1. Introduction

Turbochargers have enabled combustion engines to become smaller and more efficient while remaining equally powerful. The amount of turbocharged gasoline passenger vehicles has grown considerably the past decades. Moreover, almost all diesel engines for passenger vehicles are nowadays equipped with turbochargers [

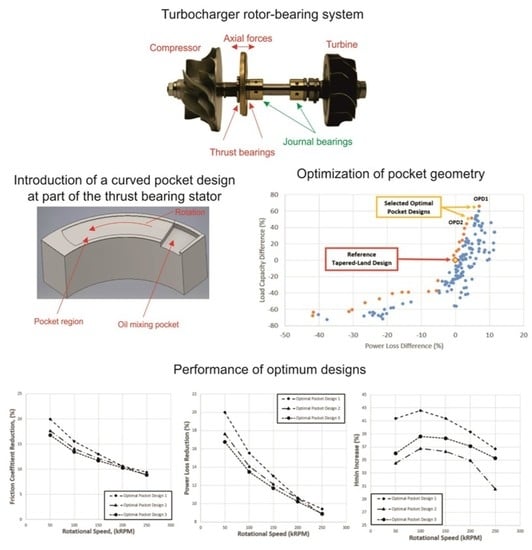

1]. A turbocharger is basically a rotor that features a turbine on one side and a compressor on the other side (

Figure 1). The turbine scavenges energy from the exhaust gas flow and delivers it to the compressor, which compresses ambient air and feeds it to the engine. As the density of the air is increased by compression, more air can be admitted at each combustion stroke and hence more power can be made [

2].

Turbochargers operate at high rotational speeds, with maxima typically well over 200 kRPM. To support the rotor at these rotation speeds, either ball bearings or fluid film bearings are used. Although fluid film bearings have, in general, higher friction losses than ball bearings, their low-cost price (when produced in large volumes) and their lower sensitivity for out of balance induced vibrations and consequent whining noise render them the bearing type of choice for the vast majority of passenger vehicle turbochargers [

2,

3,

4]. The fluid film bearing system of a turbocharger commonly consists of semi- or full floating ring bearings for radial support as well as a tapered-land thrust bearing for support in axial direction [

5].

The thrust bearing carries the following two thrust loads [

2]:

the static pressures acting on the compressor wheel and the turbine wheel.

the change of momentum of the air flowing from axial direction to radial direction in the compressor and vice versa for the turbine.

Depending on the operating condition of the turbocharger, the static thrust load is either directed towards the turbine or towards the compressor. Therefore, the thrust bearing is two-sided: it contains a taper-land profile at both sides of the bearing. Furthermore, as the exhaust gas flow of a combustion engine is mostly a pulsating flow, consequently the thrust load has a relatively high dynamic component [

6].

Minimization of friction losses is generally pursued to increase turbocharger efficiency and to decrease transient response times. Particularly at low engine speeds, turbocharger friction losses play a significant role [

7], contributing to the well-known turbo lag [

8]. Depending on the operating conditions and the design of the bearing system, the thrust bearing may be responsible for roughly half of the total friction losses of the bearing system [

7,

9]. Therefore, the friction losses of turbocharger thrust bearings have already been studied extensively [

7,

8,

9,

10,

11,

12,

13,

14].

One of the ways to reduce the friction losses in a turbocharger thrust bearing is by application of surface texture features. Recent research has been carried out to investigate the effect of periodic irregularities of various shapes (rectangular, trapezoidal, cylindrical or spherical), imprinted on part of the stator of fixed inclination thrust bearings on bearing performance. The reported numerical [

15,

16,

17,

18,

19,

20,

21,

22] and experimental studies [

23,

24,

25], demonstrated potential for improving bearing performance. As current technology has enabled the accurate manufacturing of such micro-scale patterns, contemporary research on the performance of textured bearings is growing more intense, with the optimization of texture geometry and placement being attempted by several researchers [

5,

6,

7,

8]. Apart from research aiming at identifying the potential of surface texturing to fixed pad thrust bearings, relevant studies on pivoted-pad thrust bearings have also been reported [

26,

27,

28,

29,

30], showcasing substantial performance improvements in terms of increased load carrying capacity and reduced power losses.

