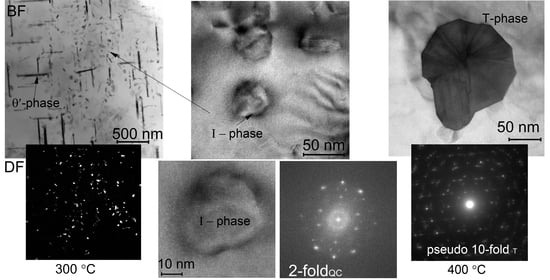

Precipitation Behavior of the Metastable Quasicrystalline I-Phase and θ′-Phase in Al-Cu-Mn Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Summary

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Korotkova, N.O.; Shurkin, P.K.; Cherkasov, S.O.; Aksenov, A.A. Effect of Copper Concentration and Annealing Temperature on the Structure and Mechanical Properties of Ingots and Cold-Rolled Sheets of Al–2% Mn Alloy. Russ. J. Non-Ferrous Met. 2022, 63, 190–200. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Korotkova, N.O.; Shurkin, P.K.; Timofeev, V.N.; Raznitsyn, O.A.; Sviridova, T.A. Structure and heat resistance of high strength Al–3.3%Cu–2.5%Mn–0.5%Zr (wt%) conductive wire alloy manufactured by electromagnetic casting. J. Alloys Compd. 2022, 891, 161948. [Google Scholar] [CrossRef]

- Dar, S.M.; Liao, H.; Xu, A. Effect of Cu and Mn content on solidification microstructure, T-phase formation and mechanical property of Al Cu Mn alloys. J. Alloys Compd. 2019, 774, 758–767. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Korotkova, N.O.; Cherkasov, S.O.; Yakovleva, A.O. Effect of Fe and Si on the Phase Composition and Microstructure Evolution in Al-2 wt.% Cu-2 wt.% Mn Alloy During Solidification, Cold Rolling and Annealing. JOM 2021, 73, 3827–3837. [Google Scholar] [CrossRef]

- SAmer, M.; Barkov, R.Y.; Prosviryakov, A.S.; Pozdniakov, A.V. Structure and Properties of New Heat-Resistant Cast Alloys Based on the Al–Cu–Y and Al–Cu–Er Systems. Phys. Met. Metallogr. 2021, 122, 908–914. [Google Scholar] [CrossRef]

- Belov, N.A.; Korotkova, N.O.; Shurkin, P.K.; Aksenov, A.A. Substantiation of the Copper Concentration in Thermally Stable Wrought Aluminum Alloys Containing 2 wt % of Mn. Phys. Met. Metallogr. 2020, 121, 1211–1219. [Google Scholar] [CrossRef]

- Meng, F.; Wang, Z.; Zhao, Y.; Zhang, D.; Zhang, W. Microstructures and Properties Evolution of Al-Cu-Mn Alloy with Addition of Vanadium. Metals 2016, 7, 10. [Google Scholar] [CrossRef] [Green Version]

- Shen, Z.; Liu, C.; Ding, Q.; Wang, S.; Wei, X.; Chen, L.; Li, J.; Zhang, Z. The structure determination of Al20Cu2Mn3 by near atomic resolution chemical mapping. J. Alloys Compd. 2014, 601, 25–30. [Google Scholar] [CrossRef]

- Shuncai, W.; Chunzhi, L.; Minggao, Y. Determination of structure of Al20Cu2Mn3 phase in Al-Cu-Mn alloys. Mater. Res. Bull. 1989, 24, 1267–1270. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, B.; Fan, J.; Zhang, D.; Li, Y. Microstructures and mechanical properties of heat-treated Al–5.0Cu–0.5Fe squeeze cast alloys with different Mn/Fe ratio. Mater. Sci. Eng. A 2013, 588, 366–375. [Google Scholar] [CrossRef]

- Gao, Y.H.; Cao, L.F.; Yang, C.; Zhang, J.Y.; Liu, G.; Sun, J. Co-stabilization of θ′-Al2Cu and Al3Sc precipitates in Sc-microalloyed Al–Cu alloy with enhanced creep resistance. Mater. Today Nano 2019, 6, 100035. [Google Scholar] [CrossRef]

