Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils

Abstract

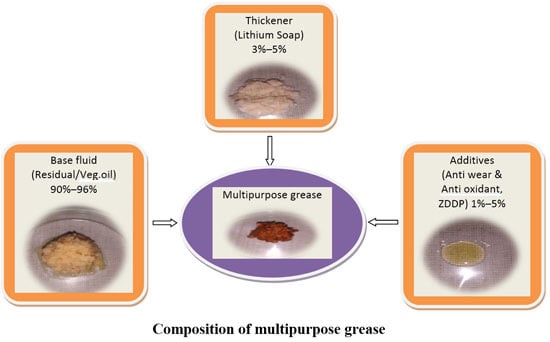

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Lithium Stearate/Oleate Soaps

2.3. Additives

2.4. Apparatus

2.5. Synthesis of Greases

2.6. Mechanical and Physico-Chemical Characterization

2.6.1. Dropping Point

2.6.2. Cone Penetration

2.6.3. Oxidation Stability

2.6.4. Temperature Effects

2.6.5. Pump Ability

2.6.6. Water Resistance

2.6.7. Anti Wear

2.6.8. Weld Load

2.6.9. Biodegradability

2.7. Toxicity

3. Results and Discussion

3.1. Formulations with Jatropha Base Oil

3.1.1. Using Lithium Stearate Soap

| Serial Number | Component | Form. 1 | Form. 2 | Form. 3 | Form. 4 | Form. 5 |

|---|---|---|---|---|---|---|

| 1 | Jatropha base oil | 96 | 93.5 | 94 | 93.5 | 93.5 |

| 2 | Lithium Stearate | 3 | 3 | 5 | 5 | 5.5 |

| 3 | Additive | 1 | 1.5 | 1 | 1.5 | 1 |

3.1.2. Using Lithium Oleate Soap

| Serial Number | Component | Form. 6 | Form. 7 | Form. 8 |

|---|---|---|---|---|

| 1 | Jatropha oil or Jatropha residual oil | 93.5 - | 90 - | - 91 |

| 2 | Lithium oleate | 5 | 5 | 4 |

| 3 | Additive | 1.5 | 5 | 5 |

3.2. Formulations with Jatropha Residual Oil

| Serial Number | Product Characteristics | Commercial Sample | Formulation Developed at IIP | Test Formed |

|---|---|---|---|---|

| 1. | Weld Load (N) | 1962 | 2452.5 | IP-239 |

| 2. | WSD (mm) | 0.525 | 0.420 | ASTMD-2266 |

| 3. | Cone penetration | NLGI-2 | NLGI-2 | ASTM D-217 |

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Panchal, T.; Chauhan, D.; Thomas, M.; Patel, J. Bio based grease A value added product from renewable resources. Ind. Crops Prod. 2015, 63, 48–52. [Google Scholar] [CrossRef]

- Kimura, H.; Onuki, Y. Properties and Applications of Synthetic Greases. J. Synth. Lubr. 2003, 20, 241–255. [Google Scholar] [CrossRef]

- Beret, S. Impact of base oil changes on grease performance. NLGI Spokesman 1993, 57, 192–198. [Google Scholar]

- Goyan, R.L.; Melley, R.E.; Wissner, P.A.; Ong, W.C. Biodegradable lubricants. Lubr. Eng. 1998, 54, 10–17. [Google Scholar]

- Voltz, M.; Yates, N.C.; Gegner, E. Biodegradability of lubricant base stocks and fully formulated products. J. Synth. Lubr. 1994, 12, 215–213. [Google Scholar] [CrossRef]

- Abel, W.D. Rapidly biodegradable greases for switches. In Proceedings of the 11th International Colloquim Tribology, Esslingen, Germany, 17–19 January 1998; pp. 225–236.

