Combating the Tribo-Corrosion of LDX2404 Lean Duplex Stainless Steel by Low Temperature Plasma Nitriding

Abstract

:1. Introduction

2. Experimental

2.1. Material and Treatments

2.2. Microstructure Characterisation

2.3. Mechanical and Chemical Properties

3. Results

3.1. Layer Structure and Chemical Composition of Plasma Nitrided Samples

3.2. Phase Identification of Plasma Nitrided Layers

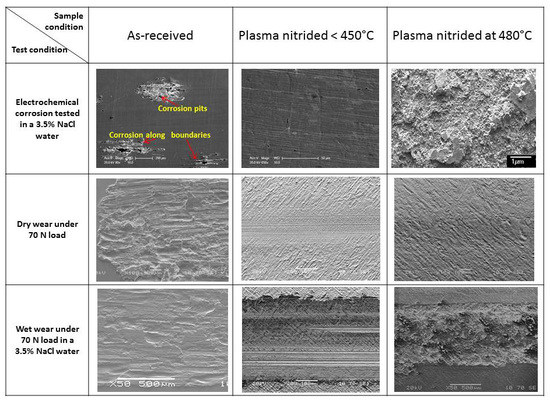

3.3. Corrosion Resistance of Plasma Nitrided Samples

3.4. Surface Hardness, Dry Wear and Corrosion-Wear

4. Discussion

4.1. The Response of LDX2404 Duplex Stainless Steel to Plasma Nitriding

4.2. Corrosion-Wear

5. Conclusions

- (1)

- Plasma nitriding of LDX 2404 lean duplex stainless steels forms a hardened surface layer with the thickness ranging from 5 to 28 μm depending on the treatment temperatures. The surface hardness of the nitrided layers is between two and four times higher than that of the untreated sample.

- (2)

- The response of the original duplex phases of ferrite and austenite to plasma nitriding differs greatly. When low temperature plasma nitrided (T < 450 °C), the original austenite grains in the surface of the LDX 2404 lean duplex stainless steel forms the S-phase (i.e., nitrogen supersaturated expanded austenite) whilst ε-Fe3N needles were precipitated from nitrogen saturated ferrite grains (αN).

- (3)

- The effect of plasma nitriding on the corrosion behaviour of LDX 2404 lean duplex stainless steel is closely related to the treatment temperature. The corrosion properties of the low-temperature treated PN390 and PN420 samples outperformed the relatively high-temperature treated PN450 and PN480 samples.

- (4)

- When tested under 30 N and 70 N, the dry wear resistance of LDX 2404 steel can be drastically improved by all the investigated plasma nitriding treatments, except for the PN390. The best performing PN450 sample can increase the dry wear resistance by 7.8 × 102 times than the untreated material.

- (5)

- Unlike dry wear, the corrosion-wear resistance of LDX2404 material can be effectively improved only by low temperature PN390 and PN420 treatments since corrosion-wear is the synergy of wear and corrosion. The PN420 treatment can provide the best improvement in corrosion-wear resistance by 8.1 times than the untreated sample.

- (6)

- Plasma nitriding for 10 h at 450 °C (i.e., PN450) and at 420 °C (i.e., PN420) have been identified as the best plasma nitriding treatments of LDX2404 lean duplex stainless steels for dry wear and corrosion-wear applications, respectively.

Author Contributions

Funding

Conflicts of Interest

References

- Elhoud, A.M.; Renton, N.C.; Deans, W.F. Hydrogen embrittlement of super duplex stainless steel in acid solution. Int. J. Hydrogen Energy 2010, 35, 6455–6464. [Google Scholar] [CrossRef]

- Li, X.Y.; Dong, H. Effect of annealing on corrosion behaviour of nitrogen S phase in austenitic stainless steel. Mater. Sci. Technol. 2003, 19, 1427–1434. [Google Scholar] [CrossRef]

- Fossati, A.; Borgioli, F.; Galvanetto, E.; Bacci, T. Corrosion resistance properties of glow-discharge nitrided AISI 316L austenitic stainless steel in NaCl solutions. Corros. Sci. 2006, 48, 1513–1527. [Google Scholar] [CrossRef]

- Dong, H. S-phase surface engineering of Fe-Cr, Co-Cr and Ni-Cr alloys. Int. Mater. Rev. 2010, 55, 65–98. [Google Scholar] [CrossRef]

- Li, X.Y.; Habibi, N.; Bell, T.; Dong, H. Microstructural characterisation of a plasma carburised low-carbon Co-Cr alloy. Surf. Eng. 2007, 23, 45–51. [Google Scholar] [CrossRef]

- Li, X.Y.; Buhagiar, J.; Dong, H. Characterisation of dual S phase layer on plasma carbonitrided biomedical austenitic stainless steels. Surf. Eng. 2010, 26, 67–73. [Google Scholar] [CrossRef]

- Li, W.; Li, X.; Dong, H. Effect of tensile stress on the formation of S-phase during low temperature plasma carburising of 316L foil. Acta Mater. 2011, 59, 5765–5774. [Google Scholar] [CrossRef]

- Liu, R.; Li, X.; Dong, H. Surface modification of medical grade Co-Cr alloys by low-temperature plasma surface alloying with nitrogen and carbon. Surf. Coat. Technol. 2013, 232, 906–911. [Google Scholar] [CrossRef]

