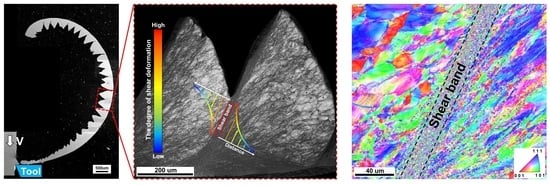

Microstructural Evolution of Shear Localization in High-Speed Cutting of CoCrFeMnNi High-Entropy Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Flom, D.G.; Komanduri, R.; Lee, M. High-Speed Machining of Metals. Annul. Rev. Mater. Sci. 1984, 14, 231–278. [Google Scholar] [CrossRef]

- Sagapuram, D.; Udupa, A.; Viswanathan, K.; Mann, J.B.; M’Saoubi, R.; Sugihara, T.; Chandrasekar, S. On the Cutting of Metals: A Mechanics Viewpoint. J. Manuf. Sci. Eng. 2020, 142, 110808. [Google Scholar] [CrossRef]

- Shaw, M.C. Metal Cutting Principles, 2nd ed.; Oxford University Press: New York, NY, USA, 2005. [Google Scholar]

- Ye, G.G.; Jiang, M.Q.; Xue, S.F.; Ma, W.; Dai, L.H. On the instability of chip flow in high-speed machining. Mech. Mater. 2018, 116, 104–119. [Google Scholar] [CrossRef]

- Molinari, A.; Musquar, C.; Sutter, G. Adiabatic shear banding in high speed machining of Ti-6Al-4V: Experiments and modeling. Int. J. Plast. 2002, 18, 443–459. [Google Scholar] [CrossRef]

- Burns, T.J.; Davies, M.A. On repeated adiabatic shear band formation during high-speed machining. Int. J. Plast. 2002, 18, 487–506. [Google Scholar] [CrossRef]

- Huang, J.; Kalaitzidou, K.; Sutherland, J.W.; Aifantis, E.C. Validation of a Predictive Model for Adiabatic Shear Band Formation in Chips Produced via Orthogonal Machining. J. Mech. Behav. Mater. 2007, 18, 243–264. [Google Scholar] [CrossRef]

- Recht, R.F. Catastrophic Thermoplastic Shear. J. Appl. Mech. 1964, 31, 189–193. [Google Scholar] [CrossRef]

- Hou, Z.B.; Komanduri, R. Modeling of thermomechanical shear instability in machining. Int. J. Mech. Sci. 1997, 39, 1273–1314. [Google Scholar] [CrossRef]

- Duan, C.; Wang, M. Some metallurgical aspects of chips formed in high speed machining of high strength low alloy steel. Scr. Mater. 2005, 52, 1001–1004. [Google Scholar] [CrossRef]

- Ye, G.G.; Xue, S.F.; Jiang, M.Q.; Tong, X.H.; Dai, L.H. Modeling periodic adiabatic shear band evolution during high speed machining Ti-6Al-4V alloy. Int. J. Plast. 2013, 40, 39–55. [Google Scholar] [CrossRef] [Green Version]

- Cai, S.L.; Dai, L.H. Suppression of repeated adiabatic shear banding by dynamic large strain extrusion machining. J. Mech. Phys. Solids 2014, 73, 84–102. [Google Scholar] [CrossRef]

- Zeng, F.; Jiang, M.Q.; Dai, L.H. Dilatancy induced ductile-brittle transition of shear band in metallic glasses. Proc. R. Soc. A-Math. Phys. Eng. Sci. 2018, 474, 20170836. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bai, Y.L.; Dodd, B. Adiabatic Shear Localization: Occurrence, Theories, and Applications; Pergamon Press: Oxford, UK, 1992. [Google Scholar]

- Meyers, M.A. Dynamic Behavior of Materials; John Wiley & Sons: New York, NY, USA, 1994. [Google Scholar]

- Rittel, D.; Landau, P.; Venkert, A. Dynamic recrystallization as a potential cause for adiabatic shear failure. Phys. Rev. Lett. 2008, 101, 165501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yan, N.; Li, Z.; Xu, Y.; Meyers, M.A. Shear localization in metallic materials at high strain rates. Prog. Mater. Sci. 2021, 119, 100755. [Google Scholar] [CrossRef]

- Jiang, M.Q.; Dai, L.H. Formation mechanism of lamellar chips during machining of bulk metallic glass. Acta Mater. 2009, 57, 2730–2738. [Google Scholar] [CrossRef] [Green Version]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R.O. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, D.; Yu, Q.; Kabra, S.; Jiang, M.; Forna-Kreutzer, P.; Zhang, R.; Payne, M.; Walsh, F.; Gludovatz, B.; Asta, M.; et al. Exceptional fracture toughness of CrCoNi-based medium- and high-entropy alloys at 20 kelvin. Science 2022, 378, 978–983. [Google Scholar] [CrossRef]

