Experimental Analysis of Grease Friction Properties on Sliding Textured Surfaces

Abstract

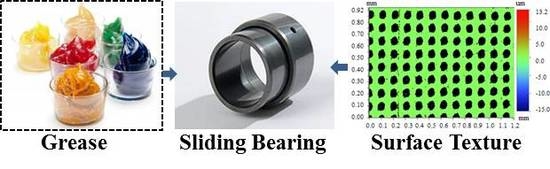

:1. Introduction

2. Materials and Methods

2.1. Specimen

2.2. Laser Surface Texturing

2.3. Friction and Wear Test

3. Results and Discussion

3.1. Effect of Texture Density on Coefficient of Friction

3.2. Effect of Texture Depth on Coefficient of Friction

3.3. Effect of Load on Friction Coefficient

3.4. Effect of Speed on Friction Coefficient

4. Conclusions

- In general, the friction coefficient is largely dependent on texture parameters, with lower and higher texture densities resulting in a higher friction coefficient at a fixed texture depth.

- The sample with texture density of 15% (T-3) and texture depth of 19 μm (H3) exhibited the best friction properties, experimentally, in all conditions because it could store more grease and trap wear debris.

- Higher load and speed increases the grease shear stress, apparent viscosity and thickener concentration, which facilitates the formation of a protective film and a smoothing phenomena, which are believed to be responsible for the reduction in friction.

- The reduction in friction by the surface texture and the main mechanism may be attributed to the hydrodynamic pressure effect, which increases the mating gap and reduces the probability of asperity contact.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ligier, J.-L.; Noel, B. Friction reduction and reliability for engines bearings. Lubricants 2015, 3, 569–596. [Google Scholar] [CrossRef]

- Sander, D.E.; Knauder, C.; Allmaier, H.; Damjanović-Le Baleur, S.; Mallet, P. Friction reduction tested for a downsized diesel engine with low-viscosity lubricants including a novel polyalkylene glycol. Lubricants 2017, 5, 9. [Google Scholar] [CrossRef]

- Nikolakopoulos, P.G.; Bompos, D.A. Experimental measurements of journal bearing friction using mineral, synthetic, and bio-based lubricants. Lubricants 2015, 3, 155–163. [Google Scholar] [CrossRef]

- Jacobson, S.; Kalvesten, E.; Pettersson, U. Effect of Surface Textures in Highly Loaded Grease Lubricated Reciprocating Sliding Contacts. In Proceedings of the 3rd World Tribology Congress, Washington, DC, USA, 12–16 September 2005. [Google Scholar]

- Etsion, I.; Burstein, L. A model for mechanical seals with regular microsurface structure. Tribol. Trans. 1996, 39, 677–683. [Google Scholar] [CrossRef]

- Etsion, I.; Halperin, G.; Greenberg, Y. Increasing Mechanical Seals Life with Laser-Textured Seal Faces; BHR Group Conference Series Publication; Mechanical Engineering Publications Limited: Maastricht, The Netherlands, 1997; pp. 3–12. [Google Scholar]

- Sudeep, U.; Tandon, N.; Pandey, R. Comparisons of tribological and vibration behaviors of textured point contacts of bearing steel lubricated with oil and grease under starved conditions. J. Tribol. 2016, 138, 031504. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Zhang, X.G.; Wu, T.H.; Xie, Y.-B. Effects of surface texturing on the tribological behavior of piston rings under lubricated conditions. Ind. Lubr. Tribol. 2016, 68, 158–169. [Google Scholar] [CrossRef]

- Arslan, A.; Masjuki, H.H.; Varman, M.; Kalam, M.A.; Quazi, M.M.; Mosarof, M.H. Effect of change in temperature on the tribological performance of micro surface textured dlc coating. J. Mater. Res. 2016, 31, 1837–1847. [Google Scholar] [CrossRef]

- Yu, R.F.; Li, P.; Chen, W. Study of grease lubricated journal bearing with partial surface texture. Ind. Lubr. Tribol. 2016, 68, 149–157. [Google Scholar] [CrossRef]

- Kanakasabai, V.; Warren, K.H.; Stephens, L.S. Surface analysis of the elastomer in lip seals run against shafts manufactured with micro-cavity patterns. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 723–736. [Google Scholar] [CrossRef]

- Sulaiman, M.H.; Christiansen, P.; Bay, N. The influence of tool texture on friction and lubrication in strip reduction testing. Lubricants 2017, 5, 3. [Google Scholar] [CrossRef]

- Fang, S.; Llanes, L.; Bähre, D. Wear characterization of cemented carbides (wc–coni) processed by laser surface texturing under abrasive machining conditions. Lubricants 2017, 5, 20. [Google Scholar] [CrossRef]

- Shen, C.; Khonsari, M. Effect of dimple’s internal structure on hydrodynamic lubrication. Tribol. Lett. 2013, 52, 415–430. [Google Scholar] [CrossRef]

- Tala-Ighil, N.; Fillon, M.; Maspeyrot, P. Effect of textured area on the performances of a hydrodynamic journal bearing. Tribol. Int. 2011, 44, 211–219. [Google Scholar] [CrossRef]

