Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure Analysis

3.2. Room Temperature Magnetic Properties

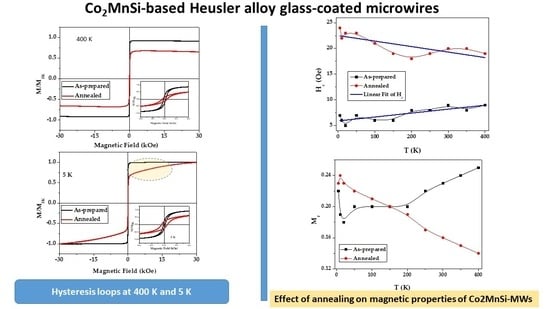

3.3. Temperature Dependence of Magnetic Behavior

3.3.1. Zero Field Cooling, Field Cooling, and Field Heating Magnetic Properties

3.3.2. M-H Loops

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taylor, G.F. A Method of Drawing Metallic Filaments and a Discussion of Their Properties and Uses. Phys. Rev. 1924, 23, 655. [Google Scholar] [CrossRef]

- Ulitovsky, A.V.; Maianski, I.M. Avramenco A I 1960 Method of Continuous Casting of Glass Coated Microwire. USSR Patent 128427, 15 May 1960. [Google Scholar]

- Zhukov, A.; Corte-Leon, P.; Gonzalez-Legarreta, L.; Ipatov, M.; Blanco, J.M.; Gonzalez, A.; Zhukova, V. Advanced Functional Magnetic Microwires for Technological Applications. J. Phys. D Appl. Phys. 2022, 55, 253003. [Google Scholar] [CrossRef]

- Jurc, R.; Frolova, L.; Kozejova, D.; Fecova, L.; Hennel, M.; Galdun, L.; Richter, K.; Gamcova, J.; Ibarra, P.; Hudak, R.; et al. Sensoric Application of Glass-Coated Magnetic Microwires, 2nd ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; ISBN 9780081028322. [Google Scholar]

- Zhukova, V.; Corte-Leon, P.; Blanco, J.M.; Ipatov, M.; Gonzalez-Legarreta, L.; Gonzalez, A.; Zhukov, A. Development of Magnetically Soft Amorphous Microwires for Technological Applications. Chemosensors 2022, 10, 26. [Google Scholar] [CrossRef]

- Baranov, S.A.; Larin, V.S.; Torcunov, A.V. Technology, Preparation and Properties of the Cast Glass-Coated Magnetic Microwires. Crystals 2017, 7, 136. [Google Scholar] [CrossRef]

- Inomata, K.; Ikeda, N.; Tezuka, N.; Goto, R.; Sugimoto, S.; Wojcik, M.; Jedryka, E. Highly Spin-Polarized Materials and Devices for Spintronics. Adv. Mater. 2008, 9, 14101. [Google Scholar] [CrossRef]

- Chumak, O.M.; Pacewicz, A.; Lynnyk, A.; Salski, B.; Yamamoto, T.; Seki, T.; Domagala, J.Z.; Głowiński, H.; Takanashi, K.; Baczewski, L.T.; et al. Magnetoelastic Interactions and Magnetic Damping in Co2Fe0.4Mn0.6Si and Co2FeGa0.5Ge0.5 Heusler Alloys Thin Films for Spintronic Applications. Sci. Rep. 2021, 11, 7608. [Google Scholar] [CrossRef]

- De Groot, R.A.; Mueller, F.M.; Engen, P.G.V.; Buschow, K.H.J. New Class of Materials: Half-Metallic Ferromagnets. Phys. Rev. Lett. 1983, 50, 2024. [Google Scholar] [CrossRef] [Green Version]

- Elphick, K.; Frost, W.; Samiepour, M.; Kubota, T.; Takanashi, K.; Sukegawa, H.; Mitani, S.; Hirohata, A. Heusler Alloys for Spintronic Devices: Review on Recent Development and Future Perspectives. Sci. Technol. Adv. Mater. 2021, 22, 235–271. [Google Scholar] [CrossRef]

