Particle Ejection by Jetting and Related Effects in Impact Welding Processes

Abstract

:1. Introduction

- How do material properties, surface properties, the collision environment, and the collision kinetics influence the characteristics of the CoP?

- What is the temperature in the joining gap due to the CoP or compressed air?

- Is the process glare a multiple superposition of different effects, depending on the process environment?

- Under which conditions can the process glare be used as a sufficient welding criterion?

2. Materials and Methods

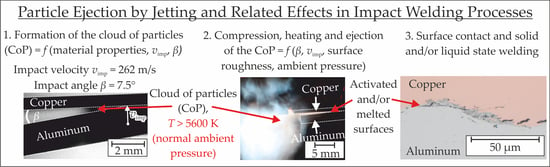

2.1. Nomenclature and Overview

2.2. Test Rig

2.3. MPW Process

3. Results

3.1. Test Rig

3.2. MPW Process for Sheets

- The temperature of the light-emitting medium is much higher at normal ambient pressure compared to the reduced pressure conditions.

- At normal ambient pressure, the temperature rises further during the propagation of the collision point. Using Wien’s displacement law (see Appendix A for discussion) and an upper boundary for the photon emission maximum of λ = 650 nm, the temperature of the process glare under normal ambient pressure can be expected to exceed 5600 K.

3.3. MPW Process for Tubes

4. Discussion

- Test rig experiments: Decreasing the grain size of the parent material led to an increase in the material’s strength and hindered plastic deformation in the joining zone. This makes it difficult to generate a sufficient CoP for the heating of the surfaces and to form a solid jet that uncovers the base materials.

- Test rig experiments: The escape of the CoP was hindered by an increased surface roughness, which also led to a reduced process glare. The high-speed picture frames as well as the melting pockets in the cross section point to the conclusion that the CoP was partly entrapped in the wavy surface during the movement of the collision point. This effect can be detrimental for the weld formation if the kinetic or thermal energy of the CoP is too high and leads to extensive melting along the interface. Furthermore, it weakens or hinders bond formation due to a lack of direct contact of the activated surfaces of the base material.

- Sheet welding setup: The surrounding gas lowered the velocity of the escaping CoP, as also reported in [27]. This led to a porous microstructure if the CoP was partially enclosed in the joining zone. In contrast, the microstructure revealed no pores when MPW was performed under vacuum-like conditions, see also [25]. Similar to the observations reported in [28], the necessary impact velocity for a successful weld seam can be reduced in vacuum compared to normal atmosphere. Moreover, the process glare is reduced significantly, either due to the absence of chemical interactions with the surrounding oxygen or because of shock compression of the gas in the joining gap, as described in [45].

- Tube welding setup: The collision kinetics have a big impact on the characteristics of the CoP. The deep and voluminous craters that are formed by the CoP in soft graphite pins indicated that the kinetic energy of the CoP was higher for larger collision angles, whereas smaller collision angles only led to a single line in the graphite witness pin with significantly reduced depth. The structures of the vaporized surfaces of the witness pins made of steel and tungsten provided insights into the thermal energy of the CoP: Small collision angles led to a higher degree of compression of the CoP in the joining gap and, thus, pronounced heating of the surfaces in the joining zone. The copper tracer that was placed at the end of the actually welded area was detectable on the surface of the witness pins. Since the impact velocity, the plastic deformation, and, thus, the heating due to forming were reduced compared to the initial collision point, the thermal and kinetic energy of the compressed CoP must have been responsible for the melting and transportation of the copper tracer towards the witness pins. The finely dispersed structure of the vaporized pin surfaces supports the hypothesis that the high temperatures in the joining gap resulted from the thermal energy of the CoP. In contrast, compression and heating were reduced for large collision angles, leading to the ragged surface of the witness pins. The surface contained larger aluminum particles and no signs of copper from the tracer surface coating. The chemical composition of the CoP was dominated by approx. 80 weight percent aluminum due to its lower melting temperature and lower strength compared to steel. Consequently, the amount of aluminum that was plastically deformed, melted and finally contributed to the CoP is higher.

- (a)

- In ambient atmosphere, the shock compression of the surrounding air led to a thermal glow. Furthermore, the remarkably high oxygen content on the witness pins provided evidence of an exothermic reaction of the metal vapor with the surrounding oxygen. This reaction contributed to the flash effects, too.

