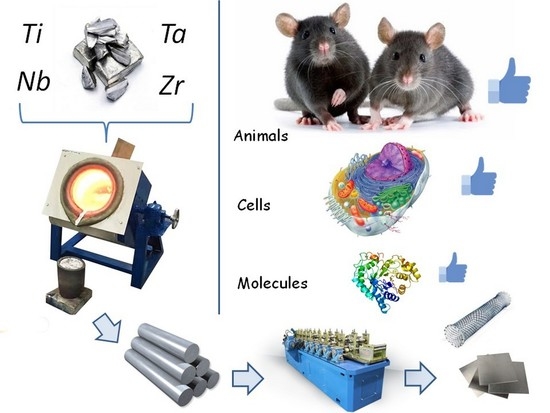

Manufacturing and Study of Mechanical Properties, Structure and Compatibility with Biological Objects of Plates and Wire from New Ti-25Nb-13Ta-5Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Manufacturing of the Ti–25Nb–13Ta–5Zr Alloy

2.2. Preparation of Ti–25Nb–13Ta–5Zr Alloy Plates and Wire

2.3. Study of Physicochemical and Mechanical Properties of the Alloy

2.4. Detection of Long-Lived Reactive Protein Species (LRPS)

2.5. Detection of Reactive Oxygen Species (ROS)

2.6. Cell Culture

2.7. Experimental Animals

2.8. Implantation Model

3. Results

3.1. Characteristics of the Ti–25Nb–13Ta–5Zr Alloy

3.2. Influence of the Ti–25Nb–13Ta–5Zr Alloy on Biological Macromolecules

3.3. Influence of the Ti–25Nb–13Ta–5Zr Alloy on Cell Cultures

3.4. Influence of the Ti–25Nb–13Ta–5Zr Alloy on Animal Tissue during Implantation

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gluck, T. Report on the Positive Results Obtained by the Modern Surgical Experiment Regarding the Suture and Replacement of Defects of Superior Tissue, as well as the Utilization of Re-absorbable and Living Tamponade in Surgery. Clin. Orthop. Relat. Res. 2011, 469, 1528–1535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Condon, R.E.; Beder, O.E. A study of titanium implants in a corrosion-producing environment. Surgery 1964, 55, 714–717. [Google Scholar] [PubMed]

- Leventhal, G.S. Titanium, a metal for surgery. J. Bone Jt. Surg. 1951, 33, 473–474. [Google Scholar] [CrossRef] [Green Version]

- Hirakawa, K. Letter to the editor on “Titanium neck-titanium stem corrosion in a modular neck stem”. Arthroplast. Today 2020, 6, 129. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef]

- Khan, W.S.; Agarwal, M.; Malik, A.A.; Cox, A.G.; Denton, J.; Holt, E.M. Chromium, cobalt and titanium metallosis involving a Nottingham shoulder replacement. J. Bone Jt. Surg. Br. 2008, 90, 502–505. [Google Scholar] [CrossRef]

- Gibson, T. Biomechanics in plastic surgery. In Biomechanics and Related Bio-Engineering Topics; Elsevier: Amsterdam, The Netherlands, 1965; pp. 129–134. [Google Scholar]

- Civjan, S.; Huget, E.F.; DeSimon, L.B. Potential applications of certain nickel-titanium (nitinol) alloys. J. Dent. Res. 1975, 54, 89–96. [Google Scholar] [CrossRef]

- Sherif, M.M.; Ozbulut, O.E. Tensile and superelastic fatigue characterization of NiTi shape memory cables. Smart Mater. Struct. 2018, 27, 015007. [Google Scholar] [CrossRef]

- Ort, M.J.; Geissler, S.; Rakow, A.; Schoon, J. The Allergic Bone Marrow? The Immuno-Capacity of the Human Bone Marrow in Context of Metal-Associated Hypersensitivity Reactions. Front. Immunol. 2019, 10, 2232. [Google Scholar] [CrossRef] [Green Version]

- Shimojo, N.; Kondo, C.; Yamashita, K.; Hoshino, T.; Hayakawa, T. Cytotoxicity analysis of a novel titanium alloy in vitro: Adhesion, spreading, and proliferation of human gingival fibroblasts. Biomed Mater. Eng. 2007, 17, 127–135. [Google Scholar]

