.; Ghorbanpour Arani, A.; Kamarian, S. Three-dimensional analysis of carbon nanotube-reinforced cylindrical shells with temperature-dependent properties under thermal environment. Polym. Compos. 2018, 39, 1161–1171. [Google Scholar] [CrossRef]

- Vuong, P.M.; Duc, N.D. Nonlinear vibration of FGM moderately thick toroidal shell segment within the framework of Reddy’s third order-shear deformation shell theory. Int. J. Mech. Mater. Des. 2019, 16, 1–20. [Google Scholar] [CrossRef]

- Ghasemi, A.R.; Mohandes, M.; Dimitri, R.; Tornabene, F. Agglomeration effects on the vibrations of CNTs/fiber/polymer/metal hybrid laminates cylindrical shell. Compos. Part B Eng. 2019, 167, 700–716. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Dabbagh, A.; Rastgoo, A. Vibration analysis of porous metal foam shells rested on an elastic substrate. J. Strain Anal. Eng. Des. 2019, 54, 199–208. [Google Scholar] [CrossRef]

- Karimiasl, M.; Ebrahimi, F.; Mahesh, V. Nonlinear forced vibration of smart multiscale sandwich composite doubly curved porous shell. Thin Walled Struct. 2019, 143, 106152. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Hafezi, P.; Dabbagh, A. Buckling analysis of embedded graphene oxide powder-reinforced nanocomposite shells. Available online: https://doi.org/10.1016/j.dt.2020.02.010 (accessed on 2 January 2020).

- Allahkarami, F.; Tohidi, H.; Dimitri, R.; Tornabene, F. Dynamic Stability of Bi-Directional Functionally Graded Porous Cylindrical Shells Embedded in an Elastic Foundation. Appl. Sci. 2020, 10, 1345. [Google Scholar] [CrossRef] [Green Version]

- Kögl, M. Free vibration analysis of anisotropic solids with the boundary element method. Eng. Anal. Bound. Elem. 2003, 27, 107–114. [Google Scholar] [CrossRef]

- Towfighi, S.; Kundu, T. Elastic wave propagation in anisotropic spherical curved plates. Int. J. Solids Struct. 2003, 40, 5495–5510. [Google Scholar] [CrossRef]

- Batra, R.; Qian, L.; Chen, L. Natural frequencies of thick square plates made of orthotropic, trigonal, monoclinic, hexagonal and triclinic materials. J. Sound Vib. 2004, 270, 1074–1086. [Google Scholar] [CrossRef]

- Demasi, L. Quasi-3D analysis of free vibration of anisotropic plates. Compos. Struct. 2006, 74, 449–457. [Google Scholar] [CrossRef]

- Lü, C.; Huang, Z.; Chen, W. Semi-analytical solutions for free vibration of anisotropic laminated plates in cylindrical bending. J. Sound Vib. 2007, 304, 987–995. [Google Scholar] [CrossRef]

- Jansen, E. The effect of geometric imperfections on the vibrations of anisotropic cylindrical shells. Thin Walled Struct. 2007, 45, 274–282. [Google Scholar] [CrossRef]

- Ferreira, A.; Fasshauer, G.; Batra, R. Natural frequencies of thick plates made of orthotropic, monoclinic, and hexagonal materials by a meshless method. J. Sound Vib. 2009, 319, 984–992. [Google Scholar] [CrossRef]

- Paiva, W.P.; Sollero, P.; Albuquerque, E.L. Modal analysis of anisotropic plates using the boundary element method. Eng. Anal. Bound. Elem. 2011, 35, 1248–1255. [Google Scholar] [CrossRef]

- Tornabene, F. 2-D GDQ solution for free vibrations of anisotropic doubly-curved shells and panels of revolution. Compos. Struct. 2011, 93, 1854–1876. [Google Scholar] [CrossRef]

- Singhal, P.; Bindal, G. Generalised differential quadrature method in the study of free vibration analysis of monoclinic rectangular plates. Am. J. Comput. Appl. Math. 2012, 2, 166–173. [Google Scholar] [CrossRef]

- Shen, H.-S. Boundary layer theory for the nonlinear vibration of anisotropic laminated cylindrical shells. Compos. Struct. 2013, 97, 338–352. [Google Scholar] [CrossRef]

- Kumar, Y. Differential transform method to study free transverse vibration of monoclinic rectangular plates resting on Winkler foundation. Appl. Comput. Mech. 2013, 7, 145–154. [Google Scholar]

- Mirzaei, M.; Asadi, M.T.; Akbari, R. On vibrational behavior of pulse detonation engine tubes. Aerosp. Sci. Technol. 2015, 47, 177–190. [Google Scholar] [CrossRef]

- Ahmadi, H.; Rasheed, H.A. Lateral torsional buckling of anisotropic laminated thin-walled simply supported beams subjected to mid-span concentrated load. Compos. Struct. 2018, 185, 348–361. [Google Scholar] [CrossRef]

- Bahrami, K.; Afsari, A.; Janghorban, M.; Karami, B. Static analysis of monoclinic plates via a three-dimensional model using differential quadrature method. Struct. Eng. Mech. 2019, 72, 131–139. [Google Scholar]

- Heyliger, P.R.; Asiri, A. A total Lagrangian elasticity formulation for the nonlinear free vibration of anisotropic beams. Int. J. Non Linear Mech. 2020, 118, 103286. [Google Scholar] [CrossRef]

