Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-Metal-Forming Processes

Abstract

:1. Introduction

2. Material and Methods

2.1. Test Material

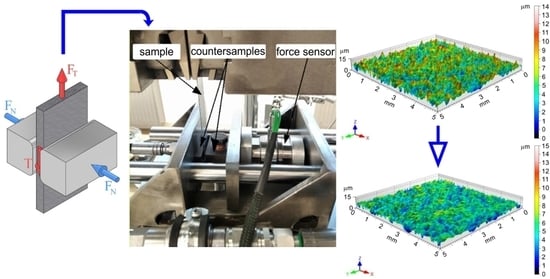

2.2. Friction Test

2.3. Surface Topography

3. Results and Discussion

3.1. Coefficient of Friction

3.2. Effectiveness of Lubrication

3.3. Surface Roughness

4. Conclusions

- The COF decreases with increasing lubricant pressure for contact pressures pN of 2–6 MPa. For the contact pressure of 8 MPa, the lubricant pressure has the least favorable effect of reducing the COF.

- Increasing the oil pressure has a positive effect on the reduction of friction, but its value is limited by the possible occurrence of leaks from the contact zone. Therefore, the lubricant pressure must be properly selected for the size of the nominal contact surface.

- Conventional lubrication (pL = 0 MPa) without the forced supply of oil under pressure causes only a slight increase in the COF with increasing contact pressures. This fact was observed for both oils tested.

- The value of the COF is the resultant of the effect of the lubricating film. The use of oil with a higher viscosity allows the development of the mechanical interaction of the surface asperities to be delayed.

- At the lowest applied lubricant pressures (pL = 6 bar), the lubrication efficiency was similar over the nominal pressures pN = 2–8 MPa.

- At the higher lubricant pressures pL = 12 bar and pL = 18 bar, the lubrication efficiency depends on the viscosity of the oil and decreases with increasing nominal pressure.

- The values of the analyzed roughness parameters Sp, Ssk, and Sku decreased. There is a tendency for the Sku parameter to decrease with increasing lubricant pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gronostajski, Z.; Pater, Z.; Madej, L.; Gontarz, A.; Lisiecki, L.; Łukaszek-Sołek, A.; Łuksza, J.; Mróz, S.; Muskalski, Z.; Muzykiewicz, W. Recent development trends in metal forming. Arch. Civ. Mech. Eng. 2019, 19, 898–941. [Google Scholar] [CrossRef]

- Sigvant, M.; Pilthammar, J.; Hol, J.; Wiebenga, J.H.; Chezan, T.; Carleer, B.; van den Boogaard, T. Friction in sheet metal forming: Influence of surface roughness and strain rate on sheet metal forming simulation results. Procedia Manuf. 2019, 29, 512–519. [Google Scholar] [CrossRef]

- Schmoeckel, D.; Frontzek, H.; von Finckenstein, E. Reduction of Wear on Sheet Metal Forming Tools. CIRP Ann. 1986, 35, 195–198. [Google Scholar] [CrossRef]

- Bang, J.; Song, J.; Bae, G.; Park, N.; Lee, M.; Kim, H. Quantitative evaluation of experimental wear behaviour for CrN-coated tool steels in sheet metal forming process of TRIP 1180. Procedia Manuf. 2020, 50, 791–794. [Google Scholar] [CrossRef]

- Domitner, J.; Silvayeh, Z.; Sabet, A.S.; Öksüz, K.I.; Pelcastre, L.; Hardell, J. Characterization of wear and friction between tool steel and aluminum alloys in sheet forming at room temperature. J. Manuf. Process. 2021, 64, 774–784. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Lemu, H.G. Study on frictional conditions of AA5251 aluminium alloy sheets using drawbead simulator test and numerical methods. Stroj. Vestn. J. Mech. Eng. 2014, 60, 51–60. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Yang, H.; Li, H. Advance and trend of friction study in plastic forming. Trans. Nonferr. Met. Soc. China 2014, 24, 1263–1272. [Google Scholar] [CrossRef]

- Nie, N.; Su, L.; Deng, G.; Li, H.; Yu, H.; Tieu, A.K. A review on plastic deformation induced surface/interface roughening of sheet metallic materials. J. Mater. Res. Technol. 2021, 15, 6574–6607. [Google Scholar] [CrossRef]