- (b)

- Under vacuum-like conditions, the intensity of the light emission was reduced, and its appearance depended on the involved materials. In [13], a bright appearance was reported for magnesium (which has a lower boiling temperature than copper), where only a dark metal jet was observed. Thus, it can be concluded that even in the absence of the surrounding air, particles of the involved joining partners with temperatures above the vaporization temperature emitted light and contributed to the process glare. Depending on the local temperatures and pressures, the formation of plasma is also conceivable, but the present study does not provide direct evidence for this phenomenon.

5. Conclusions, Research Highlights, and Outlook

6. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Blackbody Model for Temperature Estimation

References

- Kapil, A.; Sharma, A. Magnetic Pulse Welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 35–58. [Google Scholar] [CrossRef]

- Wang, H.; Wang, Y. High-Velocity Impact Welding Process: A Review. Metals 2019, 9, 144. [Google Scholar] [CrossRef] [Green Version]

- Sadeh, S.; Gleason, G.H.; Hatamleh, M.I.; Sunny, S.F.; Yu, H.; Malik, A.S.; Qian, D. Simulation and Experimental Comparison of Laser Impact Welding with a Plasma Pressure Model. Metals 2019, 9, 1196. [Google Scholar] [CrossRef] [Green Version]

- Mori, K.; Bay, N.; Fratini, L.; Micari, F.; Tekkaya, A.E. Joining By Plastic Deformation. CIRP Ann. Manuf. Technol. 2013, 62, 673–694. [Google Scholar] [CrossRef]

- Philipchuk, V.; Scituate, N.; Roy, L.F. Explosive Welding. US Patent US 3,024,526, 13 March 1962. [Google Scholar]

- Crossland, B. Explosive Welding of Metals and Its Application; Clarendon Press: Oxford, UK, 1982. [Google Scholar]

- Lueg-Althoff, J.; Bellmann, J.; Gies, S.; Schulze, S.; Tekkaya, A.E.; Beyer, E. Influence of the Flyer Kinetics on Magnetic Pulse Welding of Tubes. J. Mater. Process. Technol. 2018, 189–203. [Google Scholar] [CrossRef]

- Cowan, G.R.; Holtzmann, A.H. Flow Configurations in Colliding Plates: Explosive Bonding. J. Appl. Phys. 1963, 34, 928–939. [Google Scholar] [CrossRef]

- Stern, A.; Shribman, V.; Ben-Artzy, A.; Aizenshtein, M. Interface Phenomena and Bonding Mechanism in Magnetic Pulse Welding. J. Mater. Eng. Perform. 2014, 23, 3449–3458. [Google Scholar] [CrossRef]

- Akbari Mousavi, A.A.; Al-Hassani, S.T.S. Numerical and experimental studies of the mechanism of the wavy interface formations in explosive/impact welding. J. Mech. Phys. Solids 2005, 53, 2501–2528. [Google Scholar] [CrossRef]

- Kakizaki, S.; Watanabe, M.; Kumaji, S. Simulation and experimental analysis of metal jet emission and weld interface morphology in impact welding. Mater. Trans. 2011, 52, 1003–1008. [Google Scholar] [CrossRef] [Green Version]

- Gleason, G.; Sunny, S.; Sadeh, S.; Yu, H.; Malik, A. Eulerian Modeling of Plasma-Pressure Driven Laser Impact Weld Processes. Procedia Manuf. 2020, 48, 204–214. [Google Scholar] [CrossRef]

- Mori, A.; Tanaka, S.; Hokamoto, K. Observation for the High-Speed Oblique Collision of Metals. In Explosion Shock Waves and High Strain Rate Phenomena; Hokamoto, K., Raghukandan, K., Eds.; Materials Research Forum LLC: Puducherry, India, 2019; pp. 74–78. ISBN 978-1-64490-032-1. [Google Scholar]

- Groche, P.; Niessen, B.; Pabst, C. Process boundaries of collision welding at low energies. Mater. Werkst. 2019, 50, 940–948. [Google Scholar] [CrossRef]