- Poplawsky, J.D.; Milligan, B.K.; Allard, L.F.; Shin, D.; Shower, P.; Chisholm, M.F.; Shyam, A. The synergistic role of Mn and Zr/Ti in producing θ′/L12 co-precipitates in Al-Cu alloys. Acta Mater. 2020, 194, 577–586. [Google Scholar] [CrossRef]

- Shyam, A.; Roy, S.; Shin, D.; Poplawsky, J.D.; Allard, L.F.; Yamamoto, Y.; Morris, J.R.; Mazumder, B.; Idrobo, J.C.; Rodriguez, A.; et al. Elevated temperature microstructural stability in cast AlCuMnZr alloys through solute segregation. Mater. Sci. Eng. A 2019, 765, 138279. [Google Scholar] [CrossRef]

- Gwalani, B.; Liu, J.; Lambeets, S.; Olszta, M.; Poplawsky, J.; Shyam, A.; Devaraj, A. Rapid assessment of interfacial stabilization mechanisms of metastable precipitates to accelerate high-temperature Al-alloy development. Mater. Res. Lett. 2022, 10, 771–779. [Google Scholar] [CrossRef]

- Bahl, S.; Rakhmonov, J.U.; Kenel, C.; Dunand, D.C.; Shyam, A. Effect of grain-boundary θ-Al2Cu precipitates on tensile and compressive creep properties of cast Al–Cu–Mn–Zr alloys. Mater. Sci. Eng. A 2022, 840, 142946. [Google Scholar] [CrossRef]

- Michi, R.A.; Bahl, S.; Fancher, C.M.; Sisco, K.; Allard, L.F.; An, K.; Yu, D.; Dehoff, R.R.; Plotkowski, A.; Shyam, A. Load shuffling during creep deformation of an additively manufactured AlCuMnZr alloy. Acta Mater. 2023, 244, 118557. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, H.; Wang, R.; Peng, C.; Feng, Y.; Wang, X. Microstructure and Mechanical Properties of the Extruded Al-Cu-Mn-Sc-Zr Alloy during Single-Stage and Two-Stage Aging. J. Mater. Eng. Perform. 2022, 32, 185–198. [Google Scholar] [CrossRef]

- Belov, N.A.; Akopyan, T.K.; Shurkin, P.K.; Korotkova, N.O. Comparative analysis of structure evolution and thermal stability of commercial AA2219 and model Al-2 wt%Mn-2 wt%Cu cold rolled alloys. J. Alloys Compd. 2021, 864, 158823. [Google Scholar] [CrossRef]

- Amer, S.M.; Mamzurina, O.I.; Loginova, I.S.; Glavatskikh, M.V.; Barkov, R.Y.; Pozdniakov, A.V. Effect of Mn Addition on the Phase Composition and Strengthening Behavior of AlCuYbZr and AlCuGdZr Alloys. JOM 2022, 74, 3646–3654. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, W.; Ding, D.; Xiao, D. Microstructure of Al-5Cu-1Li-0.6Mg-0.5Ag-0.5Mn Alloys. Metals 2020, 11, 37. [Google Scholar] [CrossRef]

- Zupanič, F.; Wang, D.; Gspan, C.; Bončina, T. Precipitates in a quasicrystal-strengthened Al–Mn–Be–Cu alloy. Mater. Charact. 2015, 106, 93–99. [Google Scholar] [CrossRef]

- Bončina, T.; Albu, M.; Zupanič, F. Ageing of Al-Mn-Cu-Be Alloys for Stimulating Precipitation of Icosahedral Quasicrystals. Metals 2020, 10, 937. [Google Scholar] [CrossRef]

- Bončina, T.; Zupanič, F. In situ TEM study of precipitation in a quasicrystal-strengthened AL-alloy. Arch. Metall. Mater. 2017, 62, 5–9. [Google Scholar] [CrossRef] [Green Version]

