CFD Modeling of the Effect of Different Surface Texturing Geometries on the Frictional Behavior

Abstract

:1. Introduction

1.1. Lubrication Theory

1.2. Modelling Textured Surfaces

1.3. Simplifications to the Reynolds Equation

1.4. Reynolds vs. Navier-Stokes Equation

1.5. Load-Carrying Capacity and Coefficient of Friction Equations

2. Materials and Methods

2.1. Computational Fluid Dynamic (CFD) Analysis

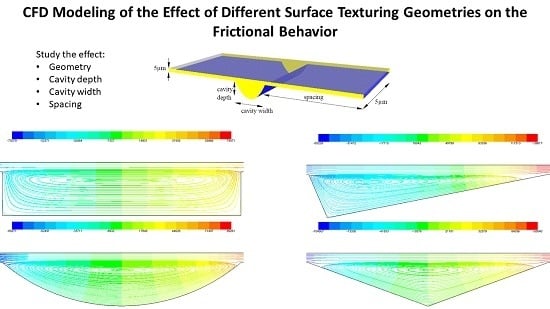

2.2. Geometrical Model

2.3. Varied Parameters

2.4. Boundary Conditions

2.5. Computational Grid

3. Results and Discussion

3.1. Influence of Cavity Geometry

3.2. Influence of Cavity Depth

3.3. Influence of Cavity Width

3.4. Influence of Distance between Cavities (Spacing/Density)

3.5. Influence of Sliding Speed

4. Conclusions

- For low Reynolds numbers, an analogous result can be obtained using the Reynolds and the Navier-Stokes equations since the pressure distribution is anti-symmetrical about the point located at the mid-plane of the cell, as shown during the present investigation. However, for large Reynolds numbers the pressure distribution becomes asymmetric, resulting in a positive net force, which requires the use of the Navier-Stokes equation.

- The CFD simulation performed in this research work discussed only the effect of the shear stress due to the presence of the micro-dimple. However, for the conditions simulated in this study (high viscosity fluid), the Reynolds number, Re << 1 shows that the convective inertia forces can be neglected. (The Reynolds number is defined as Re = ρuh/μ where ρ and μ are the density and dynamic viscosity of the fluid, h the film thickness and u is the velocity of the moving wall.) Although these results need further investigation, they clearly indicate that optimization of surface texturing for full-film lubrication can be done through CFD.

- An introduction of a micro-groove on one of the surfaces affects the flow and pressure distribution. For very small Reynolds numbers, when viscous effects are largely dominant and the approximation of the Stokes flow regime is acceptable, the pressure distribution is anti-symmetrical about the point located at x = 0 and y = 0. The shear force is also monotonically decreased by increasing values of cavity depth, due to a local increase in film thickness. The result is lower friction and thus a reduced friction coefficient. This agrees with our CFD simulation since the magnitude of pressure distribution decreases with increasing dimensionless dimple depth from 1.6 to 3.2 and 4.6.

- CFD simulation for different distances between cavities (densities) is also in agreement with the experimental results obtained under full-film lubrication in previous work [20]. They clearly showed that there exists an optimal value of spacing in terms of shear force. Furthermore, according to the CFD simulation the best hydrodynamic performance is expected with the rectangular geometry (lowest shear force).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sahlin, F.; Glavatskih, S.B.; Almqvist, T.; Larsson, R. Two-dimensional CFD-analysis of micro-patterned surfaces in hydrodynamic lubrication. Trans. ASME 2005, 127, 96. [Google Scholar] [CrossRef]

- Brajdic-Mitidieri, P.; Gosman, A. CFD Analysis of a Low Friction Pockeed Pad Bearing. ASME J. Tribol. 2005, 127, 803–812. [Google Scholar] [CrossRef]

- Marian, V.G.; Kilian, M.; Scholz, W. Theoretical and experimental analysis of a partially textured thrust bearing with square dimples. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2007, 221, 771–778. [Google Scholar] [CrossRef]