- Schumacher, E.; Rebensdorf, A.; Böhm, S. Influence of the jet velocity on the weld quality of magnetic pulse welded dissimilar sheet joints of aluminum and steel. Mater. Werkst. 2019, 50, 965–972. [Google Scholar] [CrossRef] [Green Version]

- Watanabe, M.; Kumai, S. High-Speed Deformation and Collision Behavior of Pure Aluminum Plates in Magnetic Pulse Welding. Mater. Trans. Jpn. Inst. Light Met. 2009, 50, 2035–2042. [Google Scholar]

- Hassani-Gangaraj, M.; Veysset, D.; Nelson, K.A.; Schuh, C.A. In-situ observations of single micro-particle impact bonding. Scr. Mater. 2018, 145, 9–13. [Google Scholar] [CrossRef]

- Bergmann, O.R.; Cowan, G.R.; Holtzmann, A.H. Experimental Evidence of Jet Formation During Explosion Gladding. Trans. Metall. Soc. AIME 1966, 236, 646–653. [Google Scholar]

- Drennov, O.B. Structure of a Shaped Jet Formed in an Oblique Collision of Flat Metal Plates. MSF 2004, 465, 409–414. [Google Scholar] [CrossRef]

- Deribas, A.A.; Zakharenko, I.D. Surface effects with oblique collisions between metallic plates. Translated from Fisika Goreniya, I. Vzyva 1974, 10, 409–421. [Google Scholar]

- Hammerschmidt, M.; Kreye, H. Microstructure and bonding mechanism in explosive welding. In Shock Waves and High-Strain-Rate Phenomena in Metals; Springer: Berlin/Heidelberg, Germany, 1981; pp. 961–973. [Google Scholar]

- Sharafiev, S.; Pabst, C.; Wagner, M.F.-X.; Groche, P. Microstructural characterisation of interfaces in magnetic pulse welded aluminum/aluminum joints. IOP Conf. Ser. Mater. Sci. Eng. 2016, 118, 12016. [Google Scholar] [CrossRef] [Green Version]

- Pabst, C. Ursachen, Beeinflussung, Auswirkungen sowie Quantifizierung der Temperaturentwicklung in der Fügezone beim Kollisionsschweißen; Technische Universität Darmstadt: Darmstadt, Germany, 2019. [Google Scholar]

- Niessen, B.; Groche, P. Weld interface characteristics of copper in collision welding. In Proceedings of the 22nd International ESAFORM Conference on Material Forming (ESAFORM 2019), Vitoria-Gasteiz, Spain, 8–10 May 2019; Galdos, L., Arrazola, P., Saenz de Argandoña, E., Otegi, N., Mendiguren, J., Madariaga, A., Saez de Buruaga, M., Eds.; AIP Publishing: Melville, NY, USA, 2019; p. 50018, ISBN 978-0-7354-1847-9. [Google Scholar]

- Böhme, M.; Sharafiev, S.; Schumacher, E.; Böhm, S.; Wagner, M.F.X. On the microstructure and the origin of intermetallic phase seams in magnetic pulse welding of aluminum and steel. Mater. Werkst. 2019, 50, 958–964. [Google Scholar] [CrossRef]

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Hahn, M.; Gies, S.; Beyer, E.; Tekkaya, A.E. Thermal Effects in Dissimilar Magnetic Pulse Welding. Metals 2019, 9, 348. [Google Scholar] [CrossRef] [Green Version]

- Pabst, C.; Groche, P. Identification of process parameters in electromagnetic pulse welding and their utilisation to expand the process window. Int. J. Mater. Mech. Manuf. 2018, 6, 69–73. [Google Scholar]

- Kümper, S.; Schumacher, E.; Böhm, S. Influence of the Ambient Pressure on the Weld Quality for Magnetic Pulse Welded Sheet Joints. In Proceedings of the 8th International Conference on High Speed Forming, Columbus, OH, USA, 13–16 May 2018; Daehn, G.S., Tekkaya, A.E., Eds.; The Ohio State University: Columbus, OH, USA, 2018. [Google Scholar]

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Gies, S.; Beyer, E.; Tekkaya, A.E. Parameter Identification for Magnetic Pulse Welding Applications. Key Eng. Mater. 2018, 767, 431–438. [Google Scholar] [CrossRef]