- George, E.P.; Raabe, D.; Ritchie, R.O. High-entropy alloys. Nat. Rev. Mater. 2019, 4, 515–534. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Lei, Z.; Liu, X.; Wu, Y.; Wang, H.; Jiang, S.; Wang, S.; Hui, X.; Wu, Y.; Gault, B.; Kontis, P.; et al. Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes. Nature 2018, 563, 546–550. [Google Scholar] [CrossRef]

- Pan, Q.; Zhang, L.; Feng, R.; Lu, Q.; An, K.; Chuang, A.C.; Poplawsky, J.D.; Liaw, P.K.; Lu, L. Gradient cell-structured high-entropy alloy with exceptional strength and ductility. Science 2021, 374, 984–989. [Google Scholar] [CrossRef]

- Pu, Z.; Chen, Y.; Dai, L.H. Strong resistance to hydrogen embrittlement of high-entropy alloy. Mater. Sci. Eng. A 2018, 736, 156–166. [Google Scholar] [CrossRef]

- Luo, H.; Sohn, S.S.; Lu, W.; Li, L.; Li, X.; Soundararajan, C.K.; Krieger, W.; Li, Z.; Raabe, D. A strong and ductile medium-entropy alloy resists hydrogen embrittlement and corrosion. Nat. Commun. 2020, 11, 3081. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Mao, M.M.; Wang, J.; Gludovatz, B.; Zhang, Z.; Mao, S.X.; George, E.P.; Yu, Q.; Ritchie, R.O. Nanoscale origins of the damage tolerance of the high-entropy alloy CrMnFeCoNi. Nat. Commun. 2015, 6, 10143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cai, Z.; Wei, N.; Han, Y.; Si, F.; Mi, L.; Zhang, C.; Liu, X.; Jiang, F.; Wu, T. Effect of Heat Treatment on Microstructure, Tensile Properties and High-Temperature Corrosion Resistance of the FeCrMnNi High Entropy Alloy. Metals 2022, 12, 1537. [Google Scholar] [CrossRef]

- El-Atwani, O.; Li, N.; Li, M.; Devaraj, A.; Baldwin, J.K.S.; Schneider, M.M.; Sobieraj, D.; Wróbel, J.S.; Nguyen-Manh, D.; Maloy, S.A.; et al. Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci. Adv. 2019, 5, eaav2002. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.-F.; Tian, Z.-L.; Zhang, X.-F.; Chen, H.-H.; Liu, T.-W.; Chen, Y.; Wang, Y.-J.; Dai, L.-H. “Self-sharpening” tungsten high-entropy alloy. Acta Mater. 2020, 186, 257–266. [Google Scholar] [CrossRef]

- Chen, J.; Liu, T.-W.; Cao, F.-H.; Wang, H.-Y.; Chen, Y.; Dai, L.-H. Deformation Behavior and Microstructure Evolution of CoCrNi Medium-Entropy Alloy Shaped Charge Liners. Metals 2022, 12, 811. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, S.; Alotaibi, S.M.; Liu, Y.; Wang, B.; Meyers, M.A. Adiabatic shear localization in the CrMnFeCoNi high-entropy alloy. Acta Mater. 2018, 151, 424–431. [Google Scholar] [CrossRef] [Green Version]

- Li, Z.; Zhao, S.; Ritchie, R.O.; Meyers, M.A. Mechanical properties of high-entropy alloys with emphasis on face-centered cubic alloys. Prog. Mater. Sci. 2018, 102, 296–345. [Google Scholar] [CrossRef]

- Tang, Y.; Wang, R.; Xiao, B.; Zhang, Z.; Li, S.; Qiao, J.; Bai, S.; Zhang, Y.; Liaw, P.K. A review on the dynamic-mechanical behaviors of high-entropy alloys. Prog. Mater. Sci. 2023, 135, 101090. [Google Scholar] [CrossRef]

- Wang, Q.; Lu, C.; Ye, G.G.; Dai, L.H. Modelling the tuned criticality in stick-slip friction during metal cutting. Model. Simul. Mater. Sci. Eng. 2015, 23, 055013. [Google Scholar] [CrossRef] [Green Version]

- Kubin, L.P.; Mortensen, A. Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues. Scr. Mater. 2003, 48, 119–125. [Google Scholar] [CrossRef] [Green Version]

