Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching

Abstract

:1. Introduction

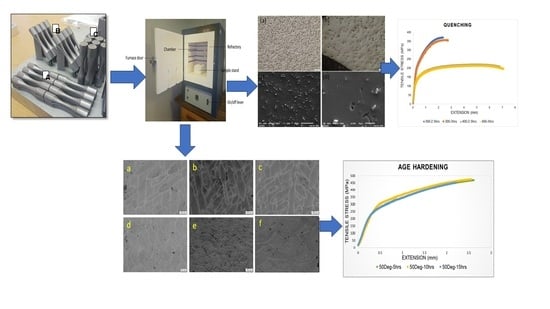

2. Experimental Procedure

2.1. Specimen Production

2.2. Heat Treatment Profiles

2.3. Characterisation Technique

3. Results and Discussion

3.1. Measurements of Hardness

3.2. Microstructural Analysis

3.2.1. Optical Microscope (OM) and Scanning Electron Microscope (SEM) for Age Hardening

3.2.2. Optical Microscope (OM) and Scanning Electron Microscope (SEM) of Ice-Water Quenching

3.3. Tensile Strength

3.4. Fractography

3.5. Residual Stress Measurements

4. Conclusions

- ○

- In this investigation, there is a justification that the age-hardening thermal treatment modifies the mechanical characteristics of AlSi10Mg constructively. There, the microstructure did not change, which was the key objective sought to be achieved for this investigation. This is observed with all samples age-hardened at temperatures of 50 °C and 100 °C for all variations in hours; even though the samples age-hardened at 50 °C for 10 h stand out as the most successful thus far in terms of hardness enhancement of 166 Hv, the rest of the age-hardened samples demonstrated a considerable hardness increase.

- ○

- In all samples, improvement was observed, although there was a minor compromise in ductility while work was performed to improve strength.

- ○

- The residual stress measurements meticulously selected the effective thermal treatment parameters to be 50 °C at 15 h and 100 °C at 8 and 12 h. The residual stresses were reduced to between 0 and −20 MPa, 0 and 10MPa, as well as between 0 and 20 MPa, respectively.

- ○

- In ice-quenched samples, whenever silicon is disintegrated at the eutectic boundaries, the microstructural and mechanical characteristics of AlSi10Mg are compromised. The idea of thermal treatment in AlSi10Mg samples is to precipitate Mg2Si and retain the scale-like microstructure, which is the original structure built, which is already near perfect and only in need of residual stress removal.

- ○

- It was observed that the residual stress was reduced to compressive residual stress at 400 °C to below 50 MPa and, for samples ice-quenched at 300 °C, the residual stress was reduced to slightly above 0 MPa, which tells us that the thermal treatment technique is effective at reducing residual stresses despite compromised mechanical characteristics.

- ○

- In future work, the quenching is suggested to be carried out at a lower temperature and samples to be quenched in water at 25 °C, which is room temperature. This should prevent thermal shock in the samples after being removed from the furnace. It also dawns that, with the stress relief thermal treatment, during air cooling or furnace cooling, the transformation still precedes; hence, the whole morphological evolution was observed with time.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mfusi, B.; Tshabalala, L.C.; Mathe, N.R. The effect of selective laser melting build orientation on the mechanical properties of AlSi10Mg parts. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012028. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Microstructure and mechanical properties of AlSi10Mg parts produced by the laser beam additive manufacturing (AM) technology. Metallogr. Microstruct. Anal. 2014, 3, 448–453. [Google Scholar] [CrossRef]

- Brandão, A.D.; Gumpinger, J.; Gschweitl, M.; Seyfert, C.; Hofbauer, P.; Ghidini, T. Fatigue properties of additively manufactured AlSi10Mg–surface treatment effect. Procedia Struct. Integr. 2017, 7, 58–66. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; Schulz, E.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, precipitates and hardness of selectively laser melted AlSi10Mg alloy before and after heat treatment. Mater. Charact. 2018, 143, 5–17. [Google Scholar] [CrossRef]

- Mfusi, B.J.; Mathe, N.R.; Tshabalala, L.C.; Popoola, P.A. The effect of stress relief on the mechanical and fatigue properties of additively manufactured AlSi10Mg parts. Metals 2019, 9, 1216. [Google Scholar] [CrossRef]