- Ishutkin, S.N.; Kirko, V.I.; Simonov, V.A. Thermal action of shock-compressed gas on the surface of colliding plates. Fiz. Goreniya/Vzryva 1979, 16, 69–73. [Google Scholar] [CrossRef]

- Khaustov, S.V.; Kuz’min, S.V.; Lysak, V.I.; Pai, V.V. Thermal processes in explosive welding. Combust. Explos. Shock Waves 2014, 50, 732–738. [Google Scholar] [CrossRef]

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Gies, S.; Beyer, E.; Tekkaya, A.E. Measurement and Analysis Technologies for Magnetic Pulse Welding: Established Methods and New Strategies. Adv. Manuf. 2016, 322–339. [Google Scholar] [CrossRef]

- Groche, P.; Wagner, M.F.-X.; Pabst, C.; Sharafiev, S. Development of a novel test rig to investigate the fundamentals of impact welding. J. Mater. Process. Technol. 2014, 214, 2009–2017. [Google Scholar] [CrossRef]

- Bellmann, J.; Ueberschär, F.; Lueg-Althoff, J.; Schulze, S.; Hahn, M.; Beyer, E.; Tekkaya, A.E. Effect of the Forming Behavior on the Impact Flash during Magnetic Pulse Welding of Tubes. In Proceedings of the 13th International Conference on Numerical Methods in Industrial Forming Processes, NUMIFORM 2019, Portsmouth, NH, USA, 23–27 June 2019; Korkolis, Y.P., Kinsey, B.L., Knezevic, M., Padhye, N., Eds.; The Minerals, Metals & Materials Society (TMS): Pittsburgh, PA, USA, 2019; pp. 651–654, ISBN 978-0-87339-769-8. [Google Scholar]

- Groche, P.; Becker, M.; Pabst, C. Process window acquisition for impact welding processes. Mater. Des. 2017, 118, 286–293. [Google Scholar] [CrossRef]

- Pabst, C.; Sharafiev, S.; Groche, P.; Wagner, M.F.X. A Novel Method to Investigate the Principles of Impact Welding: Development and Enhancement of a Test Rig, Experimental and Numerical Results. AMR 2014, 966, 500–509. [Google Scholar] [CrossRef]

- Seeberger. Datasheet 3.0255 (EN AW-1050A). Available online: https://seeberger.net/_assets/pdf/werkstoffe/aluminium/de/3.0255.pdf (accessed on 23 January 2020).

- Seeberger. Datasheet AlMgSi (EN AW-6060). Available online: http://www.seeberger.net/_assets/pdf/werkstoffe/aluminium/de/AlMgSi.pdf (accessed on 18 February 2020).

- Deutsche Edelstahlwerke. Unlegierter Vergütungsstahl 1.1191/1.1201: C45E/C45R. Available online: https://www.dew-stahl.com/fileadmin/files/dew-stahl.com/documents/Publikationen/Werkstoffdatenblaetter/Baustahl/1.1191_1.1201_de.pdf (accessed on 21 February 2019).

- Frint, S.; Hockauf, M.; Frint, P.; Wagner, M.F.-X. Scaling up Segal’s principle of Equal-Channel Angular Pressing. Mater. Des. 2016, 97, 502–511. [Google Scholar] [CrossRef]

- Pabst, C.; Pasquale, P. Identification of additional process parameters for impact welding and their influence on the process window. In Proceedings of the 8th International Conference on High Speed Forming, Columbus, OH, USA, 13–16 May 2018; Daehn, G.S., Tekkaya, A.E., Eds.; The Ohio State University: Columbus, OH, USA, 2018. [Google Scholar]

- Tucker, N. Spectra V1.0. Available online: https://www.mathworks.com/matlabcentral/fileexchange/27796-spectra-v1-0 (accessed on 29 June 2020).

