3.1. Basic Considerations

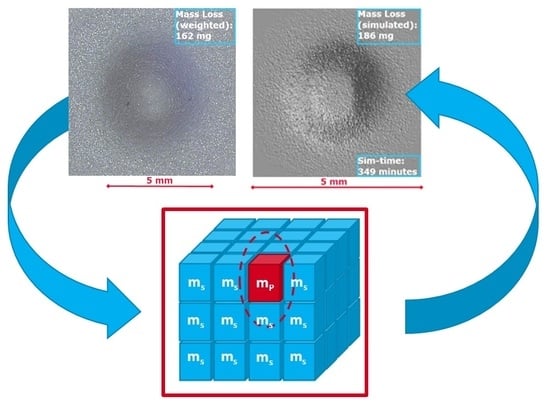

A cube (shown in

Figure 1) is the smallest volume element of interest for this alternative approach to simulate erosive wear (EROW-sim). It describes a volume of same or similar properties. The shape of these elements is not important. However, cubes can be stacked without spacings in-between. Several cube elements form a row, several rows a layer and several layers form the substrate to be simulated (see

Figure 3).

In this sense, EROW-sim can be considered as a discrete element-based method. However, these cubes do not move at all.

The size of the cube elements has no relevance for the approach itself in the sense that the substrate to be simulated is not limited to the sample dimensions shown in

Figure 1. However, for a given size, it influences the requirement for computing time and memory. A small edge length leads to an even larger number of cubes to be handled. The plotting program used to create the wear scar simulated here is limited to 255 data rows per image. Thus, the number of cube elements per row and of rows per layer was set to 250 each. As the wear scar requires an area of 5 mm × 5 mm to be simulated, the edge length of such cubes was set to 20 μm for the simulation of this erosion experiment. The number of layers was then adjusted so that the simulation would reach the maximum main memory allocated to a single program by the operating system.

EROW-sim is a step-based method. Each particle impact is considered as a single event. The incident particle interacts with the substrate according to material properties and physical processes. The next step is carried out, i.e., the next particle impacts only occurs, if all current processes are carried out. During such processes, only relevant cubes are considered at a time. Each particle incident is treated as a local event, considering only those cubes affected by the initiated processes.

Currently, the following processes are considered (see

Figure 4). If sufficient metal is present at the impact site, the incident ceramic particle has a possibility to stick (see top of

Figure 4). Sticking means that the particle (or fragments of it) stays in the area of contact after the impact. This process would still be called ‘sticking’, even if the particle is covered with substrate material. In the case that such sticking particles (see center of

Figure 4) are already present in the contact area, there is a chance that the pre-sticking particles will be embedded deeper into the substrate, due to the impact. Here, embedding means that a surface area is hit again by another particle, thus forcing particle material originating from an earlier impact, deeper into the substrate. The third main process considered is the possibility of the fragmentation of already embedded particles (see bottom of

Figure 4) and leaving from the surface. As probabilities are considered for the different processes to take place, EROW-sim also contains certain Monte-Carlo aspects. For instance, for an incident ceramic particle to stick, there has to be sufficient metal in the contact volume. The embedding process can only take place if sticking particles are already present. The same holds true for the shattering process of a particle. The latter requires the embedding processes to have occurred before a particle can shatter/fragment. The processes described above are kept as simple as possible, as the major issue is a trade-off between accuracy of simulating a single impact or getting ~2,000,000,000 such impacts calculated in a reasonable amount of time.

However, these processes are strongly governed by the properties of the actual material present in the contact volume. In case metal is dominant at the impact site of the hard, ceramic particle, the penetration depth is of critical importance (confer

Section 3.2). If the impact site is dominated by already sticking or embedded ceramic particles (remainders of earlier impacts), conditions for the formation of cracks in ceramics have to be considered (confer

Section 3.3).

3.2. Calculation of Penetration Depth

If the impact site of the actual particle consists mainly of metal, calculating the penetration depth is essential. Forrestal et al. considered the penetration of rigid spherical-nosed rods into ductile metal targets [

11]. In their work, they showed that there is no significant difference between a model for compressible or incompressible targets and experimental data in the range up to about 900 m/s. Therefore, the penetration depth

p is currently calculated as follows:

where the material constant

A is

and are the density of the incident particle and the substrate, respectively. L denotes the length of the incident particle in the z-direction. The radius of the particle and its spherical-shaped nose is labelled a. Here, this is basically set to the average value of the particle dimensions in x- and y-directions. The velocity of the incident particle is denoted vi, Young’s Modulus E and yield strength Y, respectively.

The calculated penetration depth in relation to the edge length of cubes is one major criterion to decide whether the currently impacting particle will stick. In the present simulation, the edge length of the cubes is set to 20 μm. Let’s assume that a penetration depth of 2 μm is calculated for a specific incident particle. A dice is rolled and in 10% (penetration depth/edge length × 100), the penetration depth would be converted to one cube and the particle would stick. In 90%, the penetration depth would be set to zero cubes, i.e., the particle bounces off the surface. In a small number of cases, there will be a large error in one direction, and in a large number of cases, a small error in the opposite direction. While the error for a specific particle might be substantial, this averages out over the billion impacts of the total experiment.

