Mechanical and Tribological Behavior of Austempered Ductile Iron (ADI) under Dry Sliding Conditions

Abstract

:1. Introduction

2. Experimental Procedure

3. Results

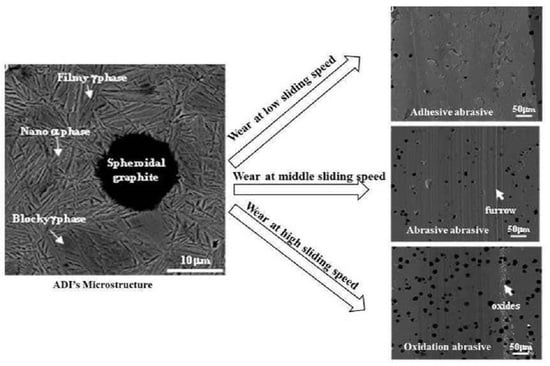

3.1. Microstructure and Mechanical Properties of ADI

3.2. Tribological Behavior of ADI under Different Wear Conditions

4. Discussion

5. Conclusions

- (1)

- A ductile iron with approximately 300/mm2 of graphite nodule distributing around the matrix was fabricated by a vertically continuous casting method, the matrix of which was composed of ferrite and pearlite.

- (2)

- Compared with the as-cast ductile iron, ADI exhibited a much higher strength with an ultimate tensile strength of approximately 1220 MPa. This high strength was because the nanoscale microstructure strengthened the alloy by grain boundaries and carbon atoms in α and γ phase strengthened the alloy by solution strengthening.

- (3)

- The friction coefficient of ADI was affected obviously by the service conditions, in which increasing normal load and sliding speed reduced the friction coefficient. This was mainly related to the amounts of graphite transferred from the matrix to the tribosurface and the formation of the graphite lubricant layer.

- (4)

- The wear rate of ADI increased with increasing the normal load but decreased with the increase in sliding speed. The temperature on tribosurface increased with the increase in sliding speed, which promoted the oxidation of wear debris and then reduced the wear rate.

- (5)

- The main wear mechanism of ADI was adhesive wear at low sliding speed, but oxidation wear was predominant under high sliding speed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Artola, G.; Gallastegi, I.; Izaga, J.; Barreña, M.; Rimmer, A. Austempered Ductile Iron (ADI) Alternative Material for High-Performance Applications. Int. J. Met. 2017, 11, 131–135. [Google Scholar] [CrossRef]

- Pereira, L.; Amaral, R.F.D.; Wolfart, M.; Barcellos, V.K.D. Microstructural and mechanical properties of Cu-Ni-Mn-Mo austempered ductile iron obtained from two-step hot air austempering. J. Mater. Res. Technol. 2020, 9, 3055–3063. [Google Scholar] [CrossRef]

- Labrecque, C.; Gagné, M. Ductile iron: Fifty years of continuous development. Can. Metall. Q. 1998, 37, 343–378. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Liu, B.; Jiang, B. Enhanced plasticity of austempered ductile iron (ADI) by partitioning treatment. Mater. Sci. Eng. A 2021, 804, 140513. [Google Scholar] [CrossRef]

- Sellamuthu, P.; Samuel, D.; Dinakaran, D.; Premkumar, V.; Li, Z.; Seetharaman, S. Austempered Ductile Iron (ADI): Influence of Austempering Temperature on Microstructure. Mechanical and Wear Properties and Energy Consumption. Metals 2018, 8, 53–64. [Google Scholar] [CrossRef]

- Wang, X.; Du, Y.; Liu, C.; Hu, Z.; Li, P.; Gao, Z.; Guo, H.; Jiang, B. Relationship among process parameters, microstructure, and mechanical properties of austempered ductile iron (ADI). Mater. Sci. Eng. A 2022, 857, 144063. [Google Scholar] [CrossRef]

- Franzen, D.; Pustal, B.; Bührig-Polaczek, A. Mechanical Properties and Impact Toughness of Molybdenum Alloyed Ductile Iron. Int. J. Met. 2021, 15, 983–994. [Google Scholar] [CrossRef]