- Mochugovskiy, A.; Tabachkova, N.; Mikhaylovskaya, A. Annealing induced precipitation of nanoscale icosahedral quasicrystals in aluminum based alloy. Mater. Lett. 2019, 247, 200–203. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. Nanodispersoids of the quasicrystalline I-phase in Mn- and Mg-bearing aluminum-based alloys. Mater. Lett. 2021, 284, 128945. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Barkov, R.Y.; Mikhaylovskaya, A.V.; Loginova, I.S.; Yakovtseva, O.A.; Pozdniakov, A.V. Structure and Properties of Al–4.5Mg–0.15Zr Compositions Alloyed with Er, Y, and Yb. Phys. Met. Metallogr. 2022, 123, 466–473. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Kotov, A.D.; Rofman, O.V.; Tabachkova, N.Y. Precipitation behavior and high strain rate superplasticity in a novel fine-grained aluminum based alloy. Mater. Sci. Eng. A 2019, 760, 37–46. [Google Scholar] [CrossRef]

- Macerl, M.; Zupanič, F.; Hočuršćak, L.; Klobčar, D.; Kovács, A.; Bončina, T. Microstructure and Properties after Friction Stir Processing of Twin-Roll Cast Al–Mn–Cu–Be Alloy. Crystals 2022, 12, 630. [Google Scholar] [CrossRef]

- Chen, R.; Wang, H.; Sun, Z.; He, B. Study of icosahedral quasi-crystalline phase T2-Al6CuLi3 and transformation in 2A97 Al-Li alloy fabricated by laser additive manufacturing. Mater. Lett. 2022, 316, 132014. [Google Scholar] [CrossRef]

- Zupanič, F.; Gspan, C.; Burja, J.; Bončina, T. Quasicrystalline and L12 precipitates in a microalloyed Al-Mn-Cu alloy. Mater. Today Commun. 2020, 22, 100809. [Google Scholar] [CrossRef]

- Mikhaylovskaya, A.V.; Kishchik, A.A.; Tabachkova, N.Y.; Prosviryakov, A.S.; Mochugovskiy, A.G. Influence of Secondary Quasicrystalline I-Phase Precipitates on the Grain Structure and Mechanical Properties of the Al–Mg–Mn Alloy. Phys. Met. Metallogr. 2022, 123, 474–481. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Tabachkova, N.Y.; Ghayoumabadi, M.E.; Cheverikin, V.V.; Mikhaylovskaya, A.V. Joint effect of quasicrystalline icosahedral and L12-strucutred phases precipitation on the grain structure and mechanical properties of aluminum-based alloys. J. Mater. Sci. Technol. 2021, 87, 196–206. [Google Scholar] [CrossRef]

- Afifi, M.A.; Wang, Y.C.; Pereira, P.H.; Wang, Y.; Li, S.; Huang, Y.; Langdon, T.G. Characterization of precipitates in an Al-Zn-Mg alloy processed by ECAP and subsequent annealing. Mater. Sci. Eng. A 2018, 712, 146–156. [Google Scholar] [CrossRef] [Green Version]

- Stan-Głowińska, K.; Lityńska-Dobrzyńska, L.; Rogal, Ł. Influence of Fe addition on the formation of a quasicrystalline phase in bulk Al-rich Al Mn base alloys. Mater. Charact. 2017, 128, 203–208. [Google Scholar] [CrossRef]

- Stan-Głowińska, K.; Lityńska-Dobrzyńska, L.; Kania, B.; Dutkiewicz, J.; Rogal, Ł.; Skuza, W.; Wojewoda-Budka, J.; Gordillo, M.A.; Wiezorek, J.M. Effects of hot-compaction on the structure and properties of Al-Mn-Fe-X alloys strengthened with quasi-crystalline icosahedral phase. Mater. Des. 2017, 126, 162–173. [Google Scholar] [CrossRef]

- Stan-Głowińska, K.; Rogal, Ł.; Góral, A.; Wierzbicka-Miernik, A.; Wojewoda-Budka, J.; Schell, N.; Lityńska-Dobrzyńska, L. Formation of a quasicrystalline phase in Al–Mn base alloys cast at intermediate cooling rates. J. Mater. Sci. 2017, 52, 7794–7807. [Google Scholar] [CrossRef] [Green Version]

- Wolf, W.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Fabrication of Al-matrix composite reinforced with quasicrystals using conventional metallurgical fabrication methods. Scr. Mater. 2019, 173, 21–25. [Google Scholar] [CrossRef]

