Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison

Abstract

:1. Introduction

1.1. Background

1.2. Aluminum Alloys Weldability

1.3. Aluminum Alloys for Automotive Field

1.4. Welding Techniques Examined

1.5. Aim of Work

2. Materials and Methods

2.1. Base Metal and Filler Wire Materials

2.2. Design of the Joint

- Cast bar with cast bar (indicated as C-C);

- Extruded bar with cast bar (indicated as E-C); and

- Extruded bar with extruded bar (indicated as E-E).

2.3. Microstructure Characterization

2.4. Hardness Test

3. Results and Discussion

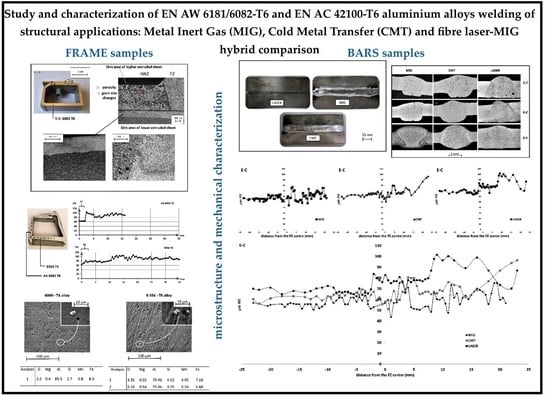

3.1. The Weld Geometry and Weld Defects

3.1.1. Frame Samples

3.1.2. Bar Samples

3.2. Material Characterization Results

3.2.1. Frame Samples

3.2.2. Bar Samples

3.3. Hardness Distribution

- Re-solubilization area (PMZ): In the PMZ, the high temperature (T > 450 °C) induces a complete dissolution of hardening precipitates. During cooling, according to times and temperature reached, the re-precipitation of hardening compounds could be possible.

- Intermediate area: The temperature exceeds 380 °C and the transformation of the equilibrium phase β takes place. Indeed, in this area, located at about 10 mm from the FZ, it is possible to observe the minimum hardness value.

- Over-aging area: 380 < T (°C) < 240. In these zones, the increase in hardness could be justified with the transformation of β” in β’.

- Slightly altered zone: Temperatures do not exceed 240 °C, thus any marked over-aging phenomena of β” can be avoided. In this area, the hardness value tends to be the base material, even if some hardness fluctuations are still present.

3.3.1. Frame Samples

3.3.2. Bar Samples

3.4. SEM Analysis

4. Conclusions

- From a quality point of view, the typical defects of welded aluminum alloys such as porosity and the incomplete penetration were observed mainly in the frame welds. Then, cracks were noticed only in the frame joints, most likely due to a greater difficulty in heat dissipation for higher thicknesses and more complex geometries. In addition, typical casting defects, mainly shrinkage cavities, were found.

- Regarding the macrostructures, a greater quality was observed for the fiber laser joint. Then, the FZ, PMZ, and HAZ microstructures were observed. All joints had similar FZ microstructures, with the weld seam characterized by fine dendrites. The chemical composition of the fusion zone was affected by the addition of UNI ER 4043 filler. The PMZ was even observed at low magnification and its width was greater in the C-C case. In general, the innovative techniques (CMT and fiber laser hybrid) allow a better microstructure to be obtained than the traditional technique (MIG).

- Hardness tests (HRF and micro-HV) demonstrated that the mechanical characteristics of the PMZ and HAZ were better for the innovative techniques due to reduced changes in their microstructure when compared to the MIG technique. In particular, the fiber laser-MIG hybrid technique showed the best behavior, and the CMT welded samples had intermediate characteristics. Considering the relationship between the local temperature peaks reached during the welding process and the hardness value obtained, four HAZ subzones were identified:

- -

- Re-solubilization area (PMZ, T > 450 °C) with a complete dissolution of hardening precipitates and subsequent re-precipitation related to cooling parameters;

- -

- Intermediate area (about 10 mm from FZ, T > 380 °C) where the β transformation takes place;

- -

- Over-aging area: (380 < T (°C) < 240) with the β” to β’ transformation; and

- -

- Slightly altered zone (T < 240 °C) where any marked over-aging phenomena of β” are avoided.