- Malekan, M.; Khosravi, A.; Zanin, A.; Aghababaei, R. On the vibrational responses of thin FGM tubes subjected to internal sequential moving pressure. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 220. [Google Scholar] [CrossRef]

- Akbaş, Ş.D. Wave propagation of a functionally graded beam in thermal environments. Steel Compos. Struct. 2015, 19, 1421–1447. [Google Scholar] [CrossRef]

- Dorduncu, M.; Apalak, M.K.; Cherukuri, H. Elastic wave propagation in functionally graded circular cylinders. Compos. Part B Eng. 2015, 73, 35–48. [Google Scholar] [CrossRef]

- Janghorban, M.; Nami, M.R. Wave propagation in functionally graded nanocomposites reinforced with carbon nanotubes based on second-order shear deformation theory. Mech. Adv. Mater. Struct. 2017, 24, 458–468. [Google Scholar] [CrossRef]

- Fourn, H.; Atmane, H.A.; Bourada, M.; Bousahla, A.A.; Tounsi, A.; Mahmoud, S. A novel four variable refined plate theory for wave propagation in functionally graded material plates. Steel Compos. Struct. 2018, 27, 109–122. [Google Scholar]

- Gul, U.; Aydogdu, M. Wave propagation analysis in beams using shear deformable beam theories considering second spectrum. J. Mech. 2018, 34, 279–289. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Seyfi, A.; Dabbagh, A.; Tornabene, F. Wave dispersion characteristics of porous graphene platelet-reinforced composite shells. Struct. Eng. Mech. 2019, 71, 99–107. [Google Scholar]

- Bouanati, S.; Benrahou, K.H.; Atmane, H.A.; Yahia, S.A.; Bernard, F.; Tounsi, A.; Bedia, E.A.A. Investigation of wave propagation in anisotropic plates via quasi 3D HSDT. Geomech. Eng. 2019, 18, 85–96. [Google Scholar]

- Dravinski, M.; Niu, Y. Three-dimensional time-harmonic Green’s functions for a triclinic full-space using a symbolic computation system. Int. J. Numer. Methods Eng. 2002, 53, 445–472. [Google Scholar] [CrossRef]

- Ebrahimi, F.; Seyfi, A. Wave propagation response of multi-scale hybrid nanocomposite shell by considering aggregation effect of CNTs. Mech. Based Des. Struct. Mach. 2019, 47, 1–22. [Google Scholar] [CrossRef]

- Rabani Bidgoli, M.; Saeed Karimi, M.; Ghorbanpour Arani, A. Nonlinear vibration and instability analysis of functionally graded CNT-reinforced cylindrical shells conveying viscous fluid resting on orthotropic Pasternak medium. Mech. Adv. Mater. Struct. 2016, 23, 819–831. [Google Scholar] [CrossRef]

- Ke, L.; Wang, Y.; Reddy, J. Thermo-electro-mechanical vibration of size-dependent piezoelectric cylindrical nanoshells under various boundary conditions. Compos. Struct. 2014, 116, 626–636. [Google Scholar] [CrossRef]

- Barati, M.R.; Zenkour, A.M. Vibration analysis of functionally graded graphene platelet reinforced cylindrical shells with different porosity distributions. Mech. Adv. Mater. Struct. 2019, 26, 1580–1588. [Google Scholar] [CrossRef]

| Boundary conditions | n | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1 | Error (%) | 2 | Error (%) | 3 | Error (%) | 4 | Error (%) | ||

| S–S | [42] | 0.01608 | 0.124 | 0.00938 | 0 | 0.02210 | 0.136 | 0.04209 | 0.285 |

| [43] | 0.01610 | 0 | 0.00938 | 0 | 0.02210 | 0.136 | 0.04208 | 0.261 | |

| Present | 0.01610 | 0.00938 | 0.02207 | 0.04197 | |||||

| C–C | [42] | 0.03276 | 7.173 | 0.01389 | 3.960 | 0.02267 | 0.176 | 0.04221 | 0.261 |

| [43] | 0.03278 | 7.108 | 0.01390 | 3.885 | 0.02267 | 0.176 | 0.04221 | 0.261 | |

| Present | 0.03511 | 0.01444 | 0.02271 | 0.04210 | |||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ebrahimi, F.; Seyfi, A. Propagation of Flexural Waves in Anisotropic Fluid-Conveying Cylindrical Shells. Symmetry 2020, 12, 901. https://doi.org/10.3390/sym12060901

Ebrahimi F, Seyfi A. Propagation of Flexural Waves in Anisotropic Fluid-Conveying Cylindrical Shells. Symmetry. 2020; 12(6):901. https://doi.org/10.3390/sym12060901

Chicago/Turabian StyleEbrahimi, Farzad, and Ali Seyfi. 2020. "Propagation of Flexural Waves in Anisotropic Fluid-Conveying Cylindrical Shells" Symmetry 12, no. 6: 901. https://doi.org/10.3390/sym12060901

APA StyleEbrahimi, F., & Seyfi, A. (2020). Propagation of Flexural Waves in Anisotropic Fluid-Conveying Cylindrical Shells. Symmetry, 12(6), 901. https://doi.org/10.3390/sym12060901