- Karolewska, K.; Ligaj, B.; Wirwicki, M.; Szala, G. Strength analysis of Ti6Al4V titanium alloy produced by the use of additive manufacturing method under static load conditions. J. Mater. Res. Tech. 2019, 8, 1365–1379. [Google Scholar] [CrossRef]

- Hao, F.; Xiao, J.; Feng, Y.; Wang, Y.; Ju, J. Tensile deformation behavior of a near-α titanium alloy Ti-6Al-2Zr-1Mo-1V under a wide temperature range. J. Mater. Res. Tech. 2020, 9, 2818–2831. [Google Scholar] [CrossRef]

- Lee, J.; Park, H.; Kim, J.; Jang, J.; Hong, S.; Oh, I. Constitutive behavior and microstructural evolution in Ti–Al–Si ternary alloys processed by mechanical milling and spark plasma sintering. J. Mater. Res. Tech. 2020, 9, 2247–2258. [Google Scholar] [CrossRef]

- Biesiekierski, A.; Wang, J.; Gepreel, M.A.N.; Wen, C. A New Look at Biomedical Ti-Based Shape Memory Alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef] [PubMed]

- Rabadia, C.D.; Liu, Y.J.; Wang, L.; Sun, H.; Zhang, L.C. Laves phase precipitation in Ti-Zr-Fe-Cr alloys with high strength and large plasticity. Mater. Des. 2018, 154, 228–238. [Google Scholar] [CrossRef]

- Jawed, S.F.; Rabadia, C.D.; Liu, Y.J.; Wang, L.Q.; Li, Y.H.; Zhang, X.H.; Zhang, L.C. Mechanical characterization and deformation behavior of β-stabilized Ti-Nb-Sn-Cr alloys. J. Alloy. Compd. 2019, 792, 684–693. [Google Scholar] [CrossRef]

- Dargusch, M.S.; Wang, G.; Kent, D.; Bermingham, M.; Venezuela, J.; Frith, J.E.; Yu, Z.; Yu, S.; Shi, Z. Comparison of the Microstructure and Biocorrosion Properties of Additively Manufactured and Conventionally Fabricated near β Ti–25Nb–3Zr–3Mo–2Sn Alloy. ACS Biomater. Sci. Eng. 2019, 5, 5844–5856. [Google Scholar] [CrossRef]

- Kuroda, D.; Kawasaki, H.; Yamamoto, A.; Hiromoto, S.; Hanawa, T. Mechanical properties and microstructures of new Ti–Fe–Ta and Ti–Fe–Ta–Zr system alloys. Mater. Sci. Eng. C 2005, 25, 312–320. [Google Scholar] [CrossRef]

- Okazaki, Y.; Rao, S.; Ito, Y.; Tateishi, T. Corrosion resistance, mechanical properties, corrosion fatigue strength and cytocompatibility of new Ti alloys without Al and V. Biomaterials 1998, 19, 1197–1215. [Google Scholar] [CrossRef]

- Okazaki, Y.; Gotoh, E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials 2005, 26, 11–21. [Google Scholar] [CrossRef]

- Ban, S. Effect of alkaline treatment of pure titanium and its alloys on the bonding strength of dental veneering resins. J. Biomed Mater. Res. 2003, 66, 138–145. [Google Scholar] [CrossRef] [PubMed]

- Sevostyanov, M.A.; Kolmakov, A.G.; Sergiyenko, K.V.; Kaplan, M.A.; Baikin, A.S.; Gudkov, S.V. Mechanical, physical-chemical and biological properties of the new Ti-30Nb-13Ta-5Zr alloy. J. Mater. Sci. 2020, 55, 14516–14529. [Google Scholar] [CrossRef]

- Konushkin, S.V.; Sergiyenko, K.V.; Nasakina, E.O.; Leontyev, V.G.; Kuznetsova, O.G.; Titov, D.D.; Tsareva, A.M.; Dormidontov, N.A.; Kirsankin, A.A.; Kannykin, S.V.; et al. Study of the physicochemical and biological properties of the new promising Ti–20Nb–13Ta–5Zr alloy for biomedical applications. Mater. Chem. Phys. 2020, 255, 123557. [Google Scholar] [CrossRef]

- Sevostyanov, M.A.; Losertova, M.; Nasakina, E.O. Corrosive researches of nonnickel shape memory alloy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 525, 012068. [Google Scholar] [CrossRef]