Detailed modeling is required for accurate representation and study of thrust bearings. In general, the use of the Reynolds equation gives satisfactory results for problems of hydrodynamic lubrication of interacting surfaces with simple geometry and low values of rotation speed. However, for more complex geometries (such as textured geometries) and high values of rotational speed, additional phenomena need to be taken into consideration. The applicability of the Reynolds equation for textured, infinite-width sliders has been investigated in [

31], where it was shown that its validity cannot be decided by the Reynolds number alone, as the geometric parameters of surface texturing (in particular the texture length-to-depth ratio) may have an equally important influence. Generally, the use of Navier-Stokes equation solvers has lately become increasingly popular for accurate flow analysis of fluid bearings. In particular, detailed CFD numerical analyses can be advantageous since (a) they provide increased calculation accuracy in cases with relatively high values of Reynolds number, especially for highly loaded thrust bearings and high values of rotational speed, (b) heat dissipation in the lubricant domain and heat transfer through the bearing and rotor solid can be efficiently simulated, and (c) flow phenomena in the bearing groove region can be accurately calculated by simulating the mixing of hot oil at the pad outlet with cold oil fed to the groove region (i.e., by detailed simulation of the hot-oil-carry-over phenomenon) [

32]. Further, lubricant behaviour at extreme conditions, in particular dependence of oil viscosity on temperature and pressure [

33], cavitation [

34,

35,

36] and shear thinning can be simulated in detail, adding to the complexity of the built models and to the required computational time. In the literature, several optimization techniques have been suggested for refining bearing design, either in terms of macroscopic geometric design parameters, [

37,

38,

39], or by introducing artificial surface texturing [

21,

22].

In the present work, a design optimization study of two different configurations of automotive turbocharger thrust bearings is performed. In particular, the two different configurations studied are a conventional taper-land bearing and a curved pocket bearing design. For both bearing configurations, a parametric CFD-based THD model is generated, capable of accounting for heat dissipation, conjugate heat transfer throughout the bearing domain including the surrounding parts, as well as shear thinning and cavitation in the lubricant domain. A design optimization problem is stated, seeking sets of design (geometric) variables that optimize the frictional behaviour of the bearing. Finally, the optimization results are evaluated for determination of bearing designs that exhibit low friction losses, while maintaining reliable operational characteristics.

2. Problem Setup

In the present work, a thermohydrodynamic (THD) approach is utilized for the study of a low-load, high-speed turbocharger thrust bearing. The present approach is based on CFD instead of the conventional Reynolds equation. Turbocharger thrust bearings are characterized by high values of rotational speed and oil temperature. Therefore, fluid inertia may play a role [

8], which is conveniently included by utilising the Navier-Stokes equations. In the present study two different thrust bearing designs are analysed, in particular (a) a tapered-land thrust bearing and (b) a pocket thrust bearing. For the optimization process, reference bearing designs have been selected based on parametric analyses utilising the Reynolds equation. Further, parametric CFD-based THD models have been generated, and optimization simulations have been carried out utilizing an in-house optimizer based on genetic algorithms.

2.1. Bearing Geometries

The thrust bearing configurations investigated in the present study consists of four sector pads. The bearings main geometric parameters are given in

Table 1. Regarding the tapered-land bearing geometry, a wedge-shaped geometry of the lubricating film is generated between the tapered part of the pad and the rotor, which leads to pressure buildup. The remaining part of the bearing is parallel to the rotor surface. Circumferentially, at the outer part of the pad, a lip is present in order to reduce side leakage and pressure drop at the high-pressure region of the bearing (

Figure 2). The shape and dimensions of the tapered-land bearing was such that an automatic mesh procedure was not feasible. It is noted that an automated meshing procedure is essential for performing unattended design optimization. To overcome this issue, an equivalent slider geometry has been generated, with main dimensions identical to those of a single bearing pad (

Figure 3). In order to better approach the physics of the bearing geometry, the velocity of the fluid in the fluid-rotor interface has been set as proportional to the radial coordinate, to accommodate the velocity variation that is observed in the thrust bearing geometry. However, the total area of the generated slider cannot be equal to that of the reference bearing, thus, differences in performance are expected. To this end, for performance comparisons, a reference slider bearing has been assumed; all optimal tapered-land designs are presented in comparison to the reference slider design.