- Humphreys, F.J.; Rohrer, G.S.; Rollett, A. Recrystallization and Related Annealing Phenomena, 3rd ed.; Elsevier: Oxford, UK, 2017. [Google Scholar]

- Mitsche, S.; Poelt, P.; Sommitsch, C. Recrystallization behaviour of the nickel-based alloy 80 A during hot forming. J. Microsc. 2007, 227, 267–274. [Google Scholar] [CrossRef] [PubMed]

- Mirzadeh, H.; Cabrera, J.M.; Najafizadeh, A.; Calvillo, P.R. EBSD study of a hot deformed austenitic stainless steel. Mater. Sci. Eng. A 2012, 538, 236–245. [Google Scholar] [CrossRef]

- Field, D.; Bradford, L.; Nowell, M.; Lillo, T. The role of annealing twins during recrystallization of Cu. Acta Mater. 2007, 55, 4233–4241. [Google Scholar] [CrossRef]

- Cao, Y.; Di, H.; Zhang, J.; Zhang, J.; Ma, T.; Misra, R.D.K. An electron backscattered diffraction study on the dynamic recrystallization behavior of a nickel–chromium alloy (800H) during hot deformation. Mater. Sci. Eng. A 2013, 585, 71–85. [Google Scholar] [CrossRef]

- Grebe, H.A.; Pak, H.-R.; Meyers, M.A. Adiabatic shear localization in titanium and Ti-6 pct Al-4 pct V alloy. Metall. Trans. A 1985, 16, 761–775. [Google Scholar] [CrossRef]

- Meyers, M.A.; Xu, Y.B.; Xue, Q.; Pérez-Prado, M.T.; McNelley, T.R. Microstructural evolution in adiabatic shear localization in stainless steel. Acta Mater. 2003, 51, 1307–1325. [Google Scholar] [CrossRef]

- Li, Z.; Wang, B.; Zhao, S.; Valiev, R.Z.; Vecchio, K.S.; Meyers, M.A. Dynamic deformation and failure of ultrafine-grained titanium. Acta Mater. 2017, 125, 210–218. [Google Scholar] [CrossRef] [Green Version]

- Li, W.; Wang, B.; Huang, X.; Liu, B.; Brechtl, J.; Liaw, P.K. Mechanical behavior and shear band of a powder-metallurgy-fabricated CoCrFeMnNi high-entropy alloy during high strain-rate deformation. J. Mater. Res. Technol. 2022, 21, 1461–1478. [Google Scholar] [CrossRef]

- Meyers, M.A.; Nesterenko, V.F.; LaSalvia, J.C.; Xue, Q. Shear localization in dynamic deformation of materials: Microstructural evolution and self-organization. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2001, 317, 204–225. [Google Scholar] [CrossRef]

- Sun, J.L.; Trimby, P.W.; Yan, F.K.; Liao, X.Z.; Tao, N.R.; Wang, J.T. Shear banding in commercial pure titanium deformed by dynamic compression. Acta Mater. 2014, 79, 47–58. [Google Scholar] [CrossRef]

- Murr, L.E.; Trillo, E.A.; Pappu, S.; Kennedy, C. Adiabatic shear bands and examples of their role in severe plastic deformation. J. Mater. Sci. 2002, 37, 3337–3360. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, M.-Y.; Zhang, W.-H.; Tan, Y.-Y.; Chen, Y.; Wang, H.-Y.; Dai, L.-H. Microstructural Evolution of Shear Localization in High-Speed Cutting of CoCrFeMnNi High-Entropy Alloy. Metals 2023, 13, 647. https://doi.org/10.3390/met13040647

Su M-Y, Zhang W-H, Tan Y-Y, Chen Y, Wang H-Y, Dai L-H. Microstructural Evolution of Shear Localization in High-Speed Cutting of CoCrFeMnNi High-Entropy Alloy. Metals. 2023; 13(4):647. https://doi.org/10.3390/met13040647

Chicago/Turabian StyleSu, Ming-Yao, Wei-Han Zhang, Yuan-Yuan Tan, Yan Chen, Hai-Ying Wang, and Lan-Hong Dai. 2023. "Microstructural Evolution of Shear Localization in High-Speed Cutting of CoCrFeMnNi High-Entropy Alloy" Metals 13, no. 4: 647. https://doi.org/10.3390/met13040647

APA StyleSu, M. -Y., Zhang, W. -H., Tan, Y. -Y., Chen, Y., Wang, H. -Y., & Dai, L. -H. (2023). Microstructural Evolution of Shear Localization in High-Speed Cutting of CoCrFeMnNi High-Entropy Alloy. Metals, 13(4), 647. https://doi.org/10.3390/met13040647