- Sailer, I.; Philipp, A.; Zembic, A. A systematic review of the performance of ceramic and metal implant abutments supporting fixed implant reconstructions. Clin. Oral Implants Res. 2009, 20, 4–31. [Google Scholar] [CrossRef] [Green Version]

- Wei, Q.; Wang, L.; Fu, Y. Influence of oxygen content on microstructure and mechanical properties of Ti–Nb–Ta–Zr alloy. Mater. Des. 2011, 32, 2934–2939. [Google Scholar] [CrossRef]

- Li, B.Q.; Xie, R.Z.; Lu, X. Microstructure, mechanical property and corrosion behavior of porous Ti-Ta-Nb-Zr. Bioact. Mater. 2020, 5, 564–568. [Google Scholar] [CrossRef]

- Chen, J.; Ma, F.; Liu, P. Effects of Nb on superelasticity and low modulus properties of metastable β-type Ti-Nb-Ta-Zr biomedical alloys. J. Mater. Eng. Perform 2019, 28, 1410–1418. [Google Scholar] [CrossRef]

- Niinomi, M. Fatigue performance and cyto-toxicity of low rigidity titanium alloy, Ti-29Nb-13Ta-4.6Zr. Biomaterials 2003, 24, 2673–2683. [Google Scholar] [CrossRef]

- Zhang, L.C.; Chen, L.Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv. Eng. Mater. 2019, 21, 1801215. [Google Scholar] [CrossRef] [Green Version]

- Kusoglu, I.M.; Gökce, B.; Barcikowski, S. Research trends in laser powder bed fusion of Al alloys within the last decade. Addit. Manuf. 2020, 36, 101489. [Google Scholar] [CrossRef]

- Barkhudarov, E.M.; Kossyi, I.A.; Anpilov, A.M.; Ivashkin, P.I.; Artem’ev, K.V.; Moryakov, I.V.; Misakyan, M.A.; Christofi, N.; Burmistrov, D.E.; Smirnova, V.V.; et al. New Nanostructured Carbon Coating Inhibits Bacterial Growth, but Does Not Influence on Animal Cells. Nanomaterials 2020, 10, 2130. [Google Scholar] [CrossRef] [PubMed]

- Dolgaev, S.I.; Lavrishev, S.V.; Lyalin, A.A.; Simakin, A.V.; Voronov, V.V.; Shafeev, G.A. Formation of conical microstructures upon laser evaporation of solids. Appl. Phys. A 2001, 73, 177–181. [Google Scholar] [CrossRef]

- Barmina, E.V.; Stratakis, E.; Barberoglou, M.; Stolyarov, V.N.; Stolyarov, I.N.; Fotakis, C.; Shafeev, G.A. Laser-assisted nanostructuring of Tungsten in liquid environment. Appl. Surf. Sci. 2012, 258, 5898–5902. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Guryev, E.L.; Gapeyev, A.B.; Sharapov, M.G.; Bunkin, N.F.; Shkirin, A.V.; Zabelina, T.S.; Glinushkin, A.P.; Sevost’yanov, M.A.; Belosludtsev, K.N.; et al. Unmodified hydrated C60 fullerene molecules exhibit antioxidant properties, prevent damage to DNA and proteins induced by reactive oxygen species and protect mice against injuries caused by radiation-induced oxidative stress. Nanomed. Nanotechnol. Biol. Med. 2019, 15, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Sharapov, M.G.; Novoselov, V.I.; Fesenko, E.E.; Bruskov, V.I.; Gudkov, S.V. The role of peroxiredoxin 6 in neutralization of X-ray mediated oxidative stress: Effects on gene expression, preservation of radiosensitive tissues and postradiation survival of animals. Free Radic. Res. 2017, 51, 148–166. [Google Scholar] [CrossRef] [PubMed]

- Ivanov, V.E.; Usacheva, A.M.; Chernikov, A.V.; Bruskov, V.I.; Gudkov, S.V. Formation of long-lived reactive species of blood serum proteins induced by low-intensity irradiation of helium-neon laser and their involvement in the generation of reactive oxygen species. J. Photochem. Photobiol. B 2017, 176, 36–43. [Google Scholar] [CrossRef]

- Gudkov, S.V.; Penkov, N.V.; Baimler, I.V.; Lyakhov, G.A.; Pustovoy, V.I.; Simakin, A.V.; Sarimov, R.M.; Scherbakov, I.A. Effect of Mechanical Shaking on the Physicochemical Properties of Aqueous Solutions. Int. J. Mol. Sci. 2020, 21, 8033. [Google Scholar] [CrossRef]