- Kraker, A.; Ostayen, R.; Van Beek, A. A Multiscale Method Modeling Surface Texture Effects. J. Tribol. 2007, 129, 221–230. [Google Scholar] [CrossRef]

- Feldman, Y.; Kligerman, Y.; Etsion, I.; Haber, S. The validity of the reynolds equation in modelling hydrostatic effects in gas lubricated textured parallel surfaces. ASME J. Tribol. 2006, 128, 345–350. [Google Scholar] [CrossRef]

- Sahlin, F.; Almqvist, A.; Larsson, R.; Glavatskih, S. A cavitation algorithm for arbitrary lubricant compressibility. Tribol. Int. 2007, 40, 1294–1300. [Google Scholar] [CrossRef]

- Ausas, R.; Ragot, P.; Leiva, J.; Jai, M.; Bayada, G.; Buscaglia, G.C. The impact of the cavitation model in the analysis of micro-textured lubricated journal bearings. ASME J. Tribol. 2007, 129, 868–875. [Google Scholar] [CrossRef]

- Adams, H.G.; Elrod, M. A computer program for cavitation. Cavitation relat. Phenom. Lubr. 1974, 103, 37–41. [Google Scholar]

- Arghir, M.; Roucou, N.; Helene, M.; Frene, J. Theoretical Analysis of the Incompressible Laminar Flow in a Macro-Roughness Cell. J. Tribol. 2003, 125, 309–318. [Google Scholar] [CrossRef]

- Echávarri Otero, J.; Guerra Ochoa, E.; Bellón Vallinot, I.; Chacón Tanarro, E. Optimising the design of textured surfaces for reducing lubricated friction coeficiente. Lubr. Sci. 2017, 29, 183–199. [Google Scholar] [CrossRef]

- Vladescu, S.-C.; Olver, A.V.; Pegg, I.G.; Reddyhoff, T. The effects of surface texture in reciprocating contacts—An experimental study. Tribol. Int. 2015, 82, 28–42. [Google Scholar] [CrossRef]

- Zavos, A.; Nikolakopoulos, P.G. Cavitation effects on textured compression rings in mixed lubrication. Lubr. Sci. 2016, 28, 475–504. [Google Scholar] [CrossRef]

- Morris, N.J.; Rahmani, R.; Rahnejat, H. A hydrodynamic flow analysis for optimal positioning of surface textures. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2017, 231, 1140–1150. [Google Scholar] [CrossRef]

- Wang, X.; Kato, K.; Adachi, K.; Aizawa, K. Loads carrying capacity map for the surface texture design of SiC thrust bearing sliding in water. Tribol. Int. 2003, 36, 189–197. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 3rd ed.; Elsevier Science Publishers: New York, NY, USA, 1993. [Google Scholar]

- Fillon, M.B.; Dobrica, M. About the validity of Reynolds equation and inertia effects in textured sliders of infinite width. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2008, 223, 69–78. [Google Scholar]

- Stachowiak, G.W.; Batchelor, A.W. Engineering Tribology, 2nd ed.; Elsevier: New York, NY, USA, 2005. [Google Scholar]

- Patankar, S.V.; Spalding, D.B. A calculation procedure for heat, mass and momentum transfer in three-dimensional parabolic flows. Int. J. Heat Mass Transf. 1972, 15, 1787–1806. [Google Scholar] [CrossRef]

- Ferziger, J.H.; Peric, M. Computational Methods for Fluid Dynamics; Springer: Berlin, Germany, 2001; ISBN 978-3-540-42074-3. [Google Scholar]

- Podgornik, B.; Vilhena, L.M.; Sedlaček, M.; RekI, Z. Effectiveness and design of surface texturing for different lubrication regimes. Meccanica 2012, 47, 1613–1622. [Google Scholar] [CrossRef]

- Deshpande, P.N.; Shankar, M.D. Fluid mechanics in the driven cavity. Ann. Rev. Fluid Mech. 2000, 32, 93–136. [Google Scholar]

- Vilhena, L.M.; Podgornik, B.; Vižintin, J.; Možina, J. Influence of texturing parameters and contact conditions on tribological behavior of laser textured surfaces. Meccanica 2011, 46, 567–575. [Google Scholar] [CrossRef]

- Hsu, S.M. Surface Texturing: Principles and Design; National Institute of Standards & Technology: Gaithersburg, MD, USA, 2006.