- Bellmann, J.; Lueg-Althoff, J.; Schulze, S.; Gies, S.; Beyer, E.; Tekkaya, A.E. Measurement of Collision Conditions in Magnetic Pulse Welding Processes. J. Phys. Sci. Appl. 2017, 7, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Cui, J.; Ye, L.; Zhu, C.; Geng, H.; Li, G. Mechanical and Microstructure Investigations on Magnetic Pulse Welded Dissimilar AA3003-TC4 Joints. J. Mater. Eng. Perform. 2020, 29, 712–722. [Google Scholar] [CrossRef]

- Saravanan, S.; Raghukandan, K. Thermal kinetics in explosive cladding of dissimilar metals. Sci. Technol. Weld. Join. 2012, 17, 99–103. [Google Scholar] [CrossRef]

- Kotte, L.; Mäder, G.; Roch, J.; Kaskel, S. Extended DC arc atmospheric pressure plasma source for large scale surface cleaning and functionalization. Contrib. Plasma Phys. 2018, 58, 327–336. [Google Scholar] [CrossRef]

- Bellmann, J. Verfahren und Vorrichtung zur Prozessüberwachung bei einer mittels Kollisionsschweißen gebildeten Schweißnaht. German Patent DE 10 2016 217 758 B3, 16 September 2016. [Google Scholar]

- Bellmann, J. Method and Device for Monitoring the Process for a Welding Seam Formed by Means of Collision Welding. U.S. Patent Application No. 16/333,917, 8 September 2017. [Google Scholar]

| Symbol | Parameter | Symbol | Parameter |

|---|---|---|---|

| E | Charging energy | Ri | Inner resistance of the pulse generator |

| g | Initial joining gap | s | Thickness of the flyer |

| I | Discharge current | S | High voltage switch |

| Imax | Maximum discharge current | T | Time |

| Li | Inner inductance of the pulse generator | tf,start | Flash starting time |

| lw | Working length (axial overlap between the workpiece and the tool coil) | Uf,max | Voltage equivalent to maximum intensity of the impact flash |

| p | Ambient pressure | vimp | Impact velocity |

| pm | Magnetic pressure | vc | Axial collision velocity |

| Ra | Mean roughness index | β | Collision angle |

| Experimental Setup | Test Rig 1 | MPW for Sheets 2 | MPW for Tubes 3 |

|---|---|---|---|

| Manufacturer | PtU4 | PST products5 | Bmax6 |

| Pulse generator | Not applicable | PS48-16 | MPW50/25 |

| Acceleration | Purely mechanical | Electromagnetic pulse technology | Electromagnetic pulse technology |

| Investigated geometry | Sheets 12 × 12 mm2 | Sheets 100 × 40 mm2 | Tubes Ø 40 mm |

| Maximum impact velocity 7 | 262 m/s | 245 m/s | 270 m/s 8 |

| Impact velocity adjustable | By rotational speed | By discharge current | By discharge current |

| Collision angle adjustable | By bending | By acceleration gap | By acceleration gap and working length |

| Ambient pressure | Normal | Normal/1 mbar | Normal |

| High-speed camera | hsfc pro by PCO 9 | hsfc pro by PCO 9 | No |

| Photonic Doppler Velocimetry (PDV) | No | Yes | No |

| Digital single-lens reflex (DSLR) camera for long time exposures | Canon10 5D with a 100 mm macro lens | Canon10 5D with a 100 mm macro lens | Canon10 EOS 700D |

| Measurement of the impact time | Electrical contact between flyer and parent | Time-resolved flash detection with phototransistor | Time-resolved flash detection with phototransistor |

| Collision angle accessible | By high-speed camera and image acquisition | By high-speed camera (limited) | By modified parent parts, see [7] |

| Number of trials for each parameter set | 1 | 1 for the lowest velocity level, otherwise <3 | 1 |

| Characterization of weld quality | Peel test [32] | Peel test [32] | |

| Microstructural characterization | Optical microscopy (GX-51 by Olympus, Tokyo, Japan), scanning electron microscopy (SEM, Neon 40 EsB by ZEISS AG, Oberkochen, Germany) and electron backscatter diffraction (EBSD, DigiView IV camera controlled by TEAM v4.5, EDAX, USA) for samples joined in vacuum-like and normal ambient atmosphere | Scanning electron microscopy, energy dispersive X-ray spectroscopy (EDS) and 3D microscopy (see Section 2.3 for details) | |

| Material | EN AW-1050 H14 1 | EN AW-6060 2 T4 3 | C45 (1.0503) 4, Normalized, Surface Polished (Ra = 1) | |