- Wolf, W.; Bolfarini, C.; Kiminami, C.S.; Botta, W.J. Designing new quasicrystalline compositions in Al-based alloys. J. Alloys Compd. 2020, 823, 153765. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Q.; Dong, B.; Liu, Z. Microstructure and Thermal Stability of Icosahedral Quasicrystals in Suction Casting Al-6 at.%Mn(−2 at.%Be) Alloys. J. Mater. Eng. Perform. 2020, 29, 447–455. [Google Scholar] [CrossRef]

- Rozman, N.; Medved, J.; Zupanič, F. Microstructural evolution in Al–Mn–Cu–(Be) alloys. Philos. Mag. 2011, 91, 4230–4246. [Google Scholar] [CrossRef] [Green Version]

- Leskovar, B.; Samardžija, Z.; Koblar, M.; Naglič, I.; Markoli, B. Development of an Al-Mn-Si-Based Alloy with an Improved Quasicrystalline-Forming Ability. JOM 2020, 72, 1533–1539. [Google Scholar] [CrossRef]

- Zupanič, F.; Bončina, T. Heat-Resistant Al-Alloys with Quasicrystalline and L12- Precipitates. Solid State Phenom. 2022, 327, 26–32. [Google Scholar] [CrossRef]

- Belov, N.A.; Eskin, D.G.; Aksenov, A.A. Multicomponent Phase Diagrams: Applications for Commercial Aluminum Alloys; Elsevier: London, UK, 2005. [Google Scholar] [CrossRef]

- Casting Aluminum Alloys; Elsevier: London, UK, 2019. [CrossRef]

- Milligan, B.; Ma, D.; Allard, L.; Clarke, A.; Shyam, A. Dislocation-θ′ (Al2Cu) interactions during creep deformation of an Al-Cu alloy. Scr. Mater. 2022, 217, 114739. [Google Scholar] [CrossRef]

- Rakhmonov, J.; Liu, K.; Chen, G.X. Effects of Compositional Variation on the Thermal Stability of θ ′-Al2Cu Precipitates and Elevated-Temperature Strengths in Al-Cu 206 Alloys. J. Mater. Eng. Perform. 2020, 29, 7221–7230. [Google Scholar] [CrossRef]

- Yin, Q.; Chen, G.; Shu, X.; Zhang, B.; Li, C.; Dong, Z.; Cao, J.; An, R.; Huang, Y. Analysis of interaction between dislocation and interface of aluminum matrix/second phase from electronic behavior. J. Mater. Sci. Technol. 2023, 136, 78–90. [Google Scholar] [CrossRef]

- Dai, H.; Wang, L.; Dong, B.; Miao, J.; Lin, S.; Chen, H. Microstructure and high-temperature mechanical properties of new-type heat-resisting aluminum alloy Al6.5Cu2Ni0.5Zr0.3Ti0.25V under the T7 condition. Mater. Lett. 2023, 332, 133503. [Google Scholar] [CrossRef]

- Bello, N.; Larignon, C.; Douin, J. Long-term thermal ageing of the 2219-T851 and the 2050-T84 Al-Cu alloys. Mater. Today Commun. 2021, 29, 102834. [Google Scholar] [CrossRef]

- Dong, X.; Guo, Y.; Wang, J.; Xia, F.; Ma, K.; Duan, H.; Yang, Z.; Wang, P.; Liang, M.; Li, J. Novel AlCu solute cluster precipitates in the Al–Cu alloy by elevated aging and the effect on the tensile properties. Mater. Sci. Eng. A 2023, 862, 144454. [Google Scholar] [CrossRef]

