Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Computer Simulation

2.3. Structural Studies

2.4. Study of Physical Mechanical Properties

3. Research Results and Discussion

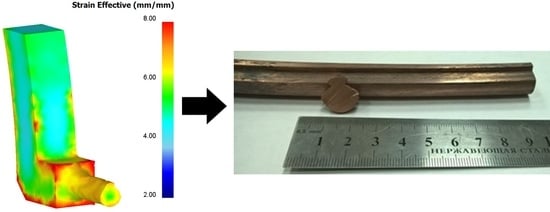

3.1. Computer Simulation of ECAP-C Processes

3.2. Physical Experiment

3.2.1. Microstructural Analysis

3.2.2. X-ray Structural Analysis

3.2.3. Physical Mechanical Properties

4. Conclusions

- A computer simulation was found that during ECAP-C with wire forming a compressive stress of ≥ 500 MPa prevailed in the deformation region, which is known to be beneficial for the material workability.

- Physical experiments enabled the processing of contact wire samples for HS railway lines with complex of physical, mechanical, and service properties that meet modern requirements. The ultimate tensile strength was 560 ± 20 MPa, with an electrical conductivity of 76 ± 2% IACS and a relative tensile elongation of 20 ± 2%.

- The maximum contribution to the refinement therewith was found to be associated with ECAP with wire forming, which resulted in the production of a band structure with a mean size of fragments inside the bands of 300 ± 20 nm (TEM), a CSR of ~110 nm, and a dislocation density of 2.65 × 1014 m−2. Secondary phase precipitations with an average size of 20 ± 2 nm (TEM) are mainly located at the boundaries of the structure fragments. The distance between particles was 160 ± 15 nm.

- Further ageing at 450 °C for 1 h led to the growth of the CSR up to 160 ± 10 nm, with a decrease in the dislocation density, down to 1.65 × 1014 m−2. The average size of fine particles increased to 30 ± 3 nm, and the distance between them decreased to 110 ± 10 nm.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Song, Y.; Liu, Z.; Duan, F.; Xu, Z.; Lu, X. Wave propagation analysis in high-speed railway catenary system subjected to a moving pantograph. Appl. Math. Mod. 2018, 59, 20–38. [Google Scholar] [CrossRef]

- Gershman, I.S.; Mironos, N.V. Requirements to contact wires for high-speed railway transport. Mess. Vniizht 2011, 3, 13–17. (In Russian) [Google Scholar]

- Loginov, Y.; Mysik, R. Continuous Casting and Rolling Methods in the Manufacture of Contact wire for Railway Transport. J. SFU Eng. Technol. 2014, 7, 316–326. (In Russian) [Google Scholar]

- Asfandiyarov, R.N.; Raab, G.I.; Aksenov, D.A. Modeling of a combined process for the production of contact wires for high-speed railways. IOP Conf. Ser. Mater. Sci. Eng. 2018, 461, 12001. [Google Scholar] [CrossRef]

- Nagasawa, H.; Aoki, S.; Kawakita, S. Production of copper alloy trolley wire and hanging stringing. JP Patent 6154838, 3 June 2014. [Google Scholar]

- Ymazaki, A. Copper alloy trolley wire. JP Patent 9279269, 28 October 1997. [Google Scholar]

- Chandler, T.; Corrado, J. Copper trolley wire and method of manufacturing copper trolley wire. U.S. Patent 6077364, 20 June 2000. [Google Scholar]

- Kubo, N.; Nanjo, K.; Sano, T. Trolley wire and manufacturing method. JP Patent 4171907, 29 October 2008. [Google Scholar]

- Kuroda, H.; Hiruta, H.; Aoyama, M. Copper alloy material, copper alloy conductor and its production method, trolley wire for overhead contact wire, and cable. JP Patent 5147040, 20 February 2013. [Google Scholar]

- Berent, V. Method of producing of contact wires. RUS Patent 2236918, 27 September 2004. (In Russian). [Google Scholar]

- Feng, H.; Jiang, H.; Yan, D.; Rong, L. Effect of continuous extrusion on the microstructure and mechanical properties of a CuCrZr alloy. Alloy. Mater. Sci. Eng. A. 2013, 582, 219–224. [Google Scholar] [CrossRef]

- Yuan, Y.; Dai, C.; Li, Z.; Yang, G.; Liu, Y.; Xiao, Z. Microstructure evolution of Cu–0.2Mg alloy during continuous extrusion process. J. Mater. Res. 2015, 30, 2783–2791. [Google Scholar] [CrossRef]

- Yuan, Y.; Li, Z.; Xiao, Z.; Zhao, Z.; Yang, Z. Microstructure evolution and properties of Cu-Cr alloy during continuous extrusion process. J. Alloys Compd. 2017, 703, 454–460. [Google Scholar] [CrossRef]

- Zhu, C.; Ma, A.; Jiang, J.; Li, X.; Song, D.; Yang, D.; Yuan, Y.; Chen, J. Effect of ECAP combined cold working on mechanical properties and electrical conductivity of Conform-produced Cu–Mg alloys. J. Alloys Compd. 2014, 582, 135–140. [Google Scholar] [CrossRef]

- Elcowire. Our Product Range. Available online: https://www.elcowire.com/wp-content/uploads/productrange.pdf (accessed on 19 August 2020).