- Uyar, A.; Sahin, O.; Nalcaci, B.; Kilicli, V. Effect of Austempering Times on the Microstructures and Mechanical Properties of Dual-Matrix Structure Austempered Ductile Iron (DMS-ADI). Int. J. Met. 2022, 16, 407–418. [Google Scholar] [CrossRef]

- Du, Y.; Wang, X.; Zhang, D.; Wang, X.; Ju, C.; Jiang, B. A superior strength and sliding-wear resistance combination of ductile iron with nanobainitic matrix. J. Mater. Res. Technol. 2021, 11, 1175–1183. [Google Scholar] [CrossRef]

- Du, Y.Z.; Gao, X.Q.; Wang, X.L.; Wang, X.; Ge, Y.F.; Jiang, B.L. Tribological behavior of austempered ductile iron (ADI) obtained at different austempering temperatures. Wear 2020, 456, 203396. [Google Scholar] [CrossRef]

- Putatunda, S.K. Development of austempered ductile cast iron (ADI) with simultaneous high yield strength and fracture toughness by a novel two-step austempering process. Mater. Sci. Eng. A 2001, 315, 70–80. [Google Scholar] [CrossRef]

- Pimentel, A.S.O.; Guesser, W.L.; da Silva, W.J.R.C.; Portella, P.D.; Woydt, M.; Burbank, J. Abrasive wear behavior of austempered ductile iron with niobium additions. Wear 2019, 440-441, 203065. [Google Scholar] [CrossRef]

- Hu, Z.; Liu, C.; Du, Y.; Wang, X.; Zhu, X.; Jiang, B. Effects of Tempering Temperature on Mechanical and Tribological Behavior of Ductile Iron. Lubricants 2022, 10, 326. [Google Scholar] [CrossRef]

- Takeuchi, E. The mechanisms of wear of cast iron in dry sliding. Wear 1968, 11, 201–212. [Google Scholar] [CrossRef]

- Masuda, K.; Oguma, N.; Ishiguro, M.; Sakamoto, Y.; Ishihara, S. Sliding wear life and sliding wear mechanism of gray cast iron AISI NO.35B. Wear 2021, 474–475, 203870. [Google Scholar] [CrossRef]

- Yang, Z.-R.; Li, D.-S.; Wang, L.; Wang, S.-Q.; Wei, M.-X. Wear Behavior and Mechanism of Spheroidal Graphite Cast Iron. J. Iron Steel Res. Int. 2013, 20, 81–86. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.-X.; Li, Q.-J.; Hong, X. Effect of matrix structure on mechanical properties and dry rolling–sliding wear performance of alloyed ductile iron. J. Iron Steel Res. Int. 2019, 26, 888–897. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

- Mussa, A.; Krakhmalev, P.; Bergström, J. Wear mechanisms and wear resistance of austempered ductile iron in reciprocal sliding contact. Wear 2022, 498–499, 204305. [Google Scholar] [CrossRef]

- Rezende, A.B.; Fonseca, S.T.; Miranda, R.S.; Fernandes, F.M.; Grijalba, F.A.F.; Farina, P.F.S.; Mei, P.R. Effect of niobium and molybdenum addition on the wear resistance and the rolling contact fatigue of railway wheels. Wear 2021, 466–467, 203571. [Google Scholar] [CrossRef]

- Liu, C.; Du, Y.; Wang, X.; Zheng, Q.; Zhu, X.; Zhang, D.; Liu, D.; Yang, C.; Jiang, B. Comparison of the tribological behavior of quench-tempered ductile iron and austempered ductile iron with similar hardness. Wear 2023, 520–521, 204668. [Google Scholar] [CrossRef]

- Laino, S.; Sikora, J.A.; Dommarco, R.C. Development of wear resistant carbidic austempered ductile iron (CADI). Wear 2008, 265, 1–7. [Google Scholar] [CrossRef]