The curved pocket bearing geometry (

Figure 4) corresponds to a simple plain parallel bearing geometry, featuring a pocket geometry with circular circumferential edges, a straight radial aft edge and a circular radial fore edge. The curved pocket bearing features an oil inlet groove in the inner surface of the bearing in order to be able to have a large inflow of fresh low temperature oil, and avoid cavitating conditions at the oil inlet region due to starvation.

2.2. Numerical Model

The conservation equations, solved with the CFD code ANSYS CFX for steady, incompressible flow, with zero gravitational and external body forces, are:

Mass conservation equation:

Energy equation, fluid domain:

Energy equation, solid domains:

where,

V is the fluid velocity vector (m/s),

p is the fluid pressure (Pa),

T is the fluid/solid temperature (K),

τ is the viscous stress tensor (Pa),

ρ is the oil density (kg/m

3),

μ is the oil dynamic viscosity (kg/(m·s)),

cpf is the oil specific heat capacity (J/(kg·K)), λ

f is the oil thermal conductivity (W/(m·K)), and λ

s corresponds to the thermal conductivity of the pad and the rotor (W/(m·K)).

In the present work, the utilized values of thermophysical properties for the lubricant are given in

Table 2. In particular, a 5W30 lubricant is assumed, characterized by a density value of 855 kg/m

3, whereas the rheological properties of the lubricant are described using the Vogel equation for the dependence of viscosity on temperature

T and the Cross equation to describe the shear-rate influence on viscosity, according to the following relation [

10]:

where

is the strain rate of the lubricant,

c the specific heat capacity and

k the thermal conductivity. Parameters

A, B, C, r, m and

K characterizing the rheological behaviour of the present lubricant are also given in

Table 2 [

10]. The thermophysical properties of the solid components of the bearing (rotor/stator) are presented in

Table 3.

Regarding cavitation, the Rayleigh-Plesset model is utilized [

13]; vapour pressure is calculated following the Antoine equation (Equation (6)) [

13].

where A

a = 10.6751275622054, B

a = 2764.82814496125 and C

a = 24.0334359061956.

The Reynolds number is defined based on the rotor velocity and the minimum film thickness, Hmin. For the thrust bearing, the rotor circumferential velocity U = ωDm/2 is taken as the reference velocity, where Dm is the bearing mean diameter. As fluid viscosity decreases due to heating and shear thinning, a local value of the Reynolds number can also be considered; in the present study, a maximum value of about 340, accounting for 250 kRPM, has been obtained, therefore the flow in the lubricant domain is laminar for all studied cases.

2.2.1. Mesh Characteristics

Appropriate unstructured meshes of the fluid and the solid domains of the systems have been generated, involving approximately 4 × 10

5 and 7 × 10

5 cells, respectively. In the fluid film region of the tapered-land bearing, a minimum of 20 cell layers in the cross-flow direction (along film thickness) has been used, whereas in the pocket bearing model, a minimum of 40 cell layers in the cross flow direction has been used (20 layers have been used in the pocket region). In

Figure 5 and

Figure 6, the meshes can be visualized for both studied geometries. A mesh dependence study has been conducted.

2.2.2. Boundary Conditions

All walls are considered impermeable, and the no-slip condition is applied. The bearing rotor of the thrust bearing is rotating at a constant angular velocity, ω, giving a circumferential local velocity

U = ω·r, where r is the local radius; rotational speed of the bearings varies from 50 kRPM to 250 kRPM. The inner fluid surface of the fluid domain (see

Figure 6), is considered to be an opening, allowing flow in both directions. For the inner surface of the lubricant, a boundary pressure of 4 bar is considered. There, the feeding oil temperature is assumed to be constant at 150 °C, being a typical value of temperature of a highly loaded automotive engine. The outer fluid surface is considered as a pressure outlet, with a constant value of 0.0 MPa relative to atmospheric; a Neumann boundary condition is considered for the velocity and temperature, while no inflow is permitted. Rotational periodicity is considered for the inflow-outflow sides of the fluid and solid domains. This boundary, applied at the fluid domain accounts for hot-oil-carry-over between consecutive pads. At the fluid-solid interfaces, continuity of temperature and heat flux is implemented. In

Table 4, all thermal boundary conditions of the model surfaces are identified. Operating conditions of the reference tapered-land bearing design are presented in

Table 5.