3.3. Considering Crack Formation

If an impacting particle can no longer hit the metallic substrate due to previously stuck/embedded ceramic particles, the conditions for crack formation are considered. For these considerations, the quasi-static indentation theory for erosion of brittle material is used. According to Slikkerveer et al., this theory can still be used for solid particle impact [

12]. The impact velocity of some hundreds of meters per second of these particles is still much smaller than the velocity of elastic and/or plastic deformation in brittle material. Verspui et al. calculated the indentation force

Fi exerted on the substrate by the impacting particle according to [

13]:

where the material constant

c1 is:

Here, vi is the velocity, D the diameter and the density of the impacting particle, while HS is the hardness of the substrate.

These calculations are based on the earlier work of Marshall et al. [

13], dealing with the lateral crack formation in ceramics caused by a Vickers indenter. As the opening angle

φ of such an indenter is 136° leading to

all such angular dependencies are neglected.

Lateral cracks are assumed to develop if a threshold load

F0 is exceeded. This threshold can be calculated as [

12]:

here,

ES is Young’s Modulus,

KIC is the fracture toughness, and

HS is the hardness of the substrate.

If the threshold load

F0 is exceeded by the impact force

Fi of the particle, a lateral crack is formed. Its length

cL can be calculated as [

14]:

where the material constant

c2 is:

The depth

h of the lateral crack is taken to be equal to the depth of the plastic zone (area marked black in

Figure 5) for a Vickers indenter [

14]:

If the lateral crack starts at a depth

h from the substrate surface and the lateral crack reaches the surfaces at a distance

cL from its origin, a cap-shaped segment is formed (see

Figure 5). The mass m of this segment is then considered to be removed per single impact on brittle material (if

Fi >

F0) and can be calculated as:

In case of a metal substrate, this removal of mass happens to sticking particles which are already embedded.

If the substrate is ceramic, the removal of mass according to the formation of cracks is the dominating process. Although the material used in this study is ductile metal, it is exposed to a stream of incident brittle particles. Depending on the exact impact conditions, these particles may form a protective layer at the surface (cladding). Thus, this situation would be treated as ‘brittle substrate’ and mass will be removed according to the formation of cracks. In any case, the ductile metal surface will be ‘injected’ with brittle fragments during erosion by solid particles. The substrate will no longer be as ductile as at the beginning of this process. Depending on the number of ceramic/brittle fragments of earlier impacts in the contact zone, there is a probability that mass can and will be removed according to the formation of cracks.

3.4. Creation of Impacting Particles

During the simulation, impacting particles were generated until their impacting mass reached 100 g. According to

Figure 1, the average ‘diameter’ is about 26 μm. For spherical particles, this would lead to a particle volume around 8800 μm

3. If particles are more angular, this ‘diameter’ would be the edge length of a cube, leading to particle volume around 16,800 μm

3. Therefore, the volumes of particles were created according to a Gaussian distribution around an average volume of 12,000 μm

3 and a width of ±4000 μm

3 (see

Figure 6a). In order to reach 100 g of impacting mass, the number of particles to be generated lies approximately between 1.6 × 10

9 and 3.1 × 10

9. Due to probability/Monte-Carlo issues, two simulations using exactly the same parameters will produce similar, but never the same results.

SEM images of the erosion powder/particles are presented in

Figure 6b,c. The circles highlight particles as an example for angular shape (red circle) and more spherical shape (blue circle). These images revealed that 90% of the particles were angular-shaped, causing slightly more damage (than spherical-shaped once) due to ploughing actions even under 90° impact angle. The dicing process was adjusted accordingly so that the respective number of particles for each shape was produced. If the current impacting particle had a ‘spherical’ shape, the third root was calculated of the particle volume in order to obtain the edge-length of the actual particle. If the particle is supposed to have an ‘angular’ shape, the process adopts a cuboid form, where at least one dimension is larger (which one is arbitrary) than the others. The respective calculations are carried out in micrometers. The dimensions of the particles are then converted into cubes.

Fractions of cubes are dealt with according to the procedure described for the conversion of the penetration depth. Currently, the particles are assumed always to hit with their long axis perpendicular to the surface. In order to keep calculation times low and still account for the ploughing action of angular particles, each such particle had a 5% chance to arbitrarily create excess damage.

Each particle was then ‘equipped’ with an impact velocity. The impact velocity of the particles was assumed to be Gaussian distributed around an average of 204 m/s with a width of ±20 m/s. In

Figure 6b, the velocity distribution of the impacting particles is presented as it was generated during the simulation.

The characteristics of the nozzle (nozzle size, particle flow rate, standoff distance, etc.), emitting the particles in the experiment was supposed to lead to a Gaussian distribution of the particle impacts on the substrate. It was assumed that the nozzle would sit directly opposite the center of a 5 mm × 5 mm area. The width of this Gaussian distribution was assumed to be 600 μm. The impact site of each current particle was generated in a dicing process accordingly.