- Tschiptschin, A.P.; Varela, L.; Pinedo, C.E.; Li, X.Y.; Dong, H. Development and microstructure characterization of single and duplex nitriding of UNS S31803 duplex stainless steel. Surf. Coat. Technol. 2017, 327, 83–92. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.Y.; Bell, T.; Dong, H. Improving the wear properties of Stellite 21 alloy by plasma surface alloying with carbon and nitrogen. Wear 2006, 264, 157–165. [Google Scholar] [CrossRef]

- Bielawski, J.; Baranowska, J. Formation of nitrided layers on duplex steel—Influence of multiphase substrate. Surf. Eng. 2010, 26, 299–304. [Google Scholar] [CrossRef]

- Li, X.Y.; Roberts, R.; Dou, W.B.; Dong, H.S. Low temperature plasma surface alloying and characterisation of a superduplex stainless steel. Int. Heat Treat. Surf. Eng. 2014, 8, 61–64. [Google Scholar] [CrossRef]

- Chiu, L.H.; Su, Y.Y.; Chen, F.S.; Chang, H. Microstructure and Properties of Active Screen Plasma Nitrided Duplex Stainless Steel. Mater. Manuf. Process. 2010, 25, 316–323. [Google Scholar] [CrossRef]

- Outokumpu-Duplex-Stainless-Steel-Data-Sheet. Available online: https://www.californiaboiler.com/product-brochures/Outokumpu-Duplex-Stainless-Steel-Data-Sheet.pdf (accessed on 19 July 2018).

- Wriedt, H.A.; Gokcen, N.A.; Nafziger, R.H. Bulletin of Alloy Phase Diagrams; Springer US: New York, NY, USA, 1987; Volume 8. [Google Scholar]

- Tayyaba, Q.; Farooq, H.; Shahid, M.; Jadoon, A.K.; Shahzad, M.; Qureshi, A.H. On the stress corrosion cracking of lean duplex steel in chloride environment. IOP Conf. Ser. Mater. Sci. Eng. 2014, 60, 012066. [Google Scholar] [CrossRef] [Green Version]

- Larisch, B.; Brusky, U.; Spies, H.J. Plasma nitriding of stainless steels at low temperatures. Surf. Coat. Technol. 1999, 116–119, 205–211. [Google Scholar] [CrossRef]

- Blawert, C.; Mordike, B.L.; Jirásková, Y.; Schneeweiss, O. Structure and composition of expanded austenite produced by nitrogen plasma immersion ion implantation of stainless steels X6CrNiTi1810 and X2CrNiMoN2253. Surf. Coat. Technol. 1999, 116–119, 189–198. [Google Scholar] [CrossRef]

- Bachus, L.; Custodio, A. Chapter 16—Avoiding wear in centrifugal pumps. In Know and Understand Centrifugal Pumps; Elsevier Inc.: Amsterdam, The Netherlands, 2003; pp. 232–237. [Google Scholar]

- Marinescu, I.D.; Rowe, W.B.; Dimitrov, B.; Inasaki, I. Tribochemistry of Abrasive Machining-15. In Tribology of Abrasive Machining Processes; Elsevier Inc.: Amsterdam, The Netherlands, 2004; pp. 587–633. [Google Scholar]

| Outokumpu Steel Name | International Steel Grade | Chemical Composition, wt % Typical Values | |||||||

|---|---|---|---|---|---|---|---|---|---|

| UNS | EN | ISO | C | N | Cr | Ni | Mo | Others | |

| LDX 2404 | S82441 | 1.4662 | 4662-824-41-X | 0.02 | 0.27 | 24.00 | 3.60 | 1.60 | 3Mn Cu |

| Sample Code | Temperature, °C | Time, h | Gas Composition |

|---|---|---|---|

| PN390/10 | 390 | 10 | 25%N2 + 75%H2 |

| PN420/10 | 420 | ||

| PN450/10 | 450 | ||

| PN480/10 | 480 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Dou, W.; Tian, L.; Dong, H. Combating the Tribo-Corrosion of LDX2404 Lean Duplex Stainless Steel by Low Temperature Plasma Nitriding. Lubricants 2018, 6, 93. https://doi.org/10.3390/lubricants6040093

Li X, Dou W, Tian L, Dong H. Combating the Tribo-Corrosion of LDX2404 Lean Duplex Stainless Steel by Low Temperature Plasma Nitriding. Lubricants. 2018; 6(4):93. https://doi.org/10.3390/lubricants6040093

Chicago/Turabian StyleLi, Xiaoying, Wenbo Dou, Linhai Tian, and Hanshan Dong. 2018. "Combating the Tribo-Corrosion of LDX2404 Lean Duplex Stainless Steel by Low Temperature Plasma Nitriding" Lubricants 6, no. 4: 93. https://doi.org/10.3390/lubricants6040093

APA StyleLi, X., Dou, W., Tian, L., & Dong, H. (2018). Combating the Tribo-Corrosion of LDX2404 Lean Duplex Stainless Steel by Low Temperature Plasma Nitriding. Lubricants, 6(4), 93. https://doi.org/10.3390/lubricants6040093