- The best behavior was observed, as expected, for the E-E samples, while the worst results were observed for the C-C combination, especially in the MIG welding, where the hardness values were typical of an annealing. This could be caused by both the high thermal input on thin samples and the high percentage of silicon (~7%) in this cast alloy (low material conductivity and difficult welding heat dissipation). Finally, the E-C coupling showed intermediate properties.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Miller, W.S.; Zhuang, L.; Bottema, J.; Wittebrood, A.J.; De Smet, P.; Haszler, A.; Vieregge, A. Recent development in aluminium alloys for the automotive industry. Mater. Sci. Eng. A 2000, 280, 37–49. [Google Scholar] [CrossRef]

- Cecchel, S.; Cornacchia, G.; Gelfi, M.A. A study of a non-conventional evaluation of results from salt spray test of aluminum High Pressure Die Casting alloys for automotive components. Mater. Corros. 2019, 70, 70–78. [Google Scholar] [CrossRef] [Green Version]

- Heinz, A.; Haszler, A.; Keidel, C.; Moldenhauer, S.; Benedictus, R.; Miller, W.S. Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 2000, 280, 102–107. [Google Scholar] [CrossRef]

- ASM Specialty Handbook. Aluminum and Aluminum Alloys; Davis, J.R., Ed.; ASM International: Geauga, OH, USA, 1993; ISBN 978-0-87170-496-2. [Google Scholar]

- Chindamo, D.; Lenzo, B.; Gadola, M. On the vehicle sideslip angle estimation: A literature review of methods, models and innovations. Appl. Sci. 2018, 8, 355. [Google Scholar] [CrossRef] [Green Version]

- Hirsch, J. Aluminium in Innovative Light-Weight Car Design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef] [Green Version]

- European Commission. Proposal for a Regulation of the European Parliament and of the Council Amending Regulation (EC) No 443/2009 to Define the Modalities for Reaching the 2020 Target to Reduce CO2 Emissions from New Passenger Cars and Proposal for a Regulation of the European Parliament and of the Council Amending Regulation (EU) No 510/2011 to Define the Modalities for Reaching the 2020 Target to Reduce CO2 Emissions from new Light Commercial Vehicles, (European Commission, 2012). Available online: http://eur-lex.europa.eu/resource.html?uri=cellar:70f46993-3c49-4b61ba277319c424cbd.0001.02/DOC_1&format=PDF (accessed on 11 December 2019).

- Helms, H.; Lambrecht, U. The potential contribution of light-weighting to reduce transport energy consumption. Int. J. Life Cycle Assess 2007, 12, 58–64. [Google Scholar]

- Cecchel, S.; Ferrario, D.; Panvini, A.; Cornacchia, G. Lightweight of a cross beam for commercial vehicles: Development, testing and validation. Mater. Des. 2018, 149, 122–134. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life-Cycle Energy and Greenhouse Gas Emission Bene fits of Lightweighting in Automobiles: Review and Harmonization. Environ. Sci. Technol. 2013, 47, 6089–6097. [Google Scholar] [CrossRef]

- ASM Metals Handbook. Welding, Brazing and Soldering, 10th ed.; American Society for Metals: Geauga, OH, USA, 1993; Volume 6. [Google Scholar]

- Cornacchia, G.; Cecchel, S.; Panvini, A. A comparative study of mechanical properties of metal inert gas (MIG)-cold metal transfer (CMT) and fiber laser-MIG hybrid welds for 6005A T6 extruded sheet. Int. J. Adv. Manuf. Technol. 2017, 94, 2017–2030. [Google Scholar] [CrossRef]

- Apelian, D.; Shivkumar, S.; Sigworth, G. Fundamental Aspects of heat treatment of cast Al−Si−Mg alloys. AFS Trans. 1989, 97, 727–742. [Google Scholar]

- Faccoli, M.; Dioni, D.; Cecchel, S.; Cornacchia, G.; Panvini, A. An experimental study to optimize the heat treatment of gravity cast Sr-modified B356 aluminum alloy. Trans. Nonferrous Met. Soc. China 2017, 27, 1698–1706. [Google Scholar] [CrossRef]

- Lados, D.A.; Apelian, D.; Wan, L. Solution treatment effects on microstructure and mechanical properties of Al−(1 to 13 pct)Si−Mg cast alloys. Metall. Mater. Trans. B 2011, 42, 171–180. [Google Scholar] [CrossRef] [Green Version]

- Dioni, D.; Cecchel, S.; Cornacchia, G.; Faccoli, M.; Panvini, A. Effects of artificial aging conditions on mechanical properties of gravity cast B356 aluminum alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 1035–1042. [Google Scholar] [CrossRef]