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B.; Vižintin, J.; Babnik, A.; Možina, J. Surface texturing by pulsed Nd:YAG laser. Tribol. Int. 2009, 42, 1496–1504. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Sedlaček, M.; Podgornik, B. Answer to the discussion of the paper entitled surface texturing by pulsed Nd:YAG laser (L.M. Vilhena, M. Sedlaček, B. Podgornik, J. Vižintin, A. Babnik, and J. Možina, tribology international 42 (2009) 1496–1504). Tribol. Int. 2018, 118, 105–107. [Google Scholar] [CrossRef]

- Vilhena, L.M.; Ramalho, A.; Cavaleiro, A. Grooved surface texturing by electrical discharge machining. (EDM) under different lubrication regimes. Lubr. Sci. 2017, 29, 493–501. [Google Scholar] [CrossRef]

| Varied Parameters | Geometry | Cavity Depth (μm) | Cavity Width (μm) | Spacing (μm) | Sliding Speed (m/s) |

|---|---|---|---|---|---|

| Study the influence of geometry | Cylindrical | 22.8 | 128 | 500 | 0.1 |

| Rectangular | 22.8 | 128 | 500 | 0.1 | |

| Triangular | 22.8 | 128 | 500 | 0.1 | |

| Wedge | 22.8 | 128 | 500 | 0.1 | |

| Study the influence of cavity depth | Cylindrical | 8 | 128 | 500 | 0.1 |

| Cylindrical | 16 | 128 | 500 | 0.1 | |

| Study the influence of cavity width | Cylindrical | 22.8 | 40 | 500 | 0.1 |

| Cylindrical | 22.8 | 80 | 500 | 0.1 | |

| Study the influence of spacing | Cylindrical | 22.8 | 128 | 150 | 0.1 |

| Cylindrical | 22.8 | 128 | 200 | 0.1 | |

| Study the influence of sliding speed | Cylindrical | 22.8 | 128 | 500 | 0.01 |

| Cylindrical | 22.8 | 128 | 500 | 0.05 | |

| Cylindrical | 22.8 | 128 | 500 | 0.2 |

| Cylindrical |  |

| Rectangular |  |

| Triangular |  |

| Wedge |  |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vilhena, L.; Sedlaček, M.; Podgornik, B.; Rek, Z.; Žun, I. CFD Modeling of the Effect of Different Surface Texturing Geometries on the Frictional Behavior. Lubricants 2018, 6, 15. https://doi.org/10.3390/lubricants6010015

Vilhena L, Sedlaček M, Podgornik B, Rek Z, Žun I. CFD Modeling of the Effect of Different Surface Texturing Geometries on the Frictional Behavior. Lubricants. 2018; 6(1):15. https://doi.org/10.3390/lubricants6010015

Chicago/Turabian StyleVilhena, Luís, Marko Sedlaček, Bojan Podgornik, Zlatko Rek, and Iztok Žun. 2018. "CFD Modeling of the Effect of Different Surface Texturing Geometries on the Frictional Behavior" Lubricants 6, no. 1: 15. https://doi.org/10.3390/lubricants6010015

APA StyleVilhena, L., Sedlaček, M., Podgornik, B., Rek, Z., & Žun, I. (2018). CFD Modeling of the Effect of Different Surface Texturing Geometries on the Frictional Behavior. Lubricants, 6(1), 15. https://doi.org/10.3390/lubricants6010015