- Zimba, J.; Samandi, M.; Yu, D.; Chandra, T.; Navara, E.; Simbi, D.J. Un-lubricated sliding wear performance of unalloyed austempered ductile iron under high contact stresses. Mater. Des. 2004, 25, 431–438. [Google Scholar] [CrossRef]

- Yan, G.; Xu, Y.; Jiang, B. The production of high-density hollow cast-iron bars by vertically continuous casting. J. Mater. Process. Technol. 2012, 212, 15–18. [Google Scholar] [CrossRef]

- Sourmail, T.; Caballero, F.G.; Moudian, F.; De Castro, D.; Benito, M. High hardness and retained austenite stability in Si-bearing hypereutectoid steel through new heat treatment design principles. Mater. Des. 2018, 142, 279–287. [Google Scholar] [CrossRef]

- Kim, K.-W.; Kim, K., II; Lee, C.-H.; Kang, J.-Y.; Lee, T.-H.; Cho, K.-M.; Oh, K.H. Control of retained austenite morphology through double bainitic transformation. Mater. Sci. Eng. A 2016, 673, 557–561. [Google Scholar] [CrossRef]

- He, T.; Wang, L.; Hu, F.; Zhou, W.; Zhang, Z.; Wu, K. Stability of retained austenite and work hardening behavior in ultra-fine medium carbon bainitic steel. J. Mater. Res. Technol. 2023, 22, 2690–2703. [Google Scholar] [CrossRef]

- Pereira, H.B.; Tschiptschin, A.P.; Goldenstein, H.; Azevedo, C.R.F. Effect of the Austenitization Route on the Bainitic Reaction Kinetics and Tensile Properties of an Alloyed Austempered Ductile Iron. Int. J. Met. 2021, 15, 1442–1455. [Google Scholar] [CrossRef]

- Caballero, F.G.; Miller, M.K.; Garcia-Mateo, C. Carbon supersaturation of ferrite in a nanocrystalline bainitic steel. Acta Mater. 2010, 58, 2338–2343. [Google Scholar] [CrossRef]

- Sugishita, J.; Fujiyoshi, S. The effect of cast iron graphites on friction and wear performance: II: Variables influencing graphite film formation. Wear 1981, 68, 7–20. [Google Scholar] [CrossRef]

- Sugishita, J.; Fujiyoshi, S. The effect of cast iron graphites on friction and wear performance I: Graphite film formation on grey cast iron surfaces. Wear 1981, 66, 209–221. [Google Scholar] [CrossRef]

- Kawamoto, M.; Okabayashi, K. Study of dry sliding wear of cast iron as a function of surface temperature. Wear 1980, 58, 59–95. [Google Scholar] [CrossRef]

- Wei, M.X.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Analysis for Wear Behaviors of Oxidative Wear. Tribol. Lett. 2011, 42, 1–7. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | S | P | Mg | Ce | Fe |

|---|---|---|---|---|---|---|---|---|

| Weight Fraction wt.% | 3.62 | 2.56 | 0.20 | 0.012 | 0.032 | 0.040 | 0.035 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Du, Y. Mechanical and Tribological Behavior of Austempered Ductile Iron (ADI) under Dry Sliding Conditions. Lubricants 2023, 11, 182. https://doi.org/10.3390/lubricants11040182

Hu Z, Du Y. Mechanical and Tribological Behavior of Austempered Ductile Iron (ADI) under Dry Sliding Conditions. Lubricants. 2023; 11(4):182. https://doi.org/10.3390/lubricants11040182

Chicago/Turabian StyleHu, Zhitao, and Yuzhou Du. 2023. "Mechanical and Tribological Behavior of Austempered Ductile Iron (ADI) under Dry Sliding Conditions" Lubricants 11, no. 4: 182. https://doi.org/10.3390/lubricants11040182

APA StyleHu, Z., & Du, Y. (2023). Mechanical and Tribological Behavior of Austempered Ductile Iron (ADI) under Dry Sliding Conditions. Lubricants, 11(4), 182. https://doi.org/10.3390/lubricants11040182