- Morita, A. Aluminium alloys for automobile applications. In Proceedings of the ICAA-6, Toyohashi, Japan, 5–10 July 1998; Volume 1, pp. 25–32. [Google Scholar]

- Andersen, S.J.; Zandbergen, H.W.; Jansen, J.; Traeholt, C.; Tundal, U.; Reiso, O. “The crystal structure of the β’’ phase in al-mg-si alloys. Acta Mater. 1998, 46, 3283–3298. [Google Scholar] [CrossRef]

- Ikeno, K.M.S.; Sato, T. Hrtem Study of Nano-Precipitation Phases in 6000 Series Aluminum Alloys. Sci. Technol. Educ. Microsc. An Overv. 2003, 152–162. [Google Scholar]

- Maisonnette, D.; Suery, M.; Nelias, D.; Chaudet, P.; Epicier, T. Effects of heat treatments on the microstructure and mechanical properties of a 6061 aluminium alloy. Mater. Sci. Eng. A Struct. Mater. 2011, 528, 2718–2724. [Google Scholar] [CrossRef] [Green Version]

- International Aluminium Institute. Primary Aluminium Production. 22/09/08. 2008. Available online: http://www.world-aluminium.org (accessed on 10 December 2019).

- Voisin, P. Métallurgie extractive de l’aluminium. Techniques de l’ingénieur. Matér. Mét. 1992, 2340, 2340. [Google Scholar]

- Liu, L.; Ren, D.; Liu, F. A Review of Dissimilar Welding Techniques for Magnesium Alloys to Aluminum Alloys. Materials 2014, 7, 3735–3757. [Google Scholar] [CrossRef] [Green Version]

- Cao, X.; Jahazi, M.; Immarigeon, J.P.; Wallace, W. A review of laser welding techniques for magnesium alloys. J. Mater. Process. Technol. 2006, 171, 188–204. [Google Scholar] [CrossRef]

- Abioye, T.E.; Olugbade, T.O.; Ogedengbe, T.I. Welding of Dissimilar Metals Using Gas Metal Arc and Laser Welding Techniques: A Review. J. Emerg. Trends Eng. Appl. Sci. 2017, 8, 225–228. [Google Scholar]

- Fang, Y.; Jiang, X.; Mo, D.; Zhu, D.; Luo, Z. A review on dissimilar metals’ welding methods and mechanisms with interlayer. Int. J. Adv. Manuf. Technol. 2019, 102, 2845–2863. [Google Scholar] [CrossRef]

- Song, Y.; Yang, X.; Cui, L.; Hou, X.; Shen, Z.; Xu, Y. Defect features and mechanical properties of friction stir lap welded dissimilar AA2024–AA7075 aluminum alloy sheets. Mater. Des. 2014, 55, 9–18. [Google Scholar] [CrossRef]

- Lean, P.P.; Gil, L.; Urena, A. Dissimilar welds between unreinforced AA6082 and AA6092/SiC/25p composite by pulsed-MIG arc welding using unreinforced filler alloys (Al–5Mg and Al–5Si). J. Mater. Process. Technol. 2003, 143–144, 846–850. [Google Scholar] [CrossRef]

- Palanivel, R.; Mathews, P.K.; Dinaharan, I.; Murugan, N. Mechanical and metallurgical properties of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 58–65. [Google Scholar] [CrossRef]

- Gungor, B.; Kaluc, E.; Taban, E.; Aydin, S.I.K. Mechanical and microstructural properties of robotic Cold Metal Transfer (CMT) welded 5083-H111 and 6082-T651 aluminum alloys. Mater. Des. 2014, 54, 207–211. [Google Scholar] [CrossRef]

- Jonckheere, C.; de Meester, B.; Denquin, A.; Simar, A. Torque, temperature and hardening precipitation evolution in dissimilar friction stir welds between 6061-T6 and 2014-T6 aluminum alloys. J. Mater. Process. Technol. 2013, 213, 826–837. [Google Scholar] [CrossRef]

- Ilangovan, M.; Boopathy, S.R.; Balasubramanian, V. Microstructure and tensile properties of friction stir welded dissimilar AA6061–AA5086 aluminium alloy joints. Trans. Nonferrous Met. Soc. China 2015, 25, 1080–1090. [Google Scholar] [CrossRef]