- Assemien, M.; Le Bot, A. Influence of sliding speed on roughness noise. In Proceedings of the 26th International Congress on Sound and Vibration, Montreal, QC, Canada, 7–11 July 2019; pp. 1–6. [Google Scholar]

- Wu, Y.; Recklin, V.; Groche, P. Strain Induced Surface Change in Sheet Metal Forming: Numerical Prediction, Influence on Friction and Tool Wear. J. Manuf. Mater. Process. 2021, 5, 29. [Google Scholar] [CrossRef]

- Juanjuan, H.; Jie, Z.; Wei, Z.; Guangchun, W. Influence of metal forming parameters on surface roughness and establishment of surface roughness prediction model. Int. J. Mech. Sci. 2019, 163, 105093. [Google Scholar]

- Trzepieciński, T.; Gelgele, H.L. Investigation of anisotropy problems in sheet metal forming using finite element method. Int. J. Mater. Form. 2011, 4, 357–359. [Google Scholar] [CrossRef]

- Trzepieciński, T. 3D elasto-plastic FEM analysis of the sheet drawing of anisotropic steel sheet metals. Arch. Civ. Mech. Eng. 2010, 10, 95–106. [Google Scholar] [CrossRef]

- Yang, T.S. Prediction of surface topography in lubricated sheet metal forming. Int. J. Mach. Tools Manuf. 2008, 48, 768–777. [Google Scholar] [CrossRef]

- Bello, D.O.; Walton, S. Surface topography and lubrication in sheet-metal forming. Tribol. Int. 1987, 20, 59–65. [Google Scholar] [CrossRef]

- Evin, E.; Tomáš, M.; Výrostek, M. Verification the numerical simulation of the strip drawing test by its physical model. Acta Mech. Slovaca 2016, 20, 14–21. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Fejkiel, R. On the influence of deformation of deep drawing quality steel sheet on surface topography and friction. Tribol. Int. 2017, 115, 78–88. [Google Scholar] [CrossRef]

- Masters, L.G.; Williams, D.K.; Roy, R. Friction behaviour in strip draw test of pre-stretched high strength automotive aluminium alloys. Int. J. Mach. Tools Manuf. 2013, 73, 17–24. [Google Scholar] [CrossRef]

- Więckowski, W.; Adamus, J.; Dyner, M.; Motyka, M. Tribological Aspects of Sheet Titanium Forming. Materials 2023, 16, 2224. [Google Scholar] [CrossRef]

- Lovell, M.R.; Deng, Z. Characterization of interfacial friction in coated sheet steels: Influence of stamping process parameters and wear mechanisms. Tribol. Int. 2002, 35, 85–95. [Google Scholar] [CrossRef]

- Gierzyńska, M. Tarcie, Zużycie i Smarowanie w Obróbce Plastycznej Metali; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 1983. [Google Scholar]

- Wang, G.; Guo, B.; Shan, D. Friction related size-effect in microforming—A review. Manuf. Rev. 2014, 1, 23. [Google Scholar] [CrossRef] [Green Version]

- Lowell, M.; Higgs, C.F.; Deshmukh, P.; Mobley, A. Increasing formability in sheet metal stamping operations using environmentally friendly lubricants. J. Mater. Process. Technol. 2006, 177, 87–90. [Google Scholar]

- Więckowski, W.; Adamus, J.; Dyner, M. Sheet metal forming using environmentally benign lubricant. Arch. Civ. Mech. Eng. 2020, 20, 51. [Google Scholar] [CrossRef]

- Lachmayer, R.; Behrens, B.-A.; Ehlers, T.; Müller, P.; Althaus, P.; Oel, M.; Farahmand, E.; Gembarski, P.C.; Wester, H.; Hübner, S. Process-Integrated Lubrication in Sheet Metal Forming. J. Manuf. Mater. Process. 2022, 6, 121. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behaviour. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Geiger, M.; Roth, S.; Becker, W. Influence of laser-produced microstructures on the tribological behavior of ceramics. Surf. Coat. Technol. 1998, 100–101, 17–22. [Google Scholar] [CrossRef]

- Kim, D.E.; Cha, K.H.; Sung, I.H.; Bryan, J. Design of surface micro-structures for friction control in micro-systems applications. CIRP Ann. Manuf. Technol. 2002, 51, 495–498. [Google Scholar] [CrossRef]

- Costa, H.L.; Hutchings, I.M. Hydrodynamic lubrication of textured steel surfaces under reciprocating sliding conditions. Tribol. Int. 2007, 40, 1227–1238. [Google Scholar] [CrossRef]