- Tomanik, E. Modelling the hydrodynamic support of cylinder bore and piston rings with laser textured surfaces. Tribol. Int. 2013, 59, 90–96. [Google Scholar] [CrossRef]

- Lu, P.; Wood, R.J.; Gee, M.G.; Wang, L.; Pfleging, W. The friction reducing effect of square-shaped surface textures under lubricated line-contacts—An experimental study. Lubricants 2016, 4, 26. [Google Scholar] [CrossRef]

- Shum, P.; Zhou, Z.; Li, K. Investigation of the tribological properties of the different textured dlc coatings under reciprocating lubricated conditions. Tribol. Int. 2013, 65, 259–264. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, D.; Hua, M.; Dong, G.; Chin, K. A study on the tribological behavior of surface texturing on babbitt alloy under mixed or starved lubrication. Tribol. Lett. 2014, 56, 305–315. [Google Scholar] [CrossRef]

- Sudeep, U.; Tandon, N.; Pandey, R. Vibration studies of lubricated textured point contacts of bearing steels due to surface topographies: Simulations and experiments. Tribol. Int. 2016, 102, 265–274. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, X.; Liu, K. Effect of surface texture on the frictional properties of grease lubricated spherical plain bearings under reciprocating swing conditions. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 125–135. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, Y.; Liu, Z.; Hu, T. Friction and wear behaviour of laser-textured surfaces under the lubrication of polyurea grease containing various additives. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2011, 225, 139–150. [Google Scholar] [CrossRef]

- Hua, X.; Puoza, J.C.; Sun, J.; Zhang, P.; Ji, J.; Wang, H.; Fu, H.; Kang, Z. Experimental analysis of friction and wear of laser microtextured surface filled with composite solid lubricant and lubricated with grease on sliding surfaces. J. Tribol. 2017, 139, 021609. [Google Scholar] [CrossRef]

- Kovalchenko, A.; Ajayi, O.; Erdemir, A.; Fenske, G.; Etsion, I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact. Tribol. Int. 2005, 38, 219–225. [Google Scholar] [CrossRef]

- Gropper, D.; Wang, L.; Harvey, T.J. Hydrodynamic lubrication of textured surfaces: A review of modeling techniques and key findings. Tribol. Int. 2016, 94, 509–529. [Google Scholar] [CrossRef]

- Peiyun, Z.; Xijun, H.; Zhihua, D.; Yonghong, F.; Wei, Z. Experimental research on grease lubrication properties of laser micro-texturing surface. Lubr. Eng. 2013, 38, 44–47. [Google Scholar]

- Zavos, A.B.; Nikolakopoulos, P.G. Simulation of piston ring tribology with surface texturing for internal combustion engines. Lubr. Sci. 2015, 27, 151–176. [Google Scholar] [CrossRef]

| Grease type | NLGI a Grade | Thickener Type | Dropping Point °C | Base Oil Viscosity | |

|---|---|---|---|---|---|

| @ 40 °C | @ 100 °C | ||||

| LGMT b 2/(pack size) | 2 | Lithium | >180 °C | 110 | 11 |

| Parameter | T-1 | T-2 | T-3 | T-4 | T-5 |

|---|---|---|---|---|---|

| Texture density (%) | 5 | 10 | 15 | 20 | 25 |

| Dimple depth (H/μm) | 12 | 12 | 12 | 12 | 12 |

| Dimple diameter (D/μm) | 60 | 60 | 60 | 60 | 60 |

| Parameter | H1 | H2 | H3 | H4 | H5 |

|---|---|---|---|---|---|

| Texture density (%) | 15 | 15 | 15 | 15 | 15 |

| Dimple depth (H/μm) | 6 | 12 | 19 | 24 | 30 |

| Dimple diameter (D/μm) | 60 | 60 | 60 | 60 | 60 |

| Test Number | V1 | V2 | V3 |

|---|---|---|---|

| Texture density (%) | 10% | 15% | 15% |

| Texture depth (H/μm) | 12 | 19 | 24 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, X.; Puoza, J.C.; Zhang, P.; Xie, X.; Yin, B. Experimental Analysis of Grease Friction Properties on Sliding Textured Surfaces. Lubricants 2017, 5, 42. https://doi.org/10.3390/lubricants5040042

Hua X, Puoza JC, Zhang P, Xie X, Yin B. Experimental Analysis of Grease Friction Properties on Sliding Textured Surfaces. Lubricants. 2017; 5(4):42. https://doi.org/10.3390/lubricants5040042

Chicago/Turabian StyleHua, Xijun, Julius Caesar Puoza, Peiyun Zhang, Xuan Xie, and Bifeng Yin. 2017. "Experimental Analysis of Grease Friction Properties on Sliding Textured Surfaces" Lubricants 5, no. 4: 42. https://doi.org/10.3390/lubricants5040042

APA StyleHua, X., Puoza, J. C., Zhang, P., Xie, X., & Yin, B. (2017). Experimental Analysis of Grease Friction Properties on Sliding Textured Surfaces. Lubricants, 5(4), 42. https://doi.org/10.3390/lubricants5040042