- Uematsu, Y.; Tozaki, Y.; Tokaji, K.; Nakamura, M. Fatigue behavior of dissimilar friction stir welds between cast and wrought aluminum alloys. Strength Mater. 2007, 40, 138–141. [Google Scholar] [CrossRef]

- Ghosh, M.; Husain, M.M.; Kumar, K.; Kailas, S.V. Friction stir-welded dissimilar aluminum alloys: Microstructure, mechanical properties, and physical state. J. Mater. Eng. Perform. 2013, 22, 3890–3901. [Google Scholar] [CrossRef]

- Wang, M.; Zou, Y.D.; Hu, H.; Meng, G.; Cheng, P.; Chu, Y.L. Tensile properties and microstructure of joined vacuum die cast aluminum alloy A356 (T6) and wrought alloy 6061. Adv. Mater. Res. 2014, 939, 90–97. [Google Scholar] [CrossRef]

- Nie, F.; Dong, H.; Chen, S.; Li, P.; Wang, L.; Zhao, Z.; Li, X.; Zhang, H. Microstructure and Mechanical Properties of Pulse MIG Welded 6061/A356 Aluminum Alloy Dissimilar Butt Joints. J. Mater. Sci. Technol. 2018, 34, 551–560. [Google Scholar] [CrossRef]

- Casalino, G.; Leo, P.; Mortello, M.; Perulli, P.; Varone, A. Effects of Laser Offset and HybridWelding on Microstructure and IMC in Fe–Al DissimilarWelding. Metals 2017, 7, 282. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Oliveira, J.P.; Zeng, Z.; Bu, X.; Peng, B.; Shao, X. Laser beam oscillating welding of 5A06 aluminum alloys: Microstructure, porosity and mechanical properties. Opt. Laser Technol. 2019, 11, 58–65. [Google Scholar] [CrossRef]

- Manti, R.; Dwivedi, D.K.; Agarwal, A. Microstructure and hardness of AlMg-Si weldments produced by pulse GTA welding. Int. J. Adv. Manuf. Technol. 2008, 36, 263–269. [Google Scholar] [CrossRef]

- Feng, J.; Zhang, H.; He, P. The CMT short-circuiting metal transfer process and its use in thin aluminium sheets welding. Mater. Des. 2009, 30, 1850–1852. [Google Scholar] [CrossRef]

- Zapico, E.P.; Lutey, A.H.; Ascari, A.; Pérez, C.R.G.; Liverani, E.; Fortunato, A. An improved model for cold metal transfer welding of aluminium alloys. J. Therm. Anal. Calorim. 2018, 131, 3003–3009. [Google Scholar] [CrossRef]

- Wang, J.; Feng, J.C.; Wan, Y.X. Microstructure of Al–Mg dissimilar weld made by cold metal transfer MIG welding. J. Mater. Sci. Technol. 2008, 24, 827–831. [Google Scholar] [CrossRef]

- Pickin, C.G.; Young, K. Evaluation of cold metal transfer (CMT) process for welding aluminium alloy. J. Sci. Technol. Weld. Join. 2006, 11, 583–585. [Google Scholar] [CrossRef]

- Katayamaa, S.; Kawahitoa, Y.; Mizutania, M. Elucidation of laser welding phenomena and factors affecting weld penetration and welding defects. Phys. Procedia 2010, 5, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Katayama, S.; Nagayama, H.; Kawahito, Y. Fiber laser welding of aluminium alloy. J. Weld. Int. 2009, 23, 744–752. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Gilmutdinov, A.K. The effect of laser beam wobbling mode in welding process for structural steels. Int. J. Adv. Manuf. Technol. 2015, 81, 1683–1691. [Google Scholar] [CrossRef]

- Aalderink, B.J.; Pathiraj, B. Seam gap bridging of laser based processes for the welding of aluminium sheets for industrial applications. Int. J. Adv. Manuf. Technol. 2010, 48, 143–154. [Google Scholar] [CrossRef]

- Hayashi, T.; Matsubayashi, K.; Katayama, S.; Abe, N.; Matsunawa, A.; Ohmori, A. Reduction mechanism of porosity in tandem twin-spot laser welding of stainless steel. Weld. Int. 2003, 17, 12–19. [Google Scholar] [CrossRef]

- Yangchun, Y.; Wang, C.; Xiyuan, H.; Wang, J.; Shengfu, Y. Porosity in fiber laser formation of 5A06 aluminum alloy. J. Mech. Sci. Technol. 2010, 24, 1077–1082. [Google Scholar]