- Bai, Z.; Shen, L.E.I.; Han, G.; Feng, Y.P. Data Storage: Review of Heusler Compounds. Spin 2012, 2, 1230006. [Google Scholar] [CrossRef] [Green Version]

- Galanakis, I.; Dederichs, P.H.; Papanikolaou, N. Slater-Pauling Behavior and Origin of the Half-Metallicity of the Full-Heusler Alloys. Phys. Rev. B 2002, 66, 174429. [Google Scholar] [CrossRef] [Green Version]

- Hazra, B.K.; Kaul, S.N.; Srinath, S.; Raja, M.M. Uniaxial Anisotropy, Intrinsic and Extrinsic Damping in Co2FeSi Heusler Alloy Thin Films. J. Phys. D Appl. Phys. 2019, 52, 325002. [Google Scholar] [CrossRef] [Green Version]

- Wurmehl, S.; Fecher, G.H.; Kandpal, H.C.; Ksenofontov, V.; Felser, C.; Lin, H.J.; Morais, J. Geometric, Electronic, and Magnetic Structure of Co2FeSi: Curie Temperature and Magnetic Moment Measurements and Calculations. Phys. Rev. B Condens. Matter. Mater. Phys 2005, 72, 184434. [Google Scholar] [CrossRef] [Green Version]

- Li, P.; Koo, J.; Ning, W.; Li, J.; Miao, L.; Min, L.; Zhu, Y.; Wang, Y.; Alem, N.; Liu, C.X.; et al. Giant Room Temperature Anomalous Hall Effect and Tunable Topology in a Ferromagnetic Topological Semimetal Co2MnAl. Nat. Commun. 2020, 11, 3476. [Google Scholar] [CrossRef]

- Belopolski, I.; Manna, K.; Sanchez, D.S.; Chang, G.; Ernst, B.; Yin, J.; Zhang, S.S.; Cochran, T.; Shumiya, N.; Zheng, H.; et al. Discovery of Topological Weyl Fermion Lines and Drumhead Surface States in a Room Temperature Magnet. Science 2019, 365, 1278–1281. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, S.J.; Boyer, C.; Niewczas, M. Magnetic and Structural Properties of Co2MnSi Based Heusler Compound. J. Alloys Compd. 2019, 781, 216–225. [Google Scholar] [CrossRef] [Green Version]

- Guillemard, C.; Petit-Watelot, S.; Pasquier, L.; Pierre, D.; Ghanbaja, J.; Rojas-Sánchez, J.C.; Bataille, A.; Rault, J.; le Fèvre, P.; Bertran, F.; et al. Ultralow Magnetic Damping in Co2Mn -Based Heusler Compounds: Promising Materials for Spintronics. Phys. Rev. Appl. 2019, 11, 064009. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.X.; Honda, Y.; Taira, T.; Matsuda, K.I.; Arita, M.; Uemura, T.; Yamamoto, M. Giant Tunneling Magnetoresistance in Epitaxial Co2MnSi/MgO/ Co2MnSi Magnetic Tunnel Junctions by Half-Metallicity of Co2MnSi and Coherent Tunneling. Appl. Phys. Lett. 2012, 101, 132418. [Google Scholar] [CrossRef] [Green Version]

- Stuelke, L.; Kharel, P.; Shand, P.M.; Lukashev, P.V. First Principles Study of Perpendicular Magnetic Anisotropy in Thin-Film Co2MnSi. Phys. Scr. 2021, 96, 125818. [Google Scholar] [CrossRef]

- Ishida, S.; Fujii, S.; Kashiwagi, S.; Asano, S. Search for Half-Metallic Compounds in Co2MnZ (Z=IIIb, IVb, Vb Element). J. Phys. Soc. Jpn. 1995, 64, 2152–2157. [Google Scholar] [CrossRef]

- Pradines, B.; Arras, R.; Abdallah, I.; Biziere, N.; Calmels, L. First-Principles Calculation of the Effects of Partial Alloy Disorder on the Static and Dynamic Magnetic Properties of Co2MnSi. Phys. Rev. B 2017, 95, 094425. [Google Scholar] [CrossRef]