- Kummel, J.; Braun, D.; Gibmeier, J.; Schneider, J.; Greiner, C.; Schulze, V.; Wanner, A. Study on micro texturing of uncoated cemented carbide cutting tools for wear improvement and built-up edge stabilisation. J. Mater. Process. Technol. 2015, 215, 62–70. [Google Scholar] [CrossRef]

- Wang, L. Use of structured surfaces for friction and wear control on bearing surfaces. Surf. Topogr. Metrol. Prop. 2014, 2, 43001. [Google Scholar] [CrossRef]

- Abdel Aal, H.A. Functional surfaces for tribological applications: Inspiration and design. Surf. Topogr. Metrol. Prop. 2016, 4, 43001. [Google Scholar] [CrossRef]

- Mousavi, A.; Sperk, T.; Gietzelt, T.; Kunze, T.; Lasagni, A.F.; Brosius, A. Effect of contact area on friction force in sheet metal forming operations. Key Eng. Mater. 2018, 767, 77–84. [Google Scholar] [CrossRef]

- Sedlaček, M.; Podgornik, B.; Vižintin, J. Influence of surface preparation on roughness parameters, friction and wear. Wear 2009, 266, 482–487. [Google Scholar] [CrossRef]

- Xie, H.C.; Chen, D.R.; Kong, X.M. An analysis of the three-dimensional surface topography of textured cold-rolled steel sheets. Tribol. Int. 1999, 32, 83–87. [Google Scholar] [CrossRef]

- Zavadil, J.; Bartunek, J.S.; Fojtik, D. Analysis of periodicities in surface topography of cold rolled sheets using data captured by camera system. Meas. Sci. Rev. 2020, 20, 145–149. [Google Scholar] [CrossRef]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant test methods for sheet metal forming. Tribol. Int. 2018, 41, 844–853. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Lemu, H.G. Recent developments and trends in the friction testing for conventional sheet metal forming and incremental sheet forming. Metals 2020, 10, 47. [Google Scholar] [CrossRef] [Green Version]

- Erbel, S.; Kuczyński, K.; Marciniak, Z. Cold Plastic Working; PWN: Warsaw, Poland, 1975. [Google Scholar]

- Prakash, V.; Kumar, D.R. Performance evaluation of bio-lubricants in strip drawing and deep drawing of an aluminium alloy. Adv. Mater. Process. Technol. 2022, 8, 1044–1057. [Google Scholar] [CrossRef]

- ISO 25178–2:2022; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2022.

- Cillaurren, J.; Galdos, L.; Sanchez, M.; Zabala, A.; Saenz de Argandoña, E.; Mendiguren, J. Contact pressure and sliding velocity ranges in sheet metal forming simulations. In Proceedings of the 24th International Conference on Material Forming ESAFORM 2021, Liège, Belgium, 14–16 April 2021. [Google Scholar]

- Djordjević, M.; Aleksandrović, S.; Djačić, S.; Sedmak, A.; Lazić, V.; Arsić, D.; Mutavdžić, M. Simulation of flat die deep drawing process by variable contact pressure sliding model. Teh. Vjesn. 2019, 26, 1199–1204. [Google Scholar]

- Filzek, J.; Groche, P. Assessment of the Tribological Function of Lubricants for Sheet Metal Forming. Bench Testing of Industrial Fluid Lubrication and Wear Properties Used in Machinery Applications, ASTM STP 1404; Totten, G.E., Wedeven, L.D., Dickey, J.R., Anderson, M., Eds.; American Society for Testing and Materials: West Conshohocken, PA, USA, 2001. [Google Scholar]

- Steiner, J.; Andreas, K.; Merklein, M. Investigation of surface finishing of carbon based coated tools for dry deep drawing of aluminium alloys. IOP Conf. Ser. Mater. Sci. Eng. 2016, 159, 012022. [Google Scholar] [CrossRef]

- Jewvattanarak, P.; Mahayotsanun, N.; Mahabunphachai, S.; Ngernbamrung, S.; Dohda, K. Tribological effects of chlorine-free lubricant in strip drawing of advanced high strength steel. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2016, 230, 974–982. [Google Scholar] [CrossRef]

- De Andragoña, E.S.; Zabala, A.; Galdos, L.; Mendiguren, J. The Effect of Material Surface Roughness in Aluminum Forming. Procedia Manuf. 2020, 47, 591–595. [Google Scholar] [CrossRef]