|---|---|---|---|---|

| Element | Weight% | Weight% | Element | Weight% |

| Si | 0.25 | 0.3–0.6 | C | 0.42–0.5 |

| Fe | 0.4 | 0.1–0.3 | Mn | 0.5–0.8 |

| Cu | 0.05 | ≤0.1 | P | <0.045 |

| Mn | 0.05 | ≤0.1 | S | <0.045 |

| Mg | 0.05 | 0.35–0.6 | Si | <0.4 |

| Cr | - | ≤0.05 | Ni | <0.4 |

| Ni | - | - | Cr | <0.4 |

| Zn | 0.07 | ≤0.15 | Mo | <0.1 |

| Ti | 0.05 | ≤0.1 | ||

| Quasi-static yield strength approx. | 102 MPa 5 | 91 MPa 5/60 MPa 6 | 490 MPa 4 | |

| Parameter | Impact Velocity 1 | Ambient Pressure | Charging Energy | Max. Discharge Current | Flash Appearance Time 1 | Welding Result 2 |

|---|---|---|---|---|---|---|

| Symbol | vimp | p | E | Imax | tf,start | |

| Unit | m/s | Pa | kJ | kA | µs | |

| ~190 | 100,000 | 15 | 352 | 19.7 | Not welded | |

| ~203 | 100 | 19 | 403 | 21.6 | Welded | |

| ~224 | 100,000 | 19 | 400 | 17.9 | Welded | |

| ~225 | 100 | 21 | 416 | 18.7 | Welded | |

| ~243 | 100,000 | 21 | 420 | 17.1 | Welded | |

| ~245 | 100 | 24 | 451 | 18.0 | Welded |

| Ambient Pressure | p = 100,000 Pa | p = 100 Pa |

|---|---|---|

| Weld length, left [mm] | 0.9 | 2.4 |

| Not welded central gap [mm] | 3.7 | 2.5 |

| Weld length, right [mm] | 1.7 | 2.4 |

| Working Length lW | 4 mm | 8 mm |

| Collision Angle β 1 | “Large” (9.5°) | “Low” (3.4°) |

| Welding result 2 | Not welded | welded |

| Voltage equivalent to maximum light intensity Uf,max 3 | 6.6 V | 5.8 V |

| Depth and shape of the penetration zone in the graphite witness pin 4 | ~1000 µm, large area | ~150 µm, line-shaped |

| Surface characteristic of the tungsten and steel witness pin | Many coarse particles | Homogenous aluminum cover layer with a few coarse particles |

| Content of copper on the tungsten witness pin | 0 wt % | 1.6 wt % |

| Content of copper on the steel witness pin | 0 wt % | 2.3 wt % |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bellmann, J.; Lueg-Althoff, J.; Niessen, B.; Böhme, M.; Schumacher, E.; Beyer, E.; Leyens, C.; Tekkaya, A.E.; Groche, P.; Wagner, M.F.-X.; et al. Particle Ejection by Jetting and Related Effects in Impact Welding Processes. Metals 2020, 10, 1108. https://doi.org/10.3390/met10081108

Bellmann J, Lueg-Althoff J, Niessen B, Böhme M, Schumacher E, Beyer E, Leyens C, Tekkaya AE, Groche P, Wagner MF-X, et al. Particle Ejection by Jetting and Related Effects in Impact Welding Processes. Metals. 2020; 10(8):1108. https://doi.org/10.3390/met10081108

Chicago/Turabian StyleBellmann, Jörg, Jörn Lueg-Althoff, Benedikt Niessen, Marcus Böhme, Eugen Schumacher, Eckhard Beyer, Christoph Leyens, A. Erman Tekkaya, Peter Groche, Martin Franz-Xaver Wagner, and et al. 2020. "Particle Ejection by Jetting and Related Effects in Impact Welding Processes" Metals 10, no. 8: 1108. https://doi.org/10.3390/met10081108

APA StyleBellmann, J., Lueg-Althoff, J., Niessen, B., Böhme, M., Schumacher, E., Beyer, E., Leyens, C., Tekkaya, A. E., Groche, P., Wagner, M. F. -X., & Böhm, S. (2020). Particle Ejection by Jetting and Related Effects in Impact Welding Processes. Metals, 10(8), 1108. https://doi.org/10.3390/met10081108