- Cheng, S.F.; Nadgorny, B.; Bussmann, K.; Carpenter, E.E.; Das, B.N.; Trotter, G.; Raphael, M.P.; Harris, V.G. Growth and Magnetic Properties of Single Crystal Co2MnX (X = Si, Ge) Heusler Alloys. IEEE Trans. Magn. 2001, 37, 2176–2178. [Google Scholar] [CrossRef]

- Jourdan, M.; Minár, J.; Braun, J.; Kronenberg, A.; Chadov, S.; Balke, B.; Gloskovskii, A.; Kolbe, M.; Elmers, H.J.; Schönhense, G.; et al. Direct Observation of Half-Metallicity in the Heusler Compound Co2MnSi. Nat. Commun. 2014, 5, 3974. [Google Scholar] [CrossRef] [Green Version]

- Wang, B.; Liu, Y. Exchange Bias and Inverse Magnetocaloric Effect in Co and Mn Co-Doped Ni2MnGa Shape Memory Alloy. Metals 2013, 3, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Dunand, D.C.; Müllner, P. Size Effects on Magnetic Actuation in Ni-Mn-Ga Shape-Memory Alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef]

- Felser, C.; Hirohata, A. (Eds.) Heusler Alloys; Springer Series in Materials Science; Springer International Publishing: Cham, Switzerland, 2016; Volume 222, ISBN 978-3-319-21448-1. [Google Scholar]

- Salaheldeen, M.; Nafady, A.; Abu-Dief, A.M.; Díaz Crespo, R.; Fernández-García, M.P.; Andrés, J.P.; López Antón, R.; Blanco, J.A.; Álvarez-Alonso, P. Enhancement of Exchange Bias and Perpendicular Magnetic Anisotropy in CoO/Co Multilayer Thin Films by Tuning the Alumina Template Nanohole Size. Nanomaterials 2022, 12, 2544. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Abu-Dief, A.M.; Martínez-Goyeneche, L.; Alzahrani, S.O.; Alkhatib, F.; Álvarez-Alonso, P.; Blanco, J.Á. Dependence of the Magnetization Process on the Thickness of Fe70Pd30 Nanostructured Thin Film. Materials 2020, 13, 5788. [Google Scholar] [CrossRef]

- Zhukov, A.; Rodionova, V.; Ilyn, M.; Aliev, A.M.; Varga, R.; Michalik, S.; Aronin, A.; Abrosimova, G.; Kiselev, A.; Ipatov, M.; et al. Magnetic Properties and Magnetocaloric Effect in Heusler-Type Glass-Coated NiMnGa Microwires. J. Alloys Compd. 2013, 575, 73–79. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Vega, V.; Caballero-Flores, R.; Prida, V.M.; Fernández, A. Influence of nanoholes array geometrical parameters on magnetic properties of Dy–Fe antidot thin films. Nanotechnology 2019, 30, 455703. [Google Scholar] [CrossRef]

- Chiriac, H.; Lupu, N.; Stoian, G.; Ababei, G.; Corodeanu, S.; Óvári, T.-A. Ultrathin Nanocrystalline Magnetic Wires. Crystals 2017, 7, 48. [Google Scholar] [CrossRef] [Green Version]

- Salaheldeen, M.; Garcia-Gomez, A.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Zhukov, A. Fabrication and Magneto-Structural Properties of Co2-Based Heusler Alloy Glass-Coated Microwires with High Curie Temperature. Chemosensors 2022, 10, 225. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Ipatov, M.; Zhukova, V.; García-Gomez, A.; Gonzalez, J.; Zhukov, A. Preparation and magnetic properties of Co2-based Heusler alloy glass-coated microwires with high Curie temperature. AIP Adv. 2023, 13, 025325. [Google Scholar] [CrossRef]