- Abe, Y.; Mori, K.; Hatashita, F.; Shiba, T.; Daodon, W.; Osakada, K. Improvement of seizure resistance in ironing of stainless steel cup with cermet die having fine lubricant pockets. J. Mater. Process. Technol. 2016, 234, 195–207. [Google Scholar] [CrossRef]

- George, E.; Kurien, G.E.; Vishal, U.; Anil, P.M. A Study on The Effect of Oil Pocket Density on The Effectiveness of Boundary Lubrication in the Liner-ring Interface. Procedia Eng. 2013, 64, 1062–1068. [Google Scholar] [CrossRef] [Green Version]

- Pereira, T.G.; Hernández, A.; Martinez, P.; Pérez, J.; Mathia, J.A. Surface topographic characterization for polyamide composite injection molds made of aluminum and copper alloy. Scanning 2014, 36, 39–52. [Google Scholar] [CrossRef]

- Sedlaček, M.; Vilhena, L.M.S.; Podgornik, B.; Vižintin, J. Surface topography modelling for reduced friction. Stroj. Vestn. J. Mech. Eng. 2011, 57, 674–680. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.Z.; Chen, H.; Hu, Y.Z.; Wang, H. Effect of surface roughness parameters on mixed lubrication characteristics. Tribol. Int. 2006, 39, 522–527. [Google Scholar] [CrossRef]

- Żaba, K.; Kuczek, Ł.; Puchlerska, S.; Wiewióra, M.; Góral, M.; Trzepieciński, T. Analysis of Tribological Performance of New Stamping Die Composite Inserts Using Strip Drawing Test. Adv. Mech. Mater. Eng. 2023, 40, 55–62. [Google Scholar] [CrossRef]

- Szewczyk, M.; Szwajka, K. Assessment of the Tribological Performance of Bio-Based Lubricants Using Analysis of Variance. Adv. Mech. Mater. Eng. 2023, 40, 31–38. [Google Scholar] [CrossRef]

| Carbon | Manganese | Phosphorus | Sulfur | Iron |

|---|---|---|---|---|

| 0.12 | 0.6 | 0.045 | 0.045 | Balance |

| Rp0.2, MPa | Rm, MPa | At, % | Hardness HV |

|---|---|---|---|

| 231.5 | 348.1 | 38.5 | 105 |

| Parameter | Value | Unit |

|---|---|---|

| Flow | 0.4 | L/min |

| Maximum pressure | 63 | bar |

| Power | 0.18 | kW |

| Working temperature | −25 … +50 | °C |

| Oil | Kinematic Viscosity at 40 °C, mm2/s |

|---|---|

| S100 Plus oil for deep-drawing (Naftochem) | 110 |

| S300 oil for deep-drawing operations (Naftochem) | 300 |

| Surface Roughness Parameter | Value | |

|---|---|---|

| Sheet Metal | Countersamples | |

| Root mean square roughness Sq, µm | 1.82 | 0.384 |

| Surface skewness Ssk | 0.553 | −2.87 |

| Surface kurtosis Sku | 3.32 | 24.7 |

| Highest peak of the surface Sp, µm | 9.13 | 4.28 |

| Maximum pit depth Sv, µm | 5.31 | 6.50 |

| 10-point peak-valley surface roughness Sz, µm | 14.4 | 10.8 |

| Average roughness Sa, µm | 1.44 | 0.237 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trzepieciński, T.; Szwajka, K.; Szewczyk, M. Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-Metal-Forming Processes. Lubricants 2023, 11, 169. https://doi.org/10.3390/lubricants11040169

Trzepieciński T, Szwajka K, Szewczyk M. Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-Metal-Forming Processes. Lubricants. 2023; 11(4):169. https://doi.org/10.3390/lubricants11040169

Chicago/Turabian StyleTrzepieciński, Tomasz, Krzysztof Szwajka, and Marek Szewczyk. 2023. "Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-Metal-Forming Processes" Lubricants 11, no. 4: 169. https://doi.org/10.3390/lubricants11040169

APA StyleTrzepieciński, T., Szwajka, K., & Szewczyk, M. (2023). Pressure-Assisted Lubrication of DC01 Steel Sheets to Reduce Friction in Sheet-Metal-Forming Processes. Lubricants, 11(4), 169. https://doi.org/10.3390/lubricants11040169