2.3. Optimization Procedure

The principal performance indices of a thrust bearing are load carrying capacity and friction coefficient. To optimize the performance of a thrust bearing, maximization of load carrying capacity will lead to larger film thickness for a given load (therefore less bearing wear and better performance in transient loads/impact loads), or to smaller bearing dimensions for a given value of minimum film thickness, which results in reduced friction power losses. Furthermore, minimization of the friction coefficient will contribute to reduced power losses. In the present study, two multi-objective optimization problems have been formulated:

| Optimization Problem 1: | Optimization Problem 2: |

| Objective functions: | Objective functions: |

| (a) maximization of load capacity | (a) maximization of minimum film thickness |

| (b) minimization of friction coefficient | (b) minimization of friction coefficient |

| Minimum film thickness is considered constant. | Thrust load is considered constant. |

5. Conclusions

The present study was concerned with the design optimization of the thrust bearing of an automotive turbocharger. The reference design is a small footprint, four-pad, grooveless, tapered-land thrust bearing design, with a lip at the outer radius of the bearing pad, in order to minimise side oil leakage. The goals of the present study were the geometry optimization of (i) a tapered-land bearing design, similar to the reference one, and (ii) a pocket bearing design with the same principal dimensions. Optimization has been carried out for a rotational speed of 200 kRPM. The optimization goals were (a) to minimize power losses and maximize minimum oil film thickness for given load capacity, and (b) to minimize friction coefficient and maximize load capacity for given minimum oil film thickness. Optimization has been performed with an in-house optimizer, which was coupled to ANSYS CFX code. The Pareto fronts of the optimization problems have been obtained, and different optimum designs have been identified. The optimum bearing designs have been further studied by means of a parametric analysis for different values of rotational speed (50 kRPM to 250 kRPM).

Regarding the tapered-land bearing, two optimal designs have been selected. Optimal design 1 exhibits the best performance for operation at 200 kRPM. In particular, for constant value of oil minimum film thickness, power loss has shown a decreasing trend by 7.5%, in comparison to the reference design. Maximum pressure has shown to exhibit a moderate decrease (approximately 6% at high values of rotational speed), in comparison to the reference design, whereas maximum temperature has exhibited a negligible decrease (approximately 1 °C at high values of rotational speed). The identified optimal taper depths are substantially higher than those of common designs, attributed to the peculiarities of the present design, characterized by very small-size, high values of rotational speed and very low values of film thickness, giving rise to high values of operating oil temperature.

Regarding the pocket bearing, three optimal designs have been identified. Optimal design 1 exhibits the best performance, in operation at 200 kRPM for a constant Load. In particular, minimum oil film thickness is increased by 40%, whereas power loss is decreased by 12%, in comparison to the reference geometry design. Maximum pressure exhibits a substantial decrease (approximately 30% at high values of rotational speed), in comparison to the reference design. Maximum temperature also exhibits a substantial decrease (reaching approximately 16 °C at high values of rotational speed). A parametric analysis of the effect of pocket depth on bearing performance reveals that pocket depths of the order of five times the value of film thickness are required for optimal bearing performance.

Based on the present results, the following conclusions can be drawn:

- (a)

Properly designed pocket bearings may aid in substantially improving the performance of turbocharger thrust bearings, by operation at higher oil film thickness and substantially reduced power losses. In the studied regime, the pocket extent should be approximately 80%, whereas the pocket depth should be approximately 4–6 times the minimum film thickness. A relatively deep oil entrance pocket is essential for providing fresh oil and minimizing the effect of hot-oil-carry-over. In all cases, the pocket curvature should be mild.

- (b)

Optimal parameters of pocket bearing designs may be different in different applications, being mostly affected by the bearing size, thrust load and environment conditions. Therefore, detailed calculations should be performed to verify optimum performance in the design stage.

- (c)

In thrust bearing applications, high loads, low values of minimum film thickness and high values of temperature give rise, on one hand to shear thinning, which may affect substantially lubricant viscosity, and on the other hand to cavitation, which may reduce bearing load capacity, degrade gradually the lubricating oil properties and increase the wear rate of the system. Therefore, detailed numerical simulations for predicting bearing performance are imperative in the design stage.