- Mfusi, B.J. The Development of an Ideal Processing Window Using Selective Laser Melting Technology for Aluminium Based Components; Tshwane University of Technology: Pretoria, South Africa, 2019. [Google Scholar]

- Tradowsky, U.; White, J.; Ward, R.; Read, N.; Reimers, W.; Attallah, M. Selective laser melting of AlSi10Mg: Influence of post-processing on the microstructural and tensile properties development. Mater. Des. 2016, 105, 212–222. [Google Scholar] [CrossRef]

- Fiocchi, J.; Tuissi, A.; Bassani, P.; Biffi, C. Low temperature annealing dedicated to AlSi10Mg selective laser melting products. J. Alloys Compd. 2017, 695, 3402–3409. [Google Scholar] [CrossRef]

- Marola, S.; Manfredi, D.; Fiore, G.; Poletti, M.G.; Lombardi, M.; Fino, P.; Battezzati, L. A comparison of Selective Laser Melting with bulk rapid solidification of AlSi10Mg alloy. J. Alloys Compd. 2018, 742, 271–279. [Google Scholar] [CrossRef]

- Rosenthal, I.; Stern, A.; Frage, N. Strain rate sensitivity and fracture mechanism of AlSi10Mg parts produced by selective laser melting. Mater. Sci. Eng. A 2017, 682, 509–517. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Maskery, I.; Tuck, C.; Ashcroft, I.; Everitt, N.M. The microstructure and mechanical properties of selectively laser melted AlSi10Mg: The effect of a conventional T6-like heat treatment. Mater. Sci. Eng. A 2016, 667, 139–146. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Neves, F.O.; Oliviera, T.L.L.; Braga, D.U.; Silva, A.S.C.d. Influence of heat treatment on residual stress in cold-forged parts. Adv. Mater. Sci. Eng. 2014, 2014, 658679. [Google Scholar] [CrossRef]

- Mathe, N.R.; Tshabalala, L.C. The validation of the microstructural evolution of selective laser-melted AlSi10Mg on the in-house built machine: Energy density studies. Prog. Addit. Manuf. 2019, 4, 431–442. [Google Scholar] [CrossRef]

- Mfusi, B.J.; Mathe, N.R.; Popoola, P.; Tshabalala, L.C. Influence of stress relieving thermal cycles on AISI10Mg specimens produced by selective laser melting. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019. [Google Scholar]

- Cabrini, M.; Lorenzi, S.; Pastore, T.; Pellegrini, S.; Ambrosio, E.; Calignano, F.; Manfredi, D.; Pavese, M.; Fino, P. Effect of heat treatment on corrosion resistance of DMLS AlSi10Mg alloy. Electrochim. Acta 2016, 206, 346–355. [Google Scholar] [CrossRef]

- Friend, C.; Luxton, S. The effect of δ alumina fibre arrays on the age-hardening characteristics of an Al-Mg-Si alloy. J. Mater. Sci. 1988, 23, 3173–3180. [Google Scholar] [CrossRef]

- Lam, L.; Zhang, D.; Liu, Z.; Chua, C. Phase analysis and microstructure characterisation of AlSi10Mg parts produced by Selective Laser Melting. Virtual Phys. Prototyp. 2015, 10, 207–215. [Google Scholar] [CrossRef]

- Mertens, A.; Dedry, O.; Reuter, D.; Rigo, O.; Lecomte-Beckers, J. Thermal treatments of AlSi10Mg processed by laser beam melting. In Proceedings of the International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2015; pp. 1007–1016. [Google Scholar]

- Cheng, B.; Chou, K. Melt pool evolution study in selective laser melting. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 25–27 July 2022; pp. 1182–1194. [Google Scholar]

- Kempen, K.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Mechanical properties of AlSi10Mg produced by selective laser melting. Phys. Procedia 2012, 39, 439–446. [Google Scholar] [CrossRef]