- Sukirno, R.F.; Bismo, S.; Nasikin, M. Biogrease based on palm oil and lithium soap thickener: Evaluation of antiwear property. World Appl. Sci. J. 2009, 3, 401–407. [Google Scholar]

- Dwivedi, M.C.; Sapre, S. Total vegetable-oil based greases prepared from castor oil. J. Synth. Lubr. 2002, 19, 229–241. [Google Scholar] [CrossRef]

- Bower, B. Environmental Capabilities of Liquid Lubricants in Solid and Liquid Lubricants for Extreme Environments; ASLE Special Publication SP-15; ASLE: Denver, CO, USA, 1984; pp. 58–69. [Google Scholar]

- Kuhn, E. Correlation between System Entropy and Structural Changes in Lubricating Grease. Lubricants 2015, 3, 332–345. [Google Scholar] [CrossRef]

- Dresel, W.; Heckler, R.-P. Chapter 16. In Lubricating Greases, Lubricants and Lubrication, 2nd ed.; Mang, T., Dresel, W., Eds.; Wiley-VCH VerlagGMbH and Co. KGaA: Weinheim, Germany, 2007; pp. 648–693. [Google Scholar]

- Adhvaryu, A.; Erhan, S.Z.; Perez, J.M. Tribological studies of thermal and chemically modified vegetable oil for use as environmentally lubricant. Wear 2004, 257, 359–367. [Google Scholar] [CrossRef]

- Núñez, N.; Alfonso, J.E.M.; Valencia, C.; Sanchez, M.C.; Franco, J.M. Rheology of new green lubricating grease formulations containing cellulose pulp and its methylated derivative as thickener agents. Ind. Crops Prod. 2012, 37, 500–507. [Google Scholar] [CrossRef]

- Rudnick, L.R. Synthetics, Mineral Oils, and Bio-Based Lubricants: Chemistry and Technology; CRC: Press, Washington, USA, 2005; p. 468. [Google Scholar]

- ASTM-D-2265-15. Standard Test Method for Dropping Point of Lubricating Grease over Wide Temperature Range; ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM-D-217-10. Standard Test Method for Cone Penetration of Lubricating Grease; ASTM International: West Conshohocken, PA, USA, 2015.

- Dixena, R.; Sayanna, E.; Badoni, R. Recycled and Virgin HDPEs as bleed inhibitors and their rheological influences on lubricating greases thickened with PP and mPP. Lubricants 2014, 2, 237–248. [Google Scholar] [CrossRef]

- Rand, S.J. Significance of Tests for Petroleum Products, “ASTM Manual” Series; ASTM International: West Conshohocken, PA, USA, 2003; Volume 1, p. 166. [Google Scholar]

- Barnes, A.M.; Bartle, K.D.; Vincent, R.A.T. A review of zinc dialkydithiophosphates (ZDDPS): Characterisation and role in the lubricating oil. Tribol. Int. 2001, 34, 389–395. [Google Scholar] [CrossRef]

- ASTM-D-2266-01. Standard Test Method for Wear Preventive Characteristics of Lubricating Grease; ASTM International: West Conshohocken, PA, USA, 2015.

- IP-239. Determination of Extreme Pressure and Anti Wear Properties of Lubricating Fluids; Energy Institute: London, UK, 2014.

- ASTM-D-5864-11. Standard Test Method for Determining Aerobic Aquatic Biodegradation of Lubricants or Their Components; ASTM International: West Conshohocken, PA, USA, 2015.

- Van Miert, K. Methods for the determination of ecotoxicity, C3Algal inhibition test. Off. J. Eur. Commun. 1993, 383, 179–185. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagendramma, P.; Kumar, P. Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils. Lubricants 2015, 3, 628-636. https://doi.org/10.3390/lubricants3040628

Nagendramma P, Kumar P. Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils. Lubricants. 2015; 3(4):628-636. https://doi.org/10.3390/lubricants3040628

Chicago/Turabian StyleNagendramma, Ponnekanti, and Prashant Kumar. 2015. "Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils" Lubricants 3, no. 4: 628-636. https://doi.org/10.3390/lubricants3040628

APA StyleNagendramma, P., & Kumar, P. (2015). Eco-Friendly Multipurpose Lubricating Greases from Vegetable Residual Oils. Lubricants, 3(4), 628-636. https://doi.org/10.3390/lubricants3040628