- Zhukova, V.; Corte-Leon, P.; González-Legarreta, L.; Talaat, A.; Blanco, J.M.; Ipatov, M.; Olivera, J.; Zhukov, A. Review of Domain Wall Dynamics Engineering in Magnetic Microwires. Nanomaterials 2020, 10, 2407. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Gonzalez, J.; Zhukov, A. Anomalous Magnetic Behavior in Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires with High Curie Temperature. J. Alloys Compd. 2022, 923, 166379. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia-Gomez, A.; Corte-León, P.; Gonzalez, A.; Ipatov, M.; Zhukova, V.; Gonzalez, J.M.; López Antón, R.; Zhukov, A. Manipulation of Magnetic and Structure Properties of Ni2FeSi Glass-Coated Microwires by Annealing. J. Alloys Compd. 2023, 942, 169026. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Garcia, A.; Corte-Leon, P.; Ipatov, M.; Zhukova, V.; Zhukov, A. Unveiling the Effect of Annealing on Magnetic Properties of Nanocrystalline Half-Metallic Heusler Co2FeSi Alloy Glass-Coated Microwires. J. Mater. Res. Technol. 2022, 20, 4161–4172. [Google Scholar] [CrossRef]

- Mitxelena-Iribarren, O.; Campisi, J.; Martínez de Apellániz, I.; Lizarbe-Sancha, S.; Arana, S.; Zhukova, V.; Mujika, M.; Zhukov, A. Glass-Coated Ferromagnetic Microwire-Induced Magnetic Hyperthermia for in Vitro Cancer Cell Treatment. Mater. Sci. Eng. C 2020, 106, 110261. [Google Scholar] [CrossRef] [PubMed]

- Talaat, A.; Alonso, J.; Zhukova, V.; Garaio, E.; García, J.A.; Srikanth, H.; Phan, M.H.; Zhukov, A. Ferromagnetic Glass-Coated Microwires with Good Heating Properties for Magnetic Hyperthermia. Sci. Rep. 2016, 6, 39300. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kozejova, D.; Fecova, L.; Klein, P.; Sabol, R.; Hudak, R.; Sulla, I.; Mudronova, D.; Galik, J.; Varga, R. Biomedical Applications of Glass-Coated Microwires. J. Magn. Magn. Mater. 2019, 470, 2–5. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Talaat, A.; Ipatov, M.; Zhukova, V.; Zhukov, A. Preparation and Magneto-Structural Investigation of Nanocrystalline CoMn-Based Heusler Alloy Glass-Coated Microwires. Processes 2022, 10, 2248. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Talaat, A.; Blanco, J.M.; Hernando, B.; Gonzalez-Legarreta, L.; Suñol, J.J.; Zhukova, V. Correlation of Crystalline Structure with Magnetic and Transport Properties of Glass-Coated Microwires. Crystals 2017, 7, 41. [Google Scholar] [CrossRef]

- Vázquez, M.; Zhukov, A.; Aragoneses, P.; Arcas, J.; Marin, P.; Hernando, A. Magneto-impedance of glass-coated amorphous CoMnSiB microwires. IEEE Trans. Magn. 1998, 34, 724–728. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; del Val, J.J.; Zhukova, V.; Chernenko, V.A. Magnetic and Structural Properties of Glass-Coated Heusler-Type Microwires Exhibiting Martensitic Transformation. Sci. Rep. 2018, 8, 621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Torcunov, A.V.; Baranov, S.A.; Larin, V.S. The Internal Stresses Dependence of the Magnetic Properties of Cast Amorphous Microwires Covered with Glass Insulation. J. Magn. Magn. Mater. 1999, 196–197, 835–836. [Google Scholar] [CrossRef]

- Guo, X.B.; Zuo, Y.L.; Cui, B.S.; Li, D.; Yun, J.J.; Wu, K.; Wang, T.; Xi, L. Post Annealing Induced Magnetic Anisotropy in CoFeSi Thin Films on MgO(0 0 1). J. Phys. D Appl. Phys. 2017, 50, 085006. [Google Scholar] [CrossRef]

- Salaheldeen, M.; Wederni, A.; Ipatov, M.; Gonzalez, J.; Zhukova, V.; Zhukov, A. Elucidation of the Strong Effect of the Annealing and the Magnetic Field on the Magnetic Properties of Ni2-Based Heusler Microwires. Crystals 2022, 12, 1755. [Google Scholar] [CrossRef]

- Gunnarsson, K.; Svedlindh, P.; Andersson, J.O.; Nordblad, P.; Lundgren, L.; Aruga Katori, H.; Ito, A. Magnetic Behavior of a Reentrant Ising Spin Glass. Phys. Rev. B 1992, 46, 8227–8231. [Google Scholar] [CrossRef]