- Brandl, E.; Heckenberger, U.; Holzinger, V.; Buchbinder, D. Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): Microstructure, high cycle fatigue, and fracture behavior. Mater. Des. 2012, 34, 159–169. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Yang, P.; Rodriguez, M.A.; Deibler, L.A.; Jared, B.H.; Griego, J.; Kilgo, A.; Allen, A.; Stefan, D.K. Effect of thermal annealing on microstructure evolution and mechanical behavior of an additive manufactured AlSi10Mg part. J. Mater. Res. 2018, 33, 1701–1712. [Google Scholar] [CrossRef]

- Liu, M.; Zhang, Z.; Breton, F.; Chen, X. Investigation of the quench sensitivity of an AlSi10Mg alloy in permanent mold and high-pressure vacuum die castings. Materials 2019, 12, 1876. [Google Scholar] [CrossRef] [PubMed]

- Xiaohui, J.; Chunbo, Y.; Honglan, G.; Shan, G.; Yong, Z. Effect of supporting structure design on residual stresses in selective laser melting of AlSi10Mg. Int. J. Adv. Manuf. Technol. 2022, 118, 1597–1608. [Google Scholar] [CrossRef]

- Strobel, K.; Lay, M.D.; Easton, M.A.; Sweet, L.; Zhu, S.; Parson, N.C.; Hill, A.J. Effects of quench rate and natural ageing on the age hardening behaviour of aluminium alloy AA6060. Mater. Charact. 2016, 111, 43–52. [Google Scholar] [CrossRef]

- Alghamdi, F.; Song, X.; Hadadzadeh, A.; Shalchi-Amirkhiz, B.; Mohammadi, M.; Haghshenas, M. Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater. Sci. Eng. A 2020, 783, 139296. [Google Scholar] [CrossRef]

- Welsch, G.; Lütjering, G.; Gazioglu, K.; Bunk, W. Deformation characteristics of age hardened Ti-6Al-4V. Metall. Trans. A 1977, 8, 169–177. [Google Scholar] [CrossRef]

- Banerjee, M. Age-hardening characteristics of aluminium–chromium alloys. J. Mater. Sci. 1997, 32, 6645–6651. [Google Scholar] [CrossRef]

- Kempen, K.; Thijs, L.; Yasa, E.; Badrossamay, M.; Verheecke, W.; Kruth, J. Process optimization and microstructural analysis for selective laser melting of AlSi10Mg. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2011; pp. 484–495. [Google Scholar]

- Xing, X.; Duan, X.; Sun, X.; Gong, H.; Wang, L.; Jiang, F. Modification of residual stresses in laser additive manufactured AlSi10Mg specimens using an ultrasonic peening technique. Materials 2019, 12, 455. [Google Scholar] [CrossRef]

- Teixeira, Ó.; Silva, F.J.; Ferreira, L.P.; Atzeni, E. A review of heat treatments on improving the quality and residual stresses of the Ti–6Al–4V parts produced by additive manufacturing. Metals 2020, 10, 1006. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Industrial Metallurgists. Causes of Residual Stress. 2022. Available online: https://www.imetllc.com/residual-stress/#:~:text=Residual%20stress%20due%20to%20temperature,during%20heat%20treating%20and%20welding (accessed on 15 October 2023).

- Mungi, M.; Rasane, S.; Dixit, P. Residual stresses in cold axisymmetric forging. J. Mater. Process. Technol. 2003, 142, 256–266. [Google Scholar] [CrossRef]

- Camurri, C.; Carrasco, C.; Dille, J. Residual stress during heat treatment of steel grinding balls. J. Mater. Process. Technol. 2008, 208, 450–456. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mfusi, B.J.; Popoola, P.A.; Mathe, N.R. Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. Metals 2024, 14, 292. https://doi.org/10.3390/met14030292

Mfusi BJ, Popoola PA, Mathe NR. Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. Metals. 2024; 14(3):292. https://doi.org/10.3390/met14030292

Chicago/Turabian StyleMfusi, Busisiwe J., Patricia Abimbola Popoola, and Ntombizodwa R. Mathe. 2024. "Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching" Metals 14, no. 3: 292. https://doi.org/10.3390/met14030292

APA StyleMfusi, B. J., Popoola, P. A., & Mathe, N. R. (2024). Optimisation of the Heat Treatment Profile for Powder-Bed Fusion Built AlSi10Mg by Age Hardening and Ice-Water Quenching. Metals, 14(3), 292. https://doi.org/10.3390/met14030292