- Chowdhury, S.H.; Chen, D.L.; Bhole, S.D.; Powidajko, E.; Weckman, D.C.; Zhou, Y. Fiber laser welded AZ31 magnesium alloy: The effect of welding speed on microstructure and mechanical properties. Metall. Mater. Trans. A 2012, 43, 2133–2147. [Google Scholar] [CrossRef]

- ASTM International. ASTM E18–03 (2003) Standard Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2003. [Google Scholar]

- ASTM International. ASTM E92–160 (2016) Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM International. ASTM E140–02 (2002) Standard Hardness Conversion Tables for Metals Relationship among Brinell Hardness, Vickers Hardness, Rockwell Hardness, Superficial Hardness, Knop Hardness, and Scleroscope Hardness; ASTM International: West Conshohocken, PA, USA, 2002. [Google Scholar]

- EN AW-6082, Metra. Available online: http://www.metra.it/aluminium/tabellaLeghe/tabellaCatalogo6082.pdf (accessed on 8 October 2019).

- Hwang, L.; Gung, C.; Shih, T. A study on the qualities of GTA-welded squeeze-cast A356 alloy. J. Mater. Process. Technol. 2001, 116, 101–113. [Google Scholar] [CrossRef]

- Missori, S.; Montanari, R.; Sili, A. Caratterizzazione meccanica mediante prove fimec di giunti saldati in lega di Al 6082. La Metall. Ital. 2001, 3, 35–39. [Google Scholar]

- Myhr, O.R.; Grong, O.; Fjaer, H.G.; Marioara, C.D. Modelling of the microstructure and strength evolution in Al–Mg–Si alloys during multistage thermal processing. Acta Mat. 2004, 52, 4997–5008. [Google Scholar] [CrossRef]

- Tang, N.-K.; Chen, J.K.; Hung, H.-Y. Effect of silicon on thermal conductivity of Al-Si alloys. In Proceedings of the Materials Science and Technology Conference and Exhibition 2013, (MS&T’13), Montreal, PQ, Canada, 27–31 October 2013. [Google Scholar]

- Zhilin, A.S.; Jianguo, L.; Yalunina, V.R.; Varlamenko, D.S.; Bykov, V.A.; Derevjankin, E.V. Influence of Silicon on Thermal Conductivity at Room Temperature of Al–Si–Fe Alloys. KnE Eng. 2018, 3, 294–297. [Google Scholar] [CrossRef]

- Stadler, F.; Antrekowitsch, H.; Werner, F.; Kaufmann, H.; Riccardo, P.E.; Peter, U. The effect of main alloying elements on the physical properties of Al-Si foundry alloys. Mater. Sci. Eng. A 2013, 560, 481–491. [Google Scholar] [CrossRef]

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Total Others El. | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| EN AW-6181 | 0.8–1.20 | 0.45 | 0.10 | 0.15 | 0.60–1.0 | 0.10 | 0.20 | 0.10 | 0.15 | Bal. |

| EN AW-6082 | 0.7–1.3 | <0.50 | <0.10 | 0.4–1.0 | 0.60–1.2 | <0.25 | <0.20 | 0.10 | <0.05 | Bal. |

| EN AC-42100 | 6.50–7.50 | <0.60 | <0.25 | <0.35 | 0.20–0.45 | - | <0.35 | <0.25 | 0.15 | Bal. |

| UNI – ER 4043 | 4.5–4.6 | 0.8 | 0.3 | 0.005 | 0.05 | - | 0.1 | - | - | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cornacchia, G.; Cecchel, S. Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison. Metals 2020, 10, 441. https://doi.org/10.3390/met10040441

Cornacchia G, Cecchel S. Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison. Metals. 2020; 10(4):441. https://doi.org/10.3390/met10040441

Chicago/Turabian StyleCornacchia, Giovanna, and Silvia Cecchel. 2020. "Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison" Metals 10, no. 4: 441. https://doi.org/10.3390/met10040441

APA StyleCornacchia, G., & Cecchel, S. (2020). Study and Characterization of EN AW 6181/6082-T6 and EN AC 42100-T6 Aluminum Alloy Welding of Structural Applications: Metal Inert Gas (MIG), Cold Metal Transfer (CMT), and Fiber Laser-MIG Hybrid Comparison. Metals, 10(4), 441. https://doi.org/10.3390/met10040441