- Li, X.Z.; Kuo, K.H. Orthorhombic crystalline approximants of the Al-Mn-Cu decagonal quasicrystal. Philos. Mag. B 1992, 66, 117–124. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, B.; He, Z.B.; Wu, B.; Ma, X.L. Atomic-scale mapping of twins and relevant defective structures in Al20Cu2Mn3 decagonal approximant. Philos. Mag. 2016, 96, 2457–2467. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Pan, S.P.; Zhu, B.X.; Liu, X.; Liu, W.H.; Tang, S.W. The evolution of orientation relationships during the transformation of a twin-free T-particle to tenfold T-twins in an Al alloy during homogenisation. Mater. Charact. 2018, 141, 59–73. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Pan, S.P.; Liu, W.H.; Liu, X.; Tang, C.P. Morphologies, orientation relationships, and evolution of the T-phase in an Al-Cu-Mg-Mn alloy during homogenisation. J. Alloys Compd. 2017, 709, 213–226. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Tang, Z.H.; Pan, S.P.; Liu, W.H.; Song, Y.F.; Liu, Y.; Zhu, B.W.; Zhou, W.; Shen, F.H. A new type of anti-phase boundaries in the T(Al20Cu2Mn3) phase and the pre-deformation effect on T phase precipitation. Intermetallics 2020, 127, 106977. [Google Scholar] [CrossRef]

- Geng, J.; Li, Y.; Liu, G.; Xiao, H.; Hong, T.; Huang, J.; Wang, M.; Chen, D.; Wang, H. Segregation of S precipitates at T/Al interfaces and relevant effects on localized corrosion mechanisms in Al-Cu-Mg alloy. Mater. Charact. 2020, 168, 110571. [Google Scholar] [CrossRef]

- Zolotorevsky, N.Y.; Solonin, A.N.; Churyumov, A.Y.; Zolotorevsky, V.S. Study of work hardening of quenched and naturally aged Al–Mg and Al–Cu alloys. Mater. Sci. Eng. A 2009, 502, 111–117. [Google Scholar] [CrossRef]

- Mochugovskiy, A.G.; Mukhamejanova, A.B.; Kotov, A.D.; Yakovtseva, O.A.; Tabachkova, N.Y.; Mikhaylovskaya, A.V. The effect of pre-straining on the annealing-induced precipitation behavior of the icosahedral I-phase in an aluminum-based alloy. Mater. Lett. 2022, 310, 131517. [Google Scholar] [CrossRef]

| Aging Regime | Compression Test Temperature | ||

|---|---|---|---|

| 20 °C * | 200 °C ** | 300 °C ** | |

| 450 °C, 4 h | 85 ± 3 | 80 ± 2 | 51 ± 2 |

| 400 °C, 32 h | 100 ± 3 | 92 ± 3 | 53 ± 2 |

| 350 °C, 48 h | 96 ± 4 | 91 ± 3 | 57 ± 1 |

| 300 °C, 148 h | 97 ± 3 | 94 ± 2 | 62 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mikhaylovskaya, A.V.; Mukhamejanova, A.; Kotov, A.D.; Tabachkova, N.Y.; Prosviryakov, A.S.; Mochugovskiy, A.G. Precipitation Behavior of the Metastable Quasicrystalline I-Phase and θ′-Phase in Al-Cu-Mn Alloy. Metals 2023, 13, 469. https://doi.org/10.3390/met13030469

Mikhaylovskaya AV, Mukhamejanova A, Kotov AD, Tabachkova NY, Prosviryakov AS, Mochugovskiy AG. Precipitation Behavior of the Metastable Quasicrystalline I-Phase and θ′-Phase in Al-Cu-Mn Alloy. Metals. 2023; 13(3):469. https://doi.org/10.3390/met13030469

Chicago/Turabian StyleMikhaylovskaya, Anastasia V., Aiymgul Mukhamejanova, Anton D. Kotov, Nataliya Yu. Tabachkova, Alexey S. Prosviryakov, and Andrey G. Mochugovskiy. 2023. "Precipitation Behavior of the Metastable Quasicrystalline I-Phase and θ′-Phase in Al-Cu-Mn Alloy" Metals 13, no. 3: 469. https://doi.org/10.3390/met13030469

APA StyleMikhaylovskaya, A. V., Mukhamejanova, A., Kotov, A. D., Tabachkova, N. Y., Prosviryakov, A. S., & Mochugovskiy, A. G. (2023). Precipitation Behavior of the Metastable Quasicrystalline I-Phase and θ′-Phase in Al-Cu-Mn Alloy. Metals, 13(3), 469. https://doi.org/10.3390/met13030469