- Simakin, A.V.; Astashev, M.E.; Baimler, I.V.; Uvarov, O.V.; Voronov, V.V.; Vedunova, M.V.; Sevost’yanov, M.A.; Belosludtsev, K.N.; Gudkov, S.V. The Effect of Gold Nanoparticles Concentration and Laser Fluence on the Laser-Induced Water Decomposition. J. Phys. Chem. B 2019, 123, 1869–1880. [Google Scholar] [CrossRef]

- Sevostyanov, M.A.; Baikin, A.S.; Sergienko, K.V.; Shatova, L.A.; Kirsankin, A.A.; Baymler, I.V.; Shkirin, A.V.; Gudkov, S.V. Biodegradable stent coatings on the basis of PLGA polymers of different molecular mass, sustaining a steady release of the thrombolityc enzyme streptokinase. React. Funct. Polym. 2020, 150, 104550. [Google Scholar] [CrossRef]

- Kaplan, M.A.; Sergienko, K.V.; Kolmakova, A.A.; Konushkin, S.V.; Baikin, A.S.; Kolmakov, A.G.; Sevostyanov, M.A.; Kulikov, A.V.; Ivanov, V.E.; Belosludtsev, K.N.; et al. Development of a biocompatible plga polymers with a thrombolytic effect for stents coatings. J. Biomater. Sci. Polym. Ed. 2020, 31, 1405–1420. [Google Scholar] [CrossRef] [PubMed]

- Williams, D.F. Titanium as a metal for implantation. Part 1: Physical properties. J. Med. Eng. Technol. 1977, 1, 195–198. [Google Scholar] [CrossRef] [PubMed]

- Lemons, J.E.; Niemann, K.M.; Weiss, A.B. Biocompatibility studies on surgical-grade titanium-, cobalt-, and iron-base alloys. J. Biomed. Mater. Res. 1976, 10, 549–553. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Hady, M.; Hinoshita, K.; Morinaga, M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scr. Mater. 2006, 55, 477–480. [Google Scholar] [CrossRef]

- Homma, T.; Arafah, A.; Haley, D.; Nakai, M.; Niinomi, M.; Moody, M.P. Effect of alloying elements on microstructural evolution in oxygen content controlled Ti-29Nb-13Ta-4.6Zr (wt%) alloys for biomedical applications during aging. Mater. Sci. Eng. A 2018, 709, 312–321. [Google Scholar] [CrossRef]

- Ishiguro, Y.; Tsukada, Y.; Koyama, T. Phase-field study of the spinodal decomposition rate of β phase in oxygen-added Ti–Nb alloys. Comput. Mater. Sci. 2020, 174, 109471. [Google Scholar] [CrossRef]

- Nagasako, N.; Asahi, R.; Isheim, D.; Seidman, D.N.; Kuramoto, S.; Furuta, T. Microscopic study of gum-metal alloys: A role of trace oxygen for dislocation-free deformation. Acta Mater. 2016, 105, 347–354. [Google Scholar] [CrossRef]

- Sergienko, K.V.; Titov, D.D.; Konushkin, S.V.; Baikin, A.S.; Nasakina, E.O.; Baskakova, M.I.; Bespamiatnova, A. Study of the coefficient of heat expansion of TiNbTaZr alloy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 525, 012092. [Google Scholar] [CrossRef]

- Levashov, E.A.; Petrzhik, M.I.; Shtansky, D.V.; Kiryukhantsev-Korneev, P.V.; Sheveyko, A.N.; Valiev, R.Z.; Gunderov, D.V.; Prokoshkin, S.D.; Korotitskiy, A.V.; Smolin, A.Y. Nanostructured titanium alloys and multicomponent bioactive films: Mechanical behavior at indentation. Mater. Sci. Eng. A 2013, 570, 51–62. [Google Scholar] [CrossRef]

- Cutright, D.E.; Bhaskar, S.N.; Perez, B.; Johnson, R.M.; Cowan, G.S., Jr. Tissue reaction to nitinol wire alloy. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. 1973, 35, 578–584. [Google Scholar] [CrossRef]