- Aluminum Association. Conform Technology: From Ingot to Electric Conductor. Available online: http://www.aluminas.ru/en/media/news/technology_conform_from_the_raw_material_to_conductive_core/ (accessed on 19 August 2020).

- Dawson, J.R. Conform Technology for Cost Effective Manufacture of Copper Strip. Available online: https://www.rautomead.com/uploads/files/1515577710BWEconformprocess.pdf (accessed on 19 August 2020).

- Faizov, I.; Raab, G.; Aksenov, D. Contributions of various strengthening mechanisms to the flow onset stress in the ECAP-processed Cu-Cr-Zr Alloy. Key Eng. Mater. 2017, 743, 197–202. [Google Scholar] [CrossRef]

- Faizov, I.A.; Raab, G.I.; Faizova, S.N.; Zaripov, N.G.; Aksenov, D.A. The role of phase transitions in the evolution of dispersion particles in chromium bronzes upon the equal channel angular pressing. Lett. Mater. 2016, 6, 132–137. (In Russian) [Google Scholar] [CrossRef] [Green Version]

- Vinogradov, A.; Ishida, T.; Kitagawa, K.; Kopylov, V.I. Effect of strain path on structure and mechanical behavior of ultrafine grain Cu–Cr alloy produced by equal-channel angular pressing. Acta. Mater. 2005, 53, 2181–2192. [Google Scholar] [CrossRef]

- Shan’gina, D.V.; Bochvar, N.R.; Dobatkin, S.V. Structure and properties of Cu-Cr alloys subjected to shear under pressure and subsequent heating. Russ. Metal. 2011, 11, 1046–1052. [Google Scholar] [CrossRef]

- Islamgaliev, R.K.; Nesterov, K.M.; Bourgon, J.; Champion, Y.; Valiev, R.Z. Nanostructured Cu-Cr alloy with high strength and electrical conductivity. J. Appl. Phys. 2014, 115, 194301. [Google Scholar] [CrossRef]

- Aksenov, D.A.; Asfandiyarov, R.; Raab, G.I.; Isyandavletova, G.B. Features of the physico-mechanical behavior of UFG low-alloyed bronze Cu-1Cr-0.08Zr produced by severe plastic deformation. IOP Conf. Ser. Mater. Sci. Eng. 2017, 4, 12001. [Google Scholar] [CrossRef] [Green Version]

- Loginov, Y. Copper and Deformable Copper Alloys; UGTU: Ekaterinburg, Russia, 2006; p. 136. (In Russian) [Google Scholar]

- Leoni, M.; Confente, T.; Scardi, P. PM2K: A flexible program implementing Whole Powder Pattern Modelling. Z. Krist. Suppl. 2006, 23, 249–254. [Google Scholar] [CrossRef]

- Morozova, A.; Mishnev, R.; Belyakov, A.; Kaibyshev, R. Microstructure and properties of fine grained Cu-Cr-Zr alloys after termo-mechanical treatments. Adv. Mater. Sci. 2018, 54, 56–92. [Google Scholar] [CrossRef]

- Utyashev, F.Z.; Raab, G.I. Mechanisms and model of structure formation in metals during severe deformation. Phys. Technol. High Press. 2006, 16, 73–78. [Google Scholar]

- Chen, X.; Jiang, F.; Jiang, J.; Xu, P.; Tong, M.; Tang, Z. Precipitation, Recrystallization, and Evolution of Annealing Twins in a Cu-Cr-Zr Alloy. Metals 2018, 8, 227. [Google Scholar] [CrossRef] [Green Version]

| State | CSR, nm | Microdeformation, ehkl, % | Dislocation Density ρ, 1014 m−2 | Lattice Parameter, Ǻ |

|---|---|---|---|---|

| Initial (radial swaging) | 220 ± 12 | 0.127 ± 0.021 | 1.71 ± 0.02 | 3.6170 ± 0.0004 |

| ECAP with a wire forming | 110 ± 10 | 0.158 ± 0.025 | 2.65 ± 0.04 | 3.6160 ± 0.0007 |

| ECAP with a wire forming + aging at 450 °C, 1 h | 160 ± 10 | 0.120 ± 0.020 | 1.65 ± 0.02 | 3.6150 ± 0.0006 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asfandiyarov, R.N.; Raab, G.I.; Aksenov, D.A. Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines. Metals 2020, 10, 1476. https://doi.org/10.3390/met10111476

Asfandiyarov RN, Raab GI, Aksenov DA. Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines. Metals. 2020; 10(11):1476. https://doi.org/10.3390/met10111476

Chicago/Turabian StyleAsfandiyarov, Rashid N., Georgy I. Raab, and Denis A. Aksenov. 2020. "Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines" Metals 10, no. 11: 1476. https://doi.org/10.3390/met10111476

APA StyleAsfandiyarov, R. N., Raab, G. I., & Aksenov, D. A. (2020). Study of the Combined Severe Plastic Deformation Techniques Applied to Produce Contact Wire for High-Speed Railway Lines. Metals, 10(11), 1476. https://doi.org/10.3390/met10111476