- Herzer, G. Anisotropies in soft magnetic nanocrystalline alloys. J. Magn. Magn. Mater. 2005, 294, 99–106. [Google Scholar] [CrossRef]

- Talaat, A.; Zhukova, V.; Ipatov, M.; del Val, J.J.; Blanco, J.M.; Gonzalez-Legarreta, L.; Hernando, B.; Churyukanova, M.; Zhukov, A. Engineering of Magnetic Softness and Magnetoimpedance in Fe-Rich Microwires by Nanocrystallization. JOM 2016, 68, 1563–1571. [Google Scholar] [CrossRef]

- Zhukova, V.; Talaat, A.; del Val, J.J.; Ipatov, M.; Zhukov, A. Preparation and Characterization of Fe-Pt and Fe-Pt-(B, Si) Microwires. IEEE Magn. Lett. 2016, 7, 5200704. [Google Scholar] [CrossRef]

- Talaat, A.; del Val, J.J.; Zhukova, V.; Ipatov, M.; Klein, P.; Varga, R.; González, J.; Churyukanova, M.; Zhukov, A. Grain size refinement in nanocrystalline Hitperm-type glass-coated microwires. J. Magn. Magn. Mater. 2016, 406, 15–21. [Google Scholar] [CrossRef]

- Serebryakov, A.V. Amorphization reactions and glass to crystal transformations in metallic materials. J. Non-Cryst. Solids 1993, 156–158, 594–597. [Google Scholar] [CrossRef]

- Onsager, L. Reciprocal relations in irreversible processes. I. Phys. Rev. 1931, 37, 405–426. [Google Scholar] [CrossRef]

- Yang, F.; Li, W.; Li, J.; Chen, H.; Liu, D.; Chen, X.; Yang, C. The Microstructure and Magnetic Properties of Co2MnSi Thin Films Deposited on Si Substrate. J. Alloys Compd. 2017, 723, 188–191. [Google Scholar] [CrossRef]

- Chiriac, H.; Ovari, T.-A. Amorphous glass-covered magnetic wires: Preparation, properties, applications. Prog. Mater. Sci. 1996, 40, 333–407. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Zhukov, A. Magnetoelastic contribution in domain wall dynamics of amorphous microwires. Phys. B Condens. Matter 2012, 407, 1450–1454. [Google Scholar] [CrossRef]

| Sample | Dg (nm) |

|---|---|

| As-prepared | 46.2 |

| Annealed at 923 K | 50.3 |

| Annealed at 1023 K | 64.2 |

| Samples | Hc (Oe) | Mr | Hk (Oe) | |||

|---|---|---|---|---|---|---|

| IP | OOP | IP | OOP | IP | OOP | |

| As-prepared | 9 ± 2 | 43 ± 2 | 0.27 ± 0.01 | 0.02 ± 0.01 | 440 ± 5 | 7655 ± 4 |

| Annealed | 24 ± 2 | 56 ± 3 | 0.15 ± 0.01 | 0.08 ± 0.01 | 3200 ± 3 | 9720 ± 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salaheldeen, M.; Ipatov, M.; Corte-Leon, P.; Zhukova, V.; Zhukov, A. Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals 2023, 13, 412. https://doi.org/10.3390/met13020412

Salaheldeen M, Ipatov M, Corte-Leon P, Zhukova V, Zhukov A. Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals. 2023; 13(2):412. https://doi.org/10.3390/met13020412

Chicago/Turabian StyleSalaheldeen, Mohamed, Mihail Ipatov, Paula Corte-Leon, Valentina Zhukova, and Arcady Zhukov. 2023. "Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires" Metals 13, no. 2: 412. https://doi.org/10.3390/met13020412

APA StyleSalaheldeen, M., Ipatov, M., Corte-Leon, P., Zhukova, V., & Zhukov, A. (2023). Effect of Annealing on the Magnetic Properties of Co2MnSi-Based Heusler Alloy Glass-Coated Microwires. Metals, 13(2), 412. https://doi.org/10.3390/met13020412