- Rajan, G.P.; Eikelboom, R.H.; Anandacoomaraswamy, K.S.; Atlas, M.D. In vivo performance of the Nitinol shape-memory stapes prosthesis during hearing restoration surgery in otosclerosis: A first report. J. Biomed. Mater. Res. Part B 2005, 72, 305–309. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Zhuang, Z.; Frenkel, K.; Klein, C.B.; Costa, M. The role of nickel and nickel-mediated reactive oxygen species in the mechanism of nickel carcinogenesis. Environ. Health Perspect. 1994, 102, 281–284. [Google Scholar] [PubMed] [Green Version]

- Sharapov, M.G.; Novoselov, V.I.; Gudkov, S.V. Radioprotective Role of Peroxiredoxin 6. Antioxidants 2019, 8, 15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Filev, A.D.; Shmarina, G.V.; Ershova, E.S.; Veiko, N.N.; Martynov, A.V.; Borzikova, M.A.; Poletkina, A.A.; Dolgikh, O.A.; Veiko, V.P.; Bekker, A.A.; et al. Oxidized Cell-Free DNA Role in the Antioxidant Defense Mechanisms under Stress. Oxidative Med. Cell. Longev. 2019, 2019, 1245749. [Google Scholar] [CrossRef] [PubMed]

- Gudkov, S.V.; Chernikov, A.V.; Bruskov, V.I. Chemical and radiological toxicity of uranium compounds. Russ. J. Gen. Chem. 2016, 86, 1531–1538. [Google Scholar] [CrossRef]

- Kumagai, J.; Masui, K.; Itagaki, Y.; Shiotani, M.; Kodama, S.; Watanabe, M.; Miyazaki, T. Long-lived mutagenic radicals induced in mammalian cells by ionizing radiation are mainly localized to proteins. Radiat. Res. 2003, 160, 95–102. [Google Scholar] [CrossRef]

| Materials | LRPS, cpm | [H2O2], nM | [•OH], nM | Nonviable Cells, % | MI, % | Density of Cells, cells/mm2 | Free Surface, % |

|---|---|---|---|---|---|---|---|

| Ti | 330 ± 19 | 5.0 ± 0.4 | 30 ± 5 | 4.0 ± 0.7 | 1.1 ± 0.2 | 1050 ± 165 | 32.2 ± 4.0 |

| TiNbTaZr | 390 ± 27 | 5.4 ± 0.6 | 35 ± 7 | 5.0 ± 0.9 | 2.1 ± 0.3 | 1490 ± 175 | 20.3 ± 3.5 |

| NiTi | 495 ± 28 | 13.4 ± 1.3 | 131 ± 15 | 5.8 ± 1.2 | 1.7 ± 0.2 | 1380 ± 225 | 27.3 ± 2.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gudkov, S.V.; Simakin, A.V.; Sevostyanov, M.A.; Konushkin, S.V.; Losertová, M.; Ivannikov, A.Y.; Kolmakov, A.G.; Izmailov, A.Y. Manufacturing and Study of Mechanical Properties, Structure and Compatibility with Biological Objects of Plates and Wire from New Ti-25Nb-13Ta-5Zr Alloy. Metals 2020, 10, 1584. https://doi.org/10.3390/met10121584

Gudkov SV, Simakin AV, Sevostyanov MA, Konushkin SV, Losertová M, Ivannikov AY, Kolmakov AG, Izmailov AY. Manufacturing and Study of Mechanical Properties, Structure and Compatibility with Biological Objects of Plates and Wire from New Ti-25Nb-13Ta-5Zr Alloy. Metals. 2020; 10(12):1584. https://doi.org/10.3390/met10121584

Chicago/Turabian StyleGudkov, Sergey V., Alexander V. Simakin, Mikhail A. Sevostyanov, Sergey V. Konushkin, Monika Losertová, Alexander Yu. Ivannikov, Alexey G. Kolmakov, and Andrey Yu. Izmailov. 2020. "Manufacturing and Study of Mechanical Properties, Structure and Compatibility with Biological Objects of Plates and Wire from New Ti-25Nb-13Ta-5Zr Alloy" Metals 10, no. 12: 1584. https://doi.org/10.3390/met10121584

APA StyleGudkov, S. V., Simakin, A. V., Sevostyanov, M. A., Konushkin, S. V., Losertová, M., Ivannikov, A. Y., Kolmakov, A. G., & Izmailov, A. Y. (2020). Manufacturing and Study of Mechanical Properties, Structure and Compatibility with Biological Objects of Plates and Wire from New Ti-25Nb-13Ta-5Zr Alloy. Metals, 10(12), 1584. https://doi.org/10.3390/met10121584